High-strength bacteriostatic antibacterial lithium disilicate glass ceramic and preparation method thereof

A technology of lithium disilicate and glass ceramics, applied in dental preparations, pharmaceutical formulas, dental prostheses, etc., can solve problems such as reducing the strength of lithium disilicate glass ceramics, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

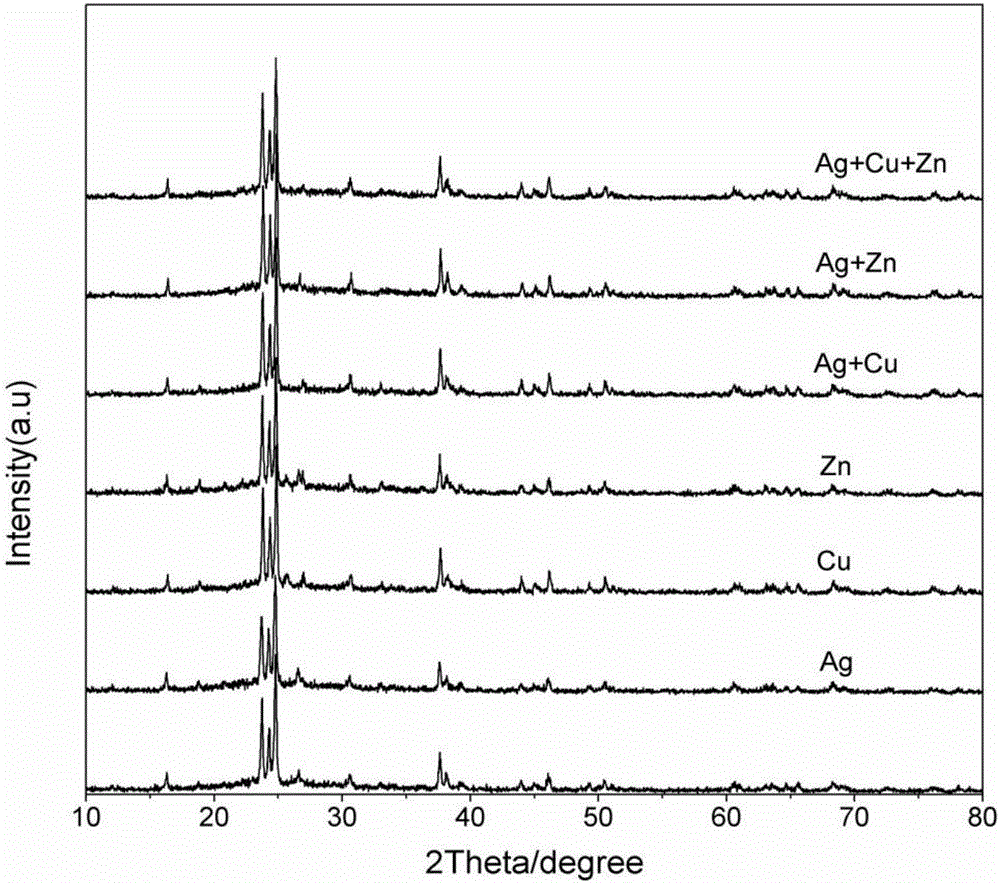

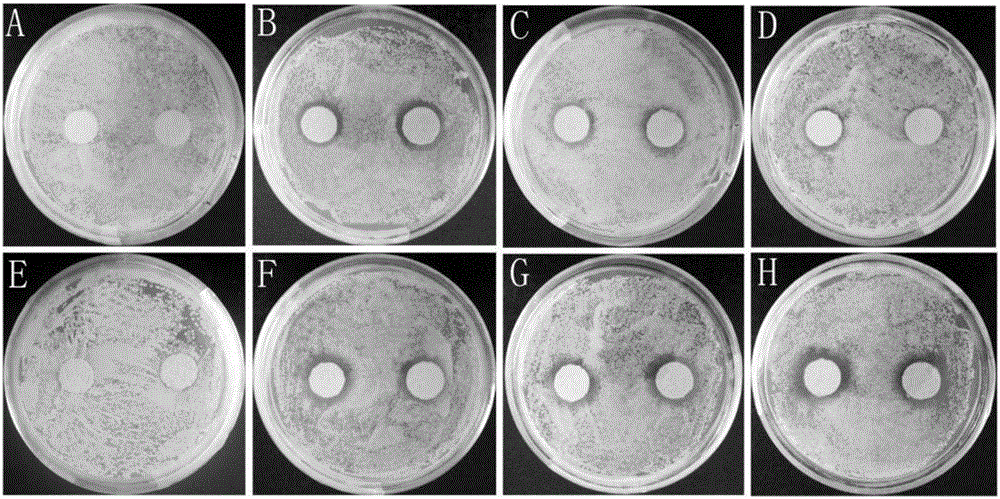

[0012] The preparation method of the high-strength antibacterial and antibacterial lithium disilicate glass-ceramic of the present invention is based on the proportion of 65-75% SiO by weight of the matrix glass 2 , 12-20%Li 2 O, 1~5%K 2 O, 1~4%Al 2 o 3 , 1~3%B 2 o 3 ,0.5~3%P 2 o 5 , 0.5-4% ZrO 2 Ingredients, SiO 2 : Li 2 The molar ratio of O is greater than or equal to 2.3:1, K 2 O: Al 2 o 3 The molar ratio of Li is greater than or equal to 1.1:1; Li 2 O is introduced in the form of carbonate, K2 O is introduced in the form of nitrate; or add 1 to 5 wt% of SrO in the ingredients, and introduce in the form of nitrate, to improve the strength of the final product high-strength antibacterial and antibacterial lithium disilicate glass ceramics and control the The final product is used as a dental all-ceramic restoration material to slowly release antibacterial metal ions in the oral cavity; in addition, the Ag in the high-strength antibacterial and antibacterial lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com