Concrete modified material and its mfg. method

A manufacturing method and concrete technology, which is applied in the field of concrete texture modification materials and its manufacture, can solve the problems of deep penetration, gelation, and small effect of non-waterproof materials, so as to prevent moisture from entering the concrete, prevent concrete from deteriorating, and prevent The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment further illustrate the present invention:

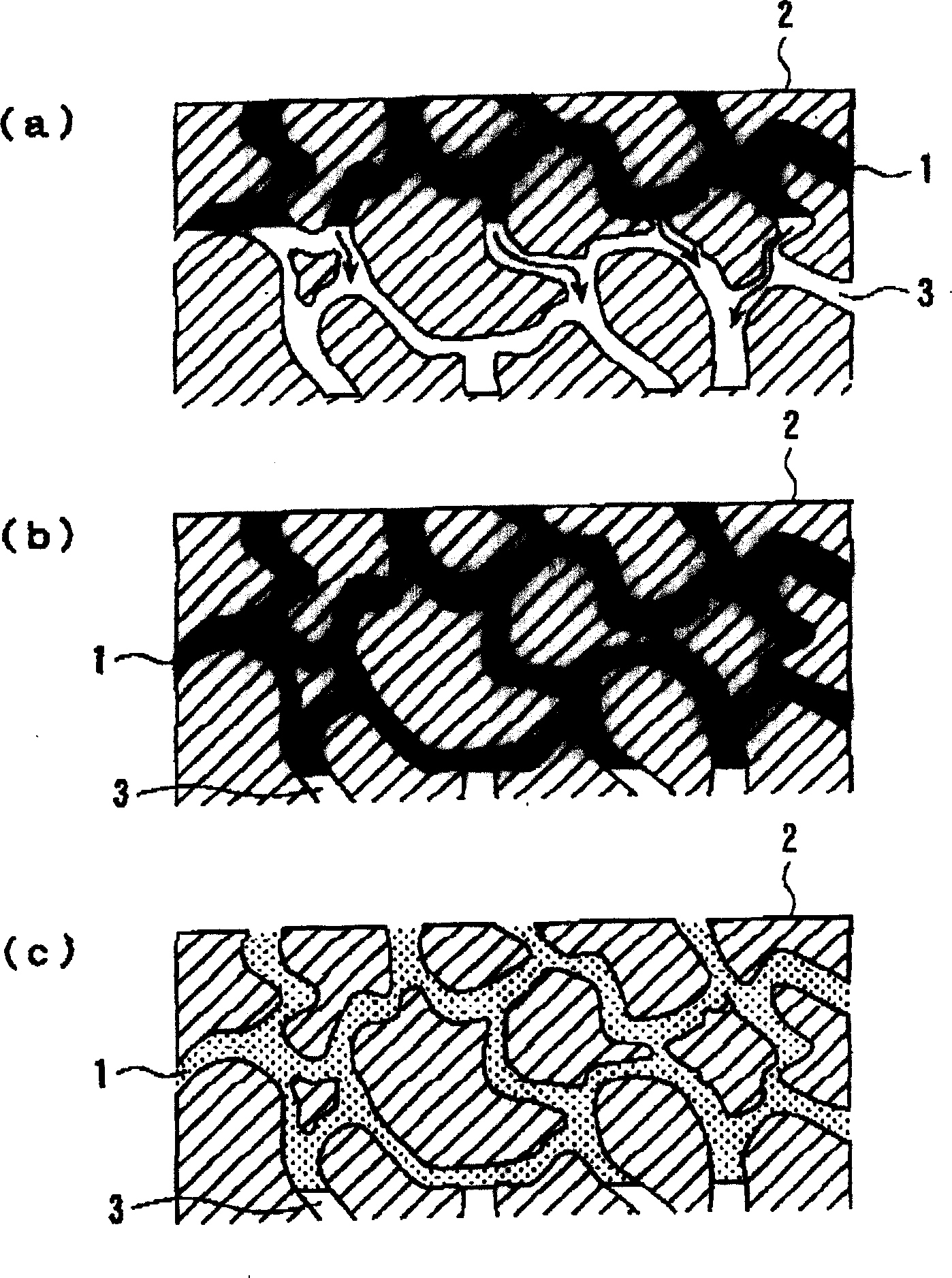

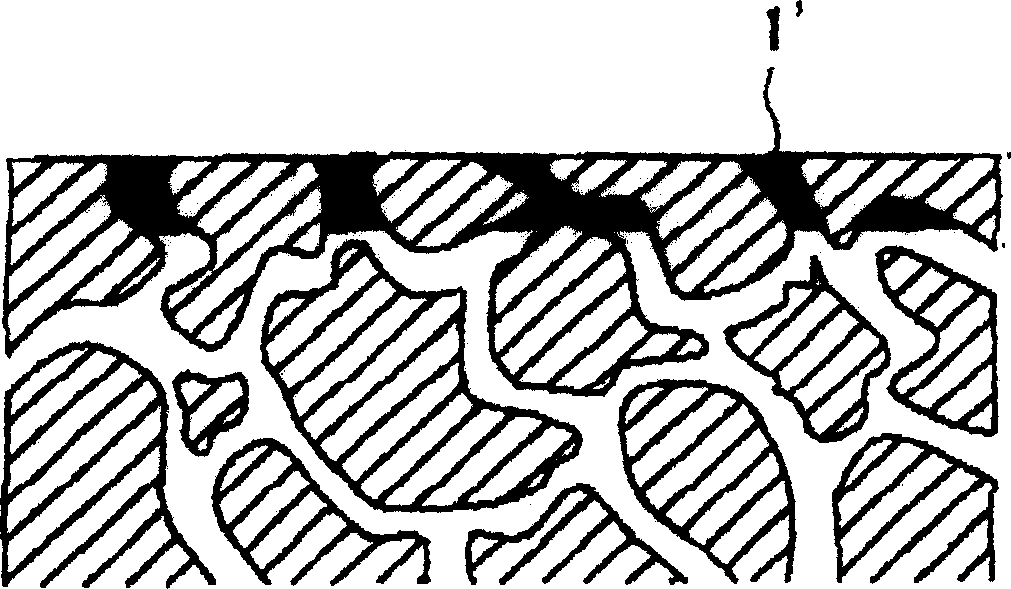

[0015] First, take a certain amount of sodium silicate and potassium silicate, mix them according to the molar ratio of 1:1, make a concentrated solution and then dilute with water, then add sodium hydroxide to the mixed solution of sodium silicate and potassium silicate , stir for about 1 hour. Then, it was filtered through a 3 μm filter to produce a concrete texture modifying material. This concrete modification material is an alkaline silicate mixed aqueous solution containing two elements, sodium and potassium. Apply this concrete modifying material on the surface of the concrete, and apply it on the surface of the pores to protect it. If there are continuous pores in the concrete, such as figure 1 As shown in (a), due to the capillary phenomenon, the reforming material penetrates deep into the continuous pores (voids) of concrete (about 200 mm), gels inside the pores, and fills the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com