Lithium metasilicate doped graphene lithium ion battery anode material and preparation method thereof

A lithium-ion battery, lithium metasilicate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems affecting graphene cycle performance and rate performance, stacking or agglomeration, etc., to achieve convenient transmission and simple preparation method , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add the silicon powder and graphite oxide mixture to the ethanol aqueous solution of lithium hydroxide, wherein the concentration of silicon powder is 7.5g / L, the mass ratio of graphite oxide in the silicon powder and graphite oxide mixture is 33%, lithium hydroxide and silicon powder The mol ratio is: lithium hydroxide: silicon powder=2:1, and the volume ratio of dehydrated alcohol and water in the ethanol aqueous solution is: V 无水乙醇 :V 水 = 3:1; Stir evenly afterwards to prepare the reaction mixture, then place it in a polytetrafluoroethylene-lined stainless steel reactor, react at a hydrothermal temperature of 180°C for 18h, filter and wash the resulting product in an oven Drying at 60°C yields Li 2 SiO 3 / GE precursor, and then sintered at 600°C in an argon atmosphere for 3 hours to obtain the product.

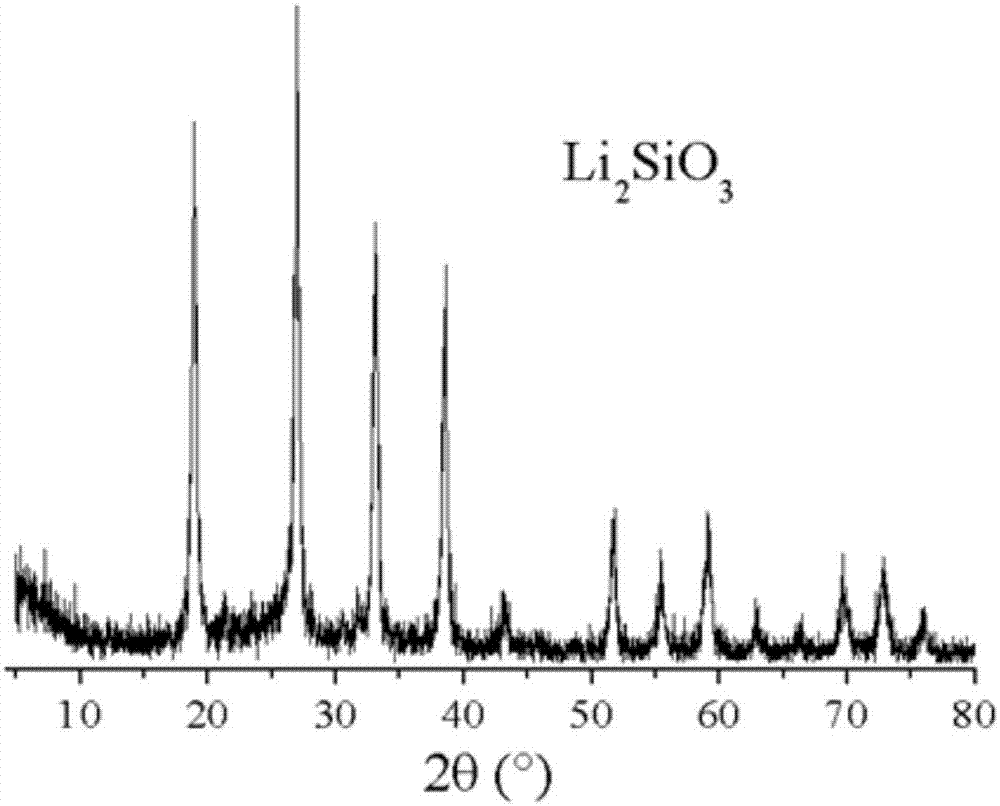

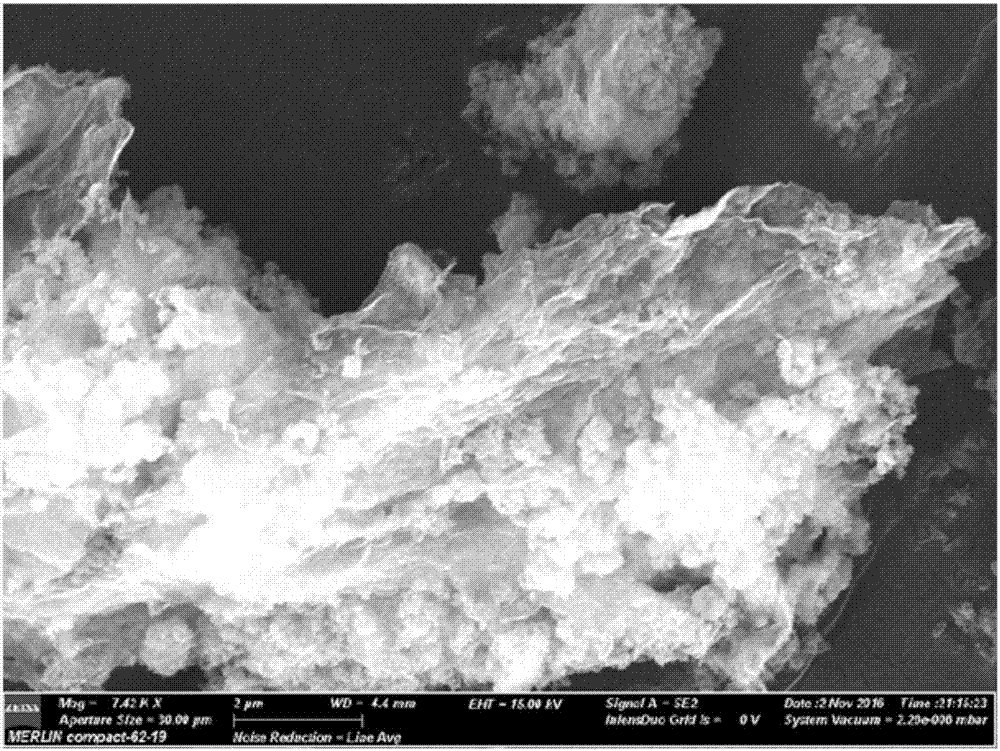

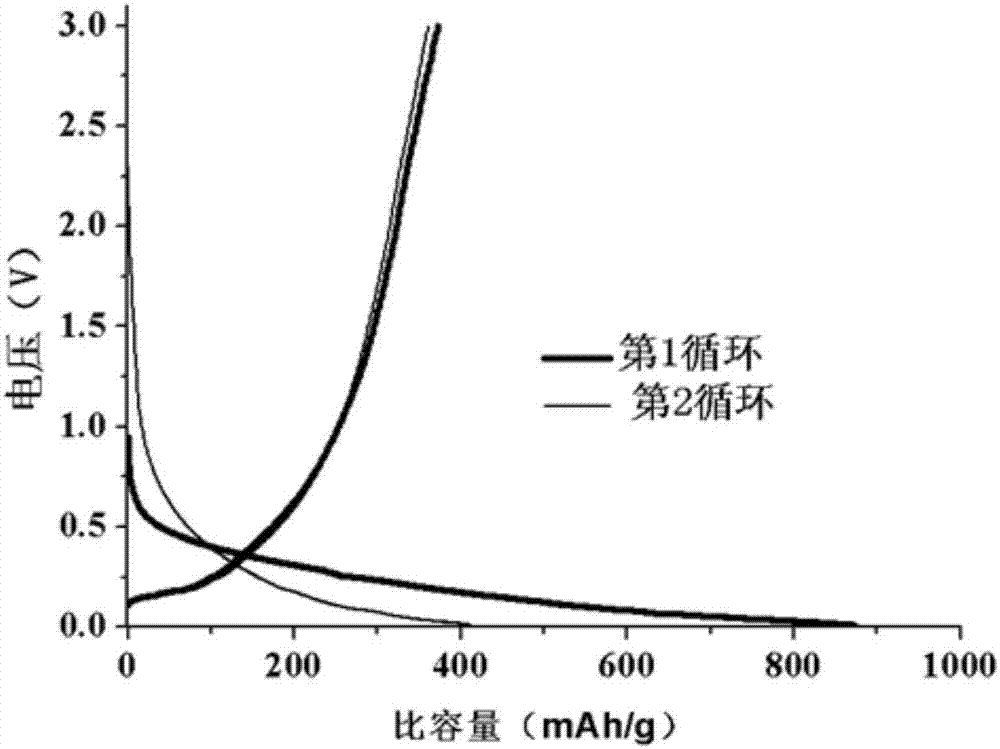

[0027] The XRD and SEM figures of the product are as follows figure 1 and figure 2 shown. Depend on figure 1 It can be seen that the main diffraction peaks o...

Embodiment 2

[0029] Add the silicon powder and graphite oxide mixture to the ethanol aqueous solution of lithium hydroxide, wherein the concentration of silicon powder is 7.5g / L, the mass ratio of graphite oxide in the silicon powder and graphite oxide mixture is 0.5%, lithium hydroxide and silicon powder The mol ratio is: lithium hydroxide: silicon powder=2:1, and the volume ratio of dehydrated alcohol and water in the ethanol aqueous solution is: V 无水乙醇 :V 水 = 3:1; Stir evenly afterwards to prepare the reaction mixture, then place it in a polytetrafluoroethylene-lined stainless steel reactor, react at a hydrothermal temperature of 160°C for 24h, filter and wash the product in an oven at 50 ℃ dried to obtain Li 2 SiO 3 / GE precursor, and then sintered in an argon atmosphere at 500 °C for 4 hours to obtain the product lithium metasilicate-doped graphene (Li 2 SiO 3 / GE) material.

Embodiment 3

[0031] Add the silicon powder and graphite oxide mixture to the ethanol aqueous solution of lithium hydroxide, wherein the concentration of silicon powder is 7.5g / L, the mass ratio of graphite oxide in the silicon powder and graphite oxide mixture is 40%, lithium hydroxide and silicon powder The mol ratio is: lithium hydroxide: silicon powder=2:1, and the volume ratio of dehydrated alcohol and water in the ethanol aqueous solution is: V 无水乙醇 :V 水 = 3:1; Stir evenly afterwards to prepare the reaction mixture, then place it in a polytetrafluoroethylene-lined stainless steel reactor, react at a hydrothermal temperature of 200°C for 16h, filter and wash the product in an oven at 80 ℃ dried to obtain Li 2 SiO 3 / GE precursor, and then sintered in an argon atmosphere at 600°C for 4 hours to obtain the product lithium metasilicate-doped graphene (Li 2 SiO 3 / GE) material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com