Steel plate with yield strength of 960MPa and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of steel plate and its manufacturing, can solve the problems of slow heating rate, coarse carbide particles, and long holding time, so as to avoid off-line cooling, improve production efficiency, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

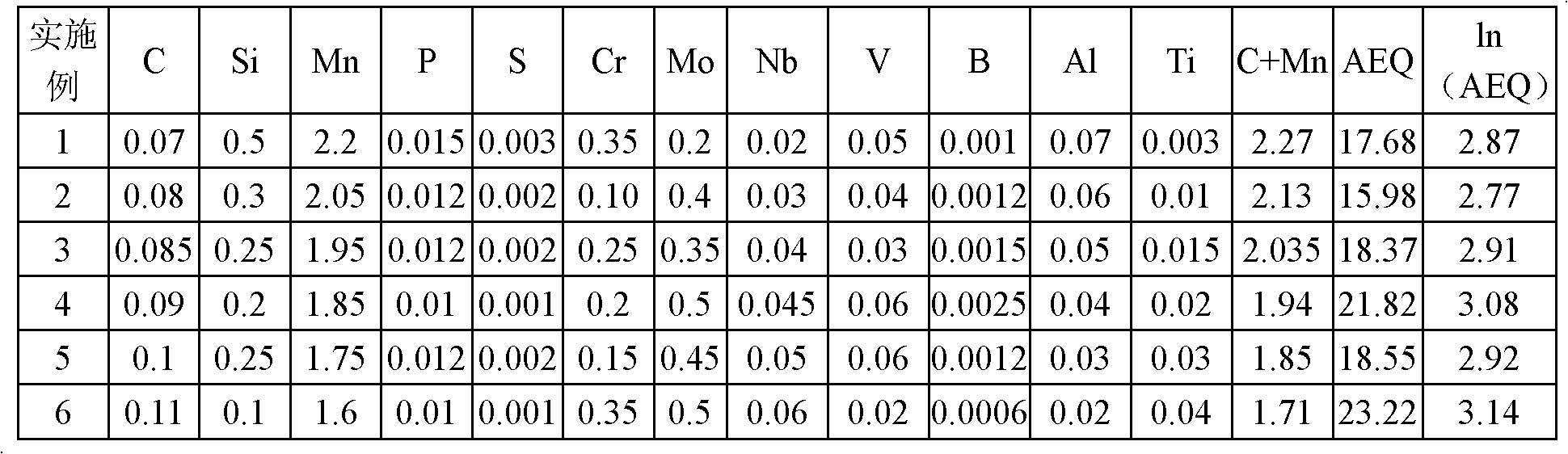

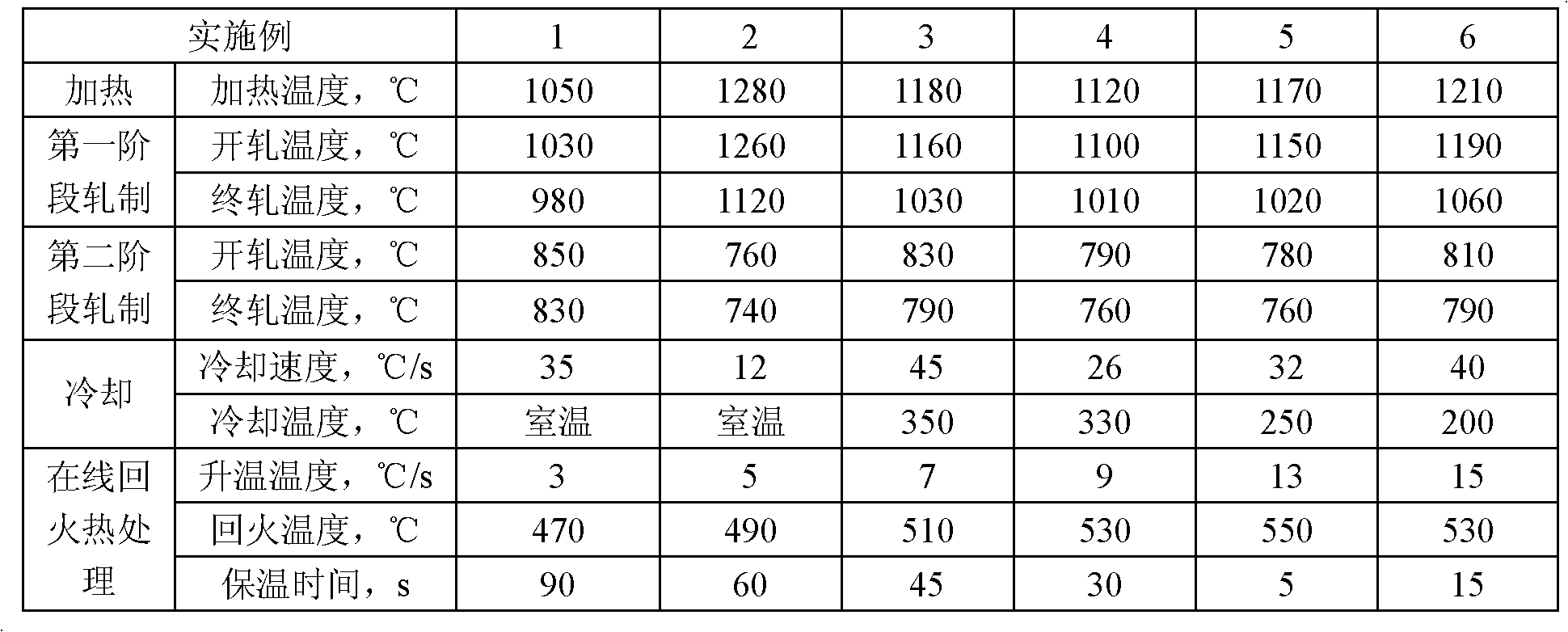

[0054] The specific steps of manufacturing the 960MPa grade steel plate with yield strength described in the present invention are as follows (see Table 1 for the chemical composition of each grade of steel in this case embodiment 1-6):

[0055] (1) Smelting: Vacuum induction furnace, converter or electric furnace is used for smelting, and after smelting, it is refined and degassed. It should be noted that smelting includes but is not limited to the above-mentioned smelting methods and processing procedures. In the embodiment of this case, vacuum induction furnace is used for smelting, and the final composition is determined by chemical spectroscopy;

[0056] (2) Casting: adopt vertical continuous casting, vertical bending continuous casting, arc continuous casting, die casting, directional solidification or electroslag remelting and other methods. It should be noted that casting includes but is not limited to the above-mentioned casting methods. The embodiment of this case ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com