Veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide and method for applying said veneering ceramic

A zirconium dioxide and yttrium stabilized technology, used in dental prostheses, dentistry, dental preparations, etc., can solve problems such as insufficient tooth edge strength and high tool wear

Active Publication Date: 2013-05-01

FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

View PDF11 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it has been shown that with this method the edge strength on the restored tooth is insufficient and high tool wear occurs during post-processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0036] Typical compositions are shown in Table 1 below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical stability | aaaaa | aaaaa |

Login to View More

Abstract

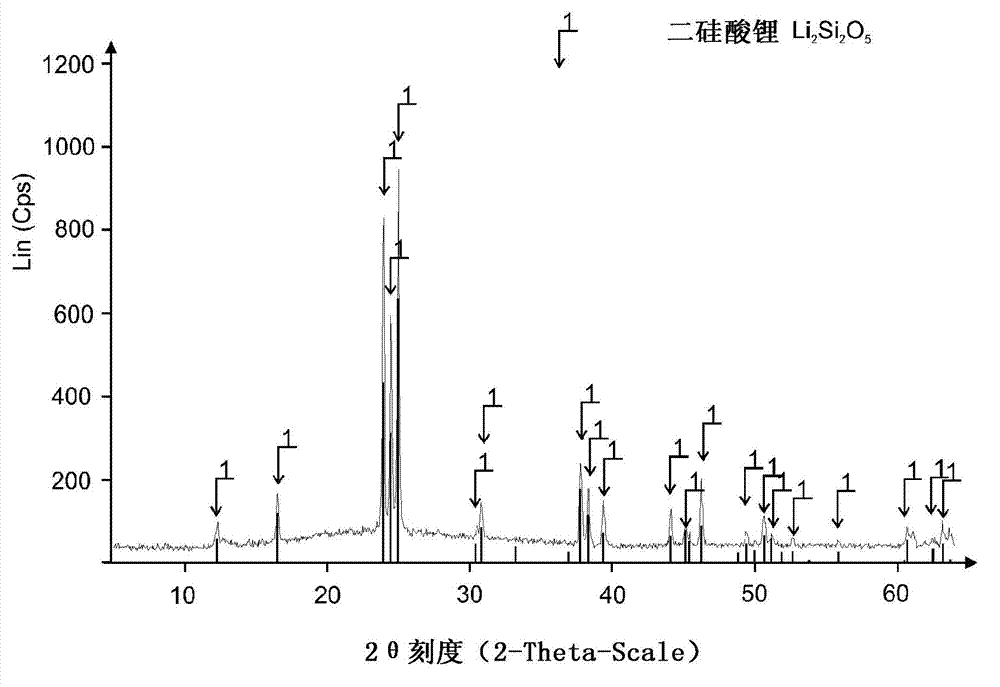

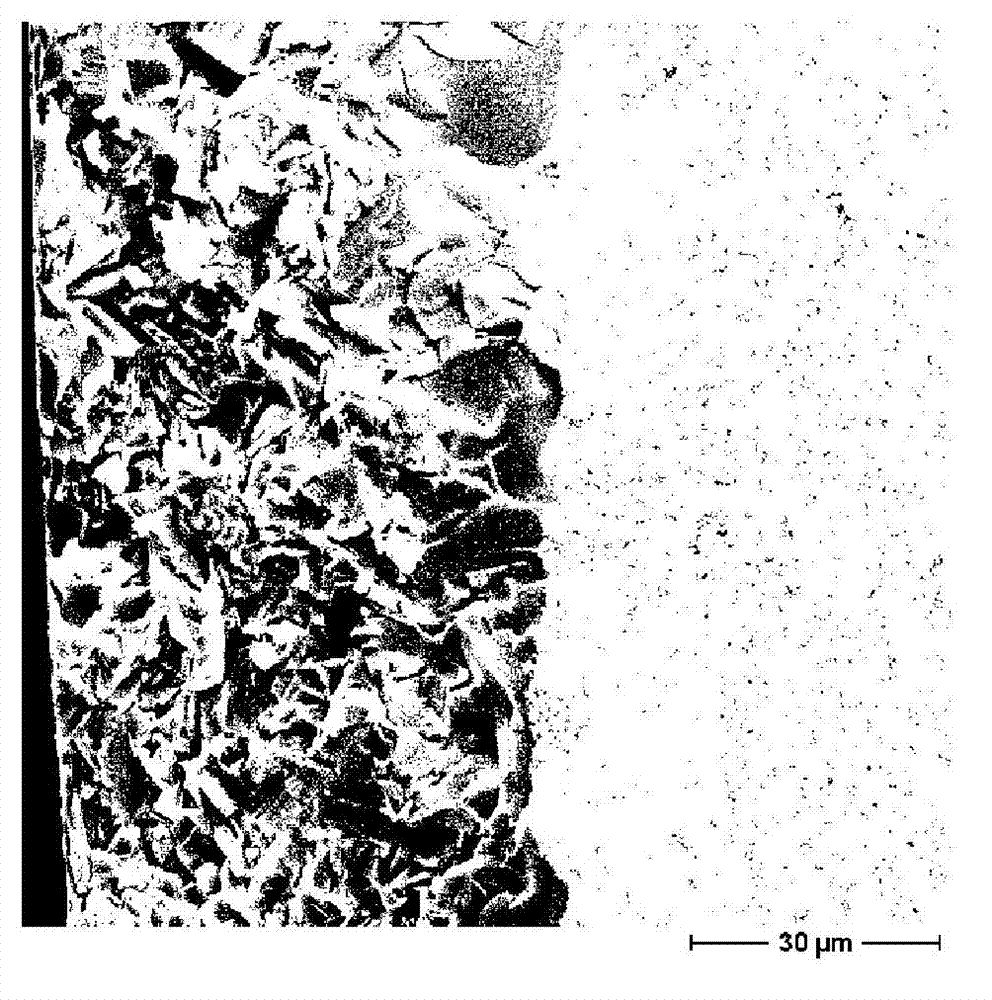

The invention relates to veneering ceramics for dental restorations, wherein the framework ceramic is made of yttrium-stabilized zirconium dioxide. The aim of the invention is to develop a translucent veneering ceramic based on lithium disilicate and a method for applying the veneering ceramic for dental restorations made of yttrium-stabilized zirconium dioxide. Said veneering ceramic should not contain any leucite, lithium metasilicate, or ss-spodumene and should have very good chemical resistance, high adhesive strength with respect to zirconium dioxide, and good surface quality. According to the invention, said aim is achieved for a veneering ceramic on yttrium-stabilized zirconium dioxide in that the veneering ceramic is produced from the following components: a) SiO2 55.0 - 72.5 mass percent; b) Nb2O5 6.0 - 19.8 mass percent; c) B2O3 1.0 - 9.0 mass percent; d) Al2O3 1.2 - 6.0 mass percent; e) Li2O 5.0 - 16.5 mass percent; f) Na2O 1.4 - 11.0 mass percent; and g) ZrO2 0.5 - 4.0 mass percent, and is provided with a thin glass layer formed during the crystallization on the surface of the veneering ceramic.

Description

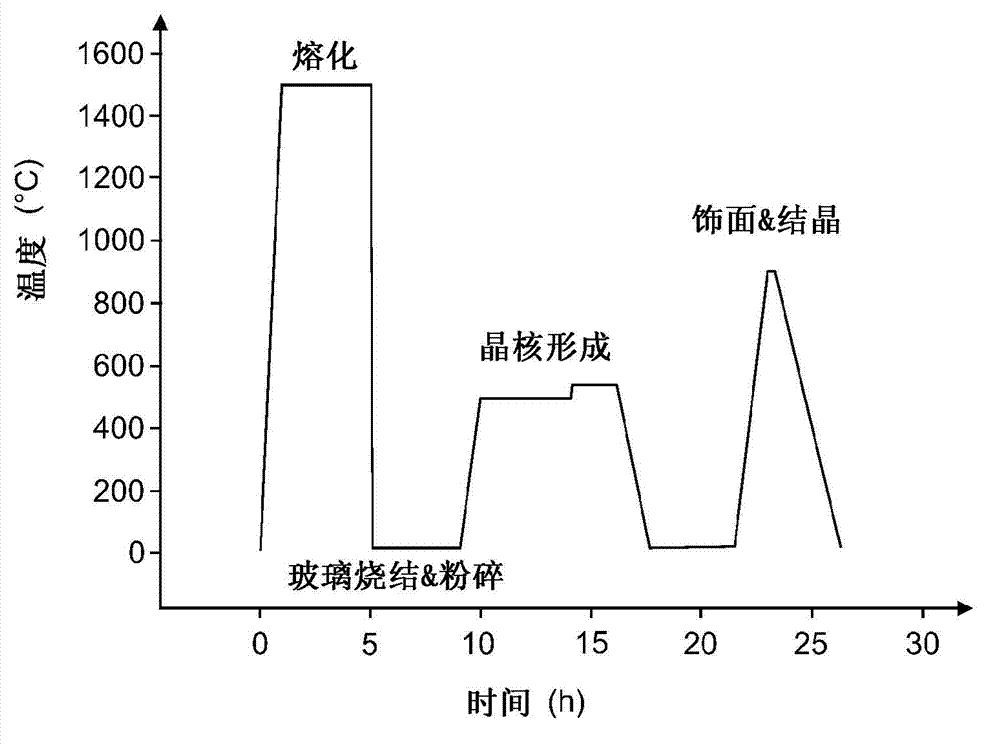

technical field [0001] The invention relates to veneering ceramics for dental restorations, wherein the support ceramic is made of yttrium-stabilized zirconia. [0002] The properties of facing ceramics are determined by the chemical composition, crystal phase, crystal structure and grain size of the starting materials. The object is to meet the high mechanical, chemical and aesthetic demands placed on the facing ceramic and at the same time to reduce the production effort in modeling the facing ceramic. Background technique [0003] For the veneering of dental restorations, the prior art is provided by leucite-containing dental ceramics. In patent US 4,798,536A, the leucite content is in the range of 35 to 60% by weight. The flexural fracture strength of veneered ceramics with leucite crystals is about 80 MPa. [0004] It is suggested in patent US4,515,634A that in the base system Li 2 O-CaO-Al 2 o 3 -SiO 2 nucleating agent P 2 o 5 Used to improve nucleation and cr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C10/04A61K6/00A61K6/027C03C8/02C04B41/86A61K6/02C04B35/16

CPCC04B2235/5445C04B2235/3409C04B35/6261C04B2235/3206C04B2235/3201C03C8/14A61K6/0273C04B2235/3232C04B41/009C04B2235/3215C04B2235/3217A61K6/0255C04B41/86C03C2205/06C03C8/02C04B2235/3203C03C10/0054A61K6/025A61K6/0017C04B2235/3284C04B2111/80A61K6/024C04B2111/00836C04B2235/3208C04B2235/3251C04B2235/3227C03C10/0027C04B2235/447C04B41/5023C04B35/62665C04B2235/445A61K6/0094C04B2235/5436C04B35/16C03C3/097C04B2235/3244A61K6/20A61K6/78A61K6/818A61K6/822A61K6/824A61K6/833C04B35/48C04B41/4539

Inventor 马丁纳·约翰内斯罗兰德·埃尔特

Owner FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com