High temperature solid state preparation method of lithium ion battery cathode material lithium metasilicate

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, silicates, secondary batteries, etc., can solve the problems of high cost, insufficient power density and energy density, etc., and achieve small grain size, good crystallization, electrical The effect of improving chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] LiOH and SiO 2 Weigh according to the stoichiometric ratio of Li:Si=2:1, mix evenly, use a planetary ball mill, add an appropriate amount of ethanol, just submerge the raw materials, use wet ball milling for 8 hours, and then dry in an oven;

[0042] Then place it at 5%H 2 -Ar (the volume of hydrogen accounted for 5% of the total volume, and the volume of Ar accounted for 95% of the total volume) gas mixture atmosphere, 300 ° C for heating pretreatment for 5 hours, after natural cooling, a powdery product was obtained;

[0043] In the planetary ball mill, use the same method to ball mill again for 6h, dry in the oven, and 2 Sintering at 780°C for 12 h under air atmosphere to obtain lithium metasilicate [Li 2 SiO 3 ] Anode material.

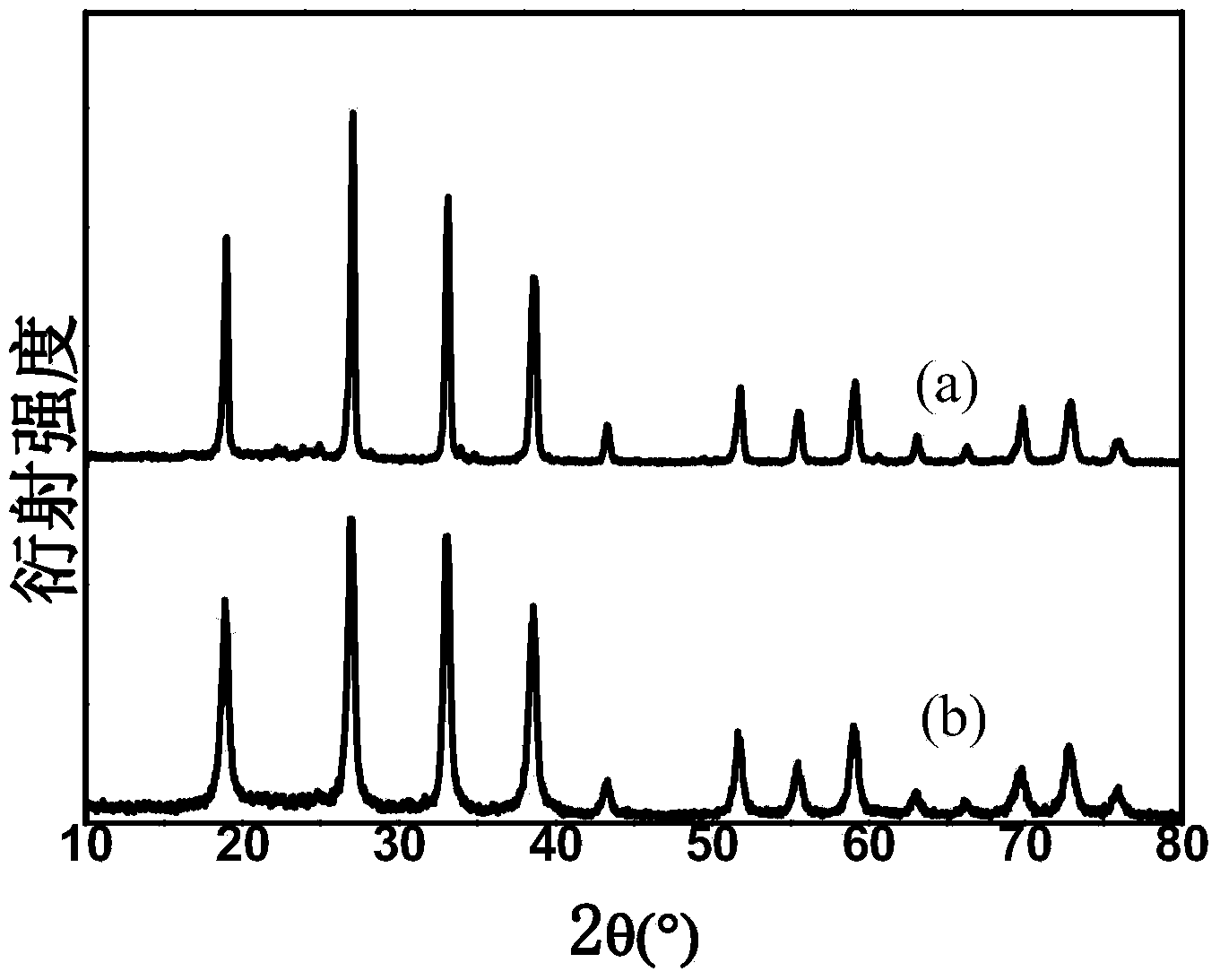

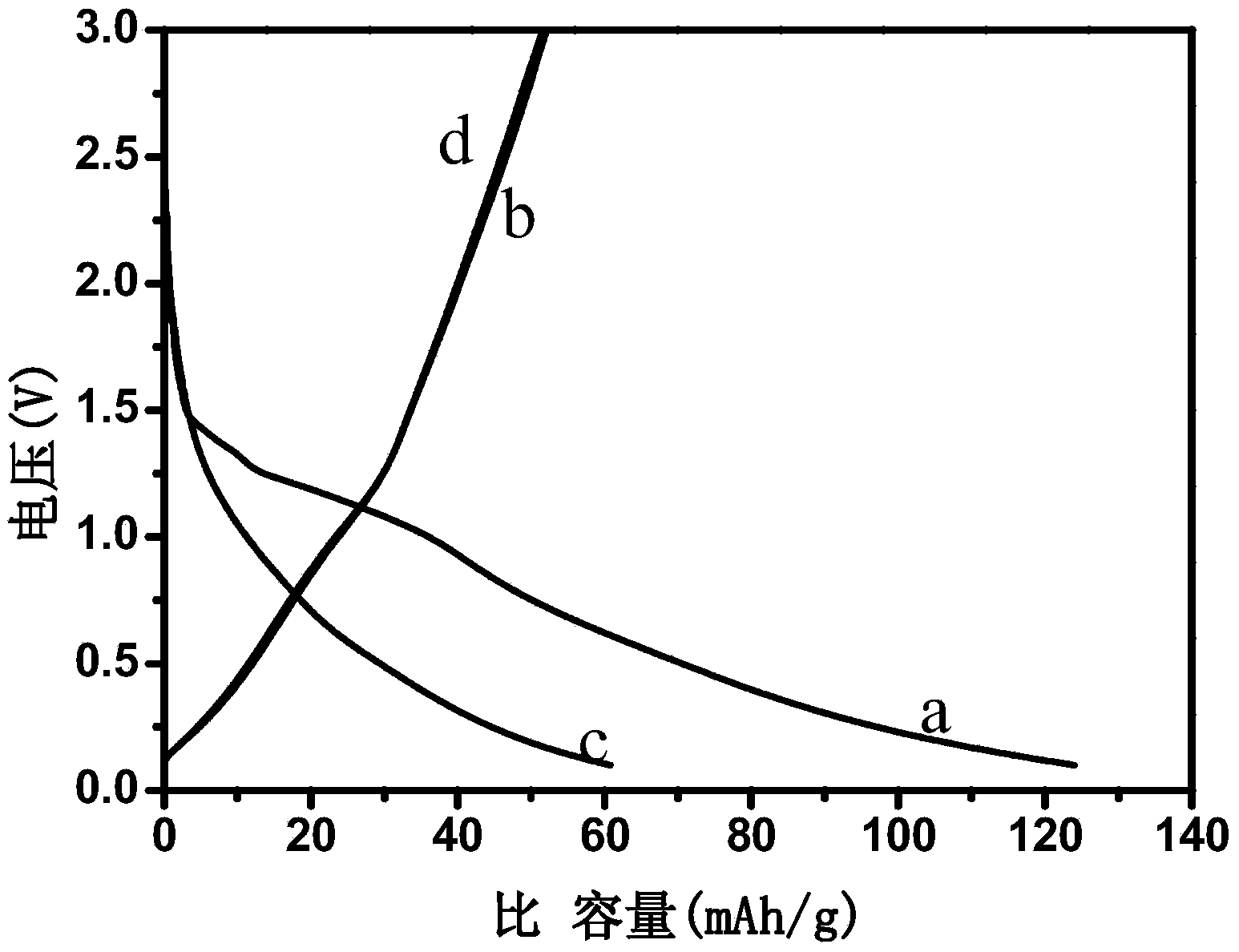

[0044] The XRD pattern of the product is shown in figure 1 The curve (a) in the figure shows that the pure-phase orthorhombic lithium metasilicate negative electrode material was synthesized by this high-temperature solid-state sinteri...

Embodiment 2

[0046] LiNO 3 and H 2 SiO 3 Weigh according to the stoichiometric ratio of Li:Si=2:1, mix evenly, use a planetary ball mill, add an appropriate amount of ethanol, just submerge the raw materials, use wet ball milling for 12 hours, and then dry in an oven;

[0047] Then it was heated and pretreated at 260°C for 8 hours under a nitrogen atmosphere, and after natural cooling, a powdery product was obtained;

[0048] The above-mentioned powdery product was ball-milled for 5 hours again in the planetary ball mill in the same way, and the 2 Sintering at 740° C. for 10 h in an Ar mixed gas atmosphere to obtain a lithium metasilicate negative electrode material. Add acetylene black accounting for 10wt% of its mass fraction in the above-mentioned powdery product as a carbon source, after manual grinding, in 5% H 2 -Ar (hydrogen accounted for 5% of the total volume, Ar accounted for 95% of the total volume) gas mixture atmosphere, 350 ℃ for 4 hours to obtain carbon-coated lithium me...

Embodiment 3

[0051] LiCH 3 COO and SiO 2 Take by weighing according to the stoichiometric ratio of Li:Si=2:1, grind in an agate mortar for 40min, and mix well;

[0052] Then carry out pretreatment at 300°C for 12 hours under air atmosphere, and after natural cooling, a powdery product is obtained;

[0053] Add citric acid accounting for 5wt% of the mass of the above powder product as a carbon source, hand grind it in an agate mortar for half an hour; sinter at 770°C for 6 hours under an argon atmosphere to obtain carbon-coated partial silicon Lithium Oxide [Li 2 SiO 3 ] Anode material.

[0054] The XRD pattern of the product is shown in Figure 8 (a), as can be seen from the figure, a pure-phase orthorhombic lithium metasilicate anode material was synthesized by high-temperature solid-state sintering. There is no impurity peak in the spectrum, and the product has high purity. Figure 9 It is a scanning electron microscope picture of the lithium metasilicate negative electrode materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com