S275JR thick borated steel plate and production method thereof

A technology of S275JR and production method, applied in the field of S275JR thick specification boron-added steel plate and its production, can solve the problems of high manufacturing cost, long production cycle, limited effect of structure improvement, etc., and achieve reasonable composition and process design, loose process system, The effect of positive social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The thickness of the slab is 250mm, the temperature of the slab out of the furnace is 1180°C, the heating time of the slab is 270 minutes, and the chemical composition (percentage by weight) of the slab is: C0.13%, Si0.2%, Mn1.0%, P0 .02%, S0.005%, Als0.017%, Ca0.0015%, B0.0011%, the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 50 mm, the detailed rolling and cold removal process is shown in Table 1, and its mechanical properties are shown in Table 2. The steel plate meets the requirements of the first-level flaw detection.

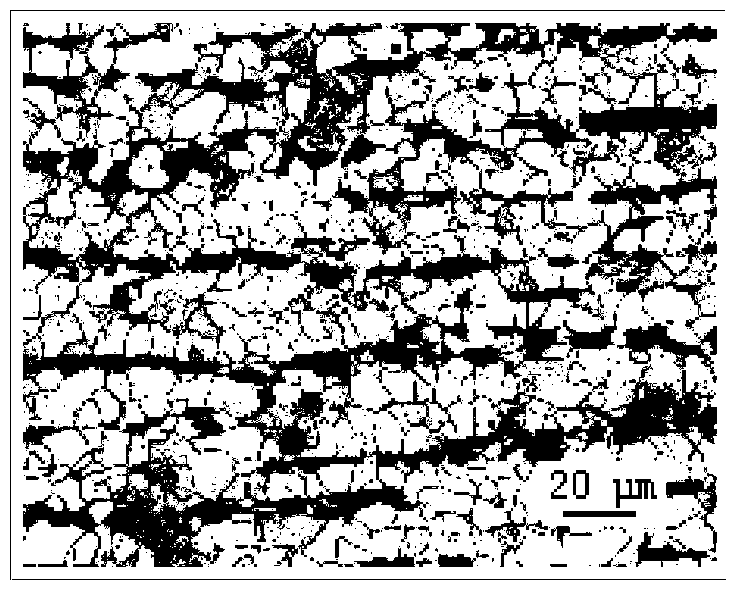

[0049] Such as figure 1 Shown is the metallographic structure diagram of the steel plate in Example 1 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is ferrite + pearlite, the ferrite is the majority, the grains are fine and uniform, and there is no mixed crystal phenomenon. Since ferrite accounts for the majority, the grains are fine, and ...

Embodiment 2

[0055] Adopting thickness is 250mm slab, and slab furnace temperature is 1220 ℃, and slab heating time is 410 minutes, and the (weight percentage) chemical composition of slab is: C0.15%, Si0.4%, Mn1.2%, P0 .014%, S0.01%, Als0.027%, Ca0.003%, B0.0016%, the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 100 mm, the detailed rolling and cold removal process is shown in Table 3, and its mechanical properties are shown in Table 4.

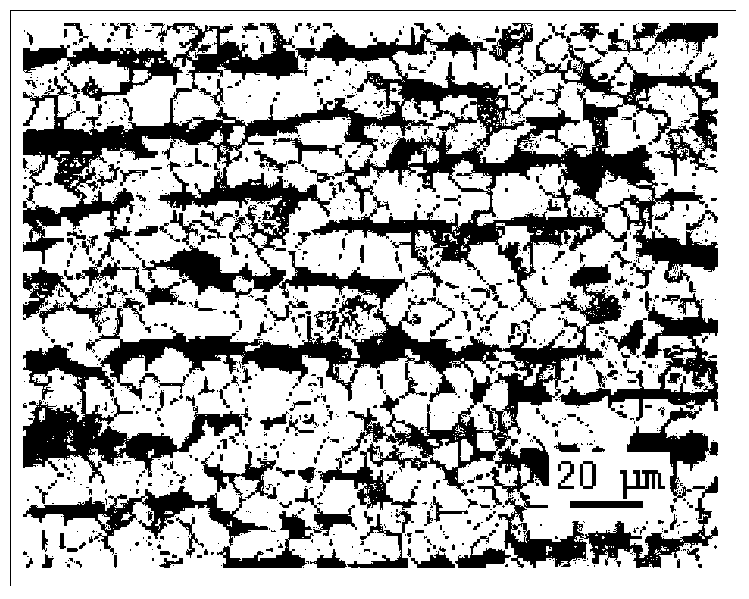

[0056] Such as figure 2 Shown is the metallographic structure diagram of the steel plate in Example 2 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is ferrite + pearlite, and the ferrite accounts for the majority. The grains along the thickness direction of the steel plate are fine and uniform, and there is no mixed crystal phenomenon. Since ferrite accounts for the majority, the grains are fine, and ferrite has good plasticity and toughness, th...

Embodiment 3

[0062] Adopting thickness is 250mm slab, and slab furnace temperature is 1205 ℃, and slab heating time is 373 minutes, and the (weight percentage) chemical composition of slab is: C0.14%, Si0.25%, Mn1.08%, P0 .013%, S0.007%, Als0.022%, Ca0.0021%, B0.0014%, the balance is Fe and unavoidable impurities. Rolled into a steel plate with a thickness of 60mm, the detailed rolling and cold removal process is shown in Table 5, and its mechanical properties are shown in Table 6.

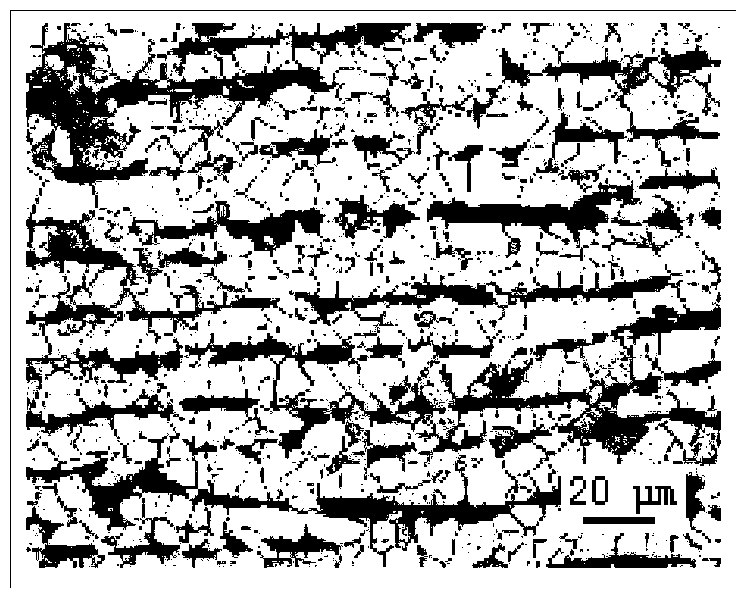

[0063] Such as image 3 Shown is the metallographic structure diagram of the steel plate in Example 3 of the present invention. It can be seen from the metallographic diagram that the structure of the steel plate is ferrite + pearlite, and the ferrite accounts for the majority. The grains along the thickness direction of the steel plate are fine and uniform, and there is no mixed crystal phenomenon. Since ferrite accounts for the majority, the grains are fine, and ferrite has good plasticity and toughness, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com