Pre-lithiated silicon monoxide/carbon composite material and preparation method and application thereof

A technology of carbon composite materials and silicon oxide, which is applied in the direction of electrochemical generators, active material electrodes, electrical components, etc., can solve the problems of difficult cycle performance, low electrical conductivity, and low initial Coulombic efficiency, and achieve excellent performance and improved The effect of conductivity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of pre-lithiated silicon oxide / carbon composite material of the present invention, comprises the following steps:

[0029] S1. Mix silicon oxide, lithium source, and endothermic agent evenly, perform heat treatment in an inert atmosphere, wash and filter;

[0030] S2. Put the above-mentioned obtained materials into a rotary kiln, heat up to a certain temperature and keep it warm, pass a certain amount of pyrolysis gas, and carry out carbon coating to obtain a pre-lithiated silicon oxide / carbon composite material

[0031] Preferably, the mass ratio of silicon oxide to lithium source in the step S1 is 1: (0.1-1), preferably, the mass ratio of silicon oxide to lithium source is 1: (0.2-0.5);

[0032] Preferably, the mass ratio of the lithium source to the endothermic agent in the step S1 is 1: (0.1-1), preferably, the mass ratio of the lithium source to the endothermic agent is 1: (0.5-1).

[0033] Preferably, the lithium source in the step S1...

Embodiment 1

[0042] A preparation and application of a pre-lithiated silicon oxide / carbon composite material, comprising the following steps:

[0043] 1) Weigh 100g of SiO, 20g of lithium hydroxide and 20g of sodium chloride in a ball milling jar, the rotation speed is 400rpm / min, and the ball milling time is 2h.

[0044] 2) Put the material obtained by ball milling into a corundum crucible, put it into a tube furnace, and raise the temperature to 600°C at 3°C / min under the protection of nitrogen, and keep it warm for 1h.

[0045] 3) After the heat preservation is completed, the obtained material is washed three times with deionized water to remove the heat-absorbing agent, and kept in a vacuum oven at 80° C. for 8 hours to remove water.

[0046] 4) Put the dried material into a rotary kiln, raise the temperature to 800° C., feed acetylene gas, and keep it warm for 1 hour to obtain a pre-lithiated silicon oxide / carbon composite material.

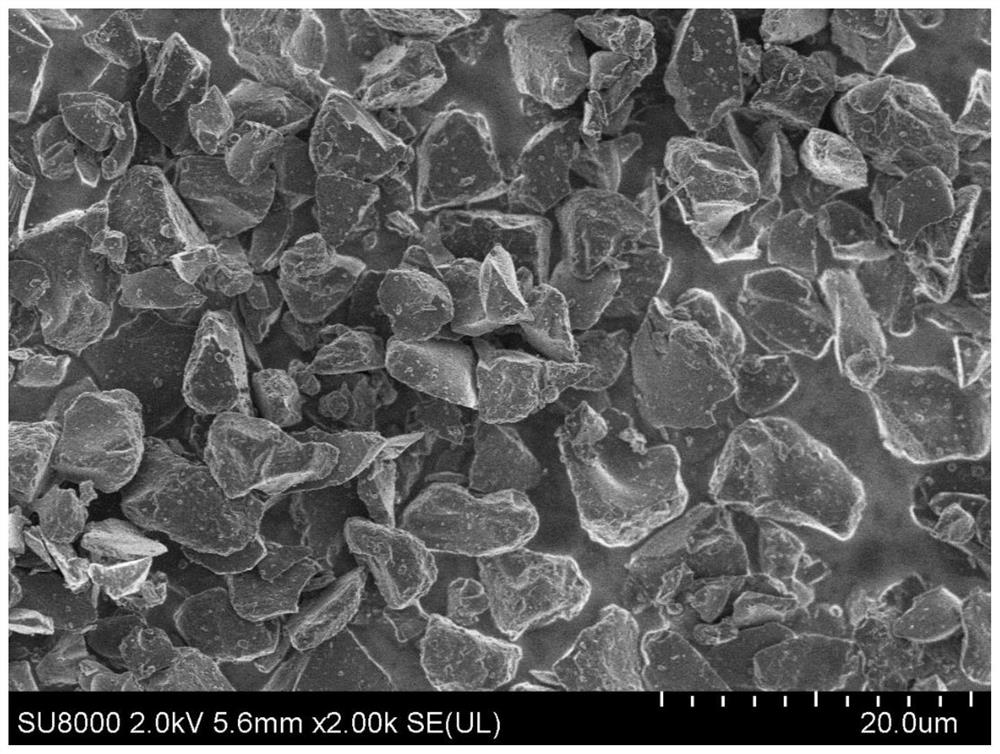

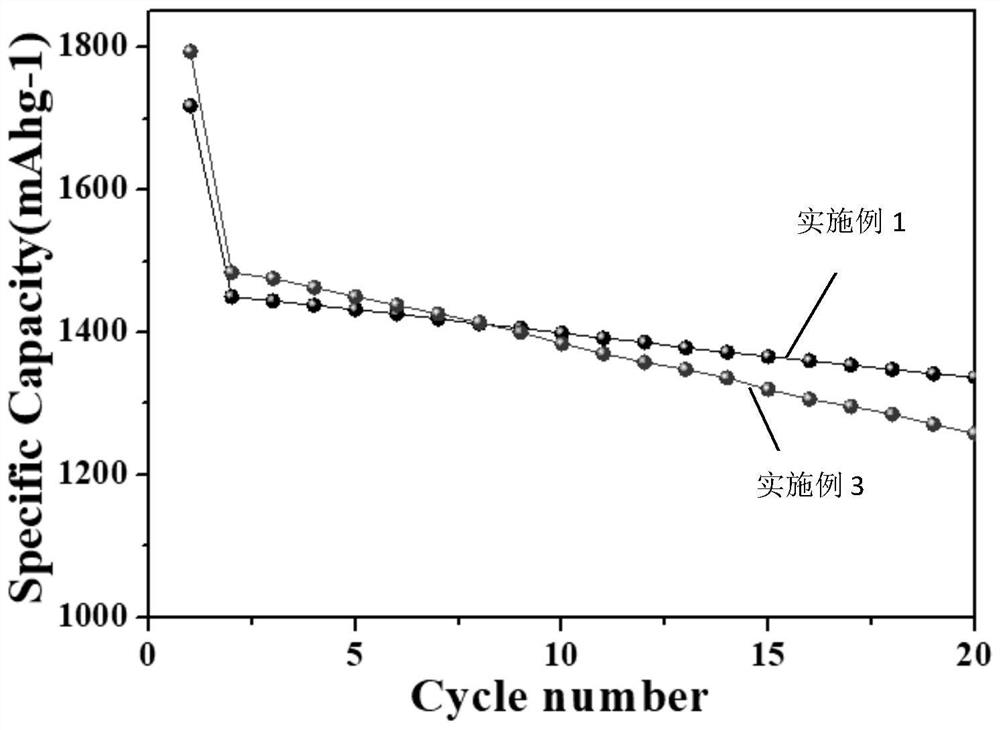

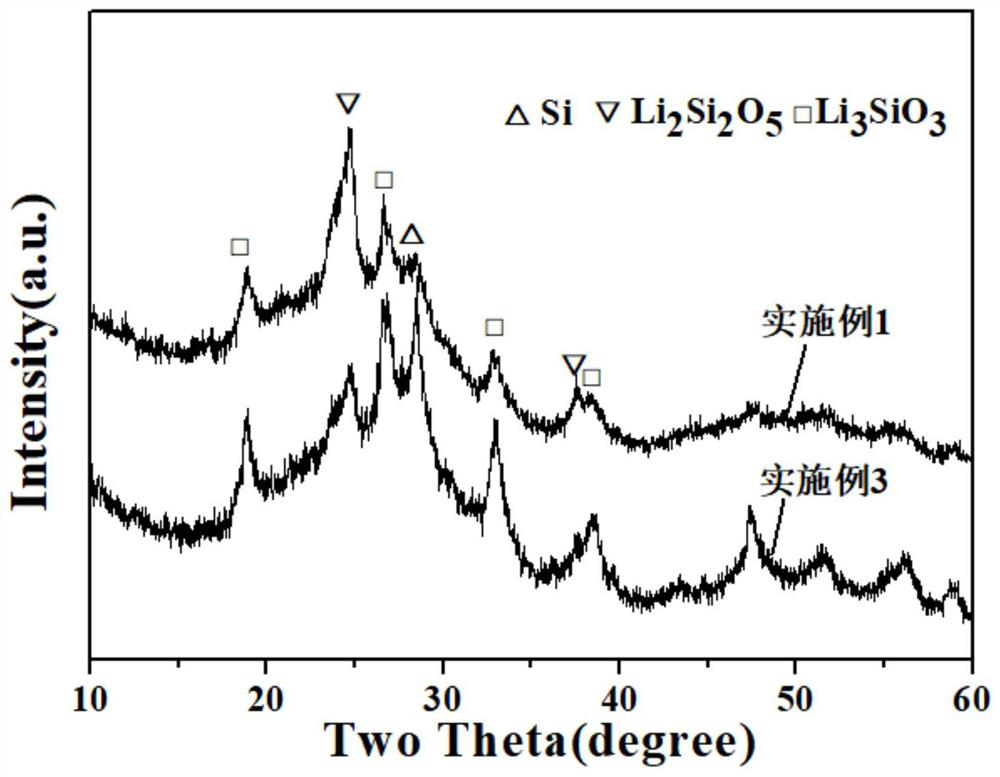

[0047] see figure 1 , it can be seen that the pa...

Embodiment 2

[0049] Compared with Example 1, sodium chloride and lithium hydroxide are not added in step 1, and all other step parameters remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com