Hot rolling wire rod for mechanical structure of 1600 Mpa level and manufacture method thereof

A technology of mechanical structure and manufacturing method, which is applied in the field of iron and steel materials and hot-rolled steel, can solve the problems of difficult realization of large-scale production, complex production process, and many alloy elements, and achieve reasonable composition and process design, simplified process flow, The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

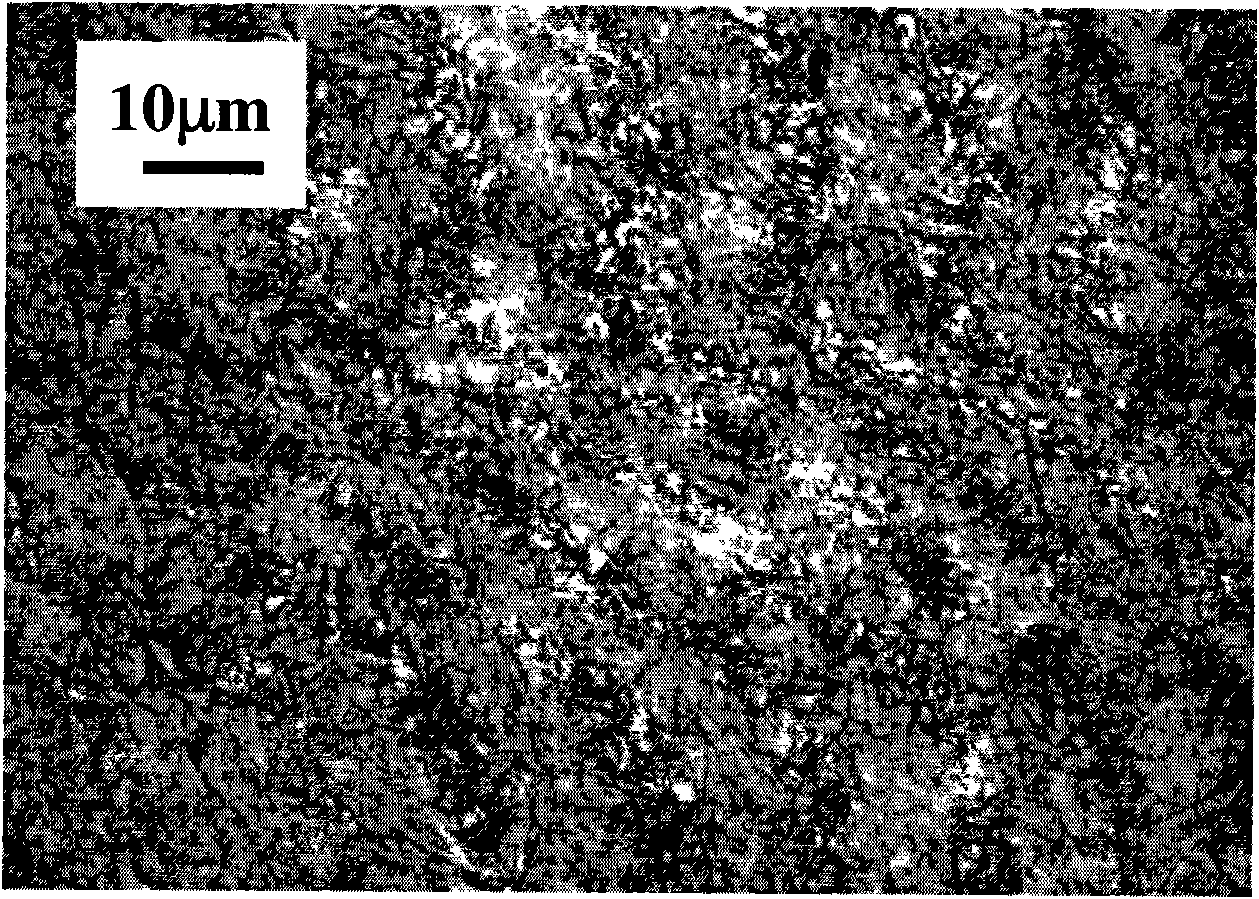

Image

Examples

Embodiment 1

[0026] The molten steel is smelted in a vacuum electromagnetic induction furnace according to the chemical composition shown in Table 1, and cast into continuous casting slabs or steel ingots. Heat the continuous casting slab or steel ingot to 1200°C, keep it warm for 115 minutes, and carry out rough rolling. The rough rolling start temperature is 1150°C, and roll into a bar with a diameter of φ22±0.5mm. Then carry out finish rolling, the finish rolling temperature is 980 ℃, roll into the wire rod of φ9±0.3mm on the continuous rolling mill, air cooling after rolling.

Embodiment 2

[0028] Embodiment is the same as embodiment 1. The heating temperature is 1220°C, and the temperature is kept for 120 minutes; the rough rolling temperature is 1165°C; the finish rolling temperature is 1000°C, and the rolling is air-cooled.

Embodiment 3

[0030] Embodiment is the same as embodiment 1. The heating temperature is 1250°C, and the heat preservation time is 125 minutes; the rough rolling temperature is 1170°C; the finishing rolling temperature is 1010°C, and the rolling is air-cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com