Heat filler type deaerator with stable deaerating function and atomizing function

A deaerator and packing type technology, applied in the field of thermal spray packing type deaerator, can solve problems such as hidden dangers of boiler safety, energy waste, unstable water level, temperature and pressure of the deaerator, so as to reduce civil construction costs and avoid Pump cavitation, ensure the effect of boiler water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

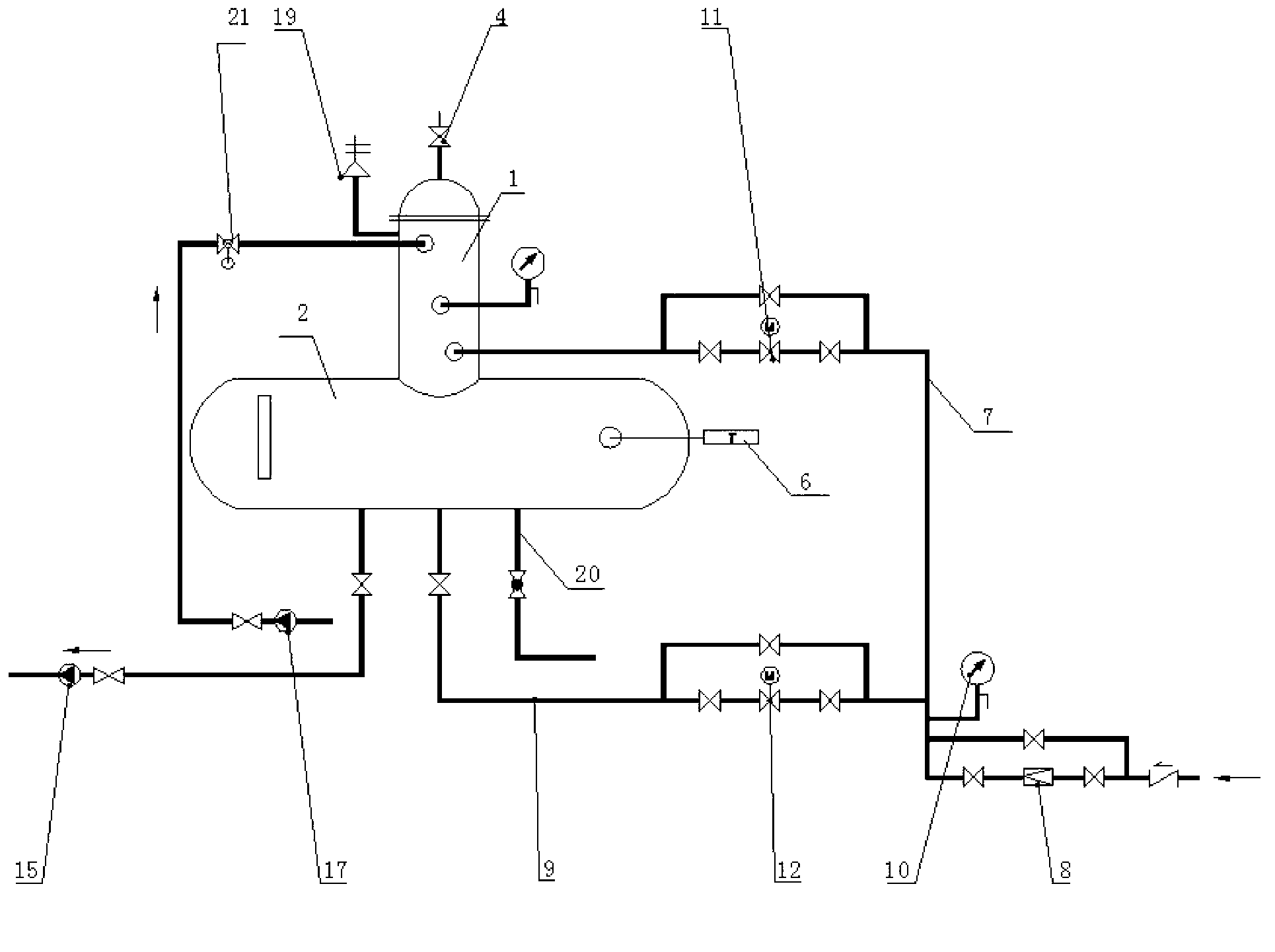

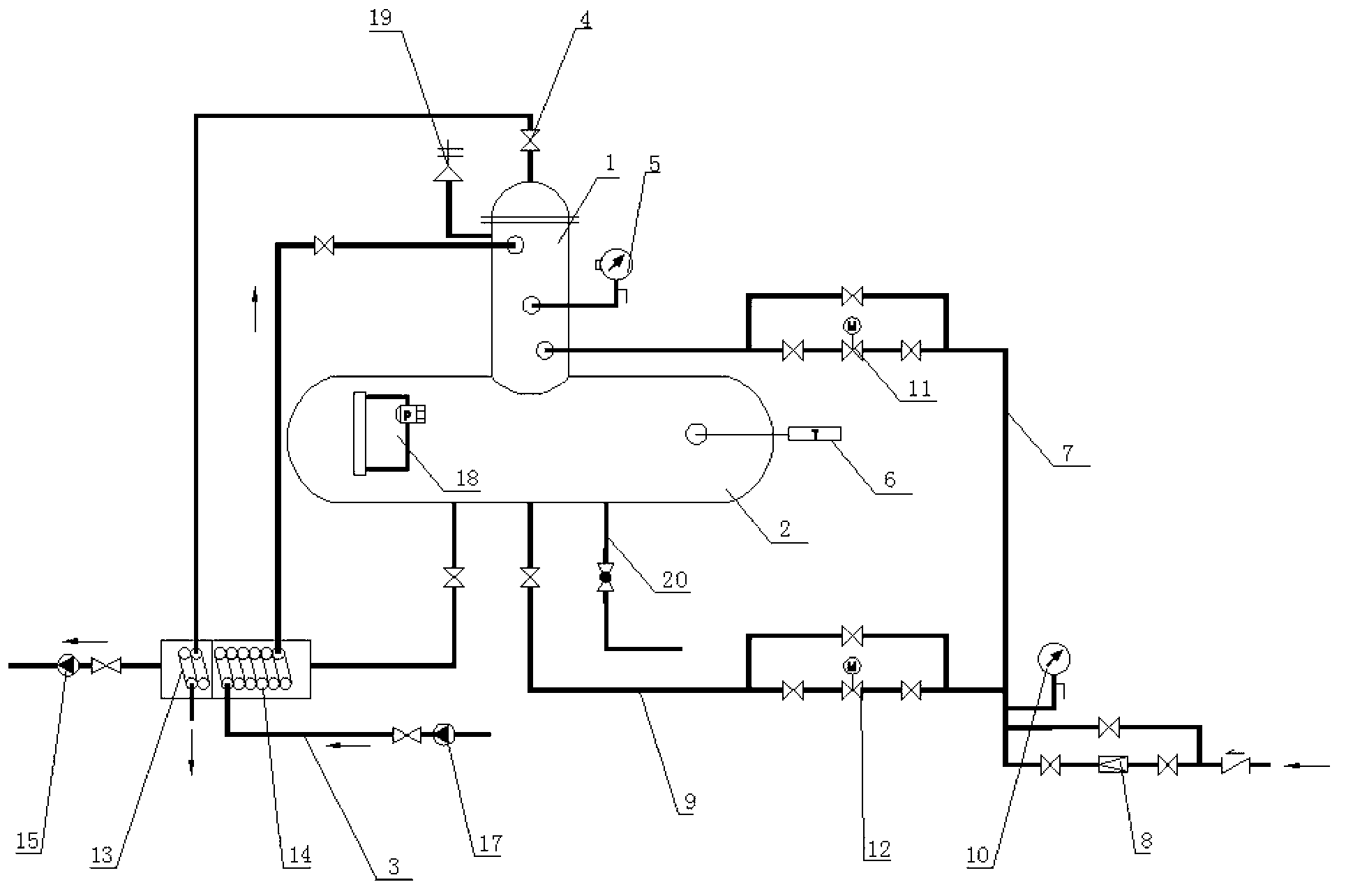

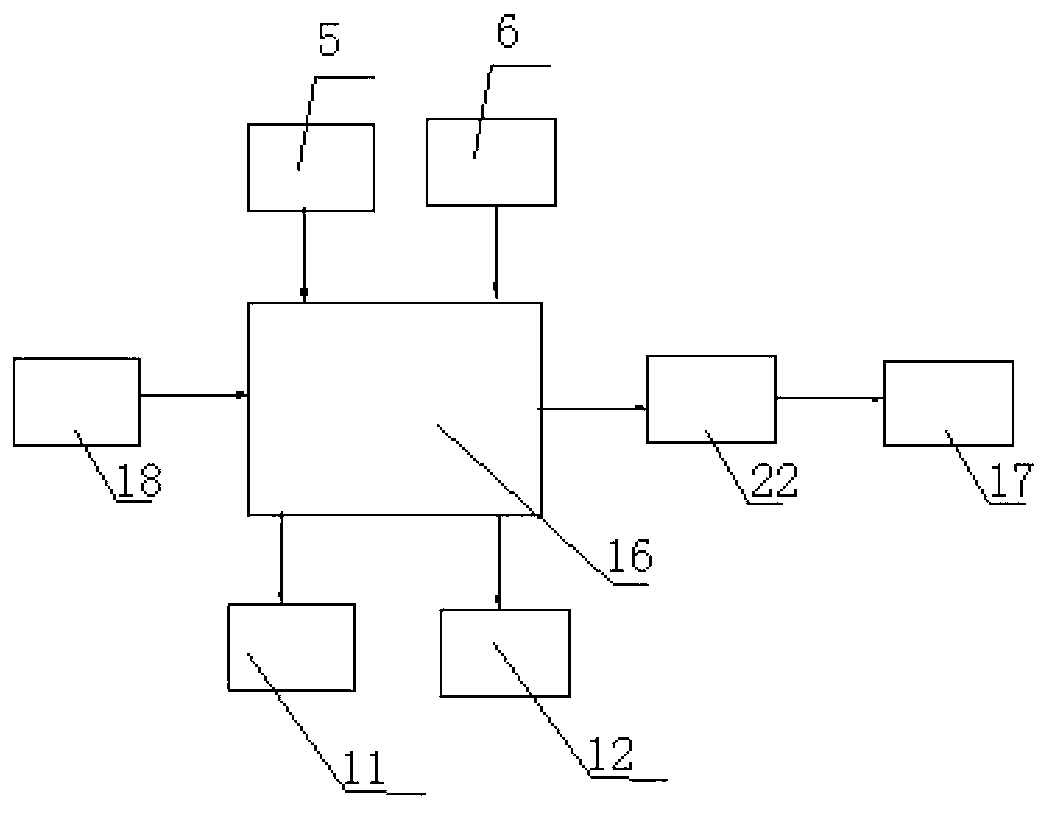

[0030] Example 1, such as Figure 2-3 As shown, the thermal spray packing type deaerator capable of stabilizing oxygen removal of the present invention includes a deaerator tower 1, a deaerator water tank 2 located below the deaerator tower 1 and communicated with it, a deaerator water supply pipe 3, and an emptying valve 4. Pressure control gauge 5, temperature sensor 6, preheating steam pipe 7, pressure reducing valve 8, reheating steam pipe 9, pressure gauge 10, preheating pipe solenoid valve 11, reheating steam solenoid valve 12, exhaust heat exchange 13, effluent heat exchanger 14, boiler feed water pump 15, controller 16, feed water pump 17, differential pressure transmitter 18, safety valve 19, sewage pipe 20 and frequency converter 22 and other components.

[0031] The deaeration tower 1 is provided with a spraying device, a filler, an air distribution pipe, etc., which is an existing design and will not be described in detail here. The deaerator tower 1 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com