Porous lithium salt aerogel coated graphite composite material and preparation method thereof

A composite material and aerogel technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of long cycle performance deviation of materials and difficulty in accommodating lithium ions, achieve reasonable pore distribution, improve initial efficiency, and improve liquid absorption. The effect of fluid retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

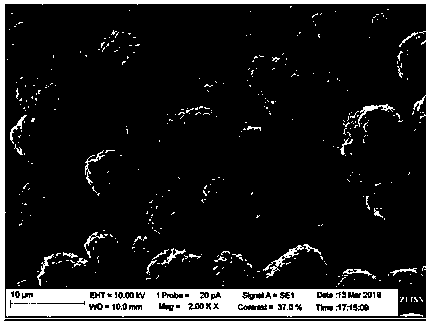

Image

Examples

Embodiment 1

[0026] A preparation method of porous lithium salt airgel coated graphite composite material, comprising the following steps:

[0027] 1) Preparation of alumina / silicon oxide / titania airgel;

[0028] Weigh 17.2g (0.13mol) of aluminum chloride into a beaker, add 172.9ml of distilled water and ethanol (96ml of distilled water and 76.9ml of ethanol) to dissolve it, stir until 10%wt alumina sol A is formed; weigh 18.9g at the same time (0.1mol) titanium chloride, add 189ml of water and ethanol (105ml of distilled water and 84ml of ethanol) and magnetically stir to make it dissolve, then add 62.4g (0.3mol) ethyl orthosilicate magnetically and 621ml of distilled water and stir for 24h and magnetically stir to make It generates 10%wt silica / titania composite sol B, then adds sol A to sol B and mixes evenly and then stirs for 30 minutes to make it disperse evenly, then adds 294g of propylene oxide and stirs rapidly for 30min, then in Let this sol stand until it forms a gel, i.e. alum...

Embodiment 2

[0034] A preparation method of porous lithium salt airgel coated graphite composite material, comprising the following steps:

[0035] 1) Preparation of alumina / silicon oxide / titania airgel;

[0036] Weigh 13.3 (0.1mol) of aluminum chloride and put it into a beaker, add 133ml of distilled water and ethanol (74ml of distilled water and 59ml of ethanol) to dissolve it, stir until 10%wt alumina sol A is formed; weigh 9.45g (0.05 mol) titanium chloride, add 94.5ml water and ethanol (52.5ml distilled water and 42ml ethanol) and magnetically stir to make it dissolve, then add 41.6g (0.2mol) ethyl tetrasilicate magnetically and 926ml distilled water and magnetically stir for 24h to make it Generate 5%wt silicon dioxide / titania composite sol B, then add sol A to sol B and stir for 30 minutes after mixing evenly, then add 193.05g of propylene oxide and stir for 30min quickly, then let it stand sol until it forms a gel, i.e. alumina / silica / titania airgel;

[0037] 2) Preparation of po...

Embodiment 3

[0042] A preparation method of porous lithium salt airgel coated graphite composite material, comprising the following steps:

[0043] 1) Preparation of alumina / silicon oxide / titania airgel;

[0044] Weigh 19.95 (0.15mol) of aluminum chloride into a beaker, add 199.5ml of distilled water and ethanol (111ml of distilled water and 88.5ml of ethanol) to dissolve it, stir until 10%wt alumina sol A is formed; weigh 37.8g at the same time (0.2mol) titanium chloride, add 378ml of water and ethanol (210ml of distilled water and 168ml of ethanol) and magnetically stir to dissolve it, then add 83.2g (0.4mol) of tetraethyl orthosilicate magnetically and 227ml of distilled water and magnetically stir for 24h to generate 20%wt silica / titania composite sol B, then add sol A to sol B, mix well and stir for 30 minutes, then add 563.8g of propylene oxide and stir for 30min quickly, then let the sol stand until It forms a gel, namely alumina / silica / titania airgel;

[0045] 2) Preparation of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com