Easy welding steel plate with yield strength of 550MPa and high toughness and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the direction of temperature control, etc., can solve the problems of increasing the cost of steel plates, achieve the effects of reducing alloy cost, reducing the content of alloy elements, and improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

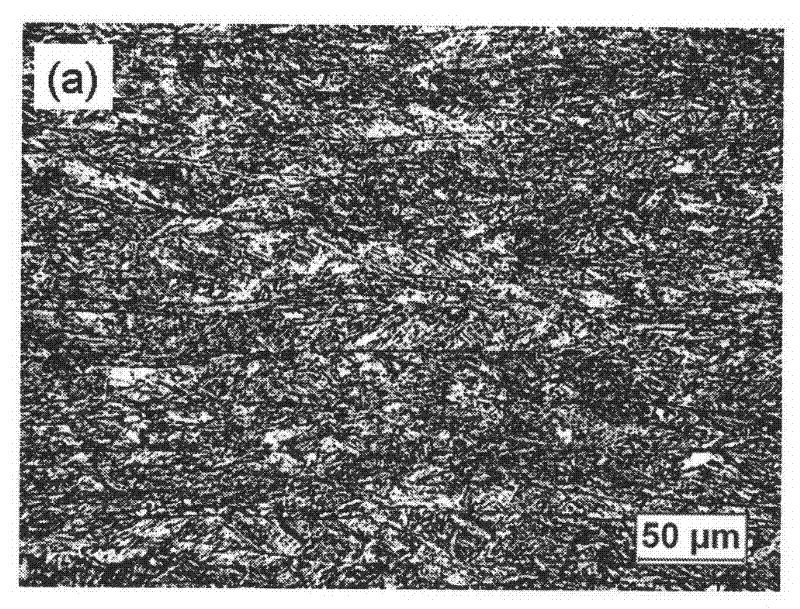

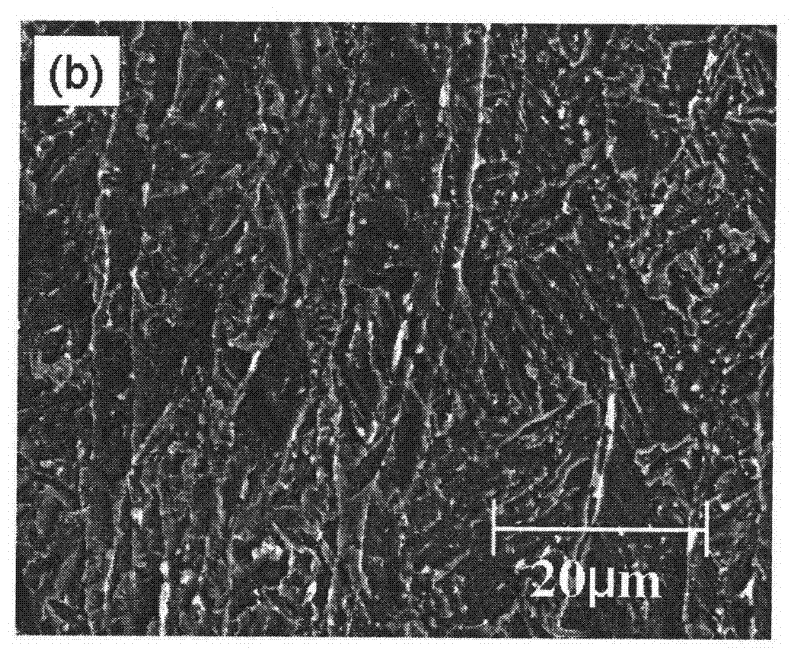

Image

Examples

Embodiment 1

[0052] According to the chemical composition shown in Table 1, it is smelted in an electric furnace or a converter, and cast into a continuous casting slab. The continuous casting slab is heated at a temperature of 1080°C and kept for 240 minutes; 80mm; the starting temperature of the second stage of rolling is 860°C, the pass deformation rate is 12-25%, the final rolling temperature is 800°C, and the thickness of the finished steel plate is 20mm; the cooling rate of the steel plate is 35°C / S, and the termination temperature is 520°C, air cooling after exiting the water.

Embodiment 2

[0054] The embodiment is the same as in Example 1, wherein the heating temperature is 1130° C., and the heat preservation is 150 minutes; the rolling start temperature of the first stage rolling is 1070° C., and the thickness of the intermediate billet is 120 mm; the rolling start temperature of the second stage rolling is 830° C., The pass deformation rate is 15-25%, the final rolling temperature is 790°C, and the thickness of the finished steel plate is 30mm; the cooling rate of the steel plate is 26°C / S, the termination temperature is 480°C, and it is air-cooled after exiting the water.

Embodiment 3

[0056] The embodiment is the same as in Example 1, wherein the heating temperature is 1130° C., and the heat preservation is 180 minutes; the rolling start temperature of the first stage rolling is 1090° C., and the thickness of the intermediate billet is 120 mm; the rolling start temperature of the second stage rolling is 800° C., The pass deformation rate is 12-28%, the final rolling temperature is 780°C, and the thickness of the finished steel plate is 40mm; the cooling rate of the steel plate is 20°C / S, the termination temperature is 460°C, and it is air-cooled after exiting the water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com