Preparation method of starch-base biodegradation material

A biodegradable material, starch-based technology, applied in the field of preparation of starch-based biodegradable materials, can solve the problems of failing to improve the film-forming performance of starch, affecting the promotion and use of products, and limiting the scope of application, etc., to achieve low cost and low performance Good, stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

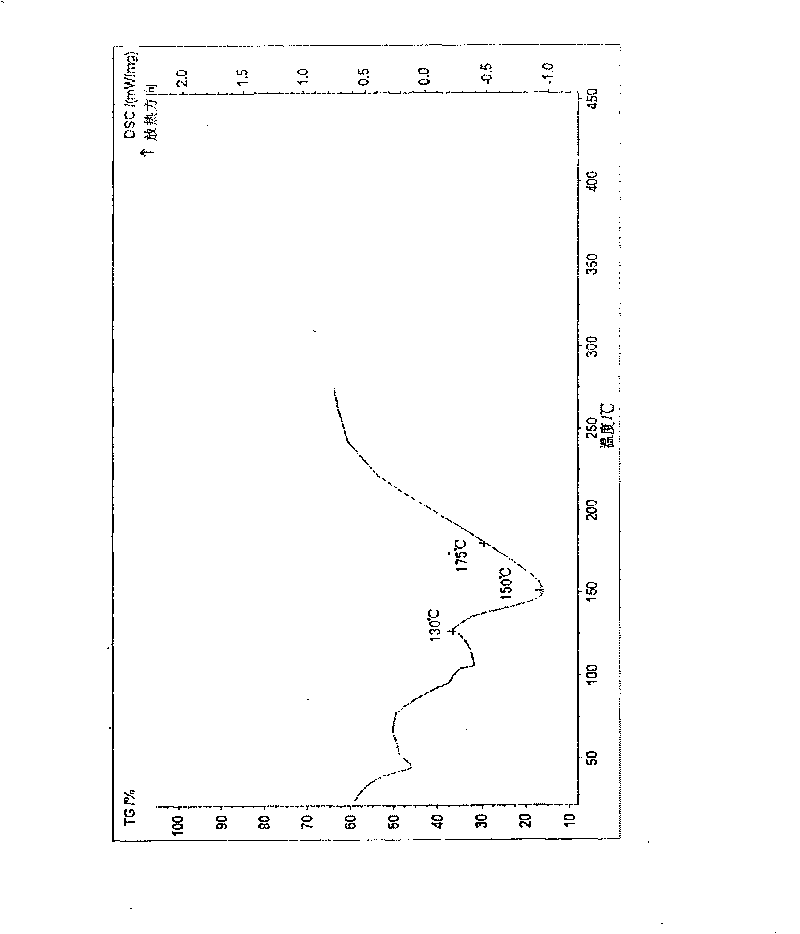

Image

Examples

Embodiment 1

[0022] 1) Add water and 0.08kg α-amylase to 80kg tapioca starch, put it into a high-speed mixing mixer, heat up to 80°C, and stir for 5 minutes to gelatinize. Wherein, the mixing ratio of starch and water is starch:water=1:0.5 in parts by weight.

[0023] 2) Add 2.7 kg of acetic anhydride to the product of step 1), and stir and react for 25 minutes at a stirring speed of 500 rpm.

[0024] 3) Add 8 kg of sorbitol to the product in step 2), and continue stirring for 15 minutes.

[0025] 4) Add 4 kg of aluminate coupling agent to the product in step 3), and continue stirring for 5 minutes to obtain starch gel.

[0026] 5) Add 5 kg of polylactic acid to the product of step 4), mix and stir for 6 minutes, discharge the material after mixing evenly, and send it to a co-rotating twin-screw extruder for extrusion and granulation to obtain a starch-based biodegradable material. Among them, the screw length-to-diameter ratio of the co-rotating twin-screw extruder is 48:1, the screw sp...

Embodiment 2

[0029] 1) Add water and 0.3kg of α-amylase to 82kg of cornstarch, put it into a high-speed mixer, raise the temperature to 120°C, and stir for 8 minutes to gelatinize. Wherein, the mixing ratio of starch and water is starch:water=1:1 in parts by weight.

[0030] 2) Add 1.4 kg of acetic acid to the product of step 1), and stir for 8 minutes at a stirring speed of 900 rpm.

[0031] 3) Add 5kg polyethylene glycol and 4kg propylene glycol to the product of step 2), and continue to stir for 30 minutes.

[0032] 4) Add 3 kg of oxidized polyethylene wax to the product in step 3), and continue stirring for 5 minutes to obtain starch gel.

[0033] 5) Add 8 kg of polybutylene succinate to the product in step 4), mix and stir for 12 minutes, discharge the material after mixing evenly, and send it to a co-rotating twin-screw extruder to extrude and granulate to obtain starch-based biodegradable Material. Among them, the screw length-to-diameter ratio of the co-rotating twin-screw extru...

Embodiment 3

[0036] 1) Add water and 0.1kg of α-amylase to 85kg of sweet potato starch, put it into a high-speed mixing mixer, heat up to 100°C, and stir for 10 minutes to gelatinize. Wherein, the mixing ratio of starch and water is starch:water=1:0.4 in parts by weight.

[0037] 2) Add 2.0 kg of vinyl acetate to the product of step 1), and stir and react for 10 minutes at a stirring speed of 800 rpm.

[0038] 3) Add 12kg of glycerol to the product in step 2), and continue to stir for 20 minutes.

[0039] 4) Add 5kg of white oil to the product in step 3), and continue stirring for 10 minutes to obtain starch gel.

[0040] 5) Add 7kg of poly-hydroxyvalerate to the product of step 4), mix and stir for 5 minutes, discharge the material after mixing evenly, and send it to a co-rotating twin-screw extruder for extrusion and granulation to obtain a starch-based biodegradable material. Among them, the screw length-to-diameter ratio of the co-rotating twin-screw extruder is 48:1, the screw speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com