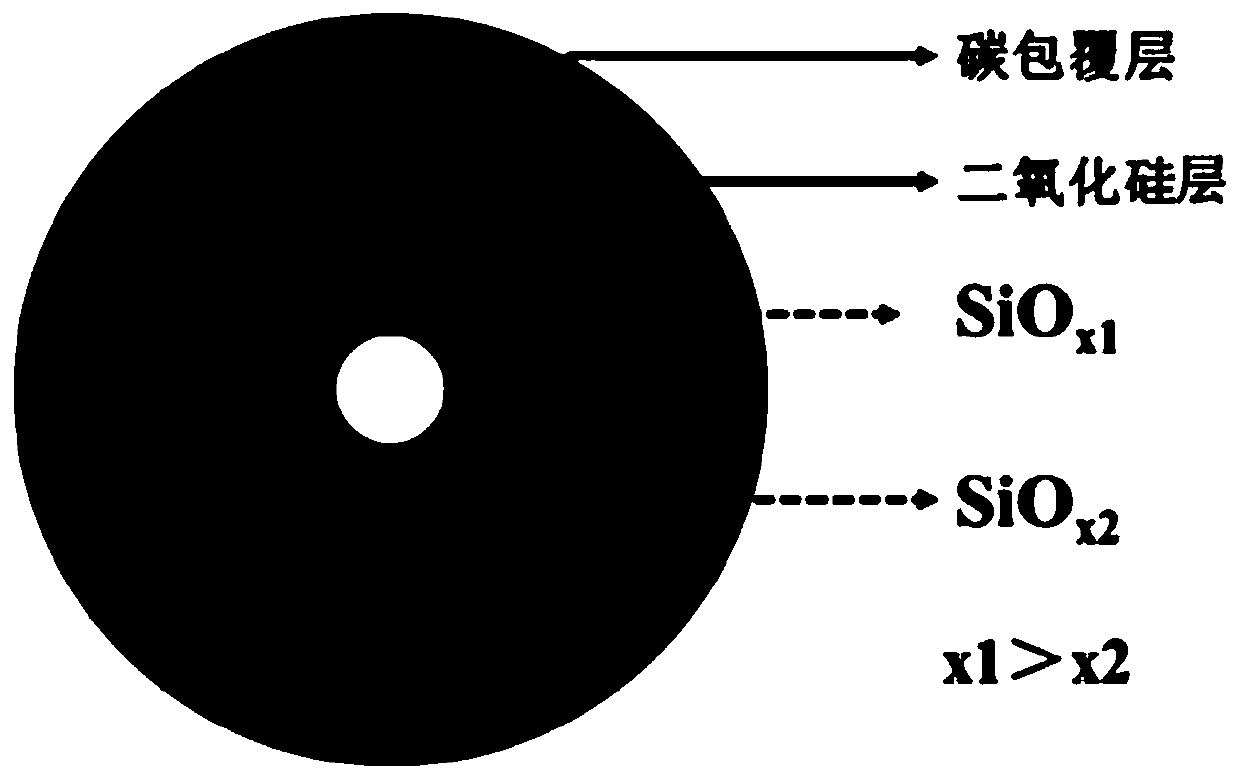

Silicon oxide composite cathode material with gradient structure and preparation method and application thereof

A silicon oxide and negative electrode material technology, which is applied in the field of lithium-ion batteries, can solve problems such as fragmentation and uneven stress, and achieve the effects of reduced surface pulverization, uniform stress, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

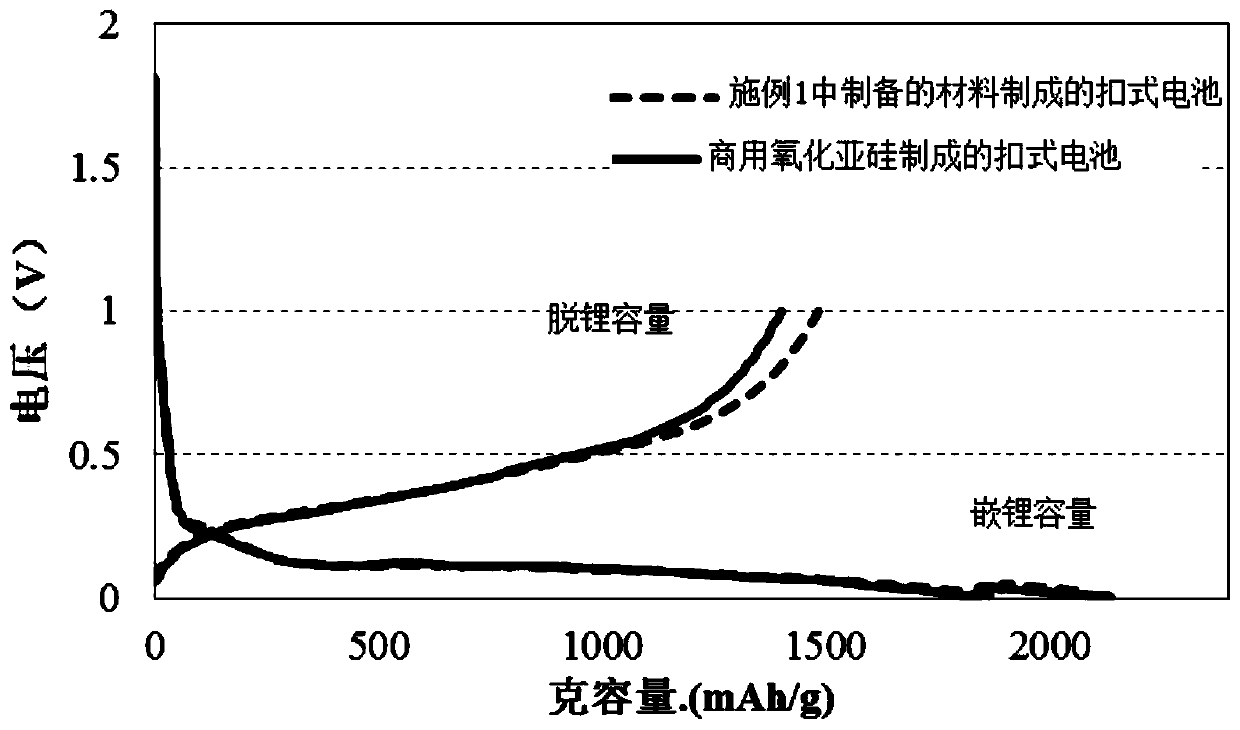

Examples

Embodiment 1

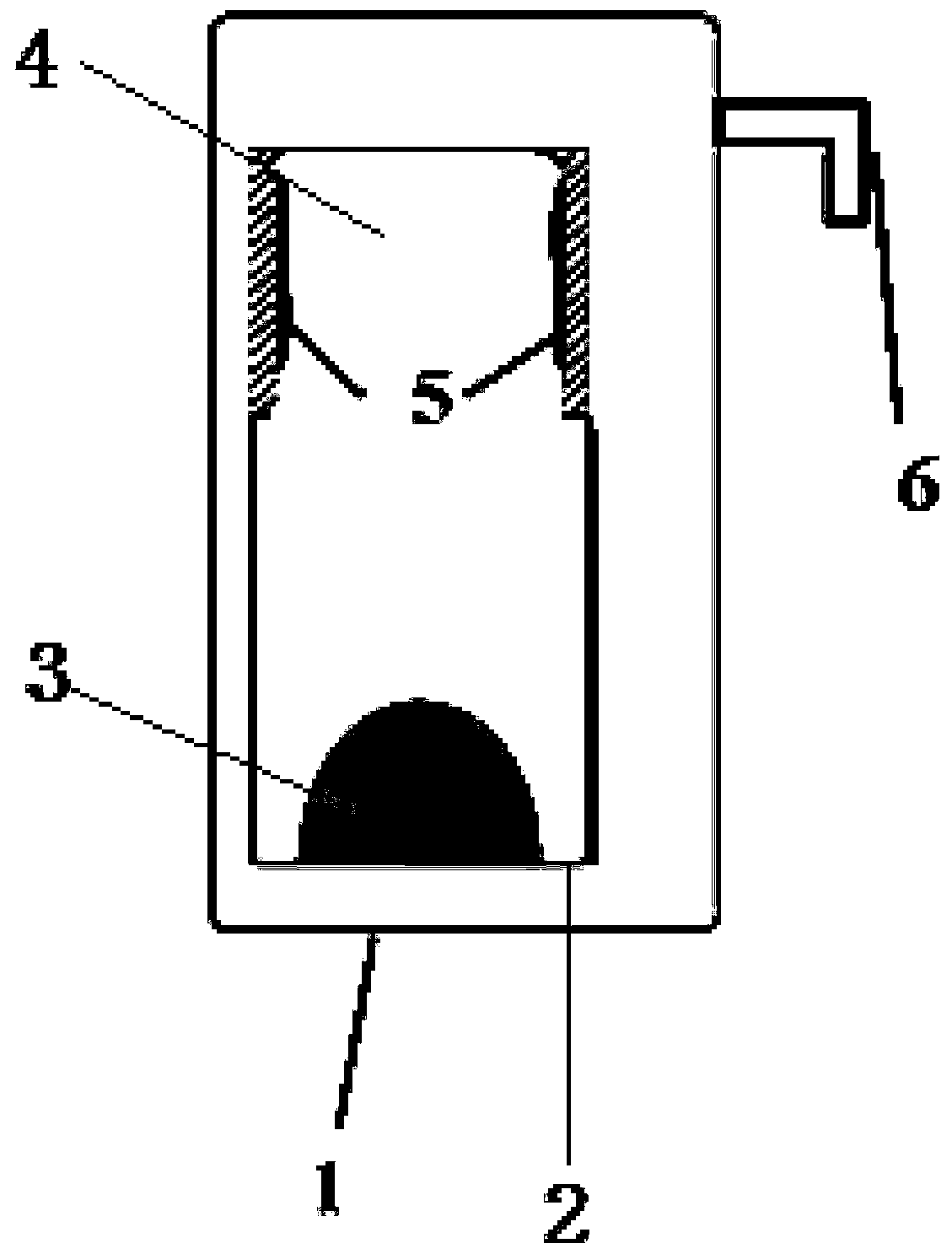

[0035] Preparation of silicon oxide composite anode material with gradient structure:

[0036](1) Uniformly disperse 40 g of monodisperse silica microspheres with a median diameter D50=300nm on a collecting device and pre-dry;

[0037] (2) The raw materials Si, SiO 2 Separately crushed to micron size, according to Si: SiO 2 The molar ratio of 1:10, 1:2, 1:1, 2:1, 10:1 is fully mixed, and an appropriate amount of deionized water is added for kneading to obtain five Si, SiO 2 Mixed material sample, denoted as A 1 , A 2 , A 3 , A 4 , A 5 ; each weighed 900g (solid content) A 1 , A 2 , A 3 , A 4 , A 5 ;

[0038] (3) First, put A 1 Put it into the furnace cavity, the vacuum cavity 1 is heated up to 200°C at a rate of 10°C per minute in a vacuum state, and kept for 1h to ensure that Si, SiO 2 The moisture in the mixed material sample is fully dried; the collection device is placed above the furnace cavity, and the furnace cavity is heated to 1350°C, A 1 Si and SiO in ...

Embodiment 2

[0048] Preparation of silicon oxide composite anode material with gradient structure:

[0049] (1) Uniformly disperse 40 g of monodisperse silica microspheres with a median diameter D50=100 nm on a collecting device and pre-dry;

[0050] (2) The raw materials Si, SiO 2 Separately crushed to micron size, according to Si: SiO 2 The molar ratio of 1:5, 3:5, 1:1, 5:3, 5:1 is fully mixed, and an appropriate amount of deionized water is added for kneading to obtain five Si, SiO 2 Mixed material sample, denoted as A 1 , A 2 , A 3 , A 4 , A 5 ; each weighed 900g (solid content) A 1 , A 2 , A 3 , A 4 , A 5 ;

[0051] (3) First, put A 1 Put it into the furnace cavity, the vacuum cavity 1 is heated up to 200°C at a rate of 10°C per minute in a vacuum state, and kept for 1h to ensure that Si, SiO 2 The moisture in the mixed material sample is fully dried; the collection device is placed above the furnace cavity, and the furnace cavity is heated to 1350°C, A 1 Si and SiO in ...

Embodiment 3

[0055] Preparation of silicon oxide composite anode material with gradient structure:

[0056] (1) Uniformly disperse 1kg of monodisperse silica microspheres with median diameter D50=1000nm on the collection device and pre-dry;

[0057] (2) The raw materials Si, SiO 2 Separately crushed to micron size, according to Si: SiO 2 The molar ratio of 1:5, 3:5, 1:1, 5:3, 5:1 is fully mixed, and an appropriate amount of deionized water is added for kneading to obtain five Si, SiO 2 Mixed material sample, denoted as A 1 , A 2 , A 3 , A 4 , A 5 ; each weighed 900g (solid content) A 1 , A 2 , A 3 , A 4 , A 5 ;

[0058] (3) First, put A 1 Put it into the furnace cavity, the vacuum cavity 1 is heated up to 200°C at a rate of 10°C per minute in a vacuum state, and kept for 1h to ensure that Si, SiO 2 The moisture in the mixed material sample is fully dried; the collection device is placed above the furnace cavity, and the furnace cavity is heated to 1300 ° C, A 1 Si and SiO in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com