Preparation method for dental lithium silicate microcrystalline glass

A technology of glass-ceramics and lithium disilicate, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of no commercial products, and achieve the effect of low block strength and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

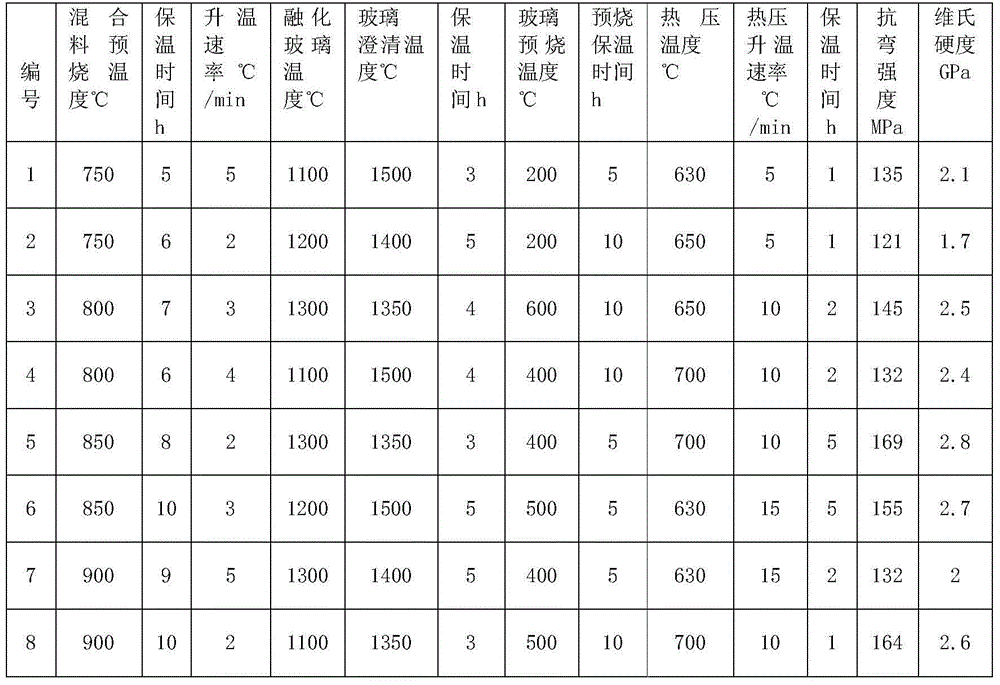

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

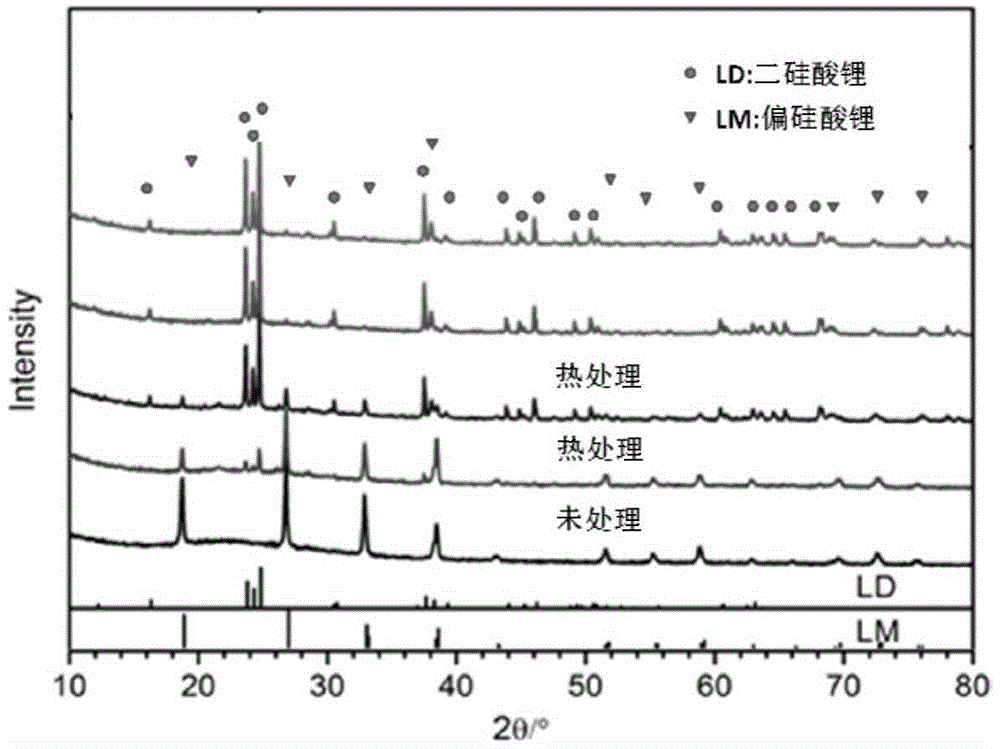

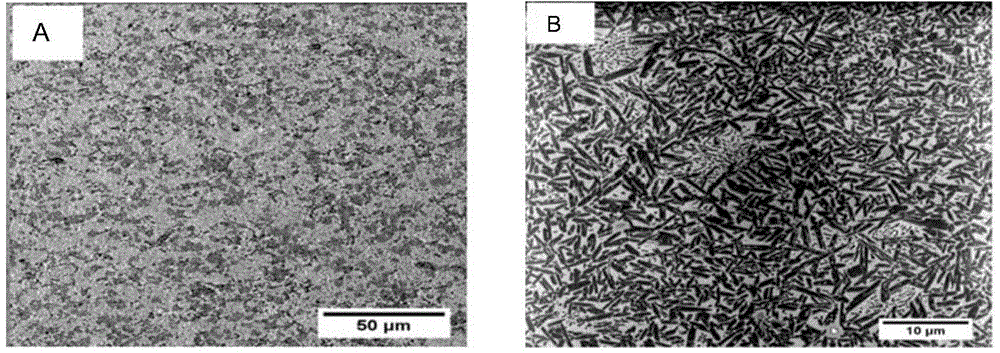

[0024] In the first stage, according to the formula ingredients in Table 1, LiO 2 、K 2 O is introduced in the form of carbonate, P 2 o 5 Take NH 4 h 2 PO 5 The raw material grade is analytically pure, the ingredients are mixed by ball milling, the ball milling medium is absolute ethanol, and the mass ratio of balls, materials, and medium is 2:1:1. The ball-milled mixture is passed through a 300-mesh sieve, put into an alumina crucible, and pre-fired in an air furnace to fully decompose the carbonate in the raw material; melt the completely decomposed mixture in a resistance furnace, and then add The temperature clarifies the glass liquid (the glass liquid can be mechanically stirred during the clarification process), and the clarified glass liquid is quickly poured into a stainless steel bucket filled with water and water-quenched to obtain a transparent gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com