Laminated glass interlayer and laminated glass

A technology of laminated glass and interlayer film, applied in glass/slag layered products, layered products, synthetic resin layered products, etc., can solve problems such as ghosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (1) Preparation of resin composition for sound insulation layer

[0097] With respect to polyvinyl butyral obtained by acetalizing polyvinyl alcohol having an average degree of polymerization of 2400 with n-butyraldehyde (acetyl group amount 12 mol%, butyral group amount 66 mol%, hydroxyl group amount 22 mol%) To 100 parts by mass, 60 parts by mass of triethylene glycol-di-2-ethylhexanoate (3GO) was added as a plasticizer, and the mixture was sufficiently kneaded with a dispersing roll to obtain a resin composition for a sound insulating layer.

[0098] (2) Preparation of resin composition for protective layer

[0099] With respect to polyvinyl butyral obtained by acetalizing polyvinyl alcohol having an average degree of polymerization of 1700 with n-butyraldehyde (1 mol% of acetyl groups, 69 mol% of butyral groups, 30 mol% of hydroxyl groups) To 100 parts by mass, 40 parts by mass of triethylene glycol-di-2-ethylhexanoate (3GO) was added as a plasticizer, and the mixt...

Embodiment 2~5

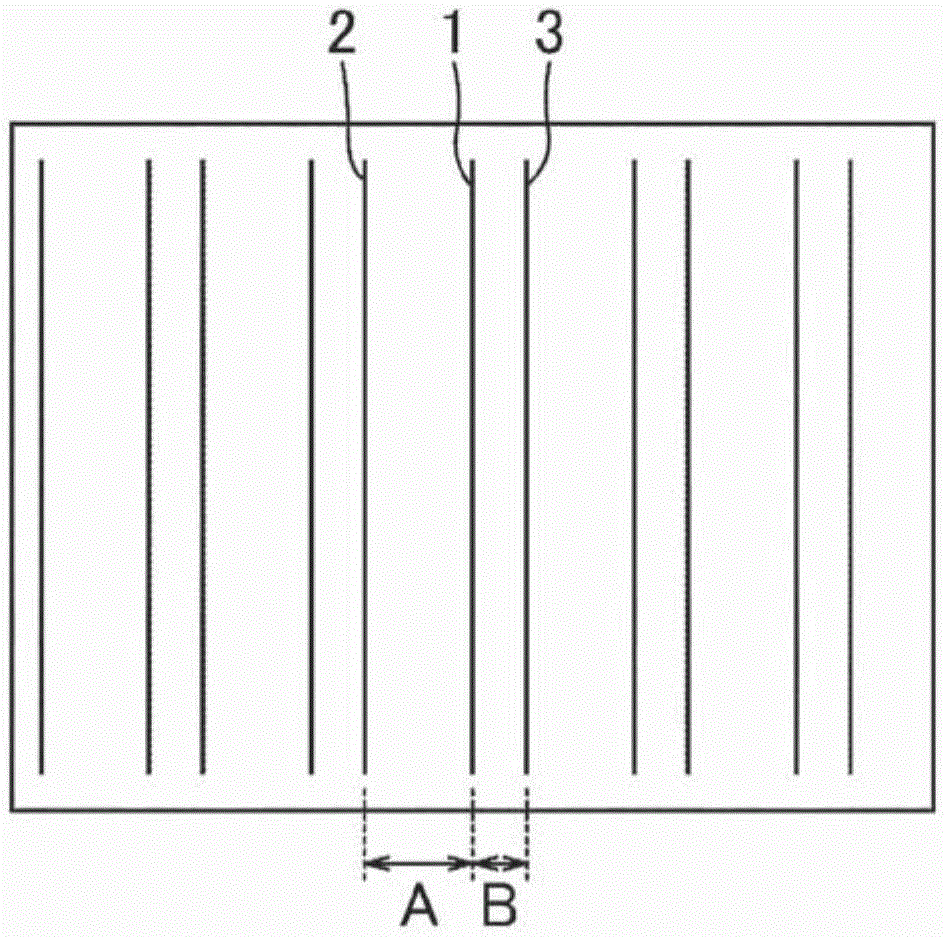

[0110] An interlayer film for laminated glass was produced by the same method as in Example 1, except that the interval between the concave portions on the surfaces of the A layer and the C layer and the groove depth (Rzg) of the concave portion were as shown in Table 1.

[0111] In addition, in the measurement of the interval of the recessed part of Examples 2-5 and Comparative Examples 1-3, the average value and the maximum value of the shortest distance of the said recessed part were the same.

Embodiment 6~10

[0113] The amount of acetyl groups, the amount of butyral groups, the amount of hydroxyl groups, and the content of plasticizers in the polyvinyl butyral used in the protective layer and the sound-insulating layer were changed as shown in Table 1. An interlayer film for laminated glass was produced by the same method as in Example 1, except that the groove depth (Rzg) of the space and the concave portion was as shown in Table 1. In addition, the polyvinyl butyral used for the protective layer and the sound insulating layer was obtained by acetalizing polyvinyl alcohol having an average degree of polymerization of 1,700 with n-butyraldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com