High-strength lithium disilicate glass ceramic and preparation method thereof

A technology of lithium disilicate and glass ceramics, which is applied in the field of dental all-ceramic materials, can solve the problems that cannot meet the requirements and limitations of the mechanical properties of dental crowns and bridges, achieve excellent processability, reduce costs, and facilitate large-scale industrialization. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

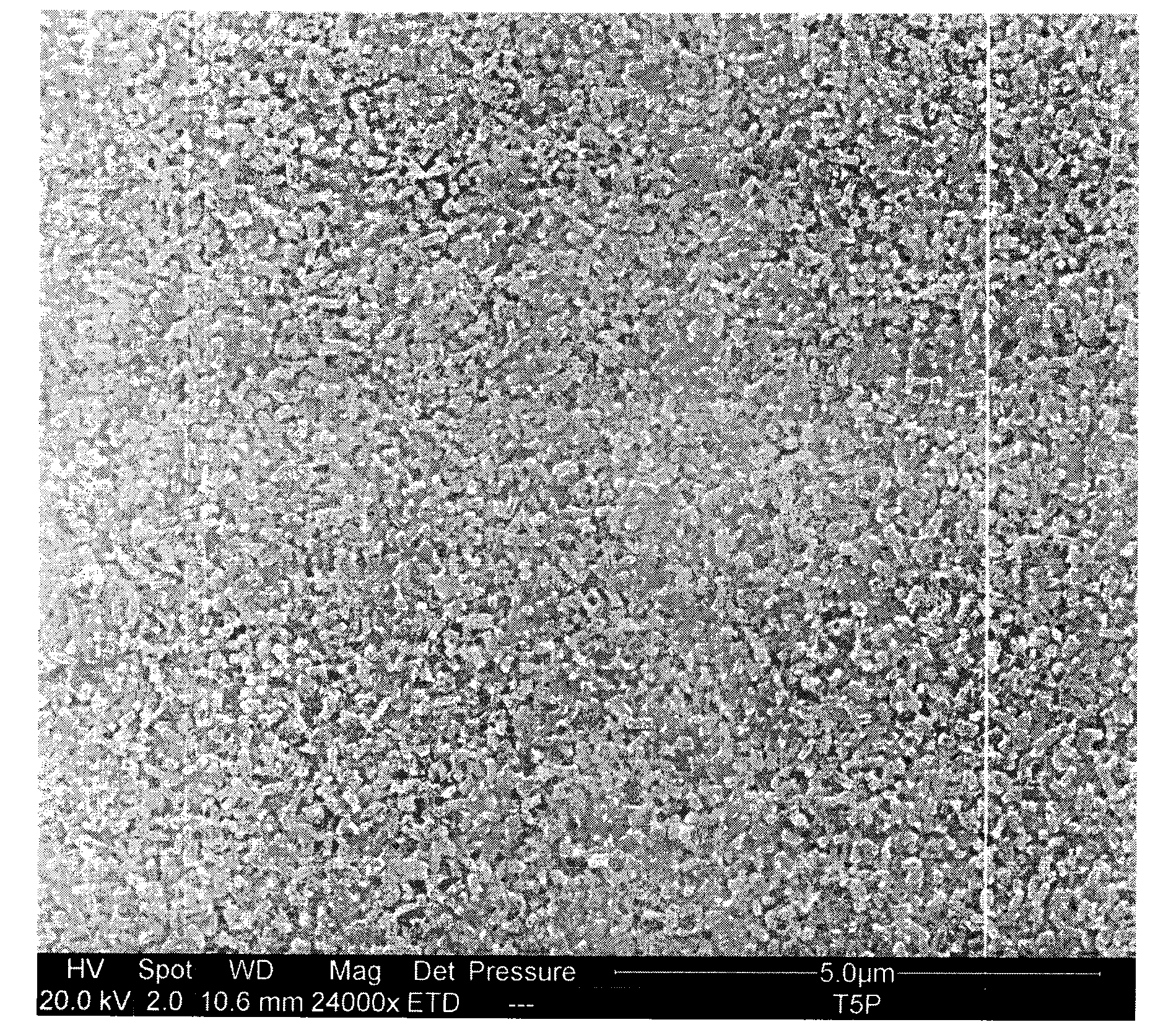

specific Embodiment 1

[0029] Specific embodiment one: in the lithium disilicate glass-ceramic (#1 sample) of the present embodiment, main chemical composition SiO 2 and Li 2 The molar ratio of O is 2.55, containing a small amount of MgO and Al 2 o 3 As a reinforcing component, P 2 o 5 as a glass nucleating agent, and other components listed in Table 1. The base glass was heat-treated in two stages at 675°C and 830°C for 30 minutes each, and Li 2 Si 2 o 5 as the main crystal phase, and a small amount of Li is precipitated 3 PO 4 , β-cristobalite and MgAl 2 Si 4 o 12 crystal phase, the obtained glass-ceramics have excellent properties, with an average three-point flexural strength of 530MPa and an average fracture toughness of 3.4MPa m 0.5 .

specific Embodiment 2

[0030] Specific embodiment two: in the lithium disilicate glass-ceramic (#2 sample) of the present embodiment, SiO 2 and Li 2 The molar ratio of O is 2.47, containing P 2 o 5 Glass nucleating agent and other components listed in Table 1. Compared with the chemical composition of specific example 1, more MgO is introduced and Al is reduced 2 o 3 The amount of addition, using three-stage heat treatment, that is, at 500 ° C for 1 hour for pre-nucleation, 700 ° C for 30 minutes for Li 2 SiO 3 to Li 2 Si 2 o 5 The crystal phase transformation, and the temperature at 820°C for 1 hour makes the crystal phase transformation complete. The main crystal phase Li in the final product 2 Si 2 o 5 It is in the shape of a short rod, and a small amount of Li is precipitated 3 PO 4 , β-quartz (quartz) and Mg 3 al 2 (SiO 4 ) 3 crystal phase, the average three-point flexural strength of the obtained glass ceramics reaches 574MPa, and the average fracture toughness is 3.5MPa m 0...

specific Embodiment 3

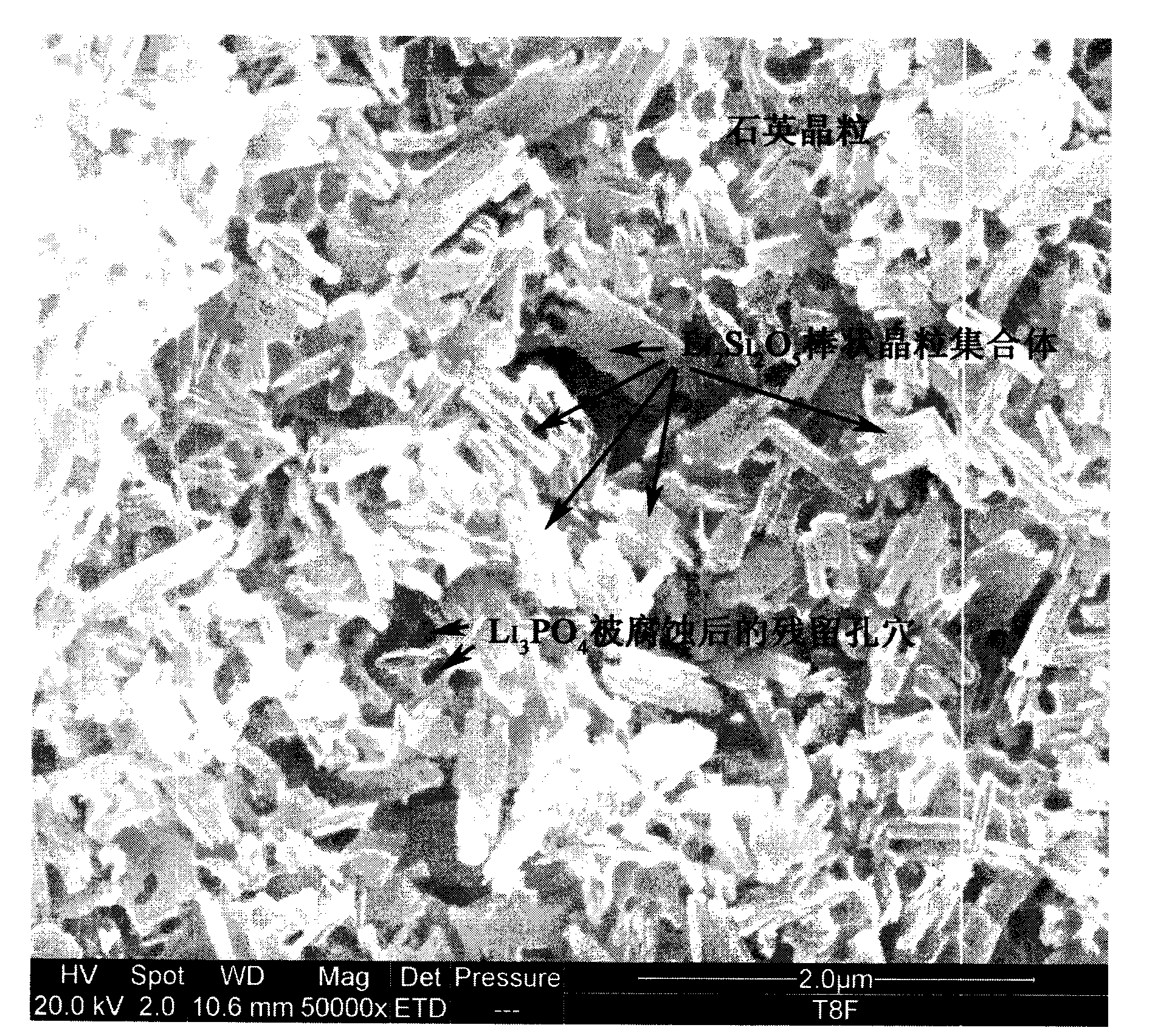

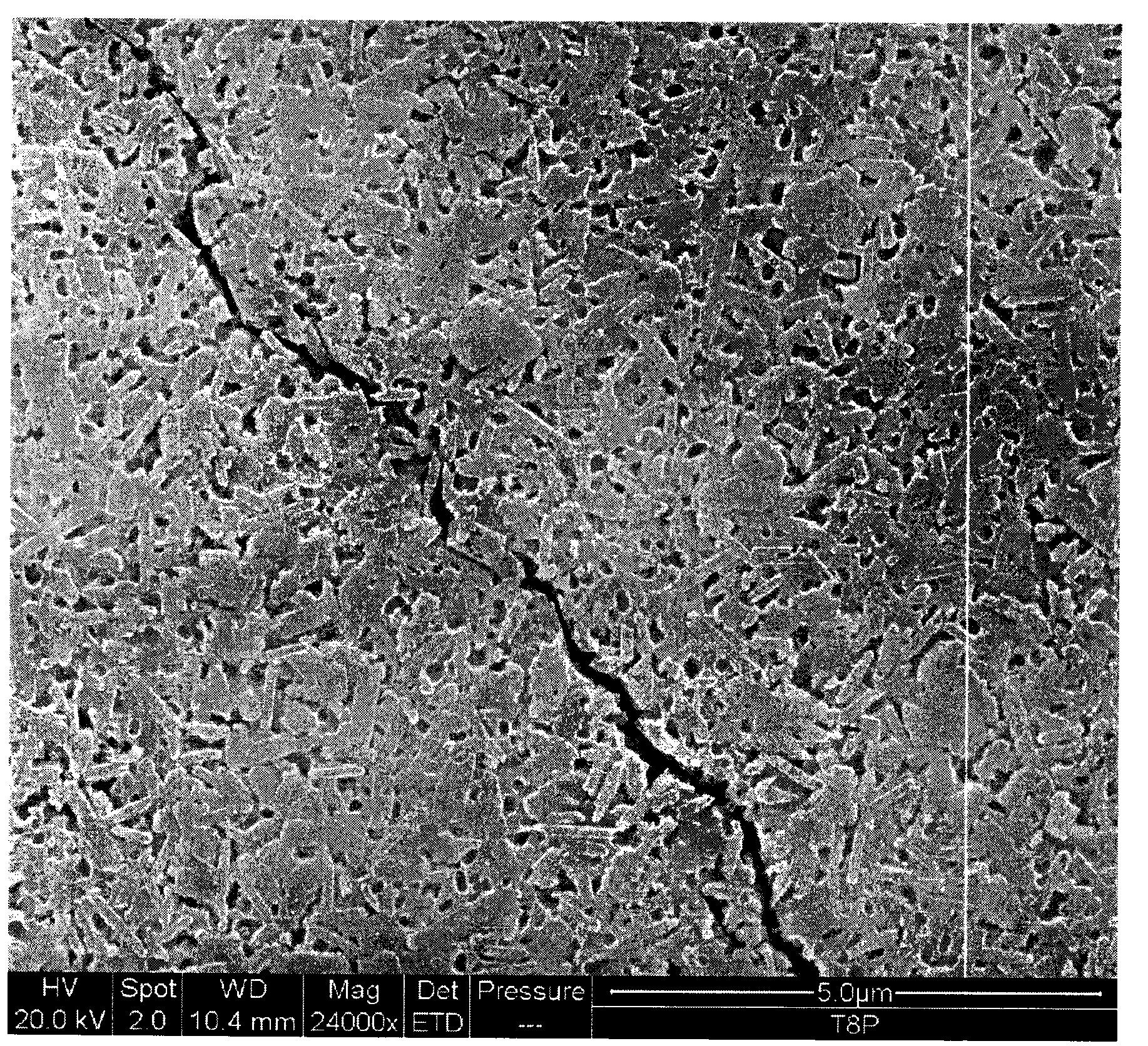

[0031] Specific embodiment three: in the lithium disilicate glass-ceramic (#3 sample) of the present embodiment, SiO 2 : Li 2 The molar ratio of O is 2.49, MgO:Al 2 o 3 The molar ratio is 1:1, P 2 o 5 is a glass nucleating agent and contains other components listed in Table 1. Three-stage heat treatment is adopted, and in the first stage heat treatment, Li 2 SiO 3 The phase is first precipitated, and after the second stage of heat treatment, the phase gradually transforms into nano-Li 2 Si 2 o 5 Phase, in the last stage of crystallization for a longer time of heat preservation. In the final glass ceramics, Li 2 Si 2 o 5 and Li 3 PO 4 Main crystal phase, and a small amount of β-quartz, β-cristobalite and MgAl are precipitated 2 Si 4 o 12 crystal phase. In the microstructure of the final glass-ceramic product, it is found that the lithium disilicate grains are rod-shaped aggregates with a three-dimensional interlocking microstructure, and the crystallization co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com