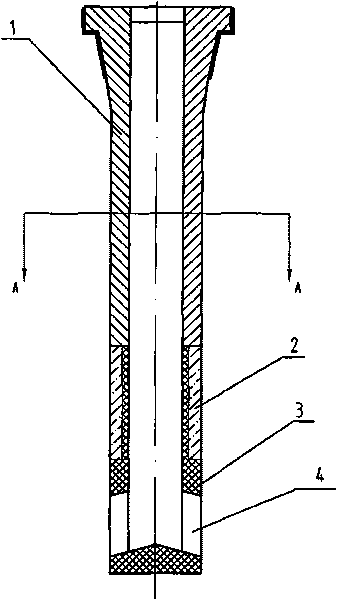

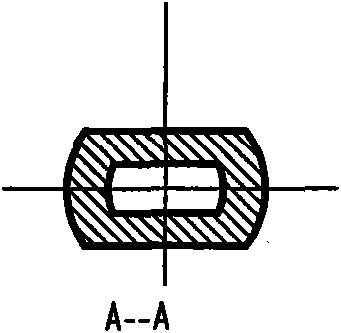

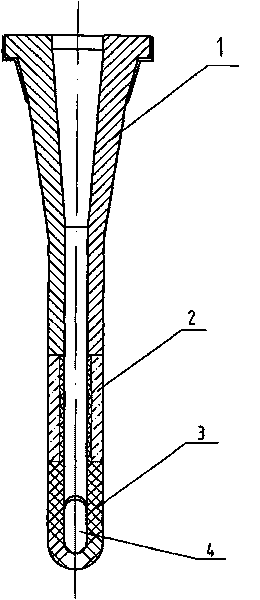

Tundish quick-replaceable sewage outlet used for metal continuous casting plate blank

A tundish and slab technology, which is applied in casting equipment, metal processing equipment, casting melt container, etc., can solve the problem of corrosion resistance, insufficient thermal shock strength, low mechanical strength, high temperature resistance, and insufficient thermal shock resistance and other issues to achieve the effect of highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] a. Mixture:

[0085] Main material: 20 parts by weight of accurately measured graphite, 24 parts by weight of high alumina bauxite # 15 parts by weight, high alumina bauxite 36 # 13 parts by weight, high alumina bauxite 150 # 25 parts by weight, 20 parts by weight of quartz, 3 parts by weight of metal silicon, and 2 parts by weight of boron glass powder, put into the high-speed mixer of the main material, add a spraying type to add a binder, mix evenly at a high speed, and set aside;

[0086] Inner slag wire material: accurately measure 25 parts by weight of graphite, 65 parts by weight of white corundum, 3 parts by weight of metal silicon powder, 2 parts by weight of silicon carbide powder, and 5 parts by weight of alumina powder, put them into the high-speed mixer for inner wire material, and add the spraying type Add binder, mix evenly at high speed, and set aside;

[0087] Outer slag strands: accurately measure 10 parts by weight of graphite, 85 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com