High-hardness wear-resistant steel plate and manufacturing method thereof

A manufacturing method and high-hardness technology, applied in the field of wear-resistant steel pipes, can solve the problems of troublesome concrete ramming, low wear resistance of boom tubes, frequent replacement, etc., and achieve reasonable composition and process design, excellent wear-resistant steel performance, The effect of loose craft system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The chemical composition of the wear-resistant steel pipe of the present invention and Comparative Example 1 (see patent CN101602079) is shown in Table 1. After smelting according to the chemical composition shown in Table 1, heat the continuous casting slab or steel ingot to 1250°C, and slowly cool after rolling. After the steel coil is annealed, the tube forming size is ф150mm, the welding power of high-frequency ERW is 280KW, the welding frequency is 290KHZ, and the production line speed is 23m / min.

[0037]The quenching temperature of the welded pipe is 850°C, the holding time is 15min, the tempering temperature is 180°C, the holding time is 25min, air cooling after tempering, the hardness is HRC62.1

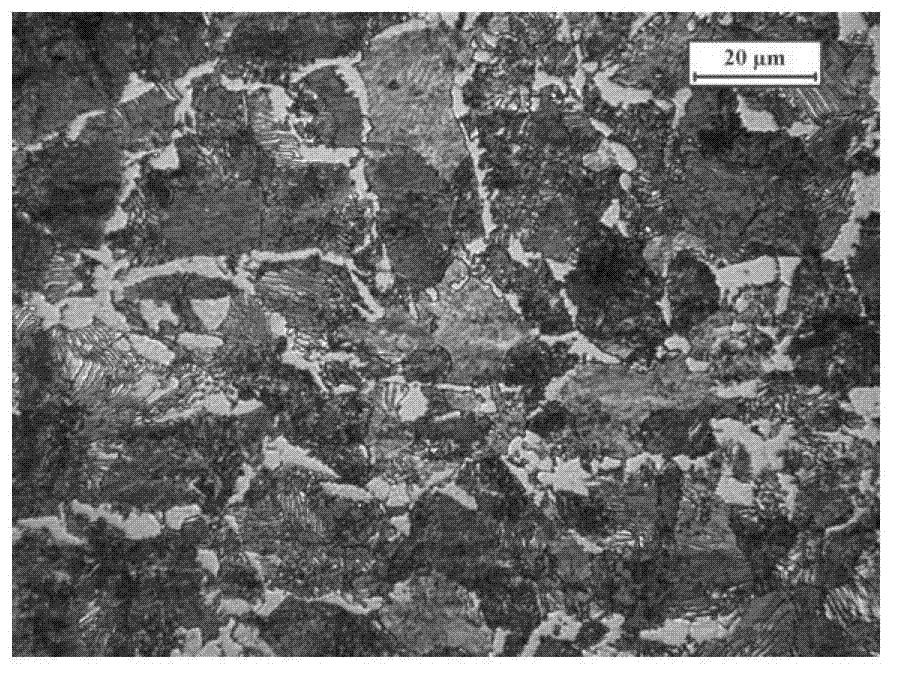

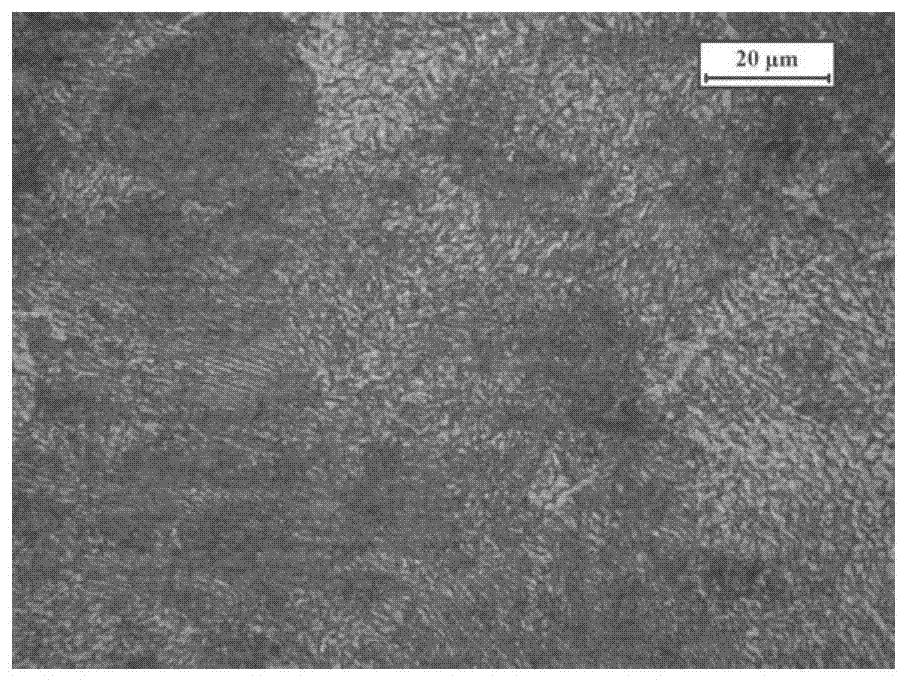

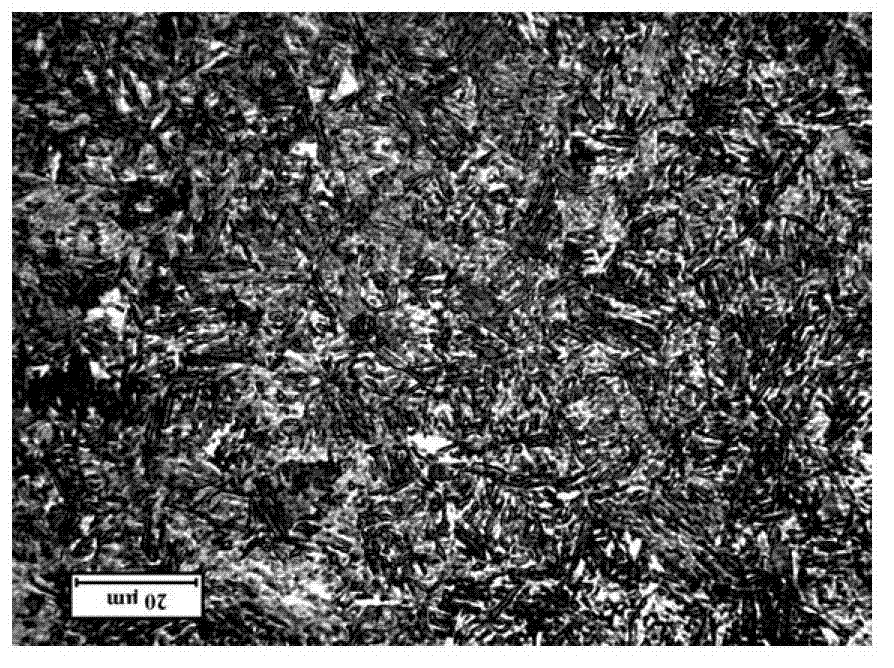

[0038] see figure 1 , figure 1 It is the as-rolled structure of the steel plate in Example 1 of the present invention, which is ferrite + pearlite, and the structure uniformity is poor. figure 2 It is the annealed structure of the steel plate of the present invent...

Embodiment 2

[0041] The implementation mode is the same as that in Example 1, wherein the heating temperature of the continuous casting slab or steel ingot is 1200° C., and it is slowly cooled after rolling. After the steel coil is annealed, the tube forming size is ф130mm, the welding power of high-frequency ERW is 250KW, the welding frequency is 290KHZ, and the production line speed is 20m / min.

[0042] The quenching temperature of the welded pipe is 830°C, the holding time is 18min, the tempering temperature is 220°C, the holding time is 20min, air cooling after tempering, the hardness is HRC62.8.

Embodiment 3

[0044] The implementation mode is the same as that in Example 1, wherein the heating temperature of the continuous casting slab or steel ingot is 1140° C., and it is slowly cooled after rolling.

[0045] After the steel coil is annealed, the pipe forming size is ф139.5mm, the welding power of high-frequency ERW is 270KW, the welding frequency is 300KHZ, and the production line speed is 25m / min.

[0046] The quenching temperature of the welded pipe is 830°C, the holding time is 28min, the tempering temperature is 270°C, the holding time is 46min, air cooling after tempering, the hardness is HRC63.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com