Patents

Literature

39results about How to "Sufficient dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

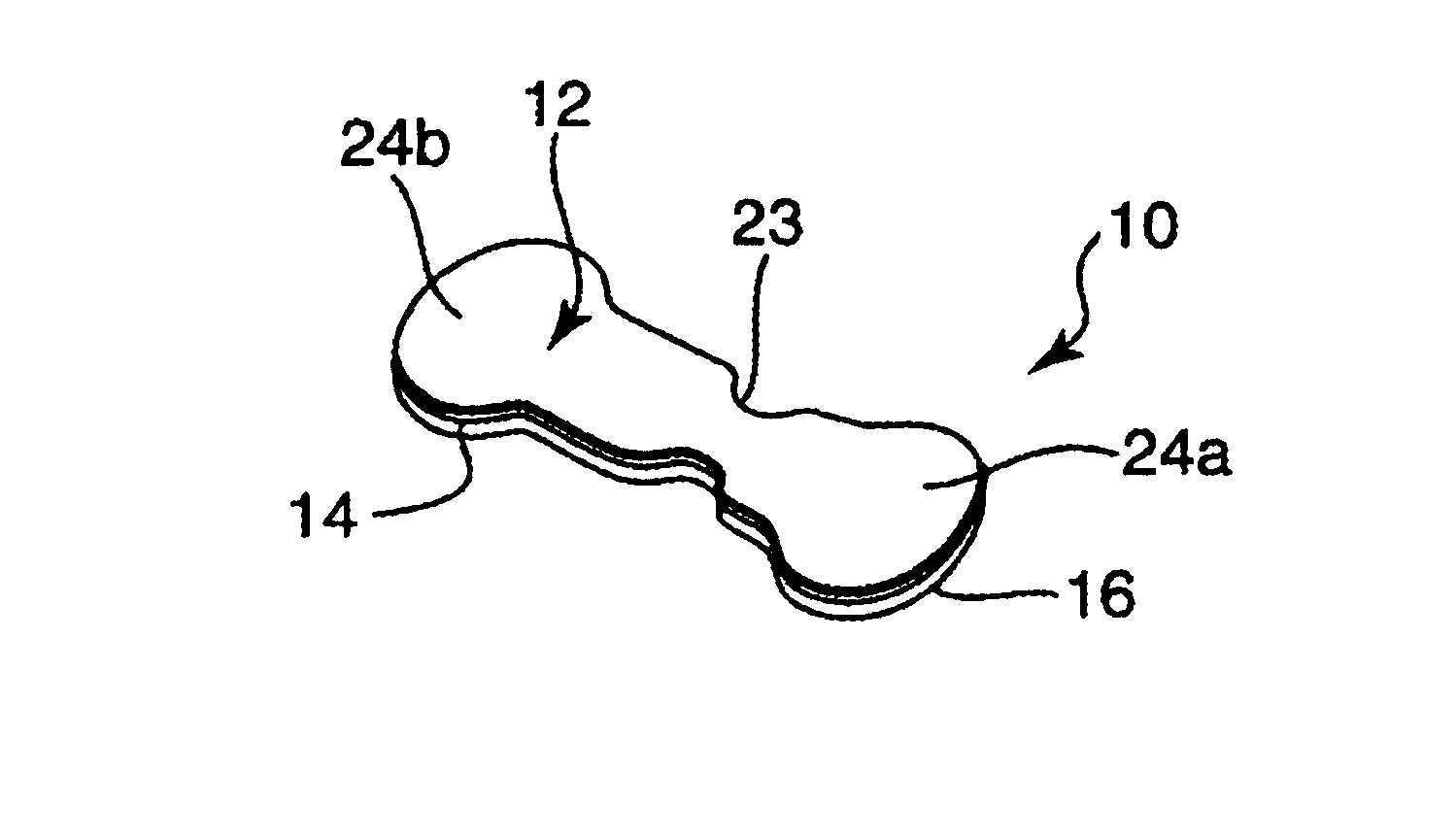

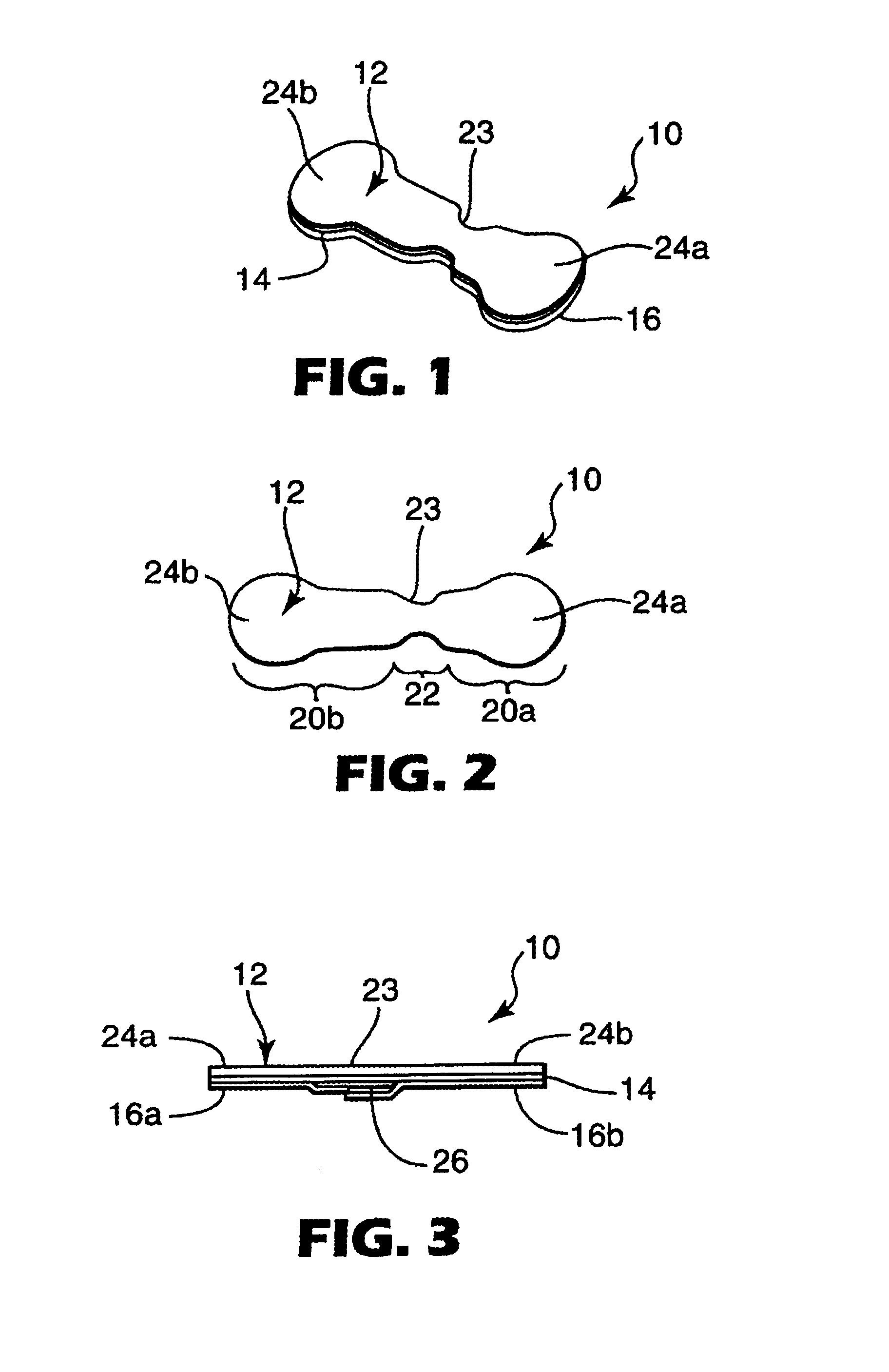

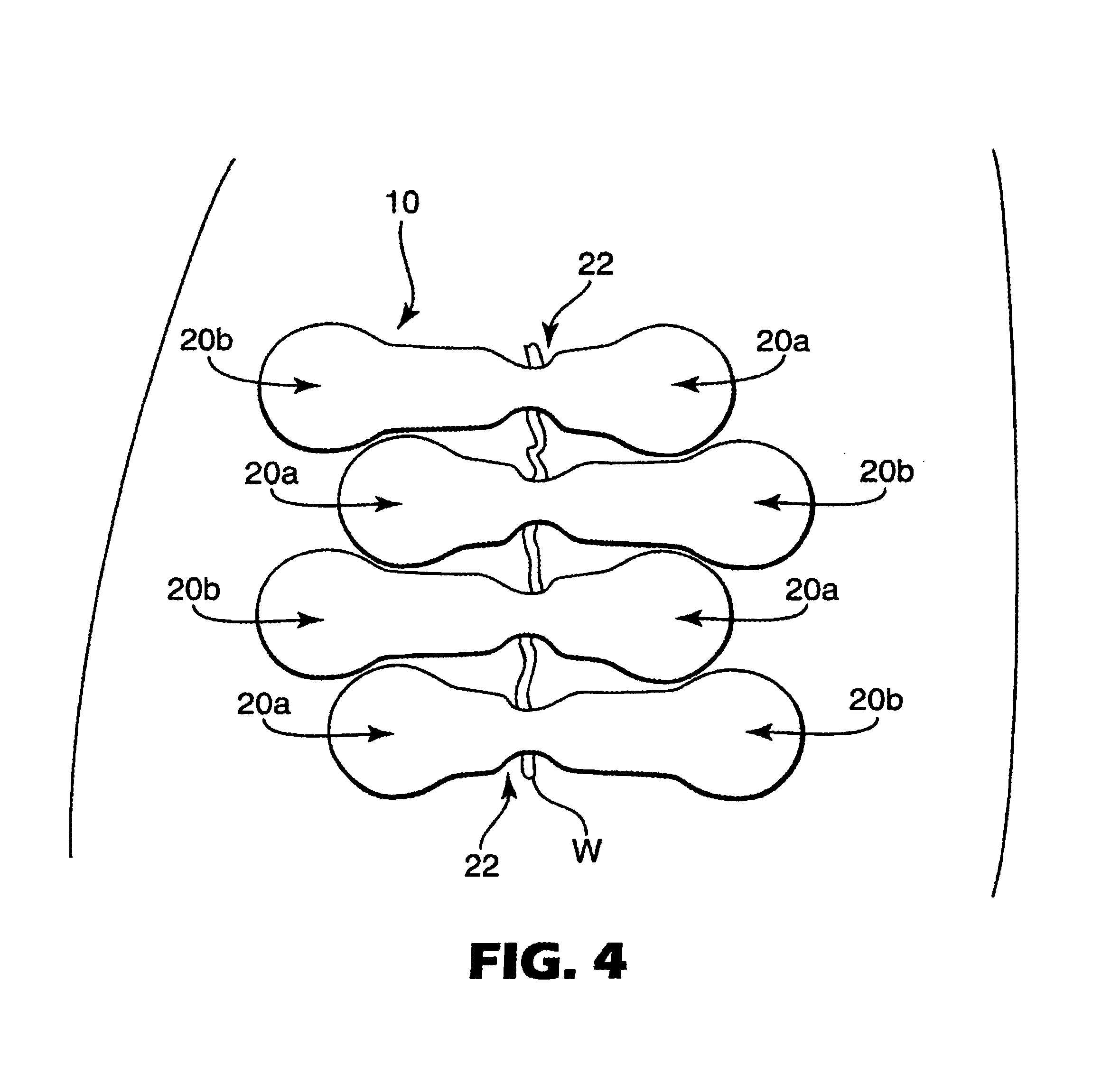

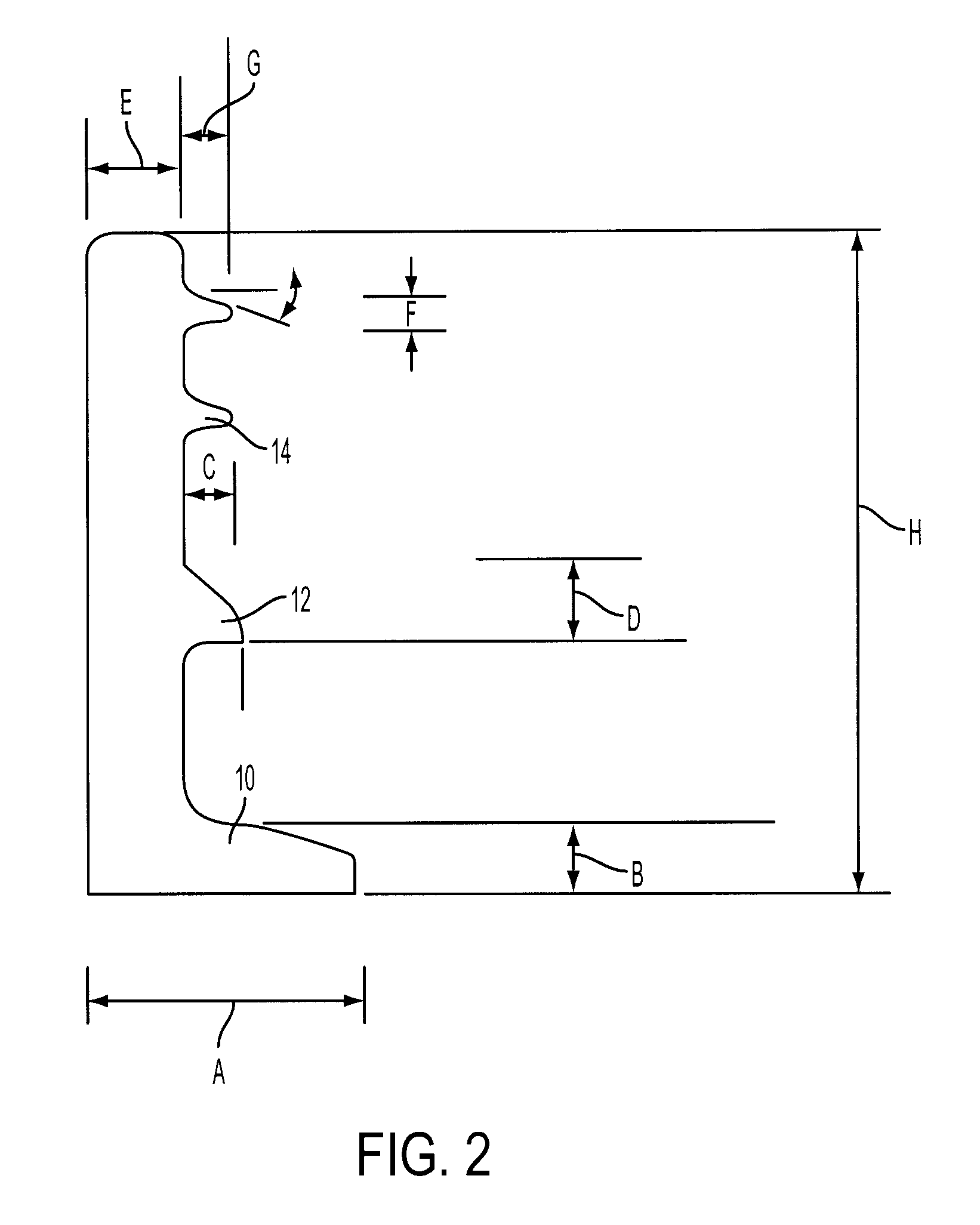

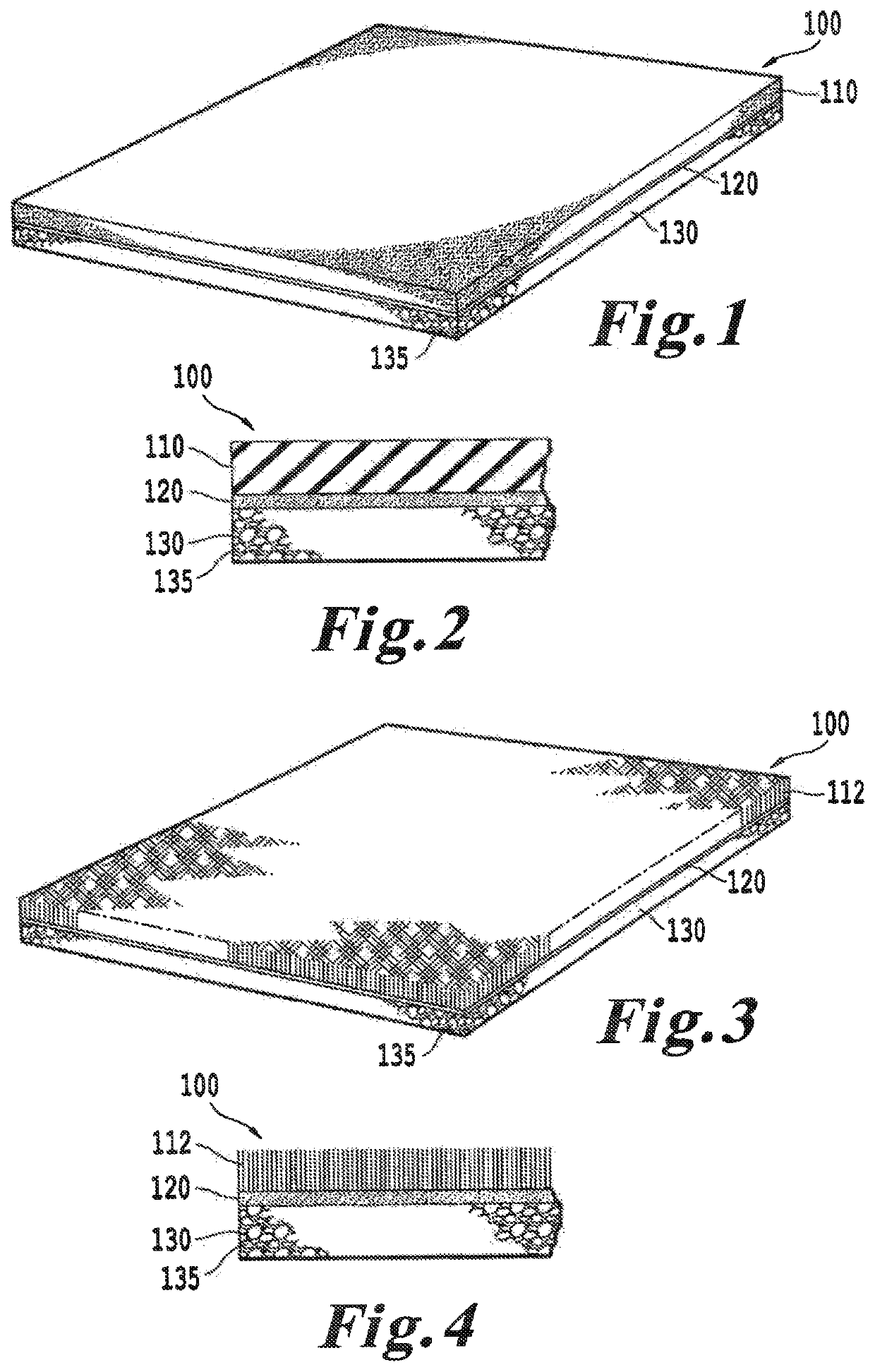

Conformable adhesive wound closures

InactiveUS7066182B1Sufficient dimensional stabilityGood conformabilityHead bandagesNeck bandagesBiomedical engineeringWound edge

A wound closure including a wound bridging portion that has sufficient dimensional stability to hold the wound edges in proper alignment, even in the face of substantial stretching of the wound closure as a whole, is disclosed. The wound closure is dimensionally stable directly over the wound. The remainder of the wound closure is preferably substantially more extensible and elastic than the wound bridging portion to improve conformability and adhesion of the wound closure to the patient. The wound closures may include opposing end portions of unequal lengths yielding an asymmetric shape that facilitates close placement of the wound closures along a wound.

Owner:3M INNOVATIVE PROPERTIES CO

Methods for preparing articles from processable and dimensionally stable elastomer compositions

ActiveUS7608216B2Inhibit substantial creep and sagHigh green strengthImpression capsElectric discharge tubesElastomerVulcanization

Owner:FREUDENBERG NOK GEN PARTNERSHIP

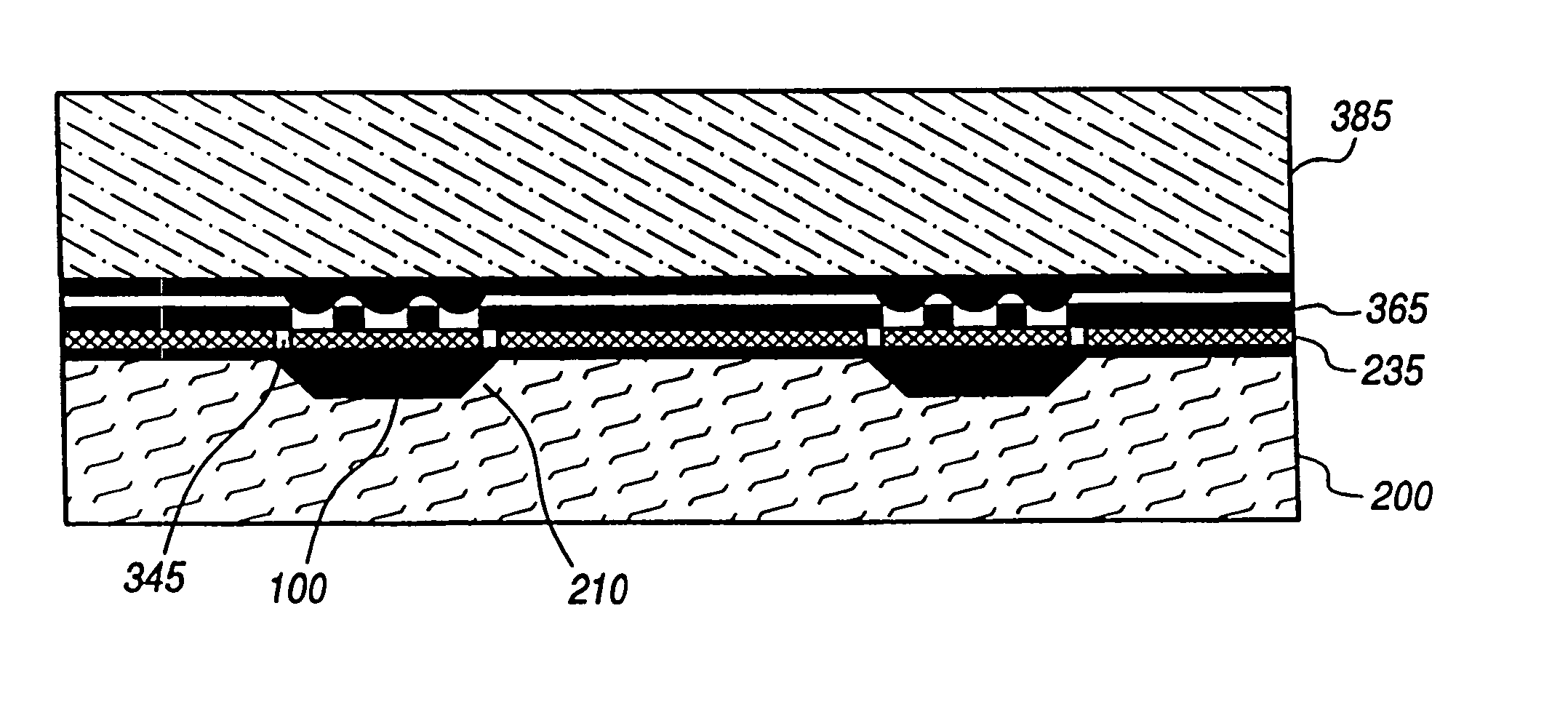

Method of making a flexible substrate containing self-assembling microstructures

InactiveUS20060210769A1Maintain dimensional stabilitySufficient dimensional stabilitySemiconductor/solid-state device detailsSolid-state devicesElastic modulusMicrostructure

A substrate has embossed thereon a plurality of shaped recesses of a predetermined precise geometric profile, each recess having a flat bottom surface having a major dimension of about 1000 μm or less, the substrate being capable of undergoing a thermal cycle of about one hour at about 150° C. while maintaining about ±10 μm or less dimensional stability of the embossed shaped indentations, and wherein the substrate comprises an amorphous thermoplastic material. During the thermal cycle the substrate has an elastic modulus greater than about 1010 dynes / cm2 and a viscoelastic index of less than about 0.1.

Owner:ALIEN TECHNOLOGY

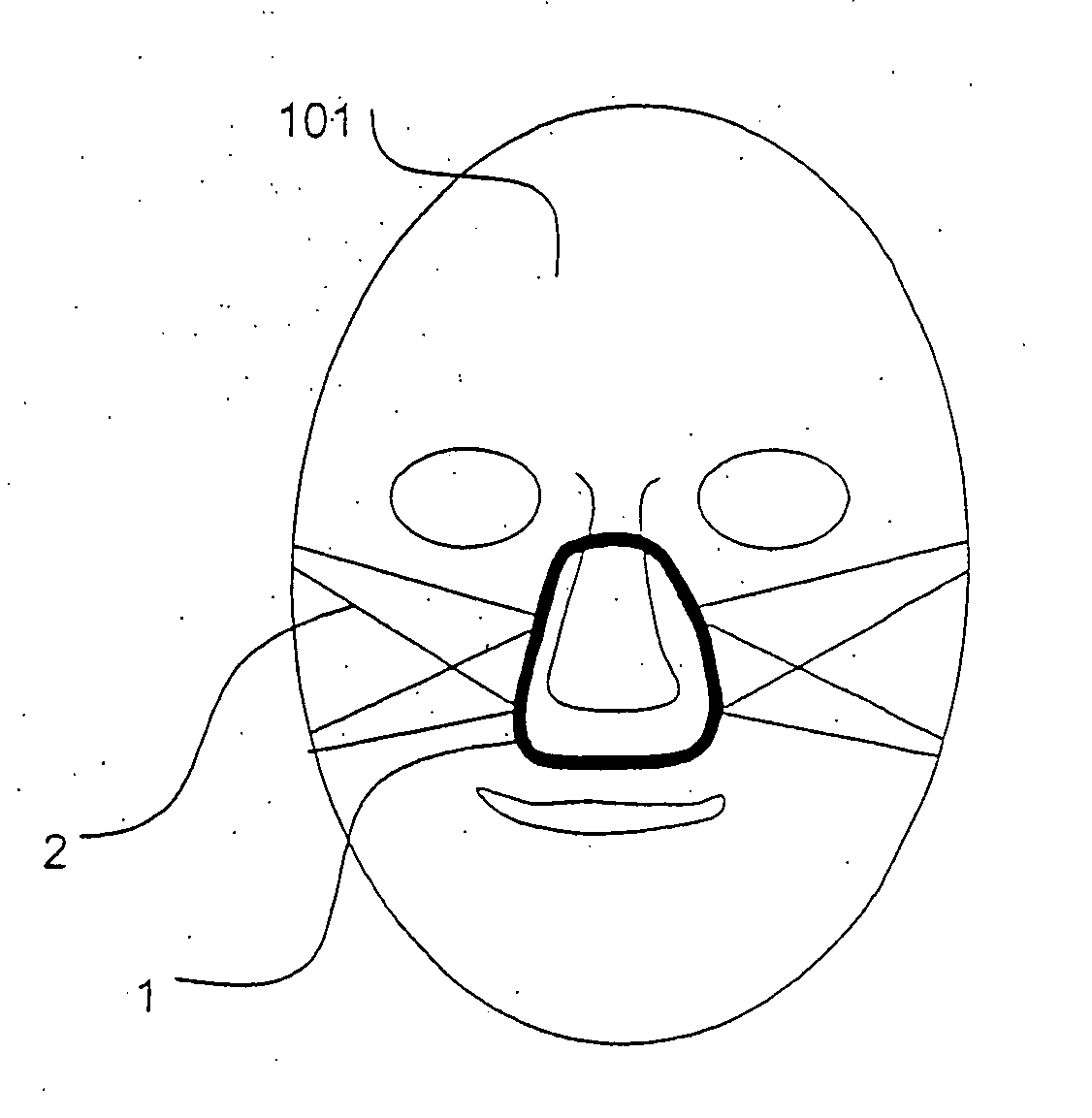

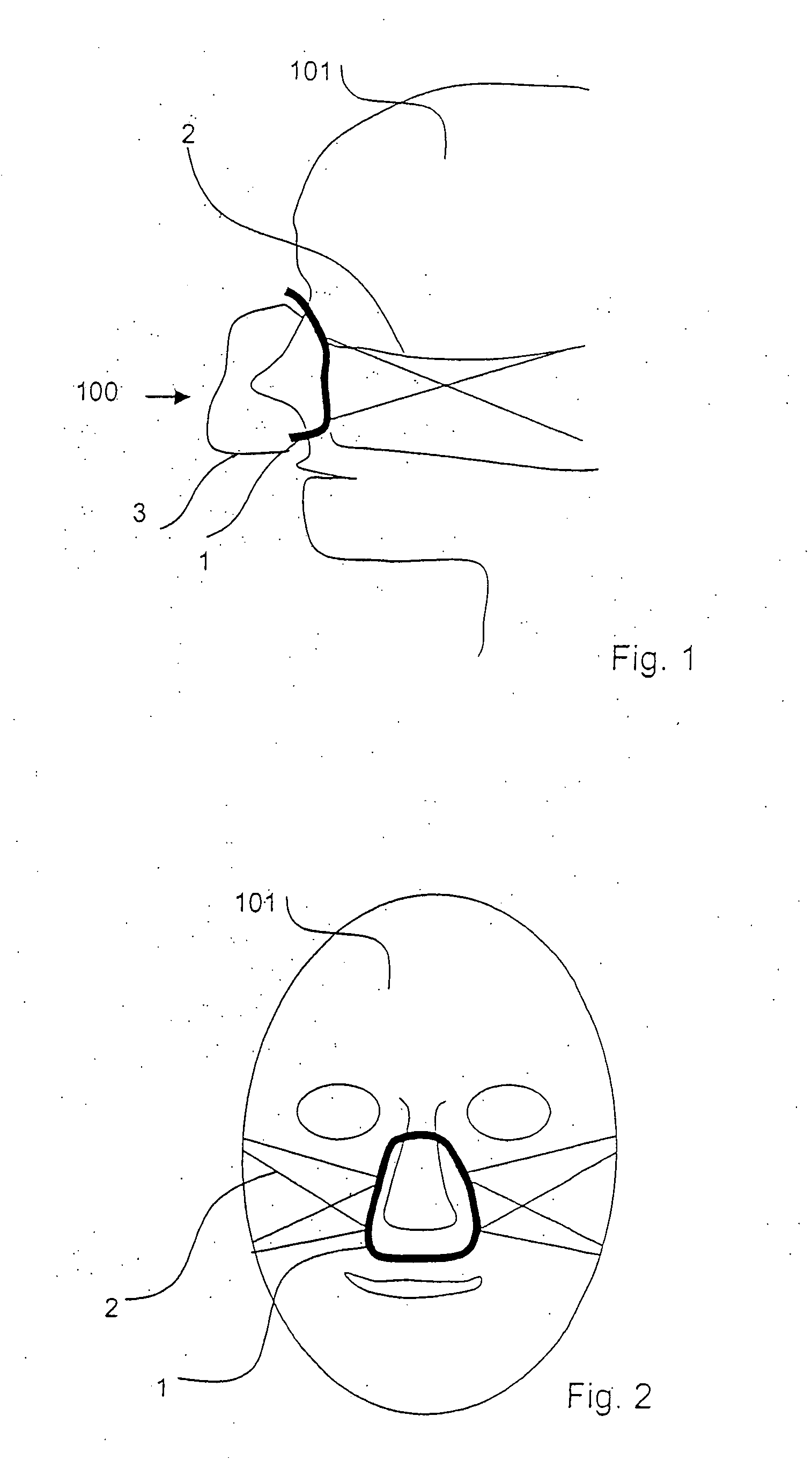

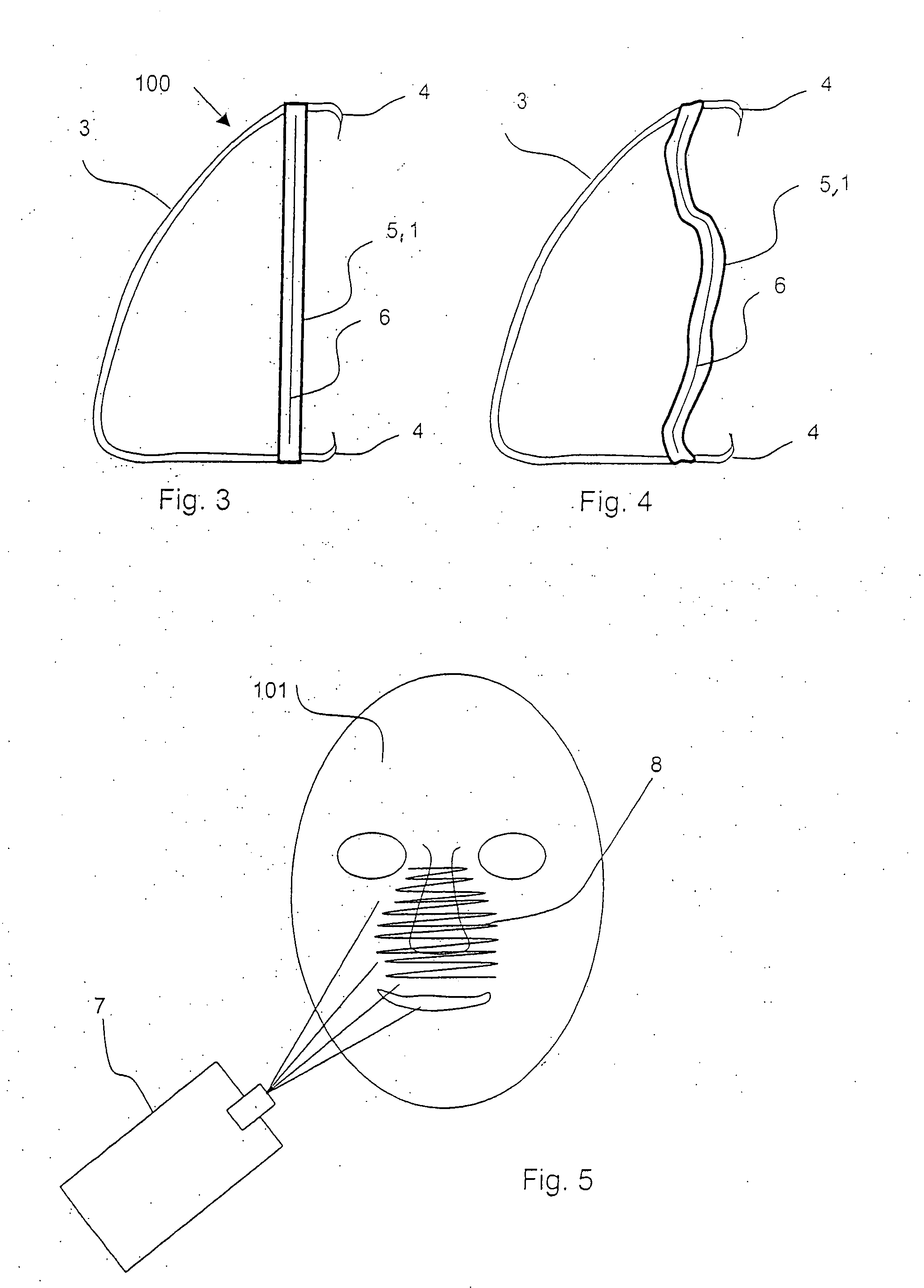

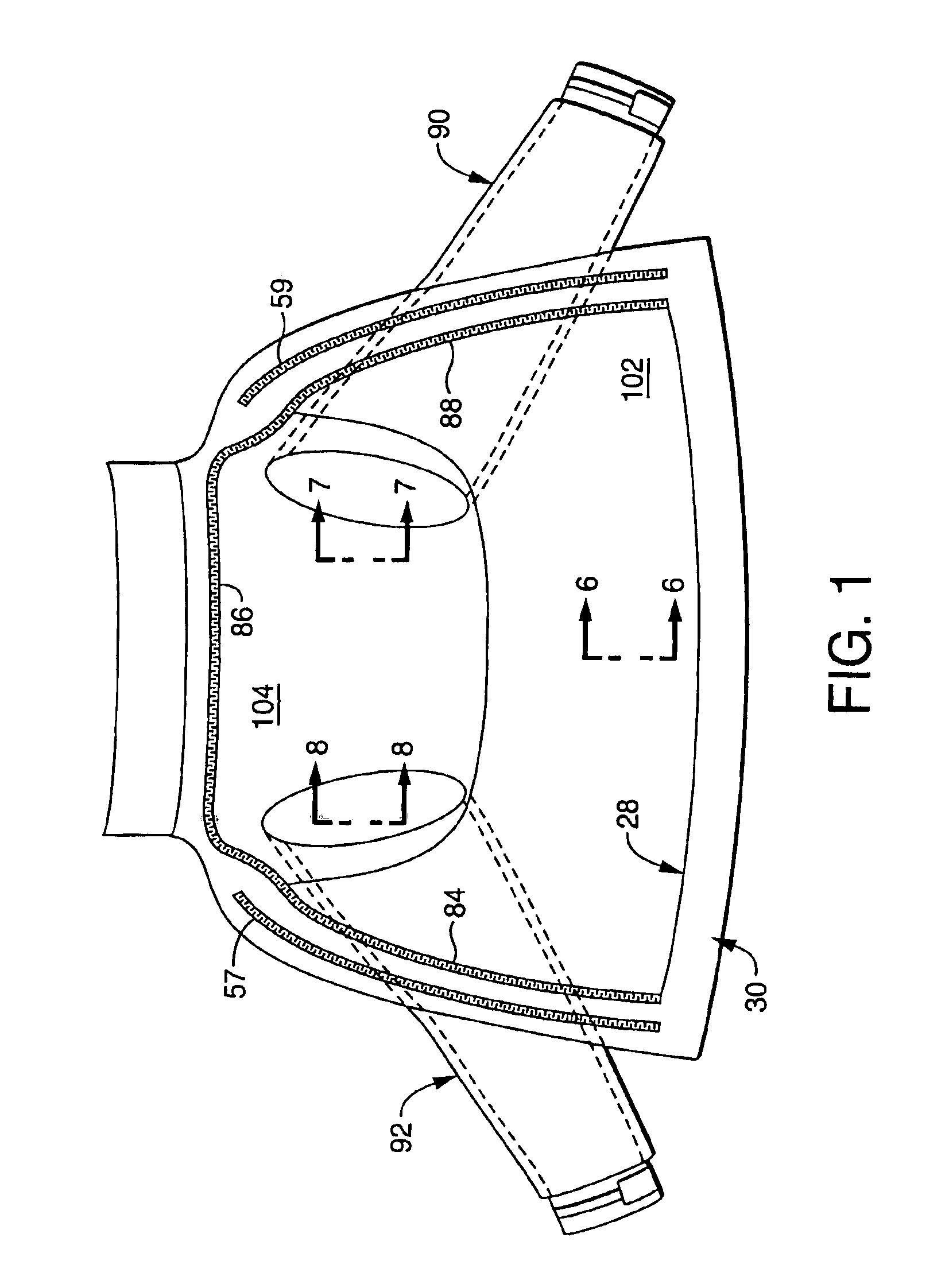

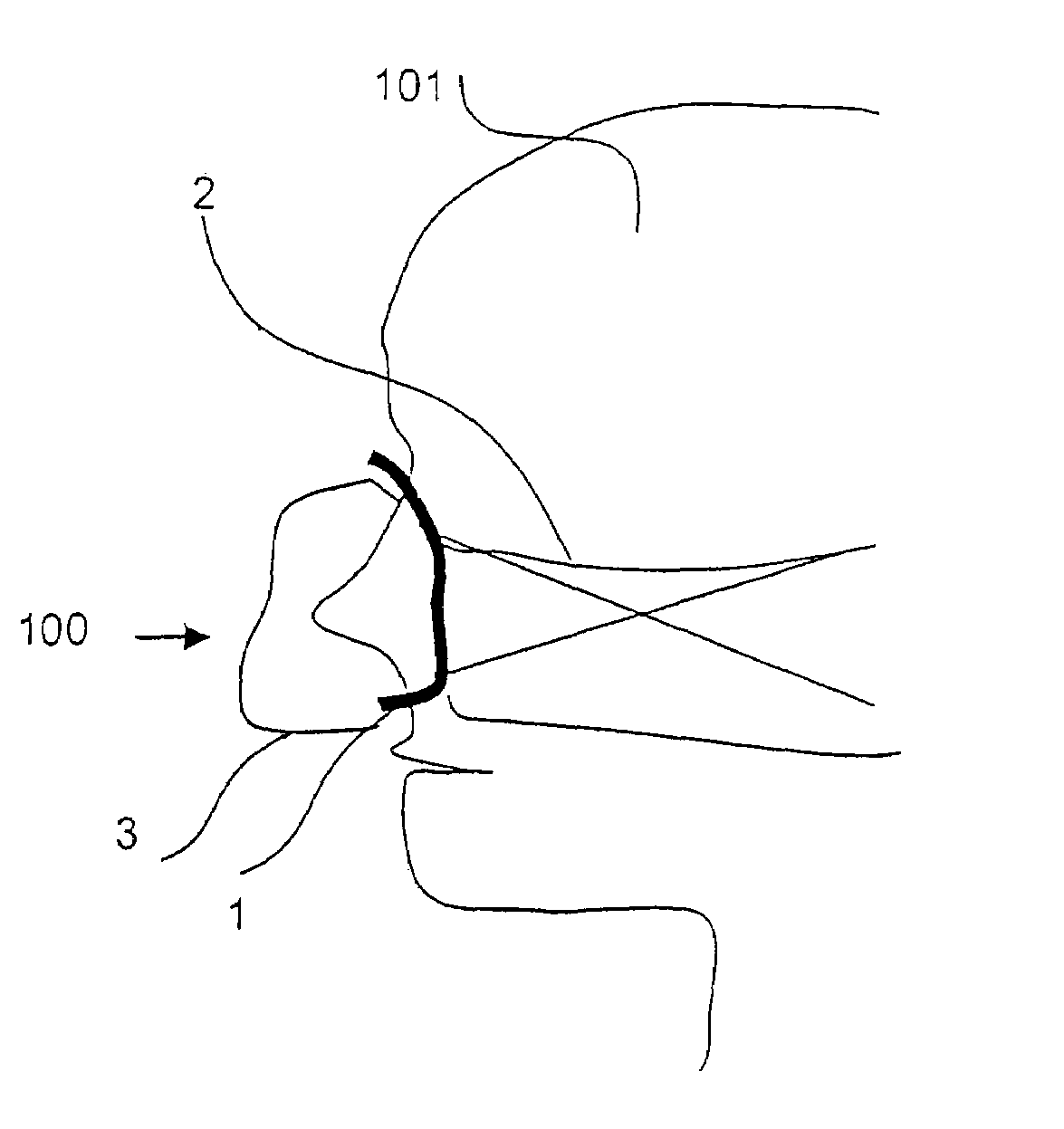

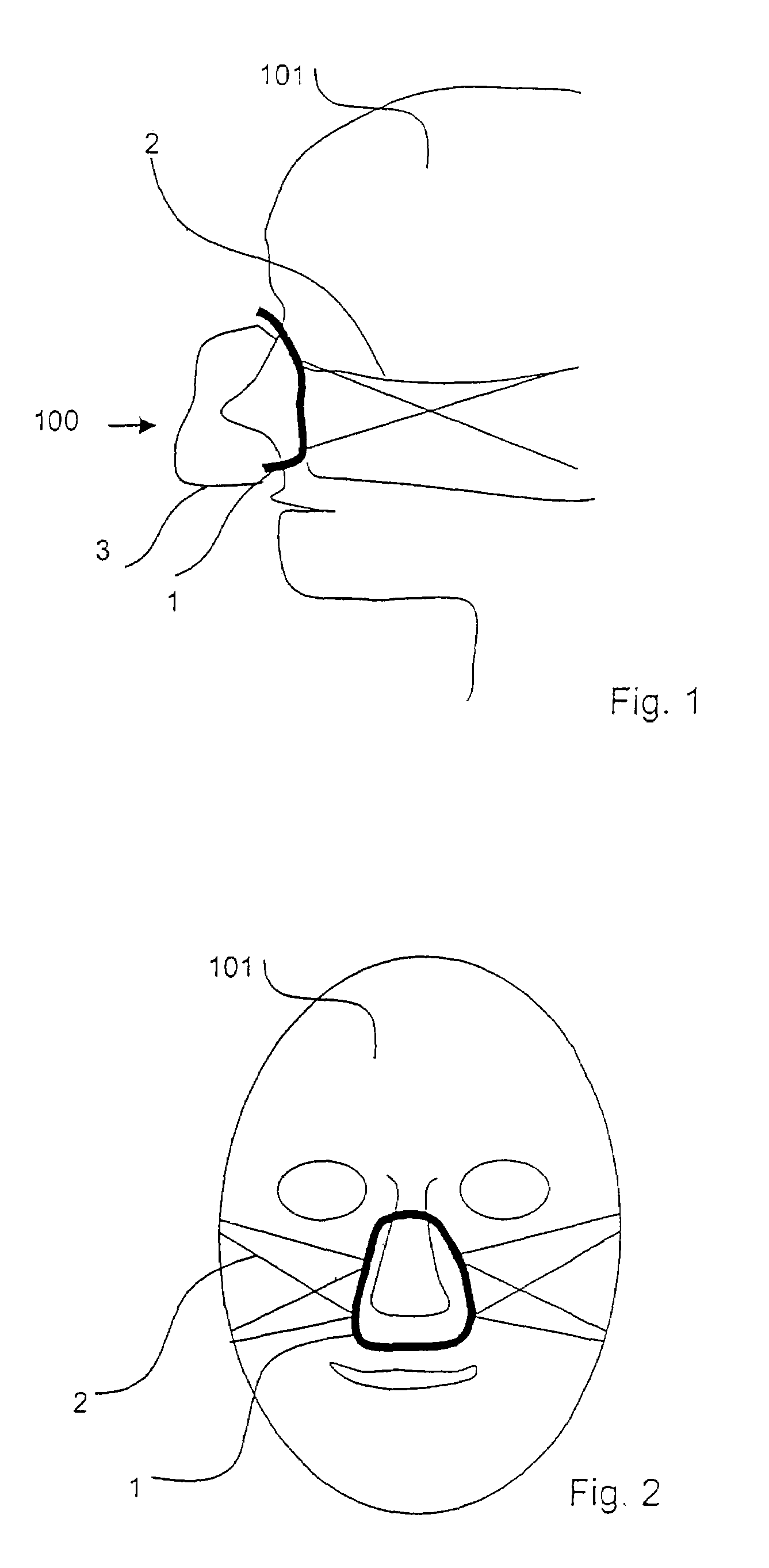

Breathing mask with individual adaptation to the shape of the face

InactiveUS20050284478A1Rigidity of the sealing frame can be setEvenly distributedBreathing filtersBreathing masksMetal stripsPlastic materials

Owner:DRAGERWERK AG

Highly oriented fluoropolymer films

InactiveUS6465103B2Less likelihoodImprove bindingLayered product treatmentSynthetic resin layered productsPolymer sciencePolyolefin

The present invention provides highly oriented multilayer films. They are produced by coextruding or laminating films having at least one layer of a fluoropolymer, at least one layer of a polyolefin homopolymer or copolymer and an intermediate adhesive layer of a polyolefin having at least one functional moiety of an unsaturated carboxylic acid or anhydride thereof. With this structure the polyolefin layer allows the fluoropolymer layer to be stretched up to ten times its original length. Such a high orientation ratio for the fluoropolymer film increases the mechanical strength, toughness, and water vapor barrier properties of the film while using a thinner gauge fluoropolymer film. Coextrusion processing can be done at higher temperatures, i.e. in the range of from at about 280° C. to about 400° C. These temperatures allow films to be produced in the absence of polymer degradation and film melt fracture.

Owner:ALLIED SIGNAL INC

Roll printing paper suitable for cold set printing and process for its production

InactiveUS6413370B1Offset printing processSufficient dimensional stabilityNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryPaper sheet

A coated roll printing paper for printing with the cold-set offset-printing process is described, which gives a printing result comparable with that of low-weight coated matte grades. The paper is characterized by a high proportion of a fine calcium carbonate in the coating pigment, and a relatively low proportion of highly active binders.

Owner:HAINDL PAPIER

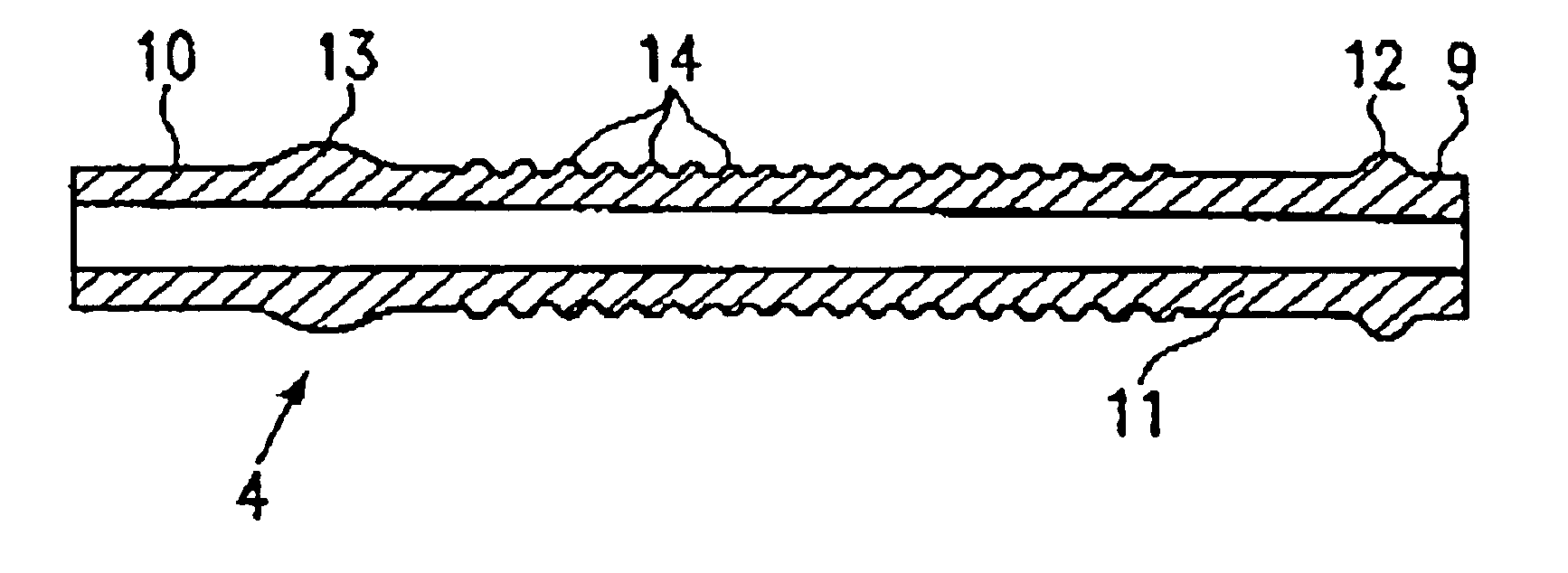

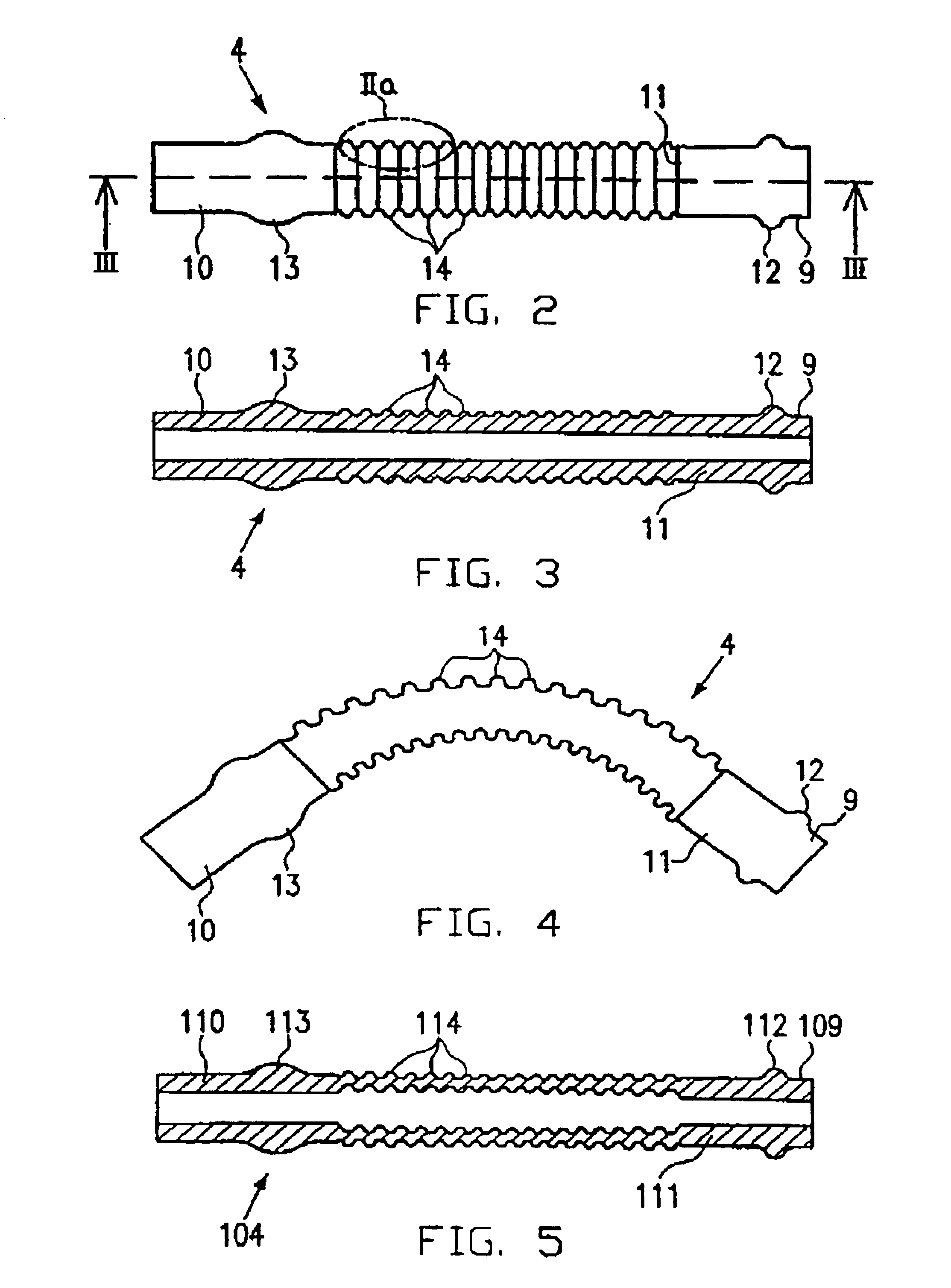

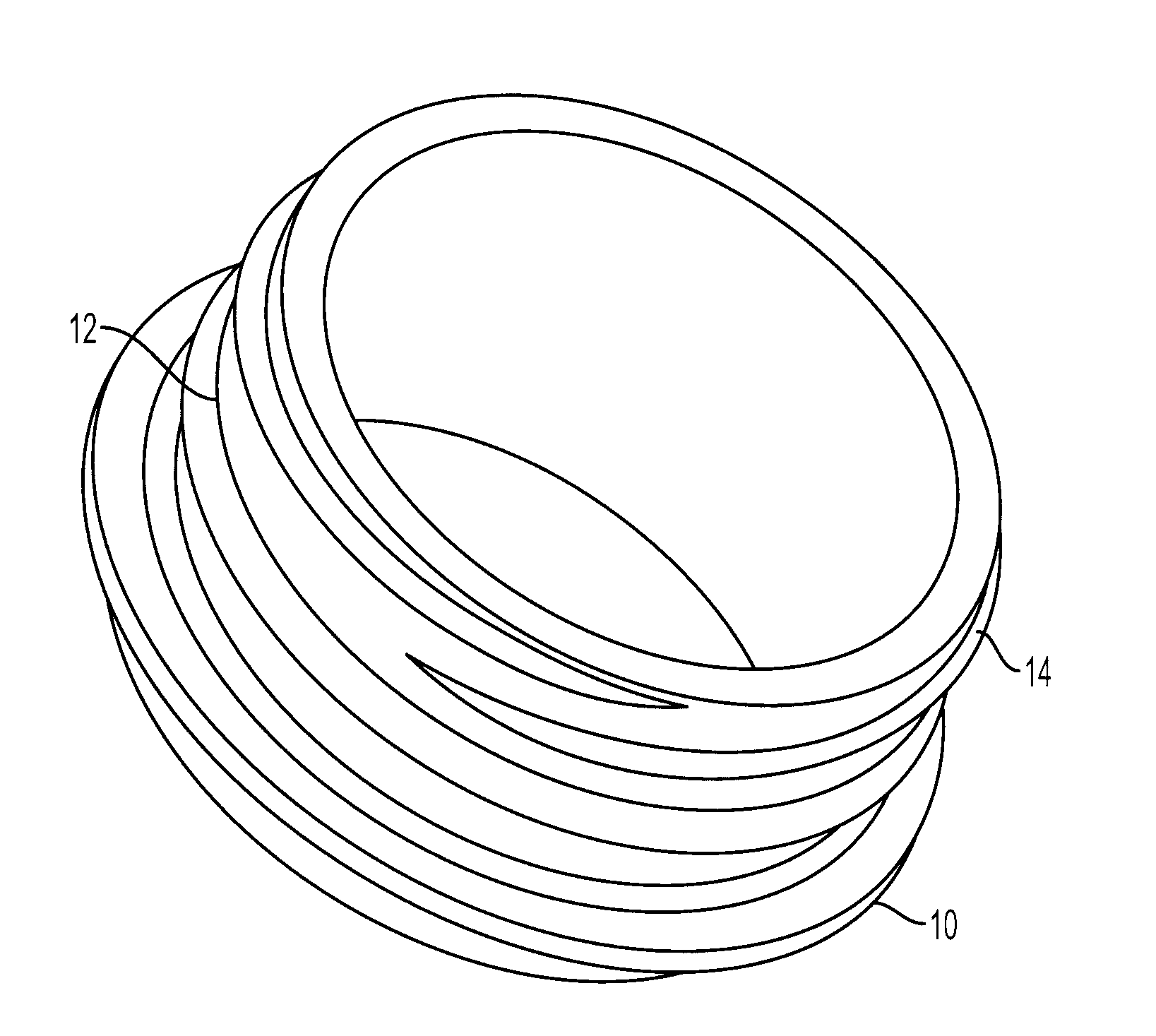

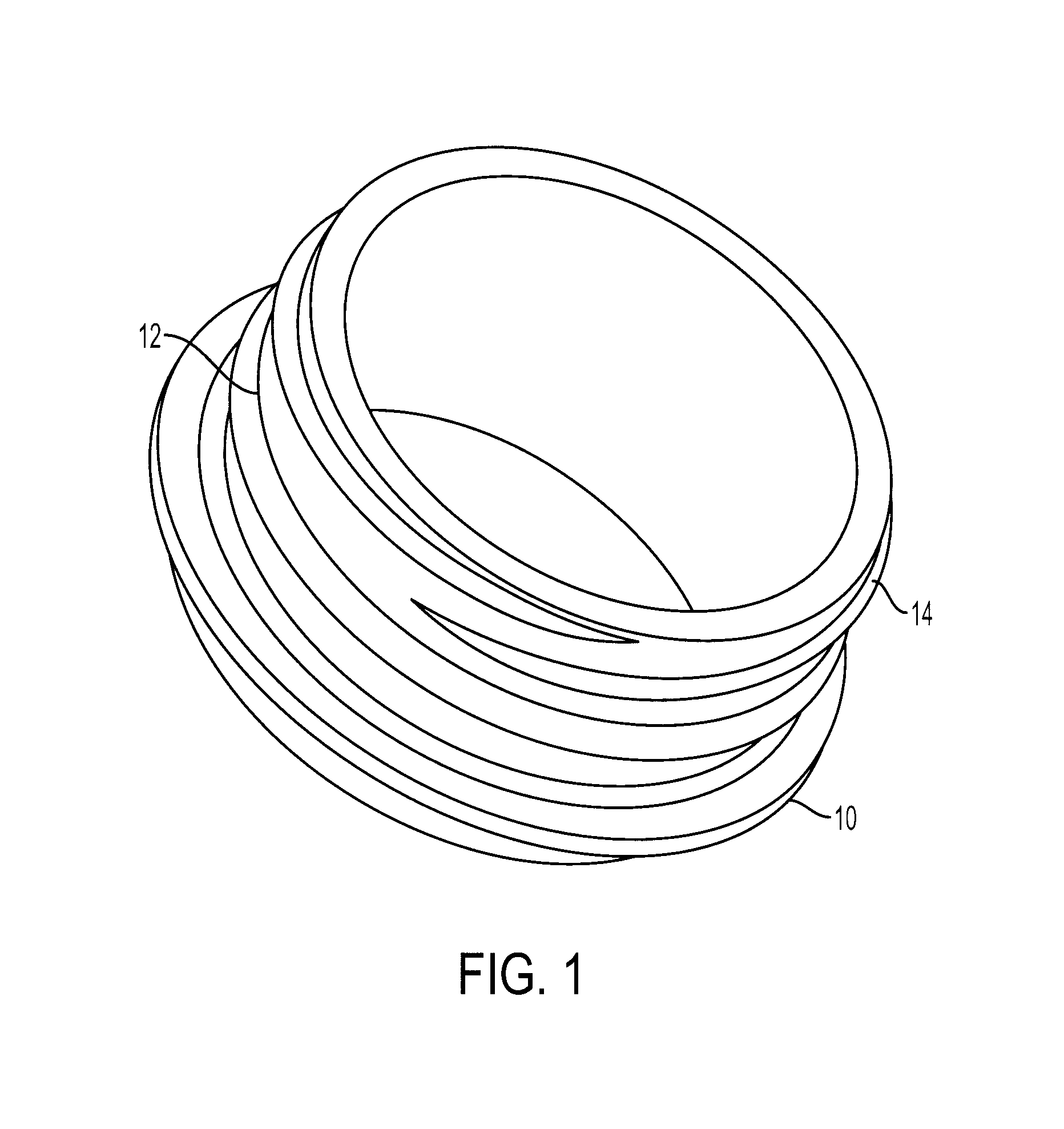

Flexible milk hose for an automatic milking plant

InactiveUS6895890B1Guaranteed mechanical stabilityUniform materialFlexible pipesMilking devicesMechanical stabilityAutomatic milking

An automatic milking plant is provided with a short milk hose, which, due to spaced-apart elevations in its center piece, has sufficient mechanical stability vis-a-vis pressure differences as well as a high flexibility. The use of the short milk hose according to the present invention leads to a reduction of the mechanical strain on the udder and thus also reduces irritations of the animal to be milked.

Owner:MAIER JR JAKOB

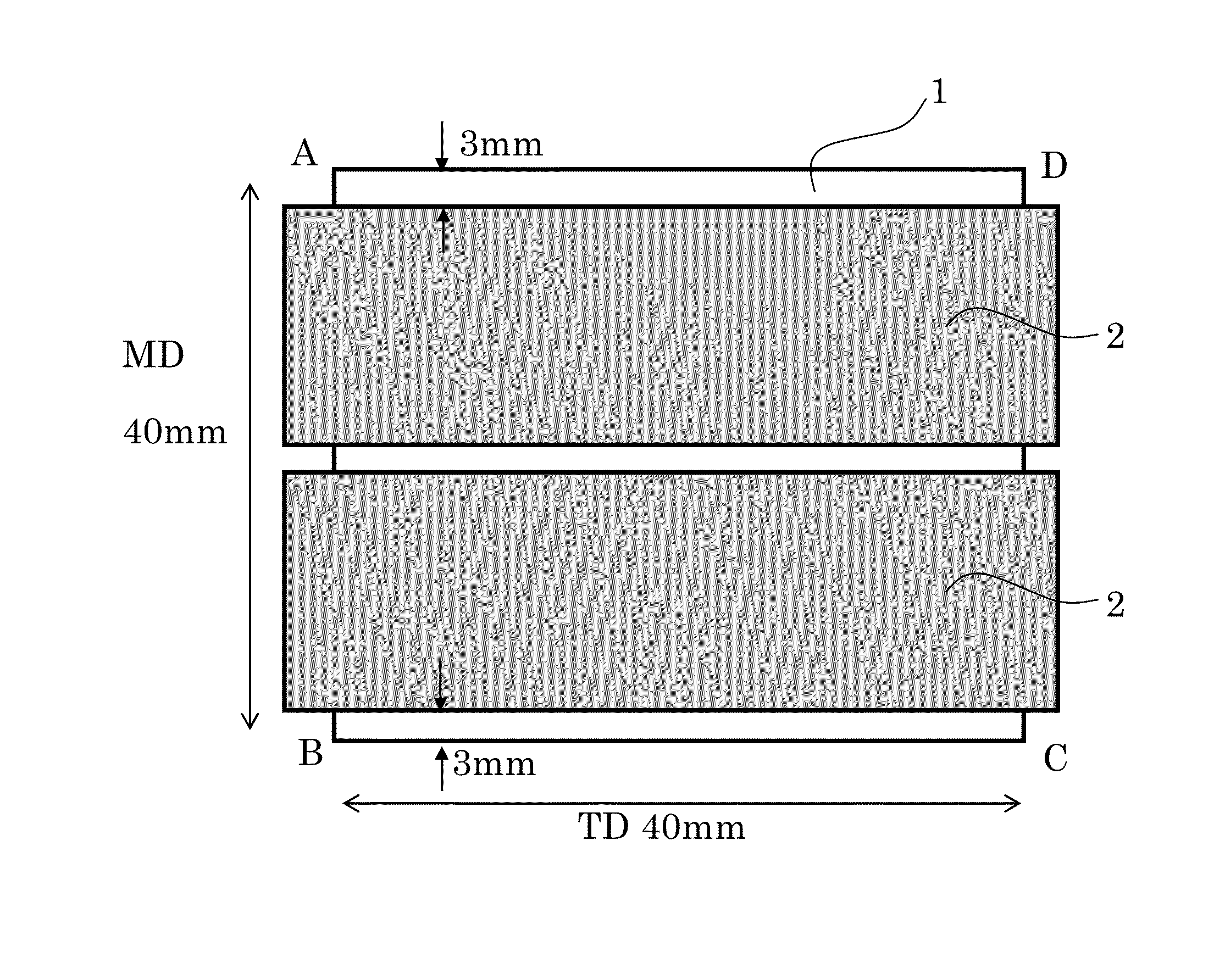

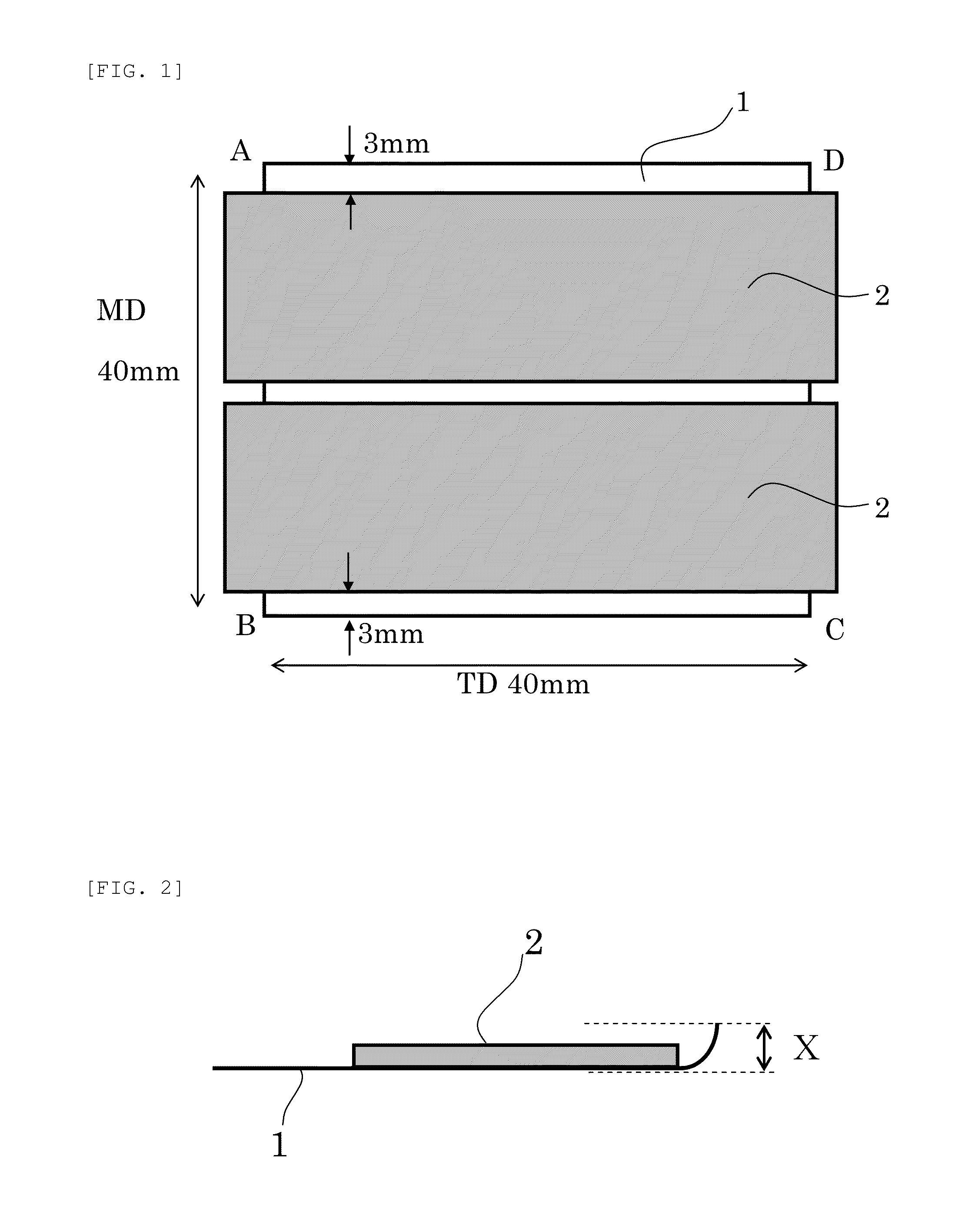

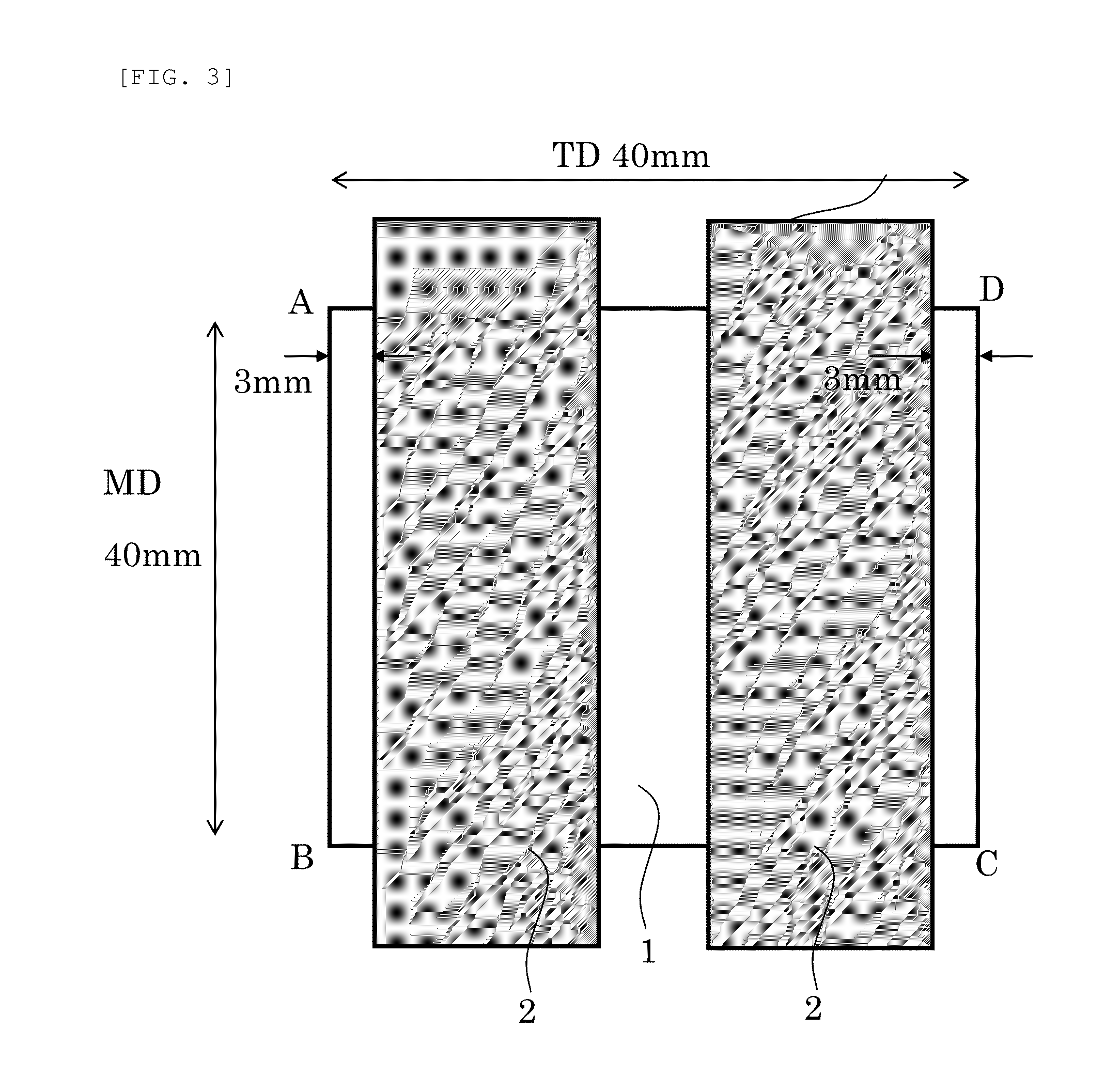

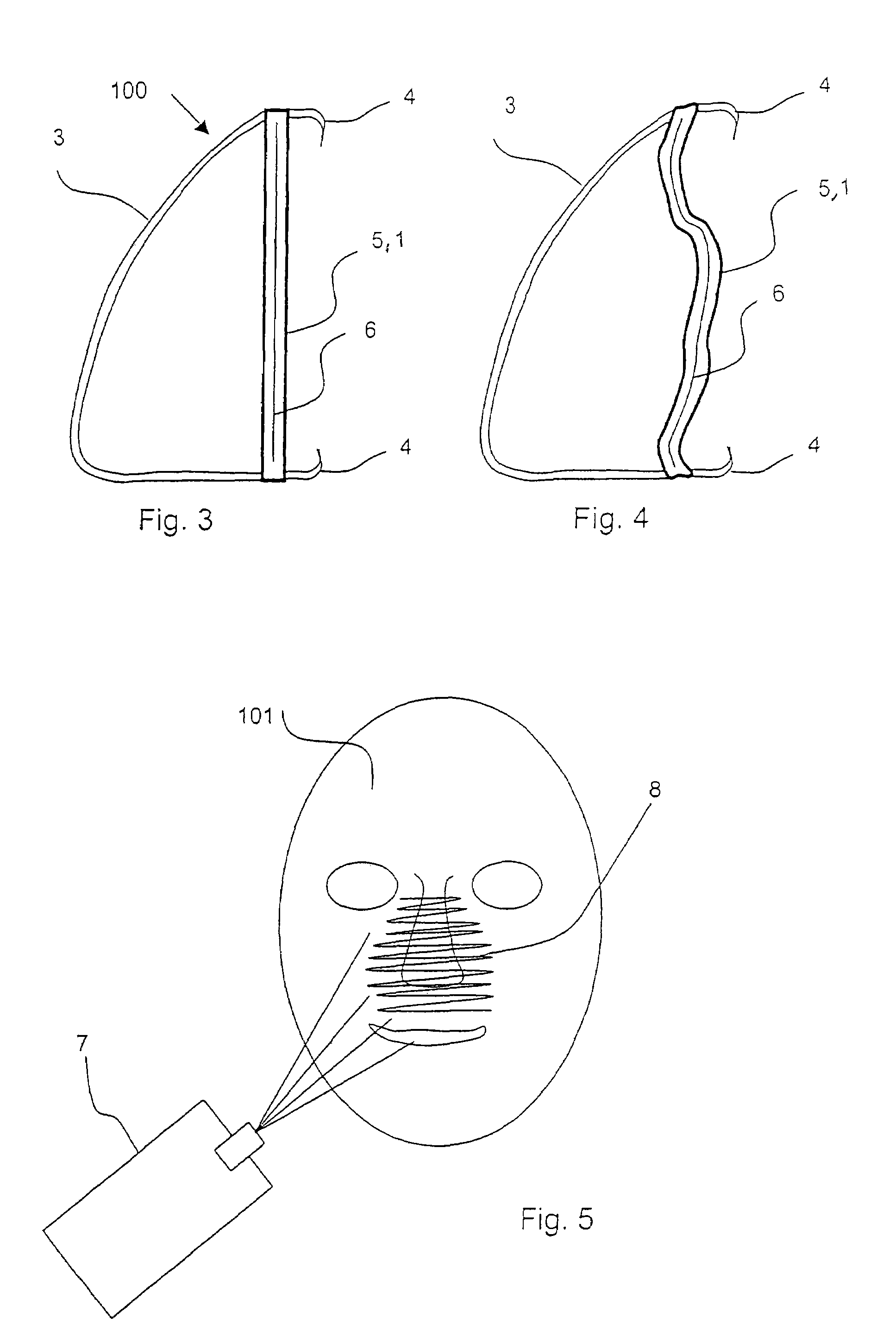

Non-aqeous secondary cell separator and non-aqueous secondary cell

InactiveUS20160268571A1Reduce the amount requiredSufficient dimensional stabilityCell seperators/membranes/diaphragms/spacersSecondary cellsParticulatesComposite film

A separator composed of a composite film including a porous base material containing a thermoplastic resin and a heat-resistant porous layer provided on one surface of the porous base material and containing an organic binder and an inorganic filler, wherein the organic binder is a particulate polyvinylidene fluoride type resin, the heat-resistant porous layer has a porous structure in which the particulate polyvinylidene fluoride type resin and the inorganic filler are connected to each other, the ratio of the thickness Ta of the heat-resistant porous layer to the thickness Tb of the composite film (Ta / Tb) is 0.10 to 0.40, the content of the inorganic filler in the heat-resistant porous layer is 85 to 99 mass % relative to the total mass of the organic binder and the inorganic filler, and the curl amounts of the composite film in the longitudinal direction and the width direction are both 0.5 mm or less.

Owner:TEIJIN LTD

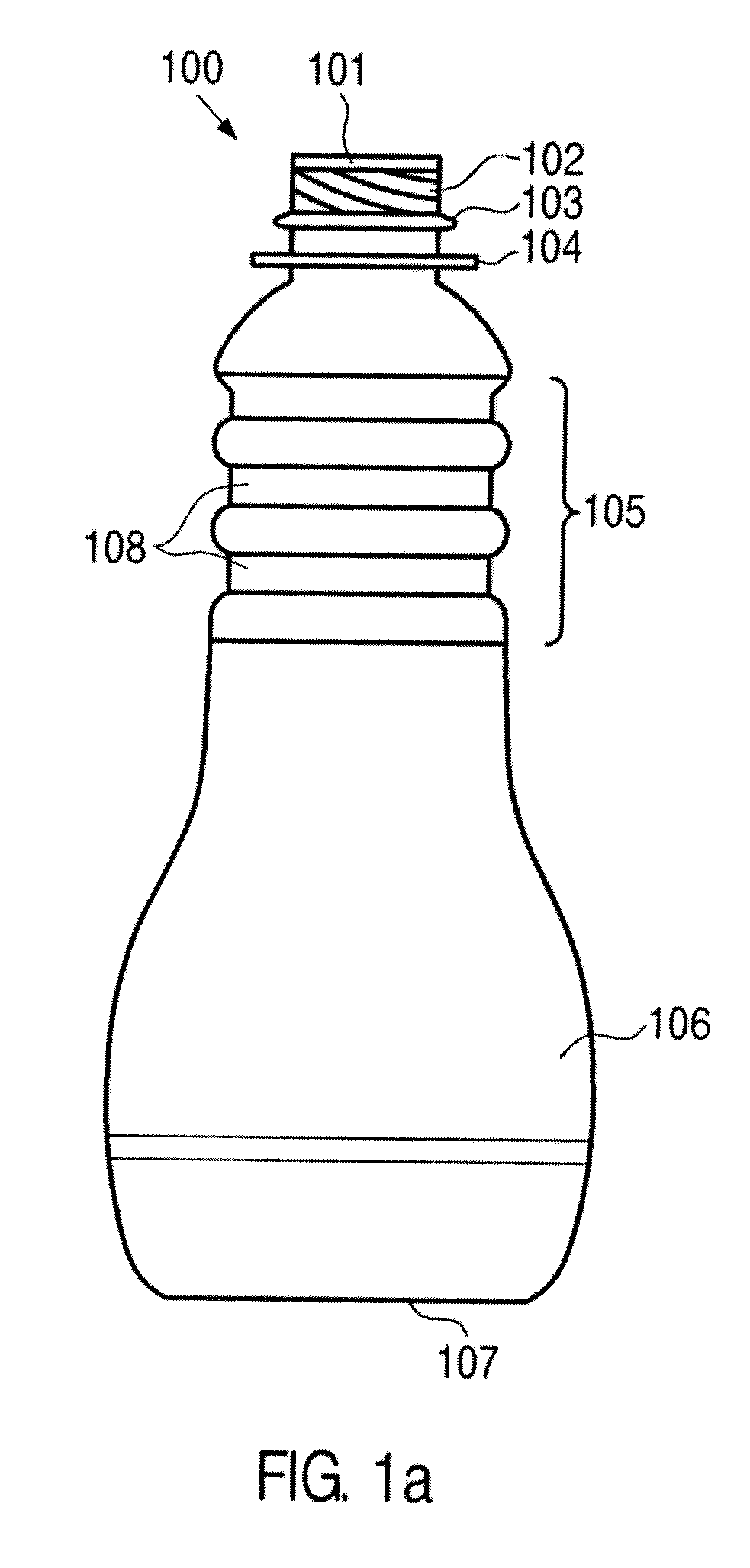

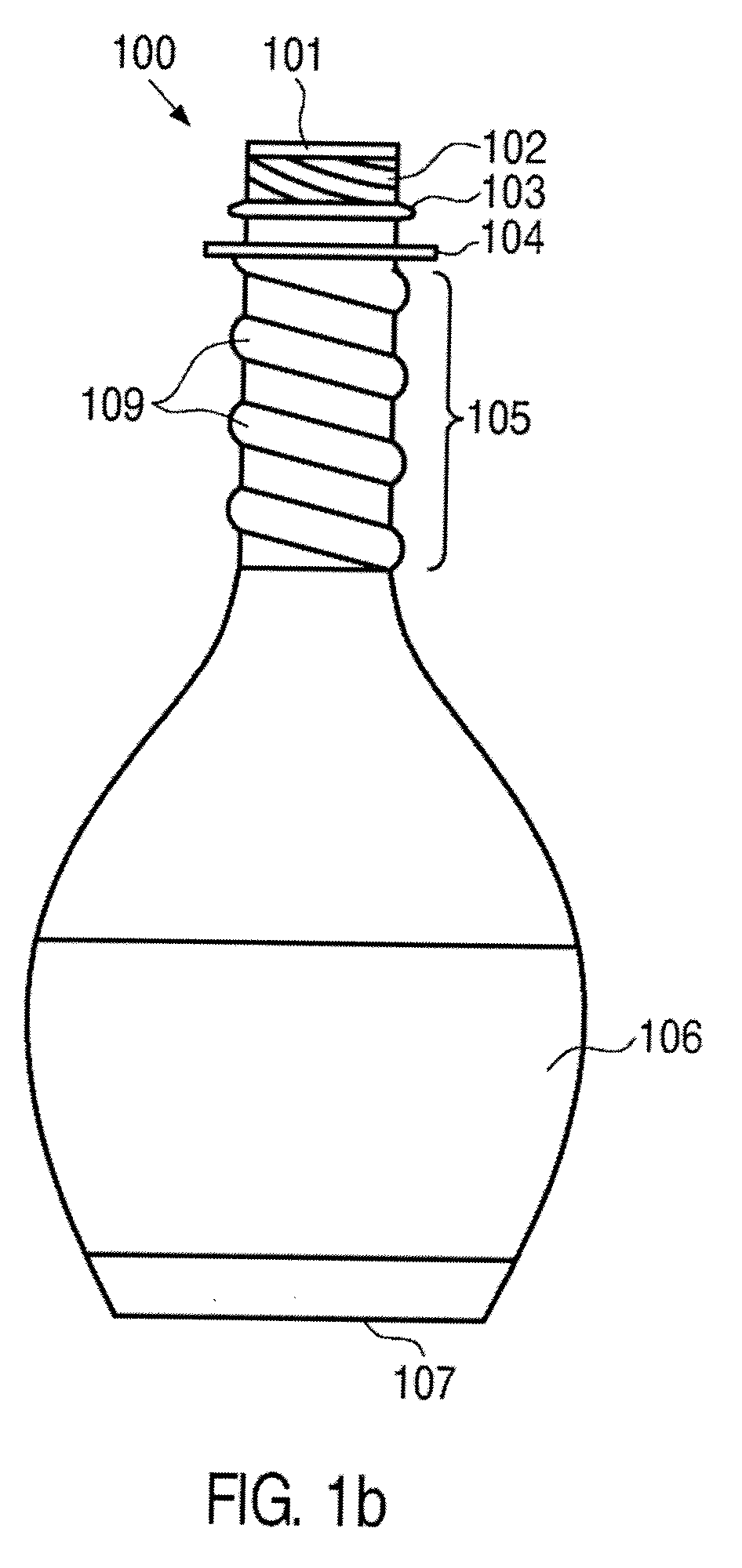

Pouch Bottle

InactiveUS20090095701A1Reduce material consumptionReduce weightCapsClosure capsBottleMaterials science

Owner:KRONES AG

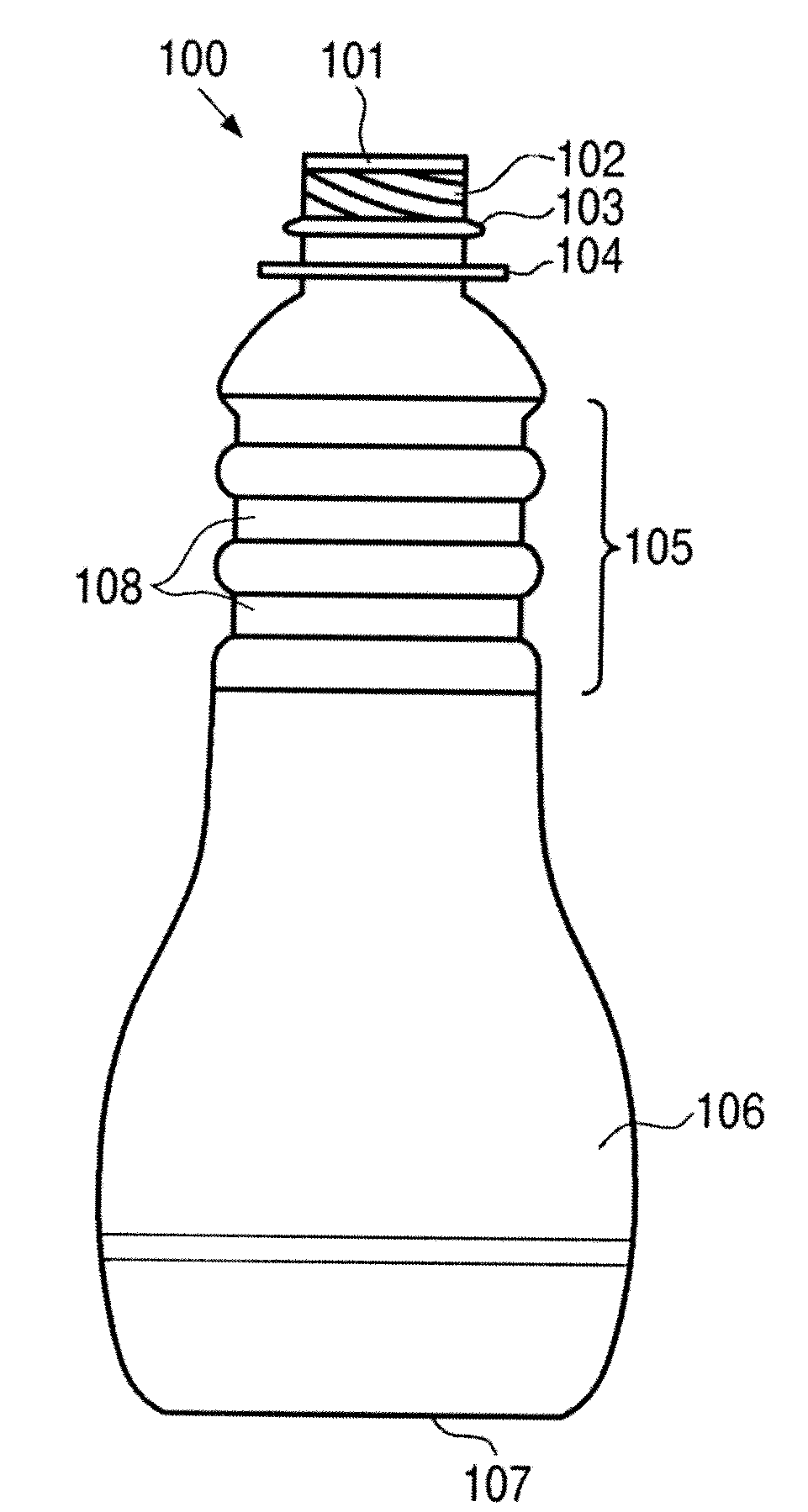

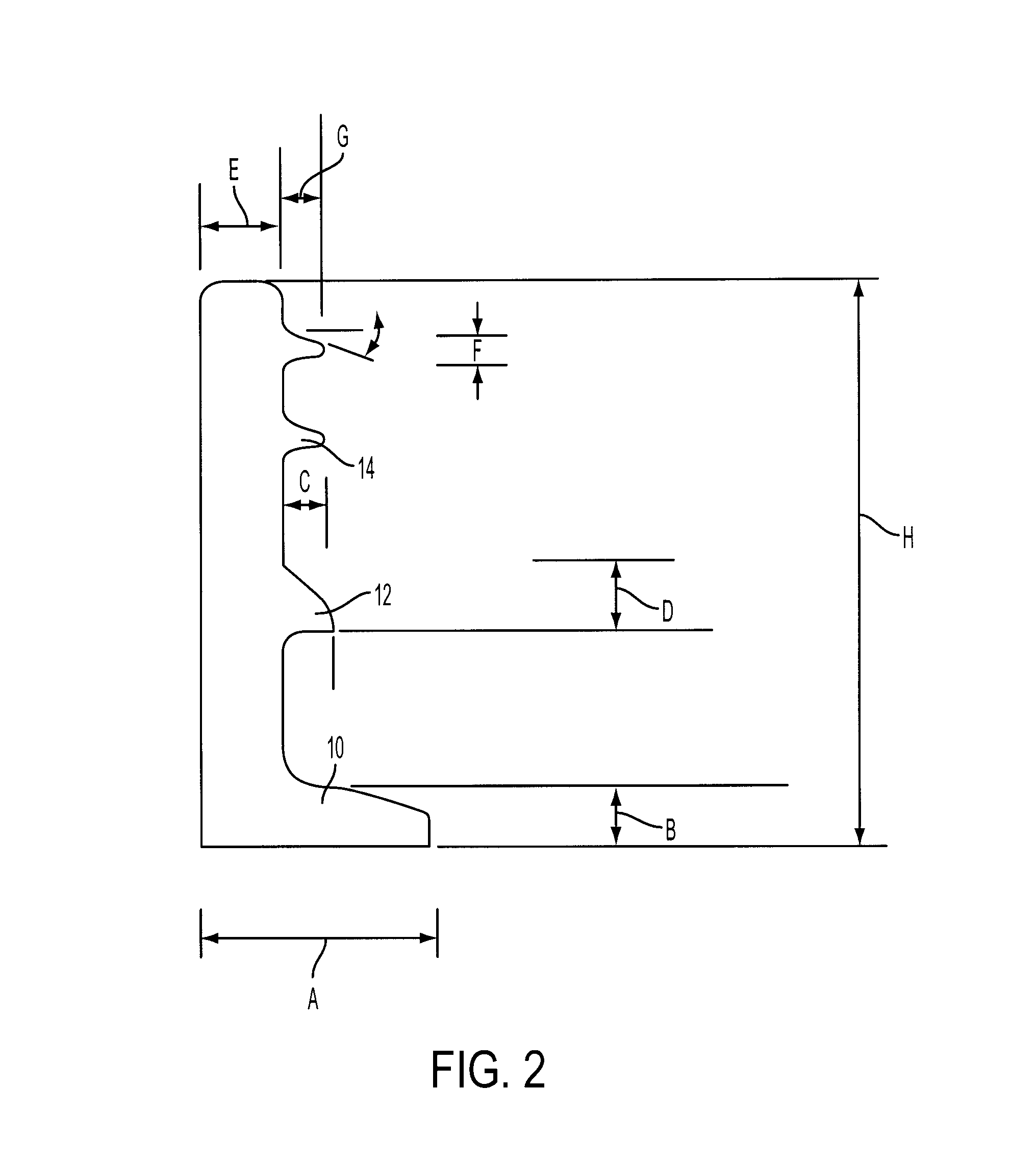

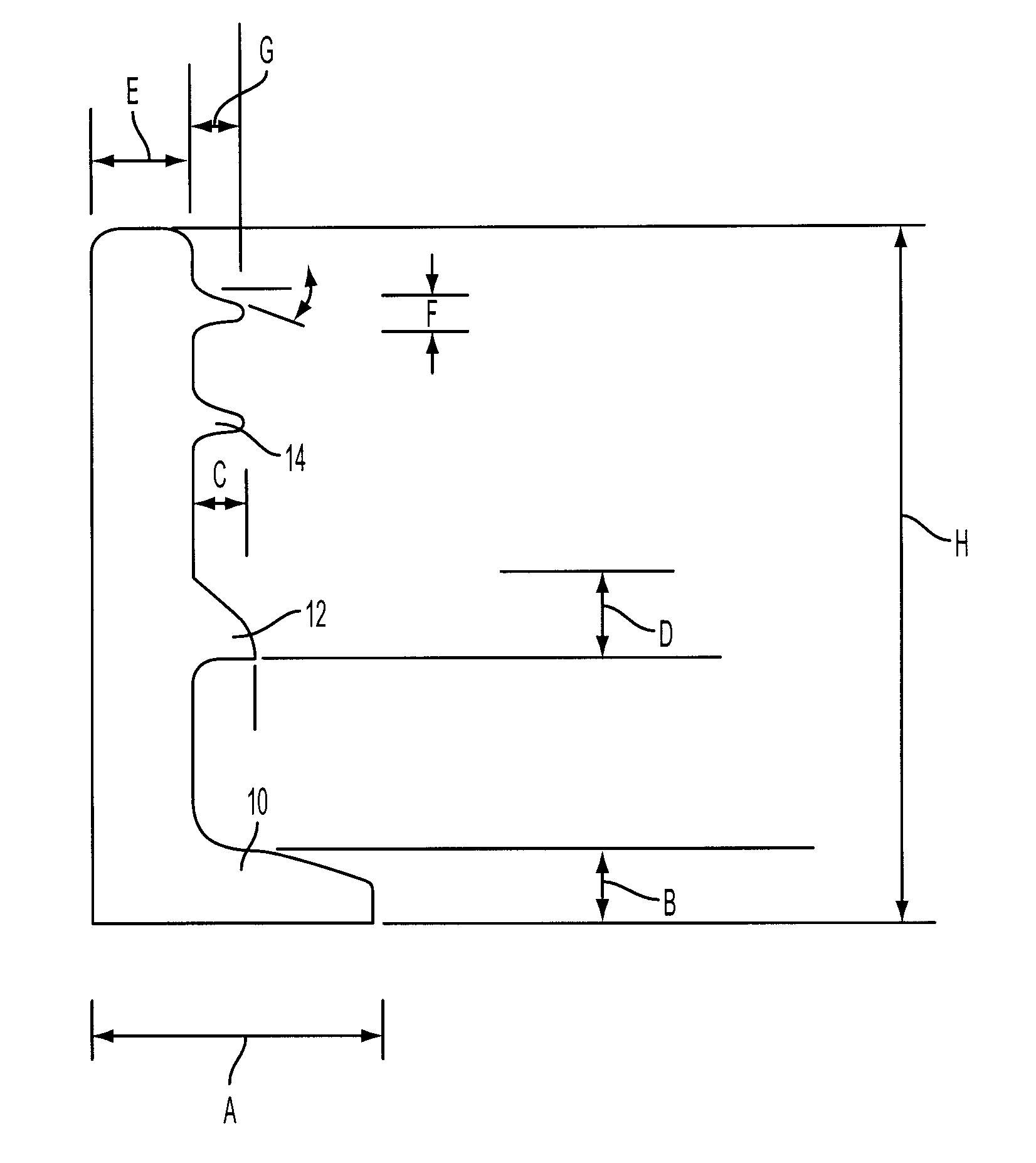

Lightweight Finish for Hot-fill Container

ActiveUS20090078668A1Less materialSufficient dimensional stabilityCapsClosure capsEngineeringMechanical engineering

A lightweight finish for a hot-fill container uses less material compared to existing hot-fill container finishes. The lightweight finish yields a cost savings while still providing adequate dimensional stability to allow the container to maintain its shape during the hot-fill process.

Owner:STOKLEY VAN CAMP INC

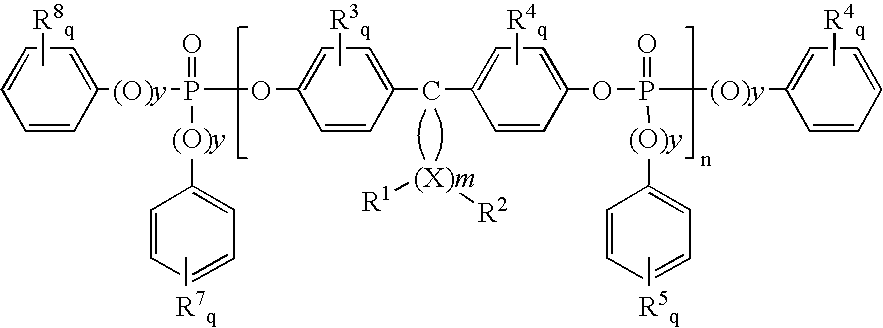

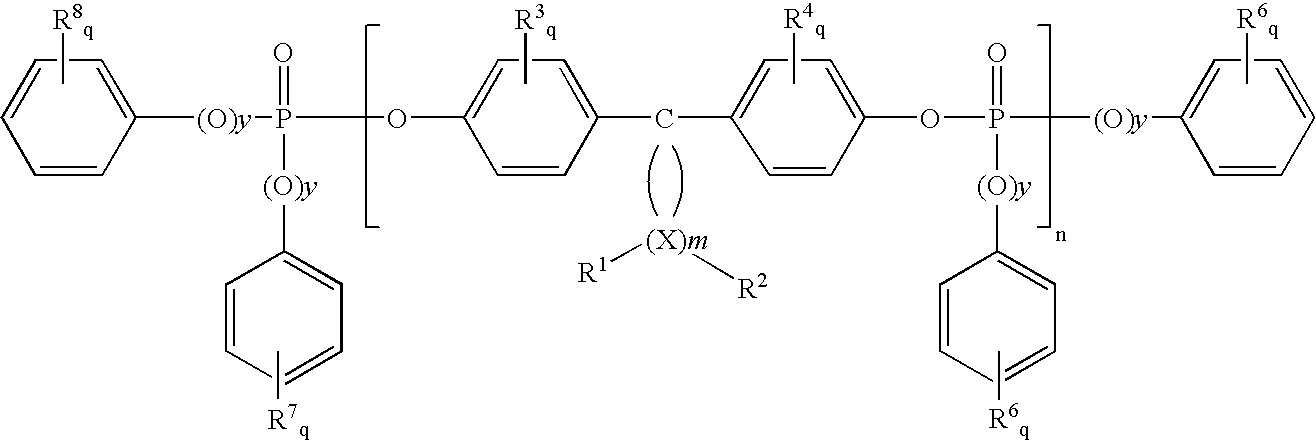

Flame retardants which contain phosphorus, and flame-retardant thermoplastic molding compositions

InactiveUS7019056B2Low dimensional stabilityGood dimensional stabilityNanostructure manufacturePhosphorus organic compoundsFire retardantToughness

An oligophosphate of general formula is disclosed. The oligophosphate is suitable as a flame retardant for thermoplastic molding compositions that exhibit a good flame-retardant effect, improved dimensional stability under the effect of heat, a good level of toughness and excellent flowability.

Owner:COVESTRO DEUTSCHLAND AG

Highly oriented fluoropolymer films

InactiveUS20010008694A1Good orientationLess likelihoodLamination ancillary operationsLayered product treatmentPolymer sciencePolyolefin

The present invention provides highly oriented multilayer films. They are produced by coextruding or laminating films having at least one layer of a fluoropolymer, at least one layer of a polyolefin homopolymer or copolymer and an intermediate adhesive layer of a polyolefin having at least one functional moiety of an unsaturated carboxylic acid or anhydride thereof. With this structure the polyolefin layer allows the fluoropolymer layer to be stretched up to ten times its original length. Such a high orientation ratio for the fluoropolymer film increases the mechanical strength, toughness, and water vapor barrier properties of the film while using a thinner gauge fluoropolymer film. Coextrusion processing can be done at higher temperatures, i.e. in the range of from at about 280° C. to about 400° C. These temperatures allow films to be produced in the absence of polymer degradation and film melt fracture.

Owner:ALLIEDSIGNAL INC

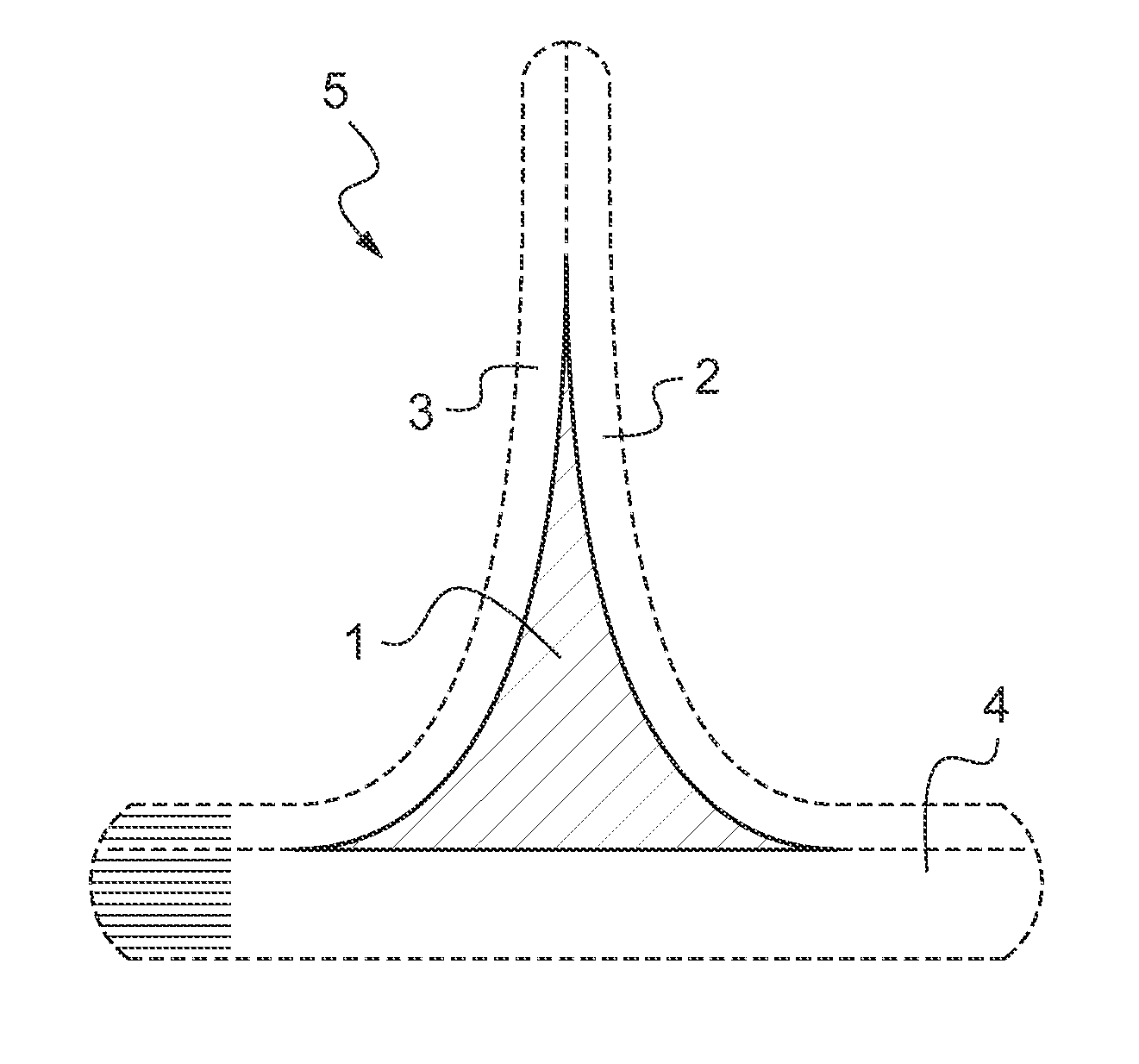

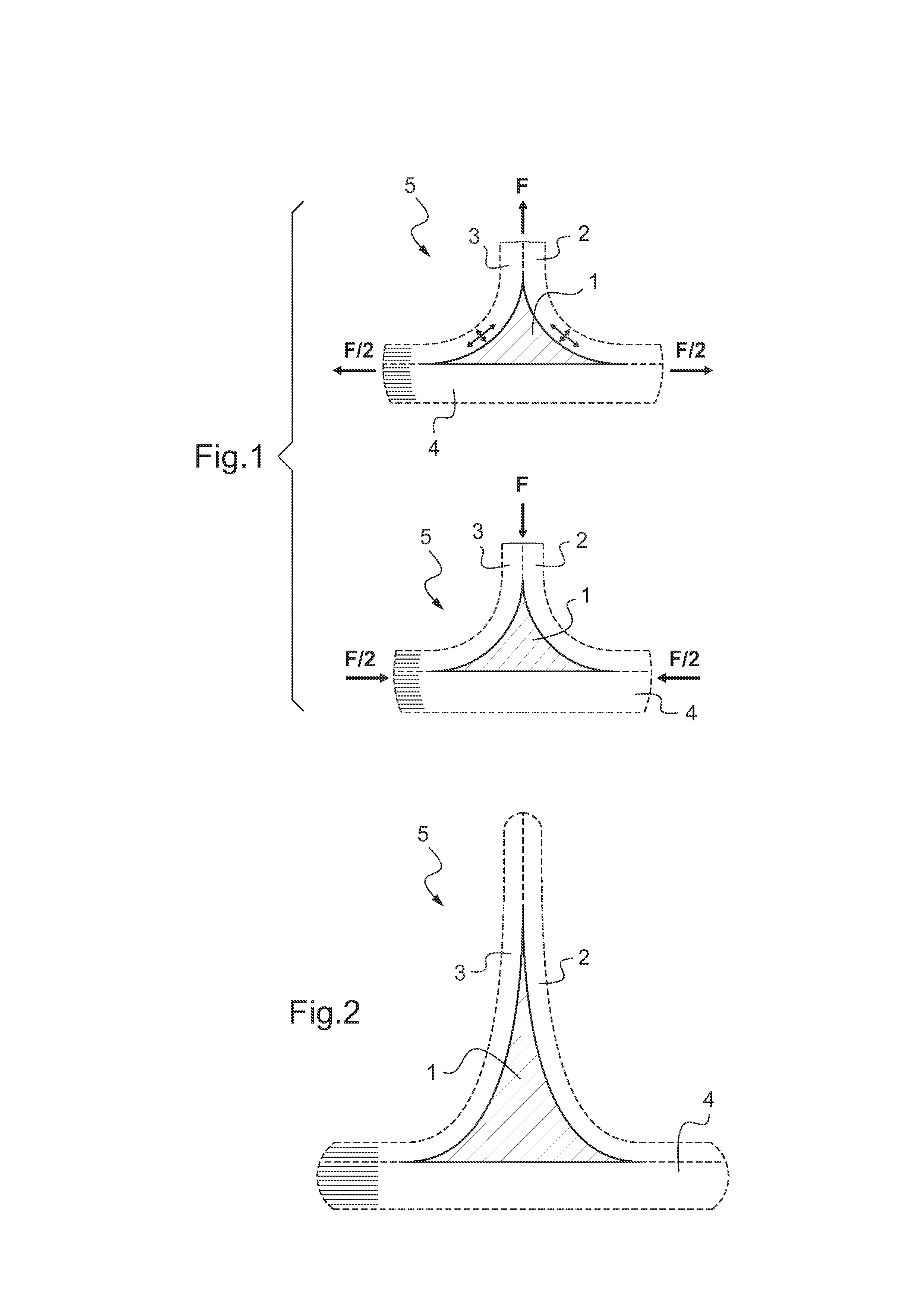

Composite gusset filler and method of manufacture of said composite gusset filler

InactiveUS20130171895A1High strengthImproves Structural IntegrityLayered productsWarp knittingYarnFiber

A composite gusset filler (1) of cut-off material from fiber fabrics (2, 3) trimmed into fragments of 2 min-10 mm length, separated into single yarn or roving elements mixed to quasi-homogeneous raw material for a semi-finished gusset filler (1). The present invention relates as well to specific shapes and a method of manufacture of said composite gusset filler (1) and to applications of said composite gusset filler (1).

Owner:AIRBUS HELICOPTERS DEUT GMBH

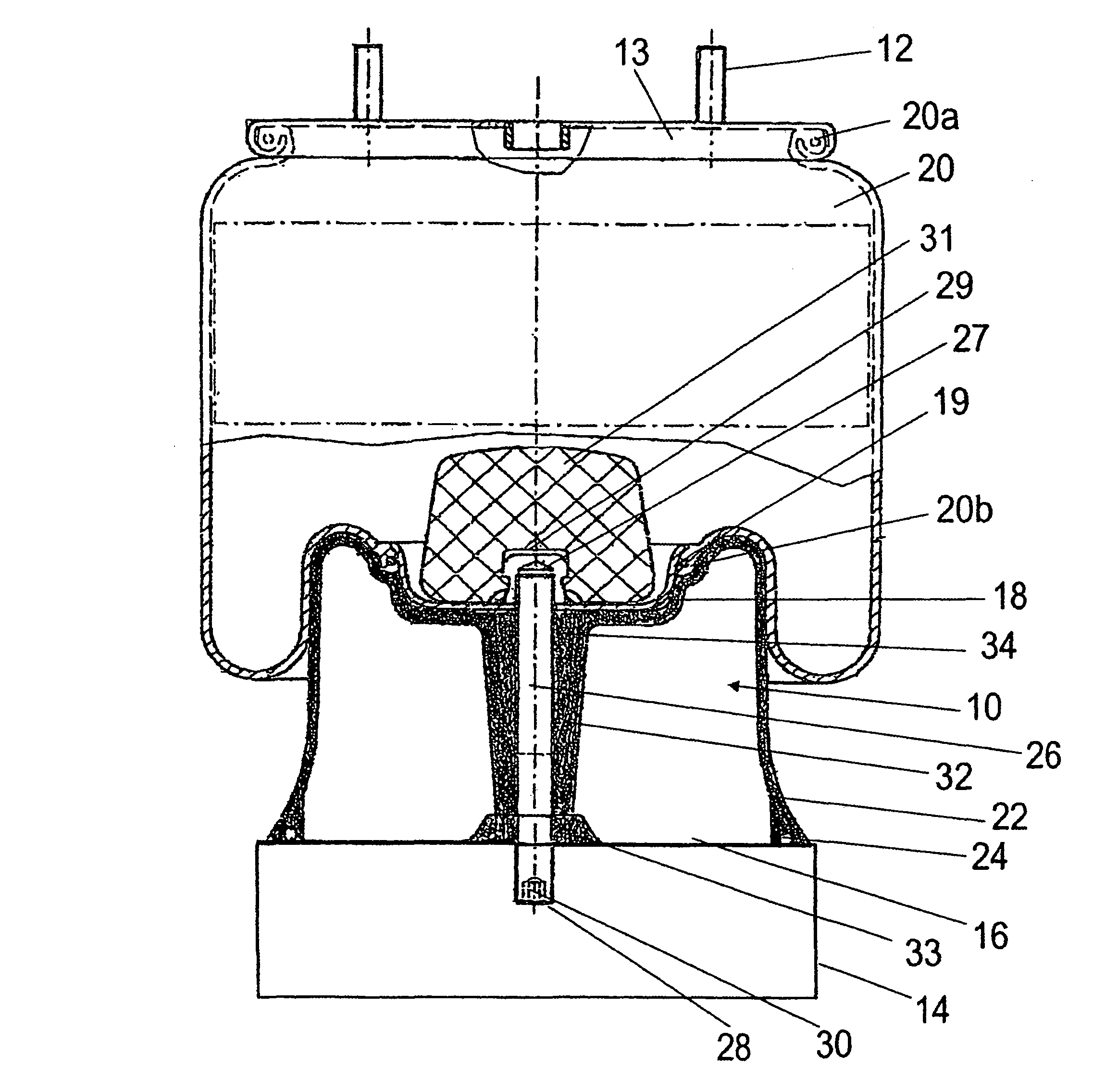

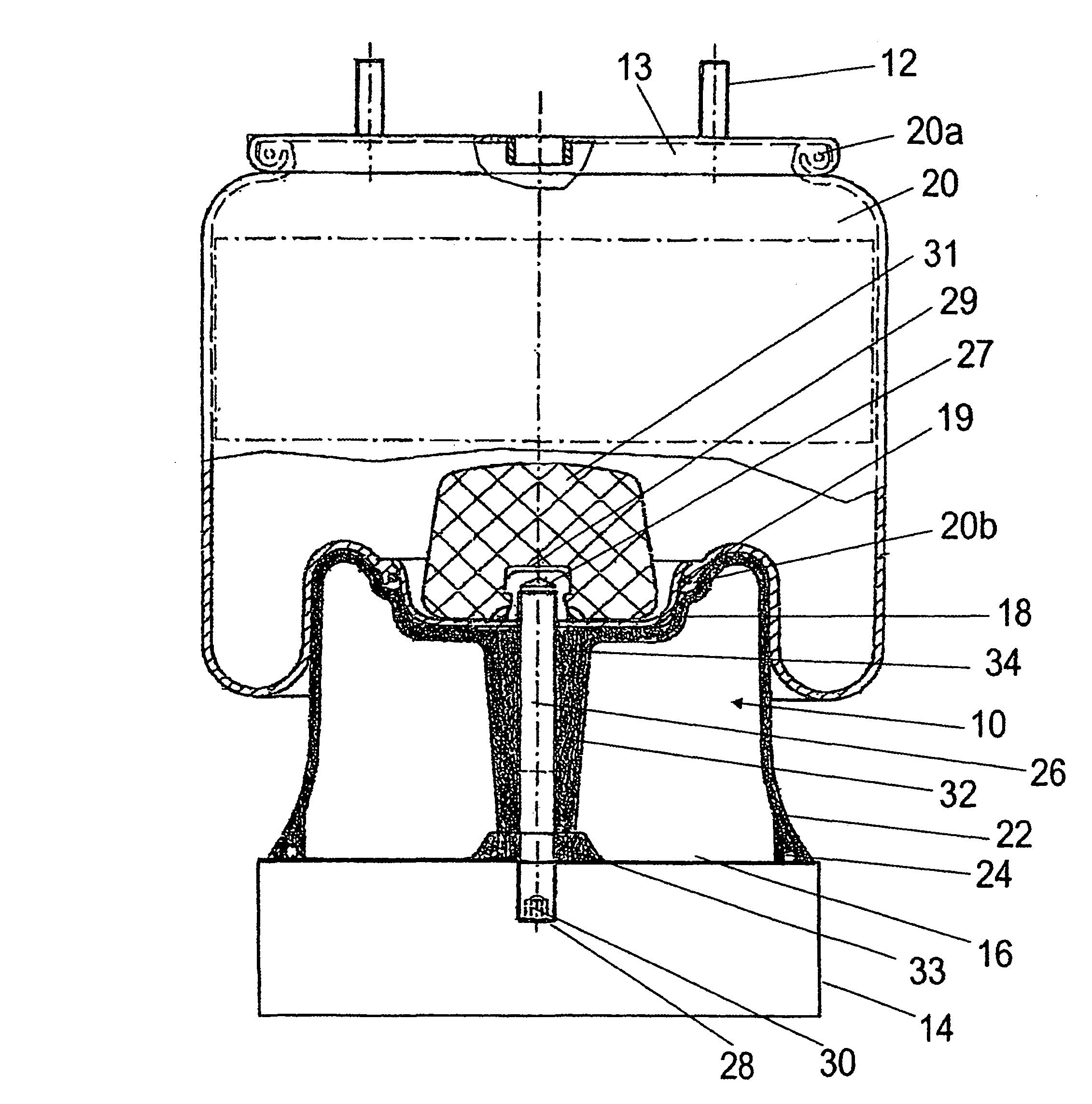

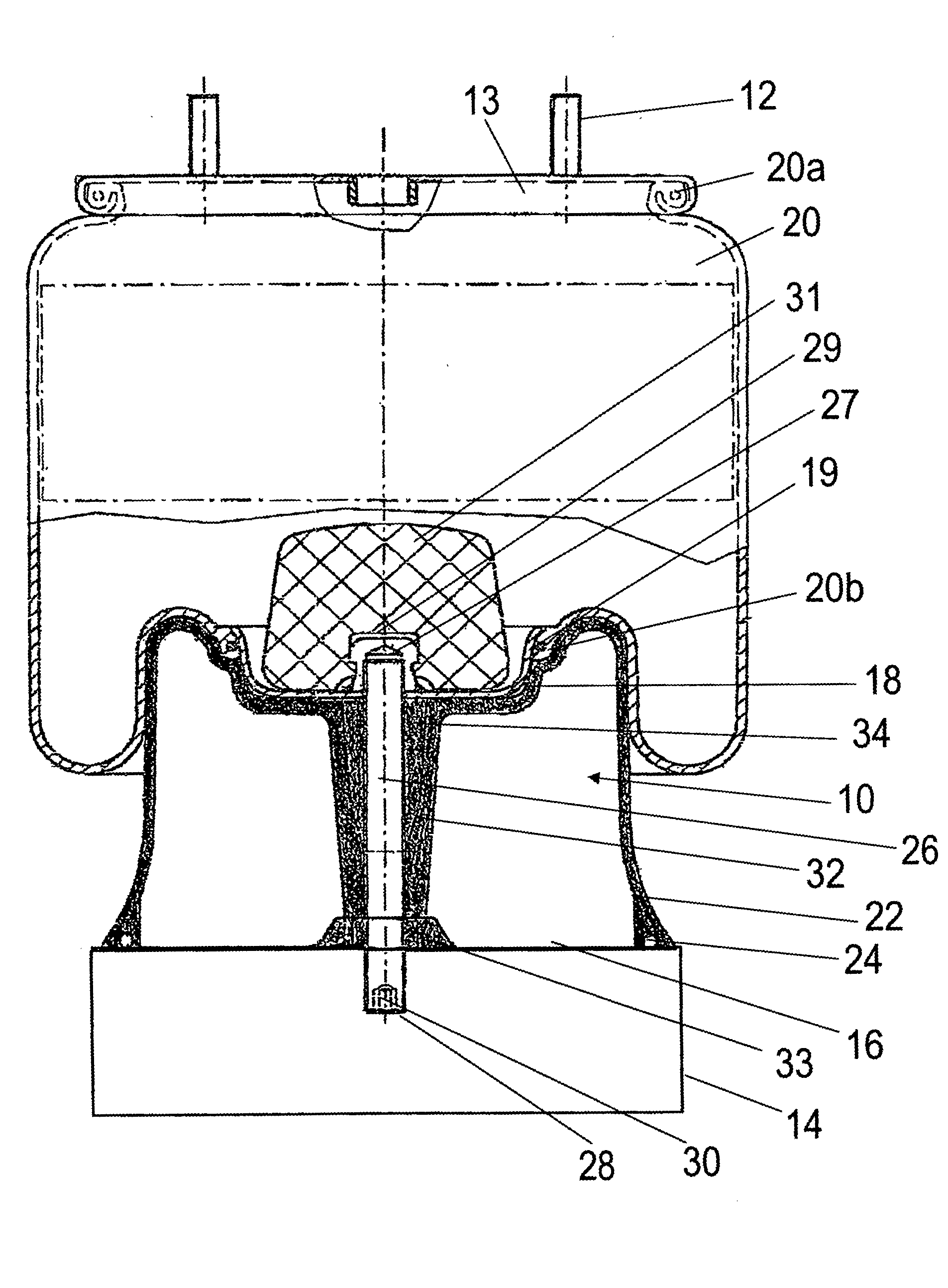

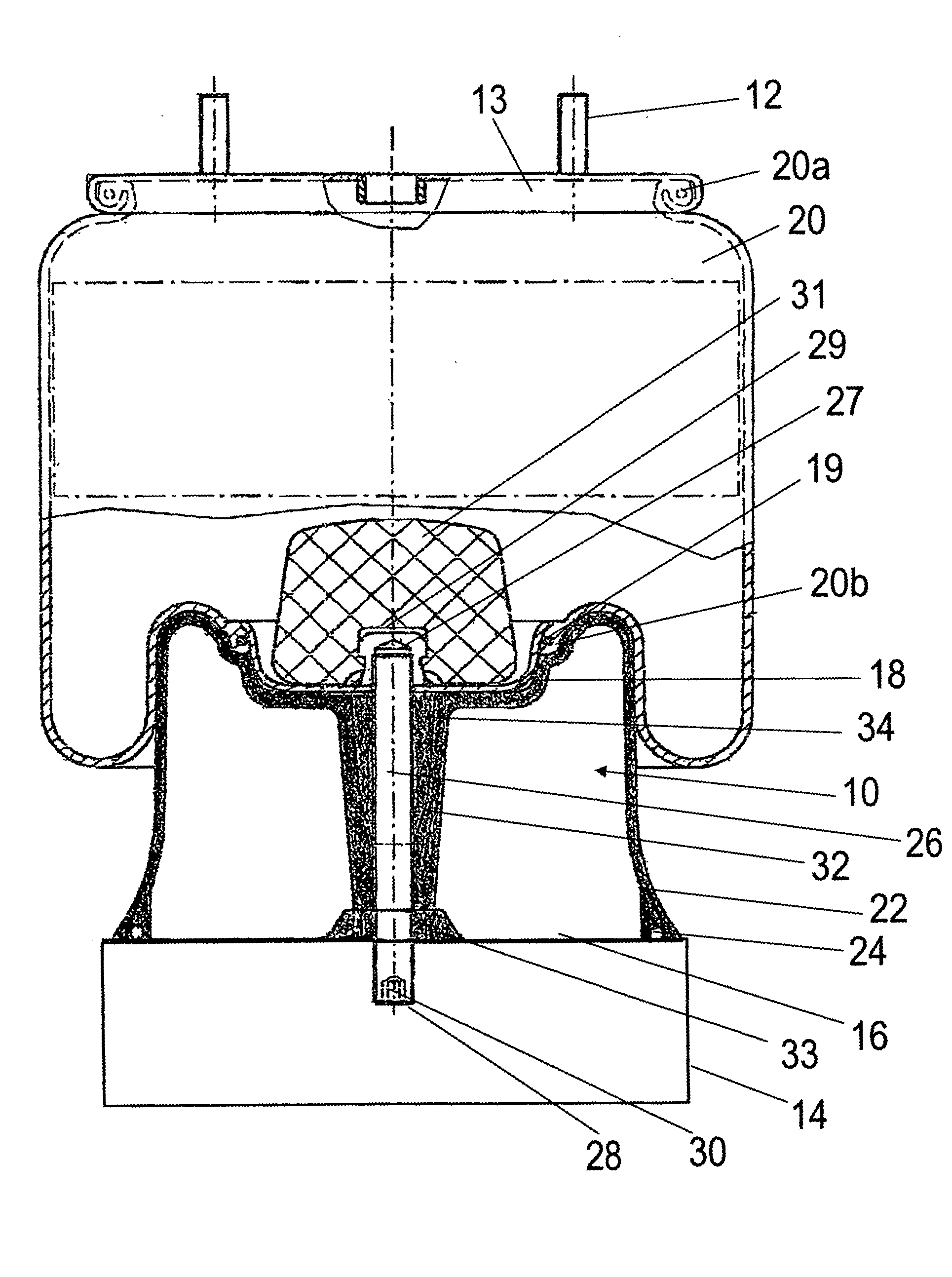

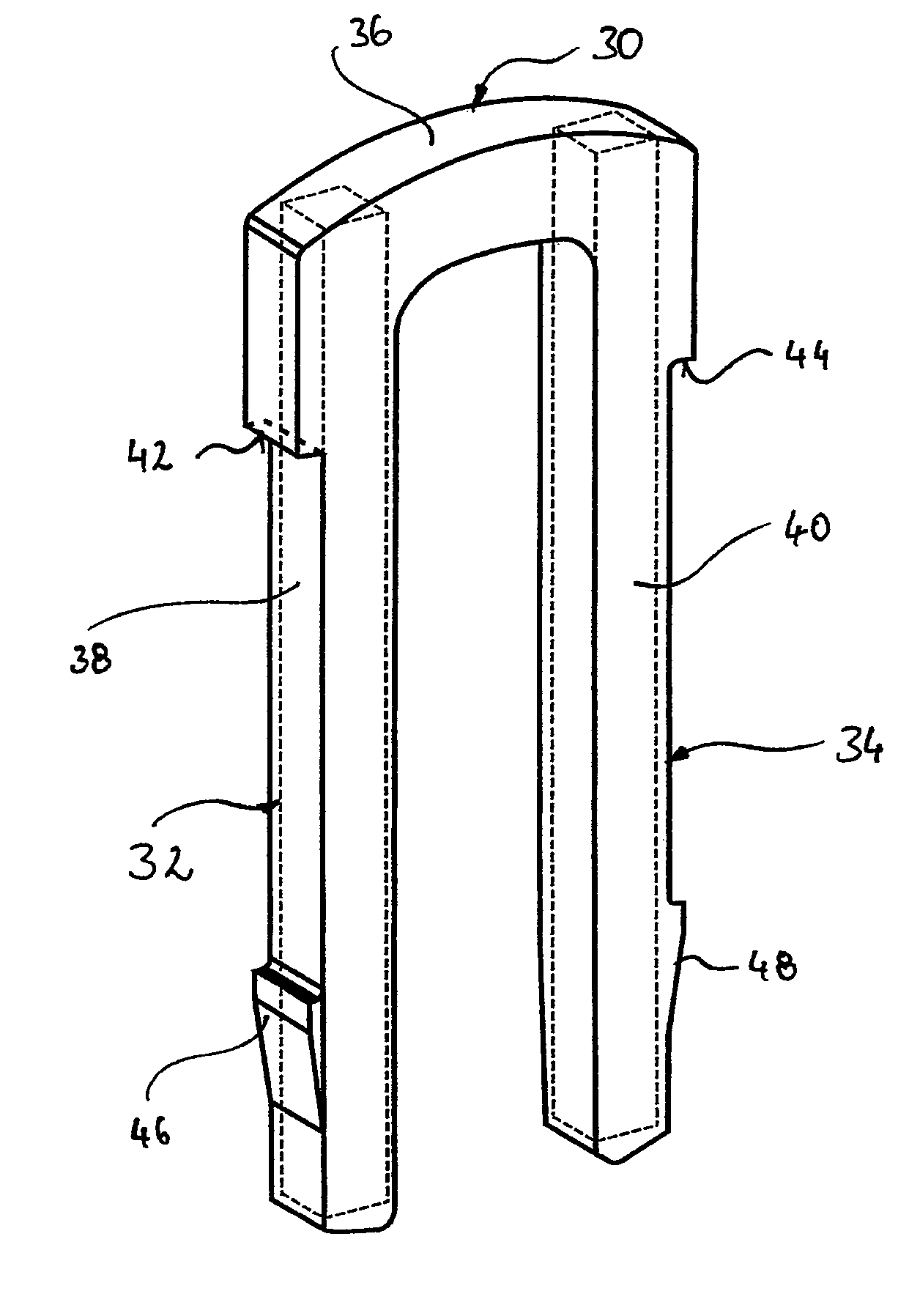

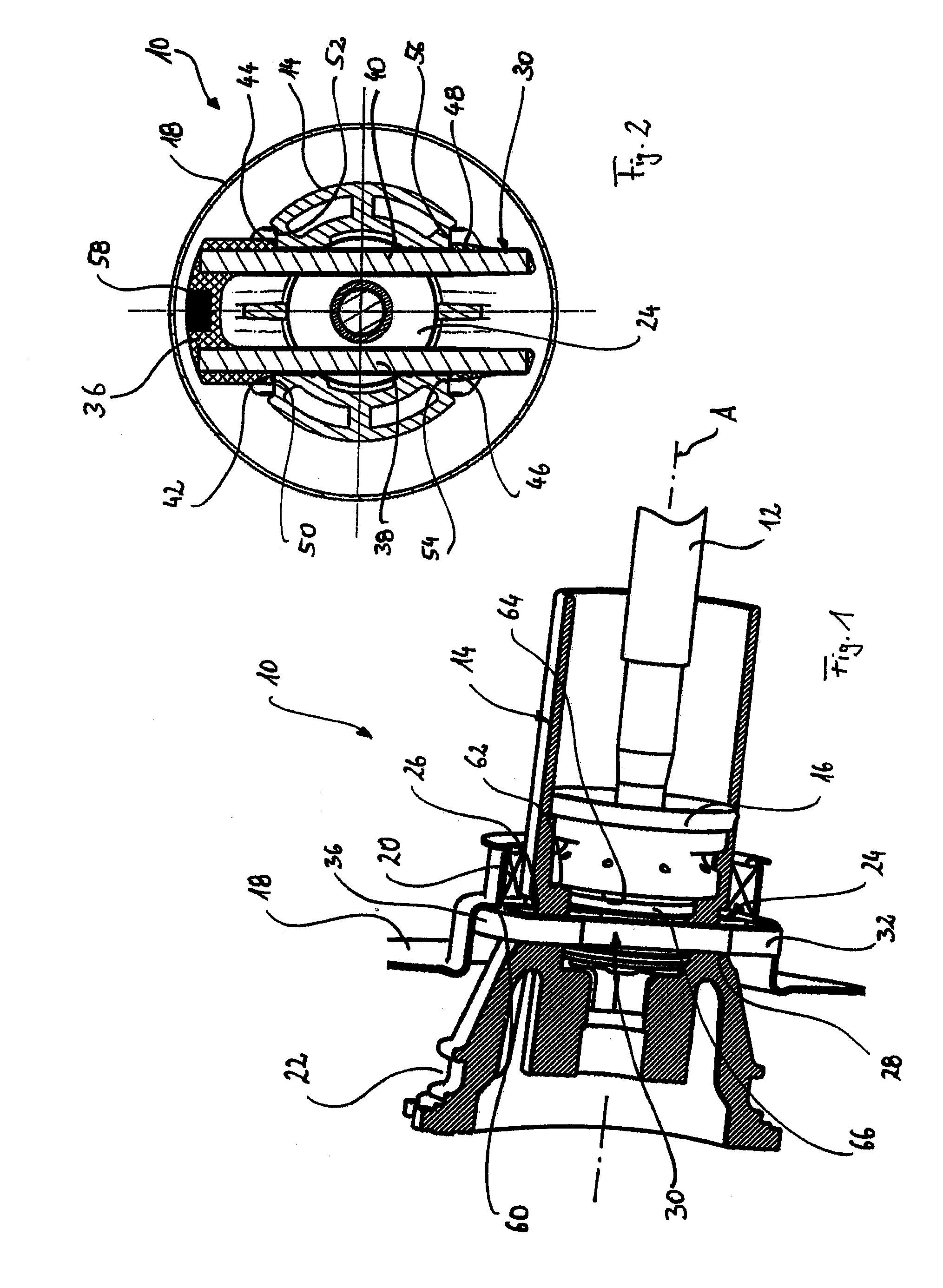

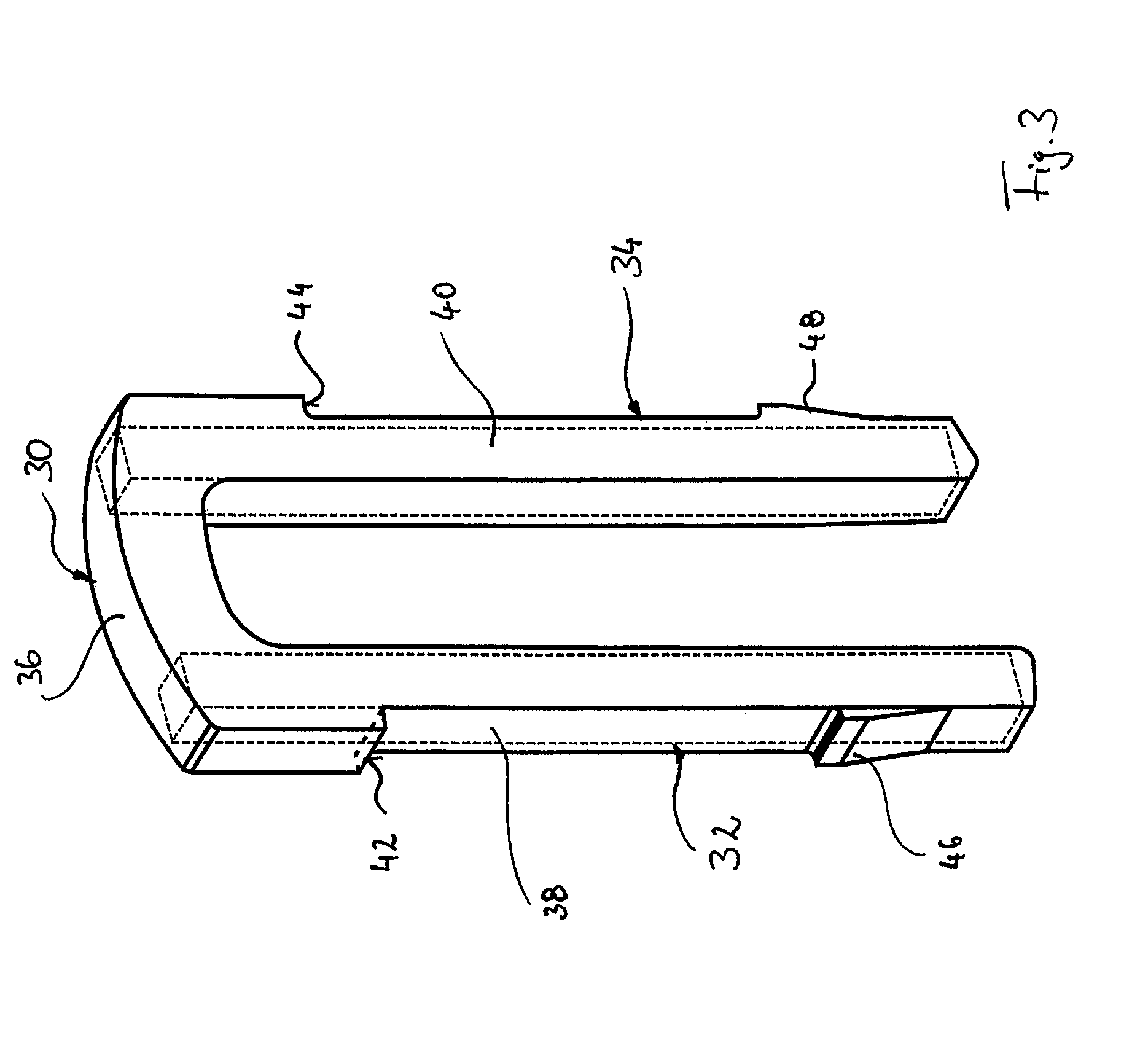

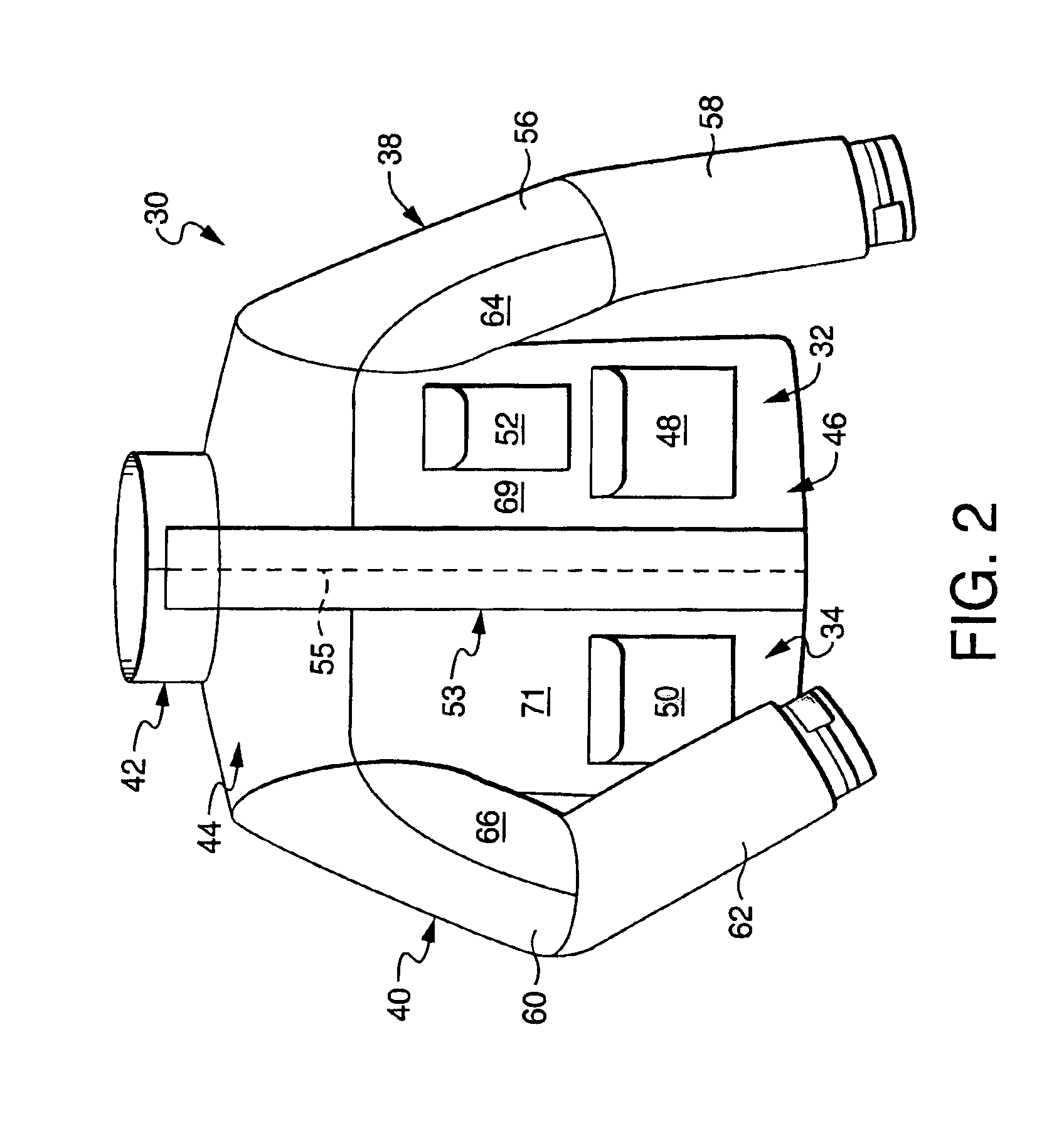

Plunger piston made from plastic for an air spring

InactiveUS8123202B2Sufficient dimensional stabilityProduced cost-effectivelySpringsGas based dampersMobile vehicleVehicle frame

A plunger piston for an air spring. The air spring being active between a component which is to be cushioned by springs, in particular the vehicle frame, and a sprung component, in particular the axle carrier of a motor vehicle. The plunger piston is configured as a hollow piston which is connected to the sprung component at the lower plunger-piston end and to a pneumatic-spring bellows which can be loaded with compressed air at an upper plunger-piston head. The pneumatic-spring bellows is connected on the other side to the component which is cushioned by springs, and rolls on the outside of the plunger-piston skirt during suspension movements. The lower plunger-piston end has an open configuration and has a reinforcing element which encircles the edge region of the opening.

Owner:LKH KUNSTWERK

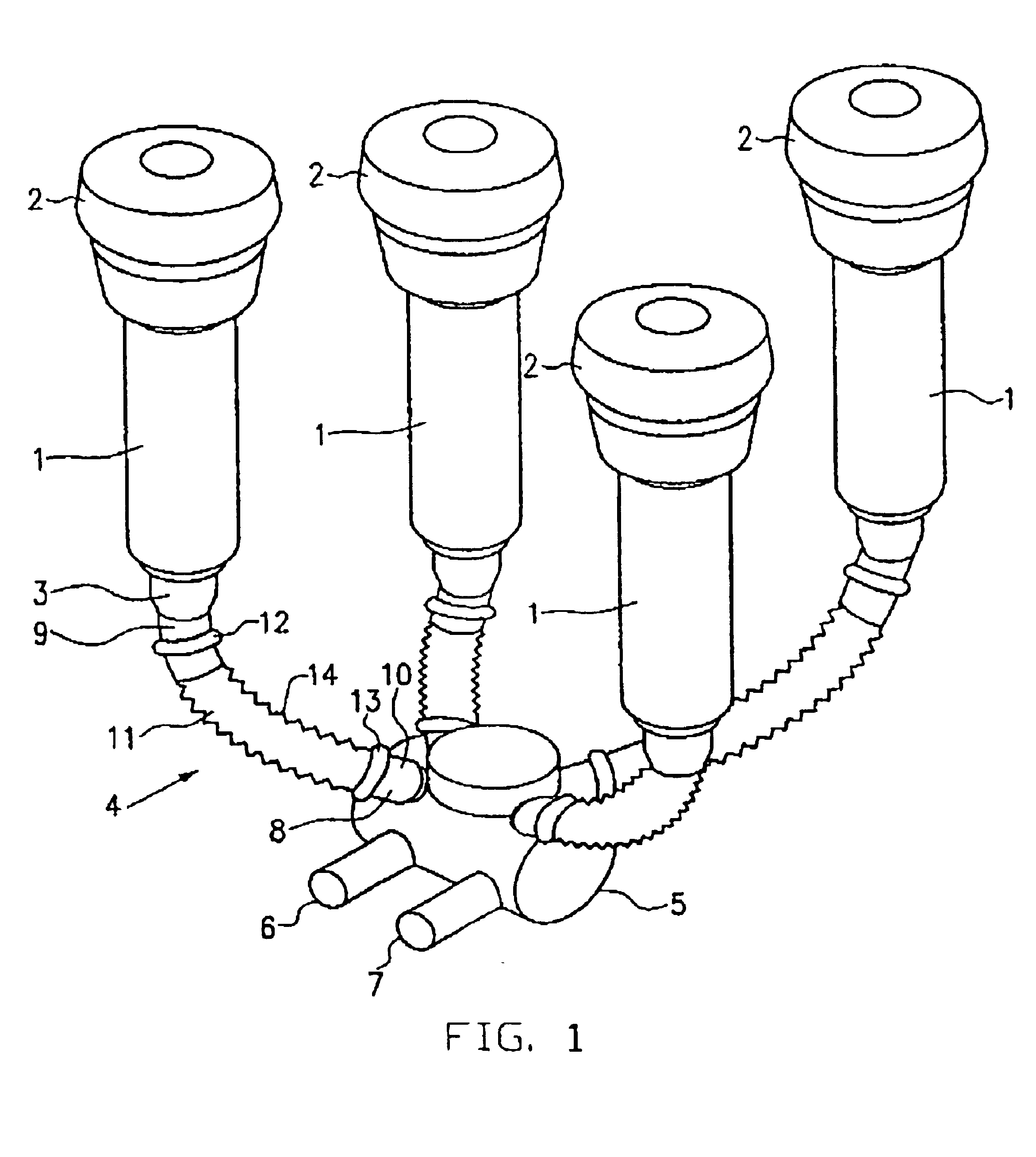

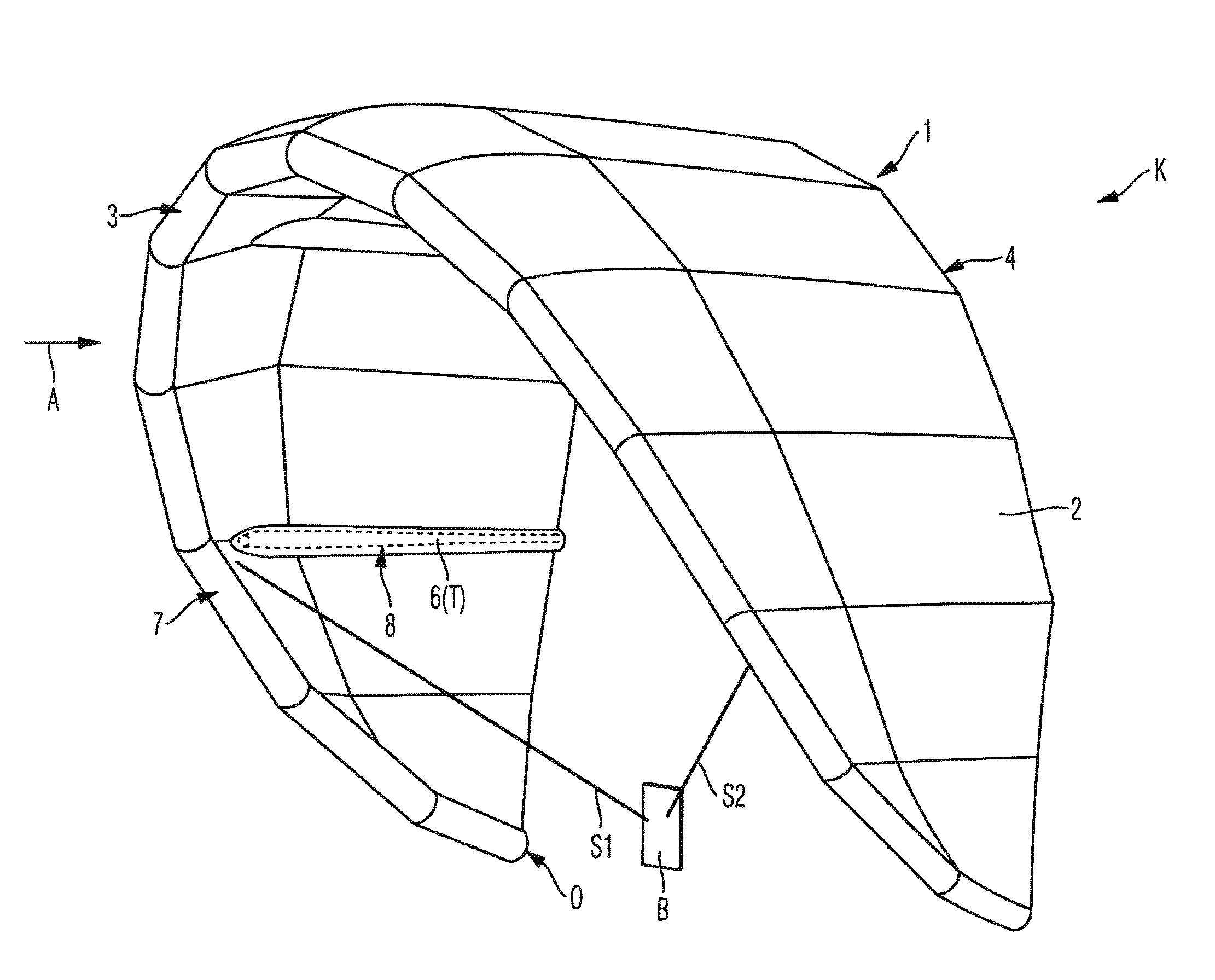

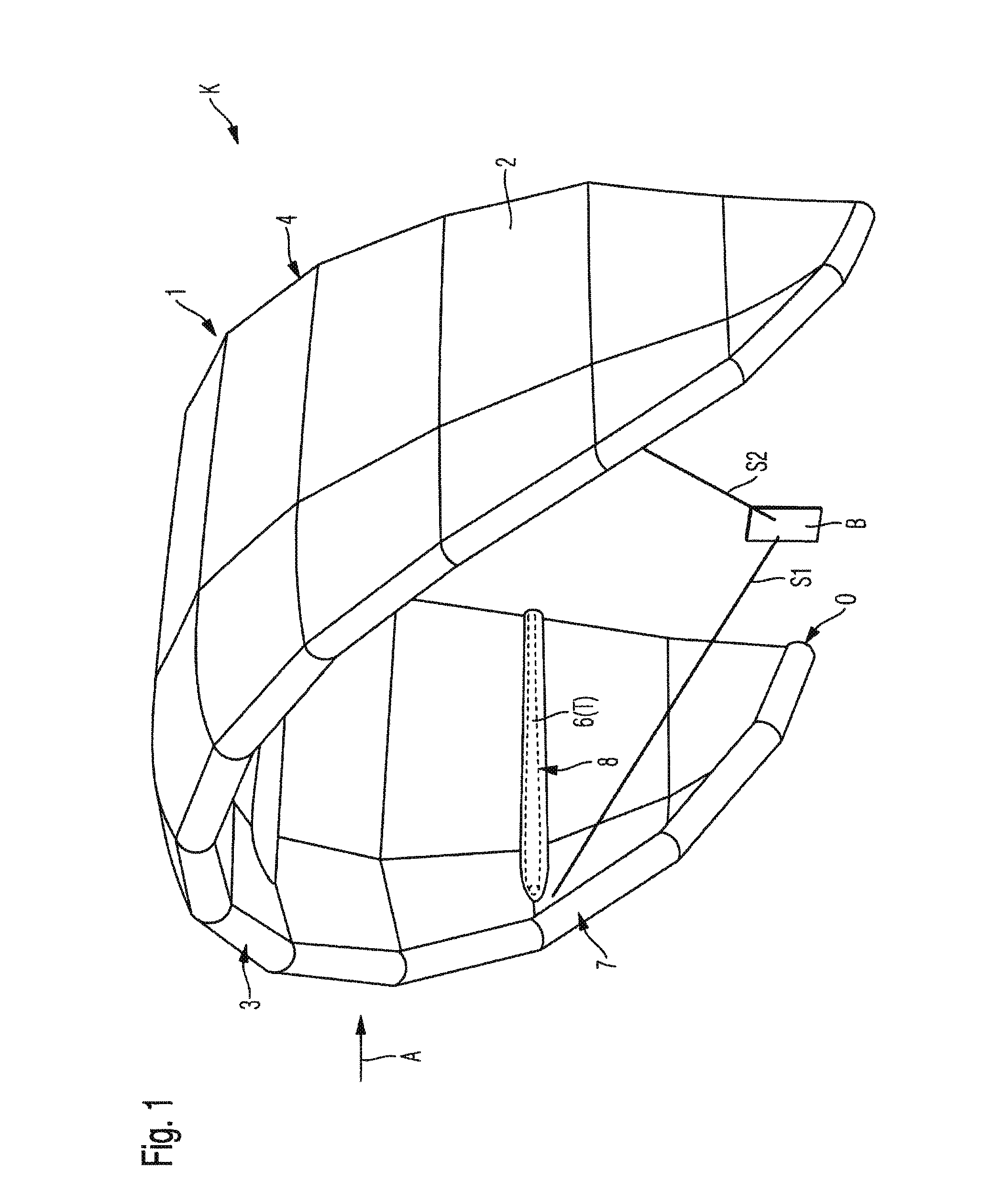

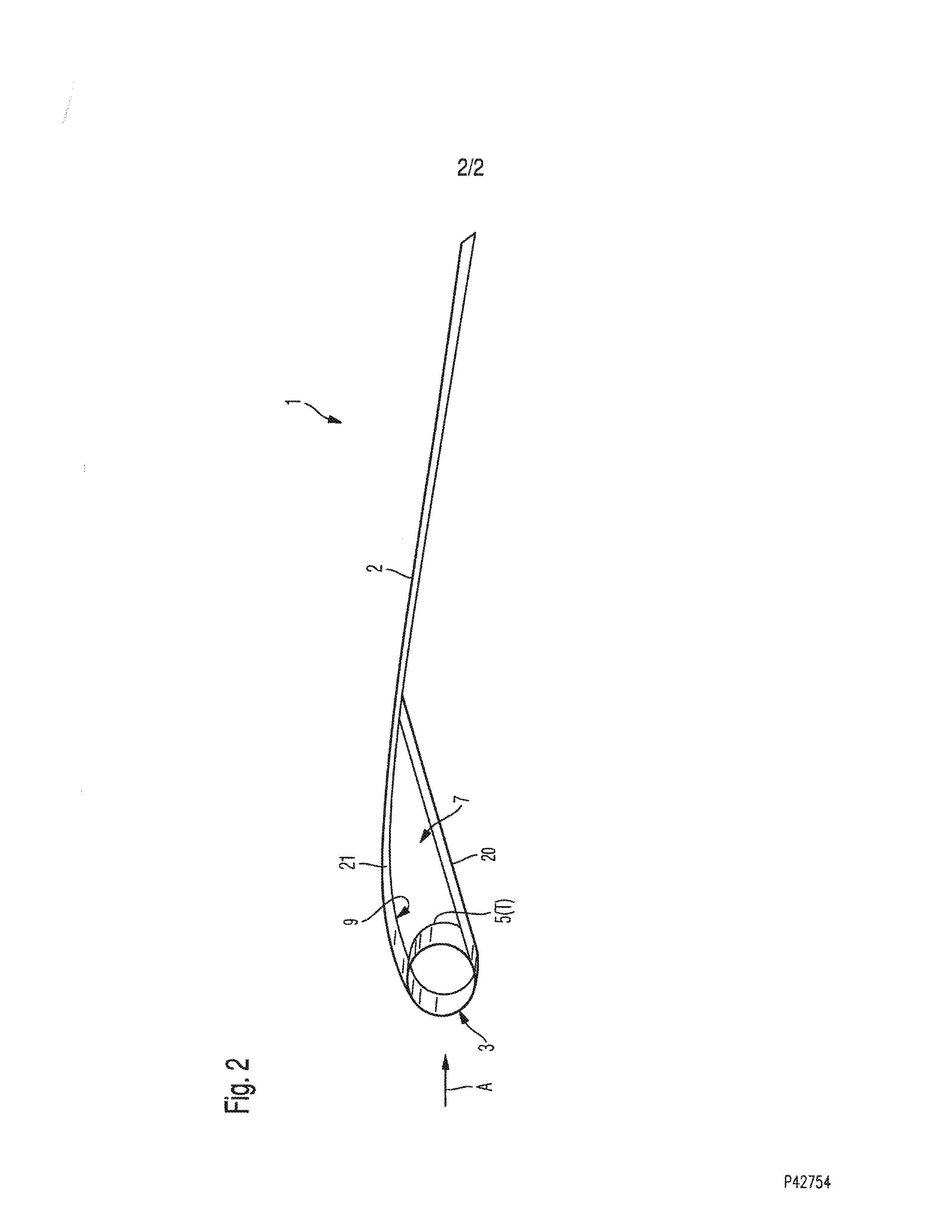

Control sail for a kite

InactiveUS20140070055A1Reduce tensionStable designAircraft componentsWaterborne vesselsLeading edgeControl line

A control sail for a kite has an airfoil with a leading edge and a trailing edge, and a tube system comprising a front tube which extends along the leading edge and at least one transverse tube which extends between the leading edge and the trailing edge. The front tube is situated in a freely movable manner within a chamber which extends along the leading edge of the airfoil whereby an aerodynamically advantageous profile at the leading edge may be continuously maintained, even when the angle of attack of the control sail changes. The invention further relates to a kite having a control sail according to the invention, with control lines connected to the control sail.

Owner:RIDE BEST

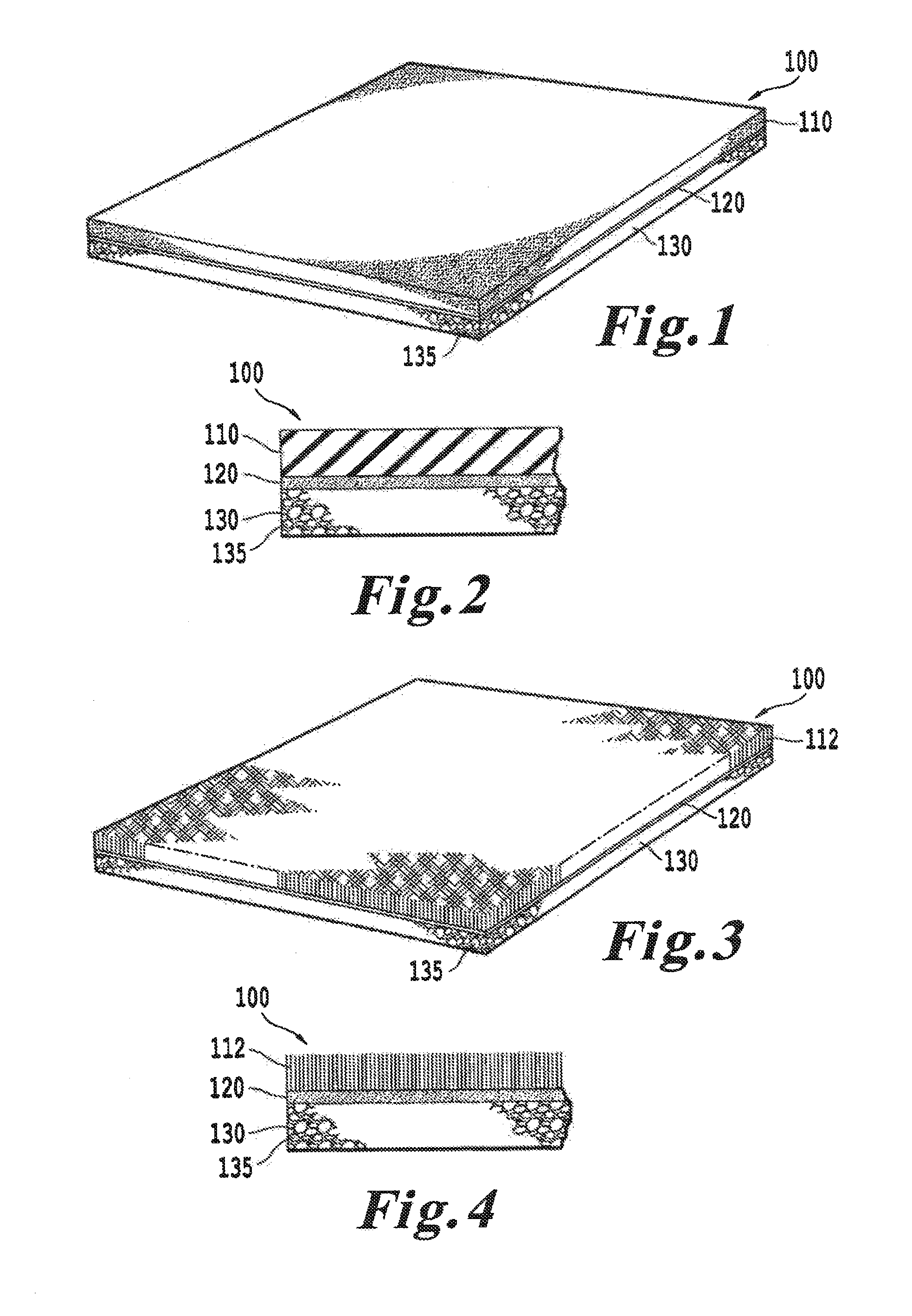

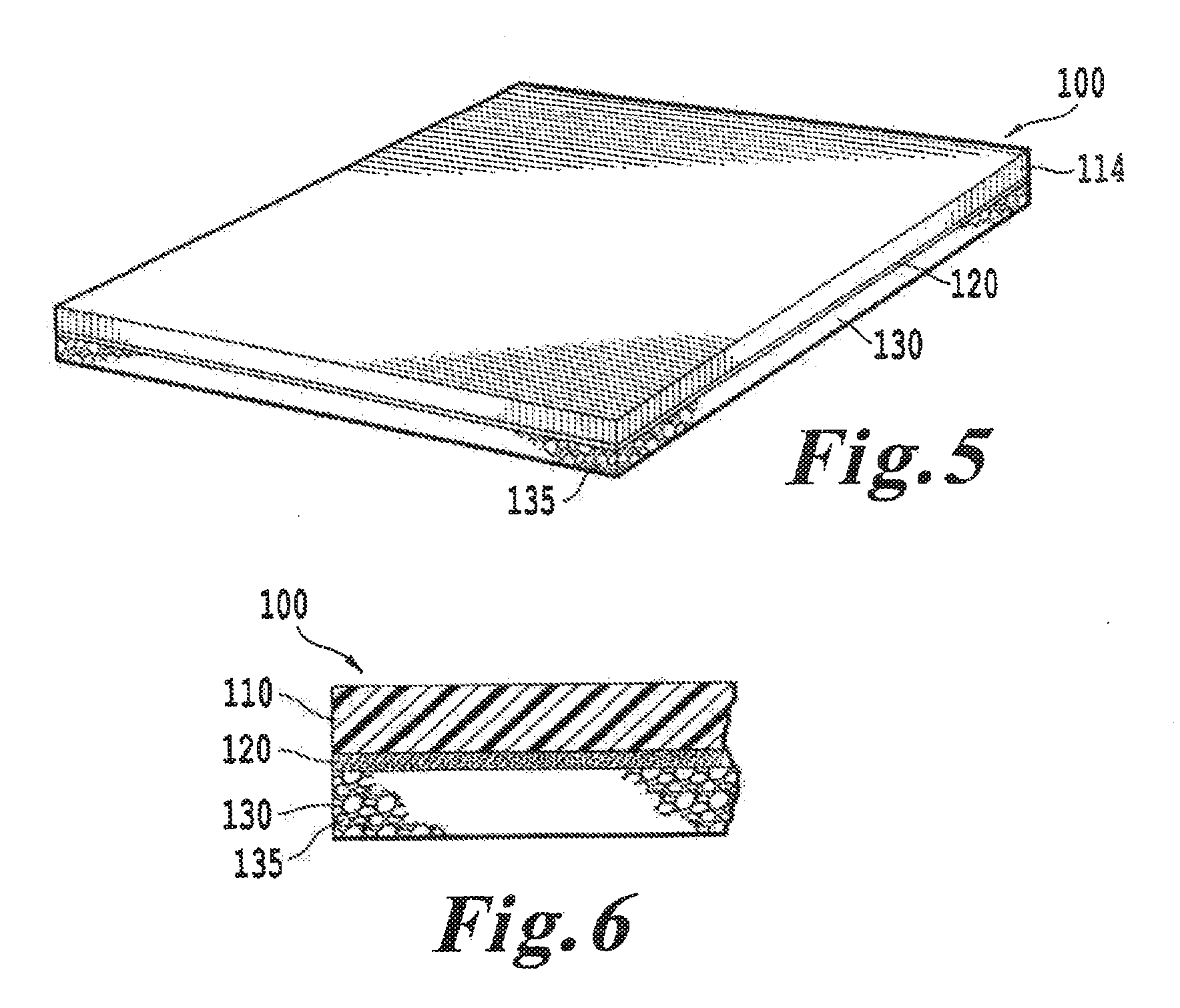

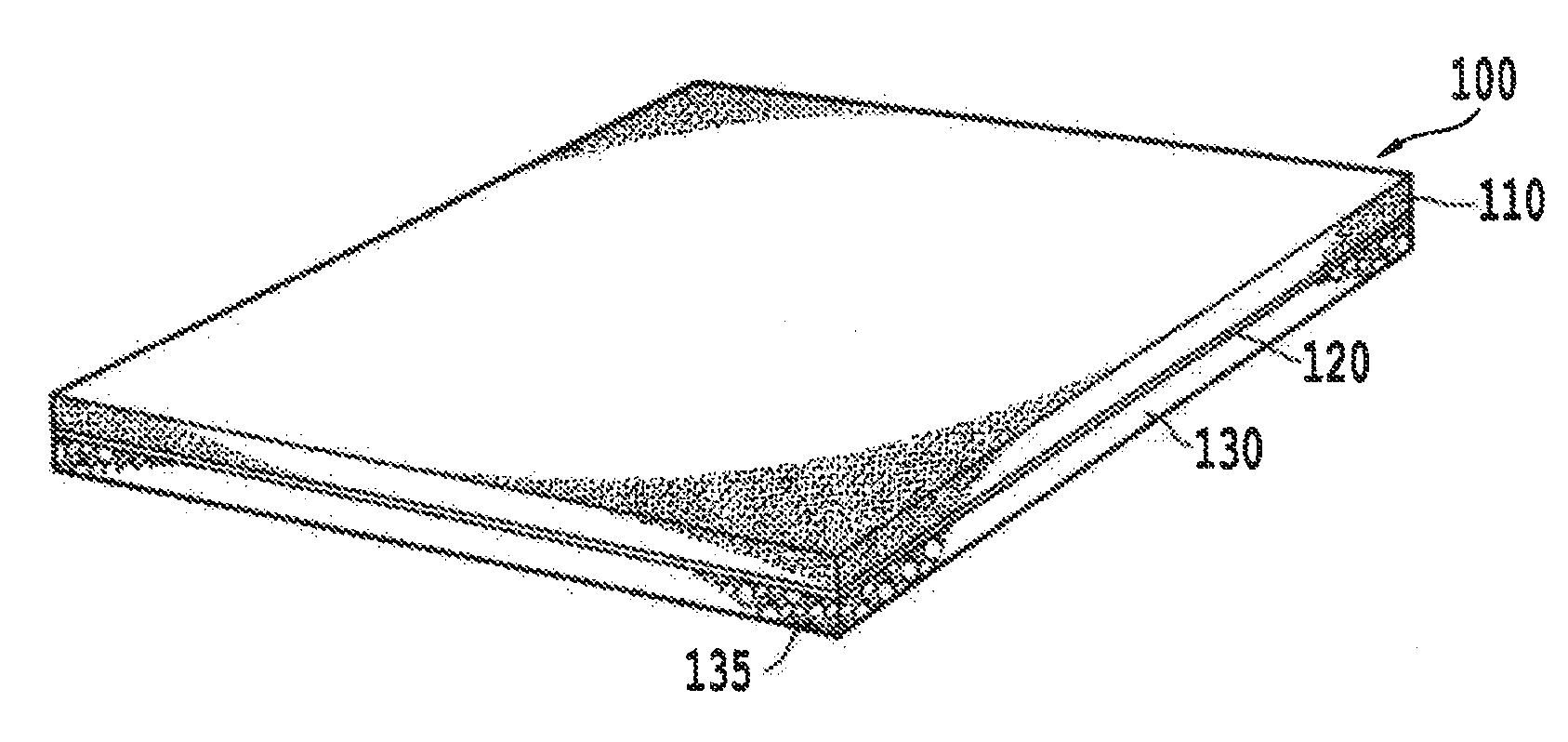

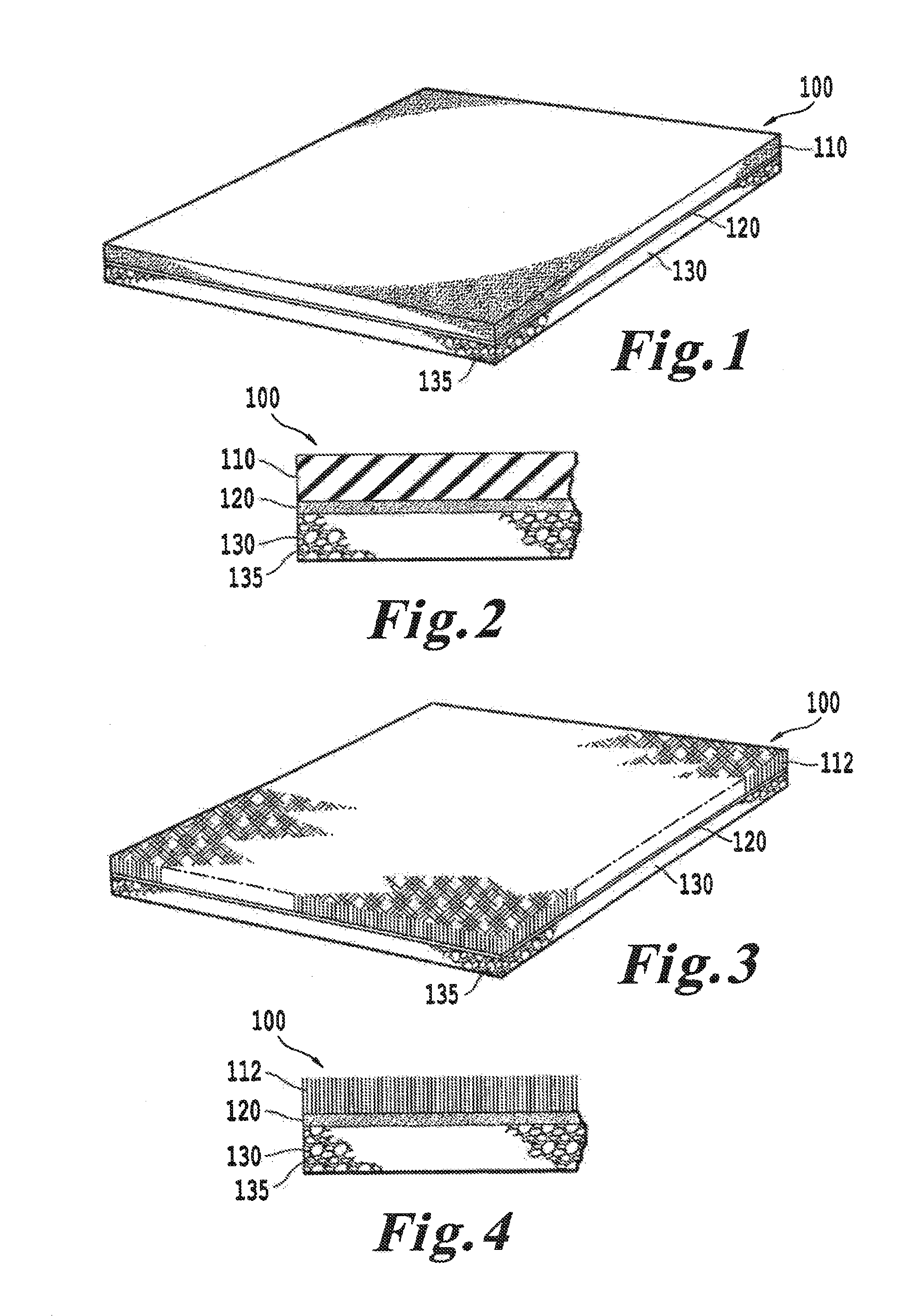

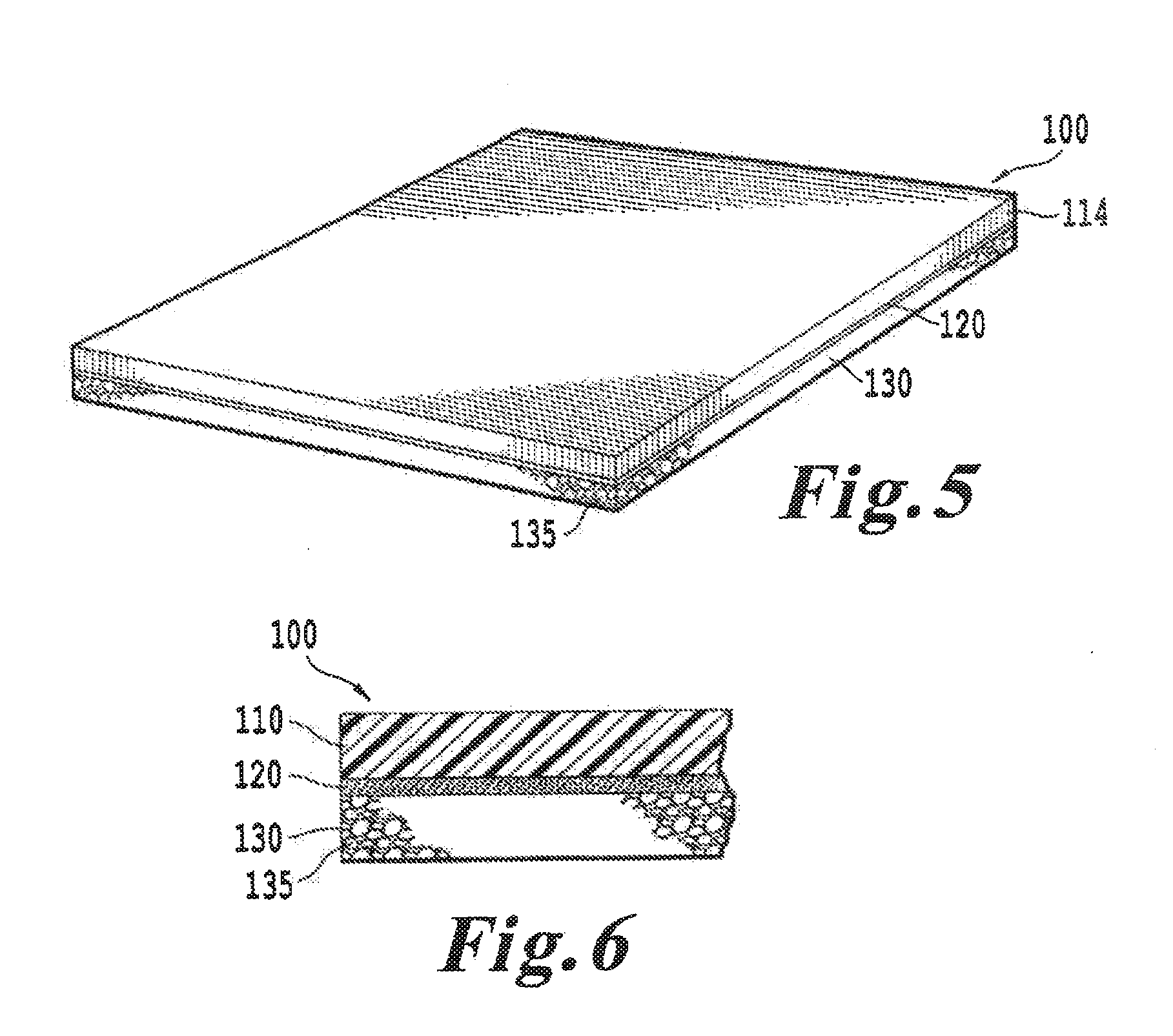

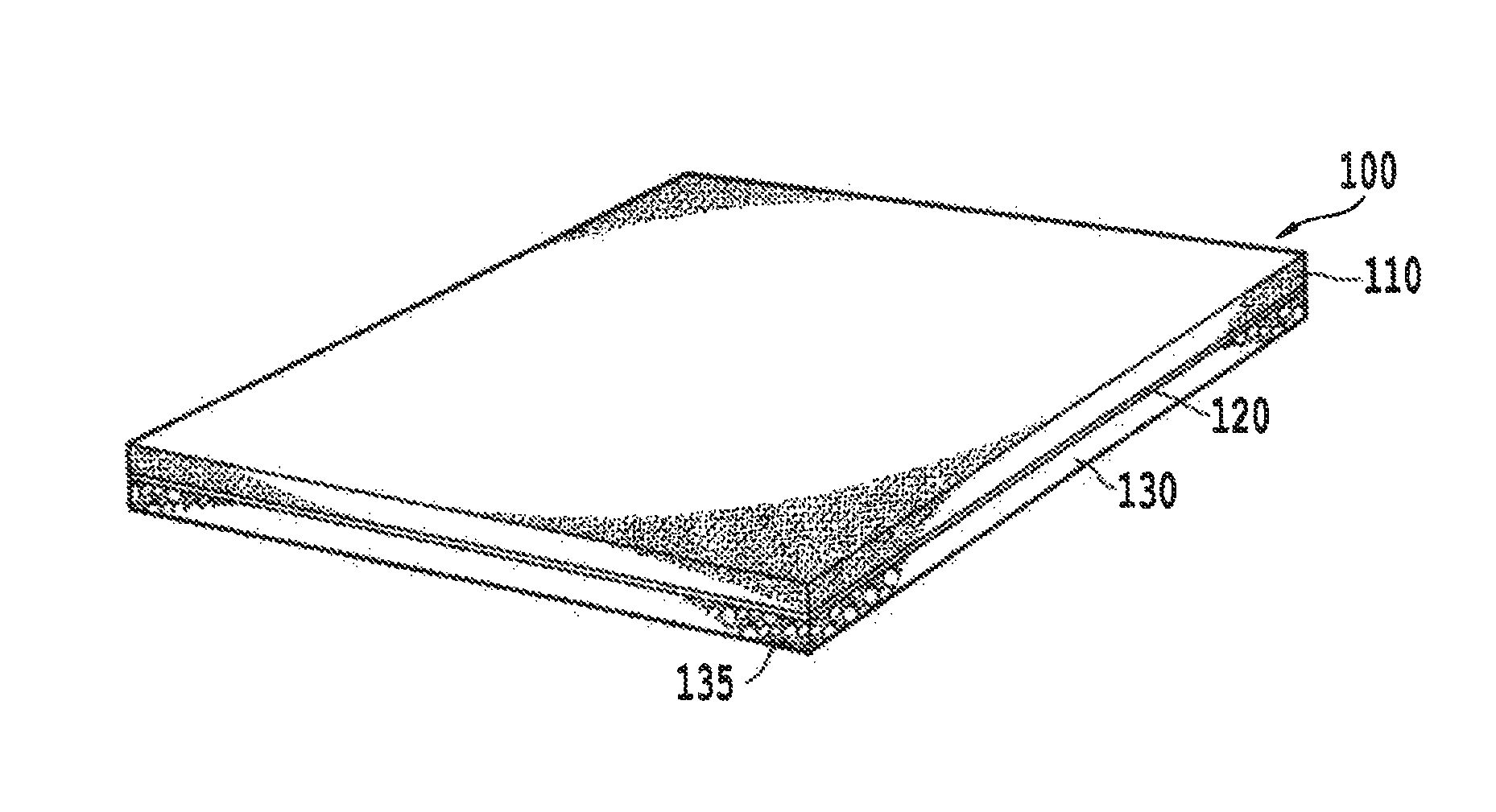

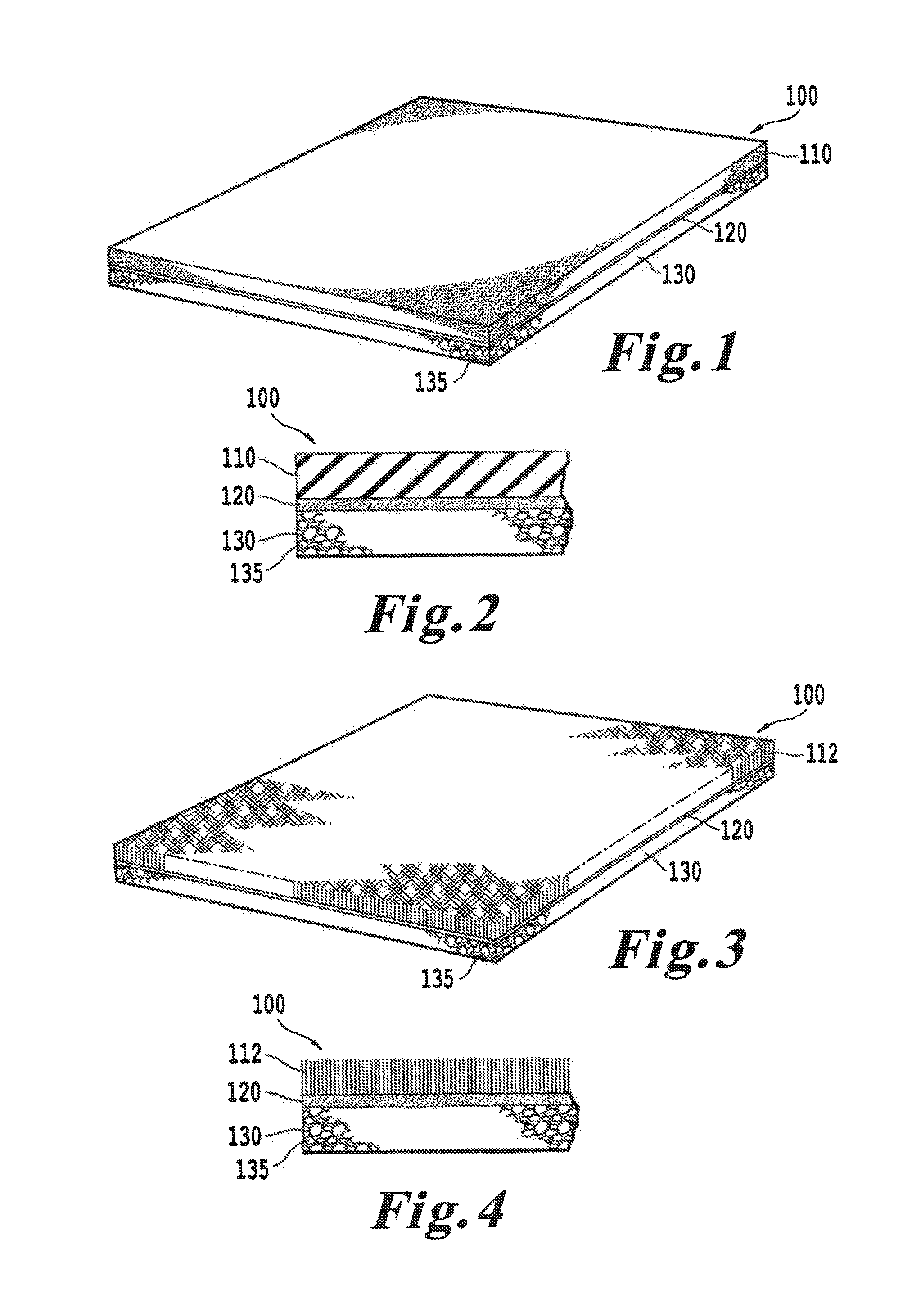

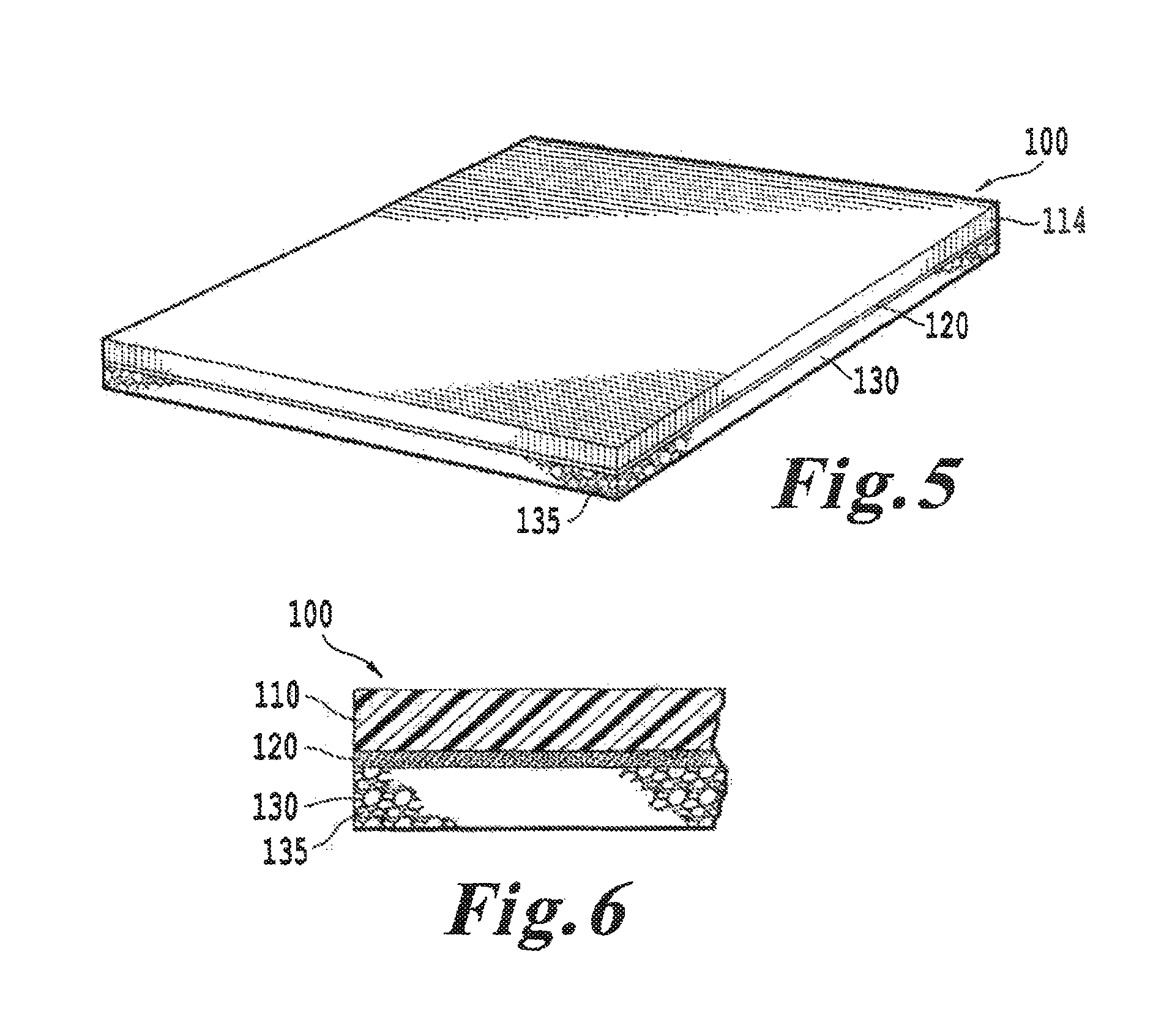

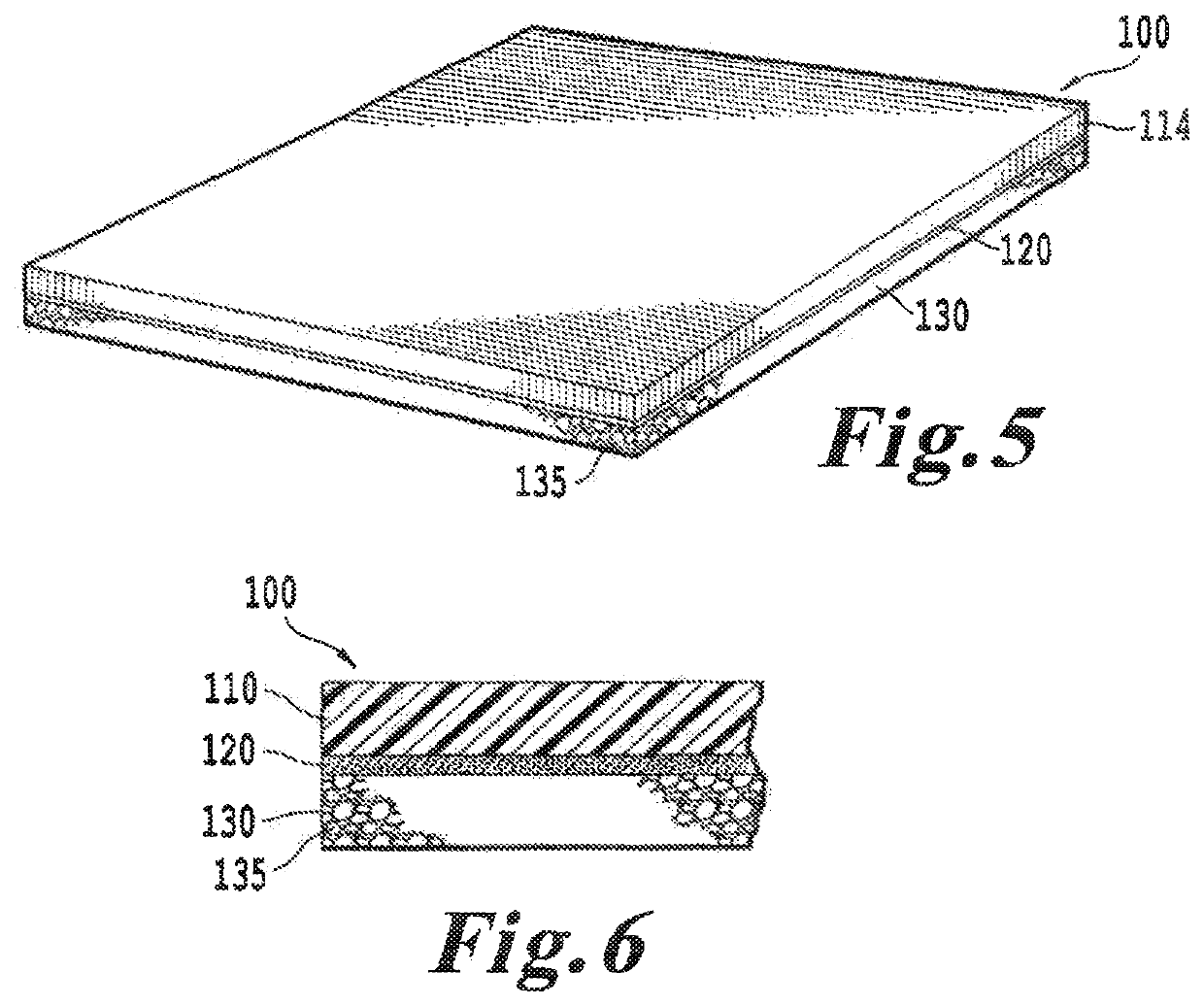

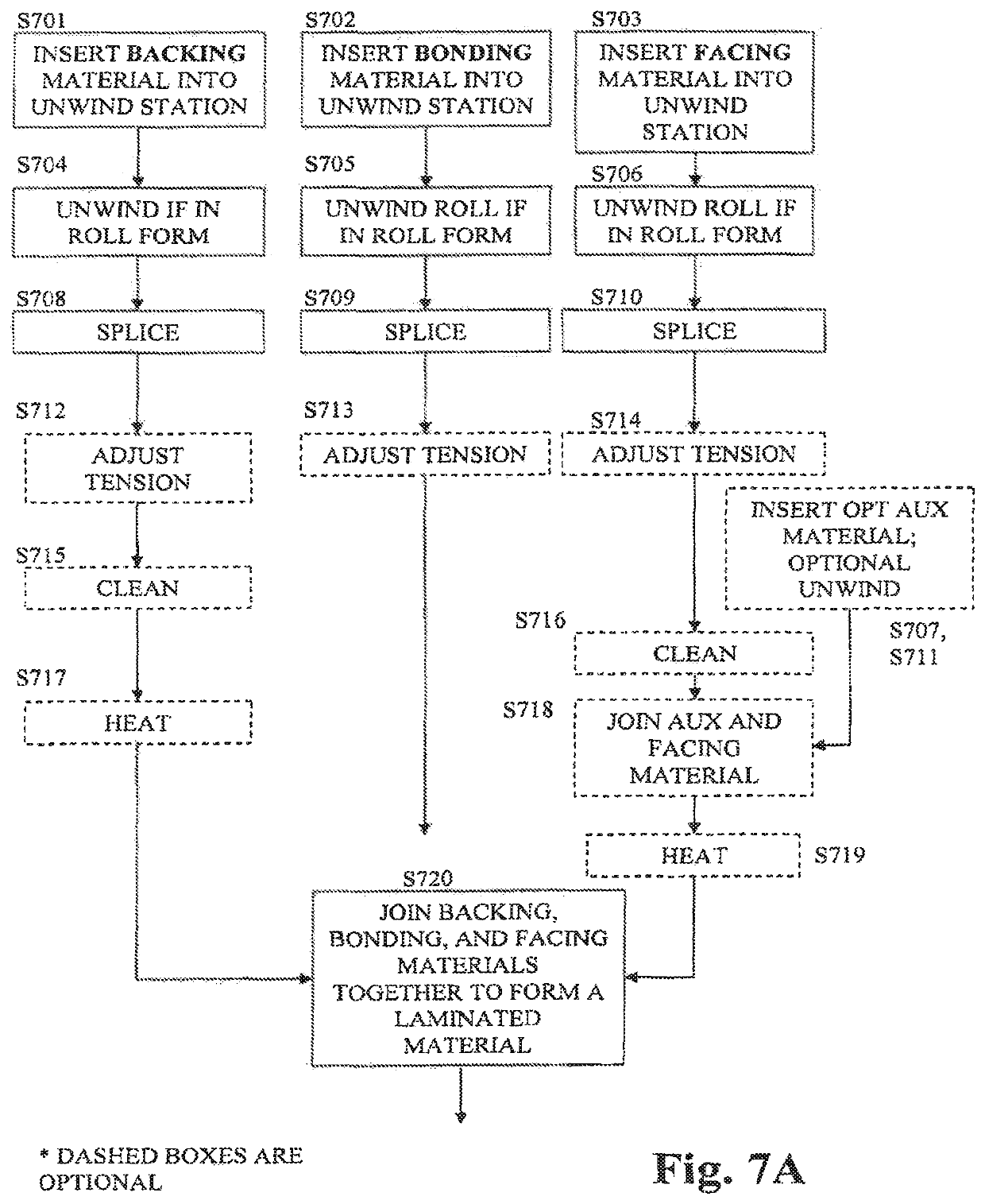

Recycled rubber backed cushioned vinyl

ActiveUS20160361901A1Sufficient massSufficient weightCoatingsThin material handlingEngineeringSurface cover

A laminated surface covering including a facing material made of vinyl and a backing material comprising a rubber component. The rubber component comprising at least a matrix of bonded rubber granules. A bonding material disposed between the facing material and the backing material. The facing material configured to melt at a temperature between 165° F. and 248° F. infiltrating the backing material thereby essentially encasing the rubber granules of the matrix and providing fire retardation and smoke suppression qualities.

Owner:ECORE INT

Recycled rubber backed cushioned vinyl

ActiveUS20130209810A1Sufficient massImprove impact absorption performanceCovering/liningsGlass/slag layered productsEngineeringSurface cover

A laminated surface covering including a facing material made of vinyl and a backing material comprising a rubber component. The rubber component comprising at least a matrix of bonded rubber granules. A bonding material disposed between the facing material and the backing material. The facing material configured to melt at a temperature between 165° F. and 210° F. infiltrating the backing material thereby essentially encasing the rubber granules of the matrix and providing fire retardation and smoke suppression qualities.

Owner:ECORE INT

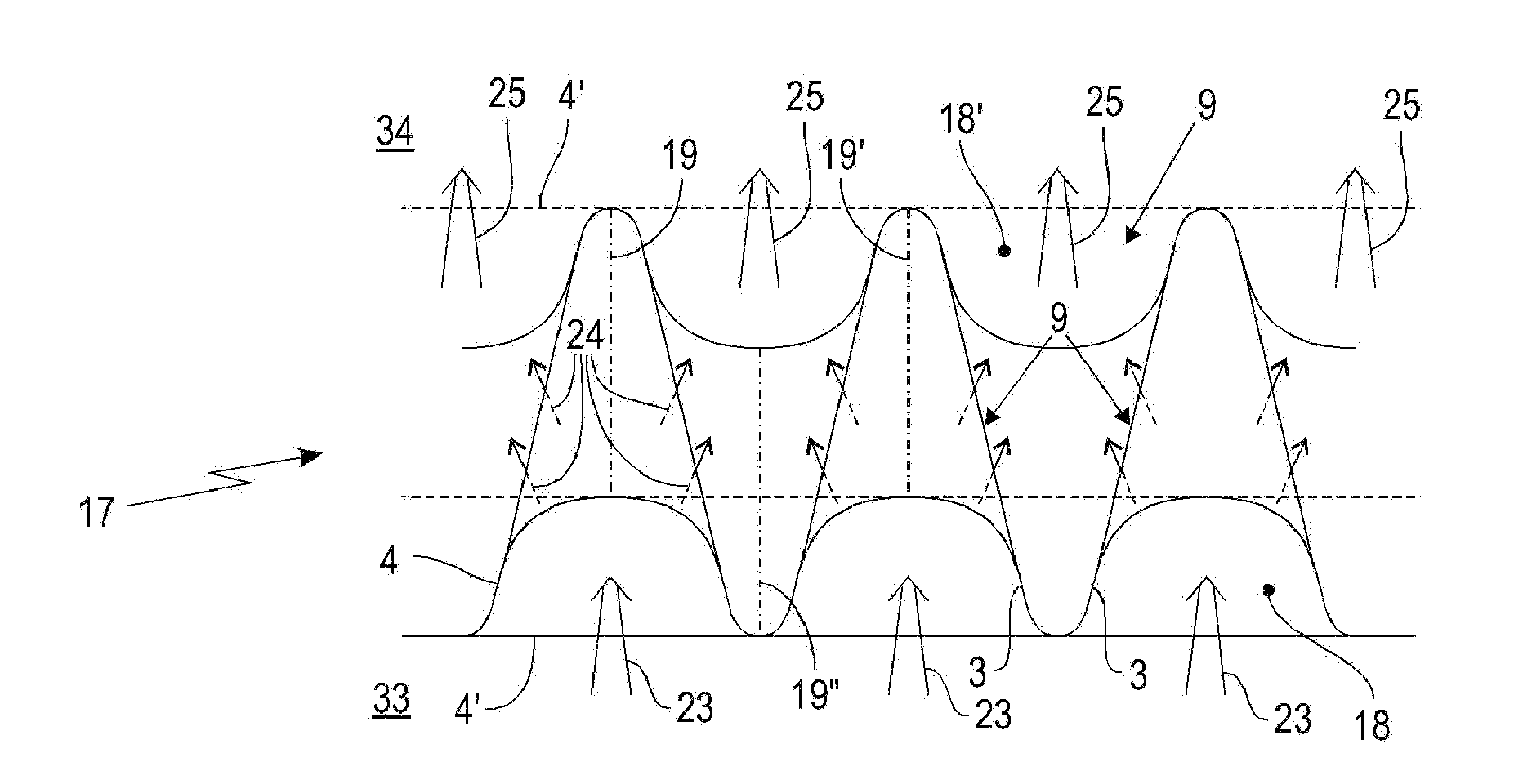

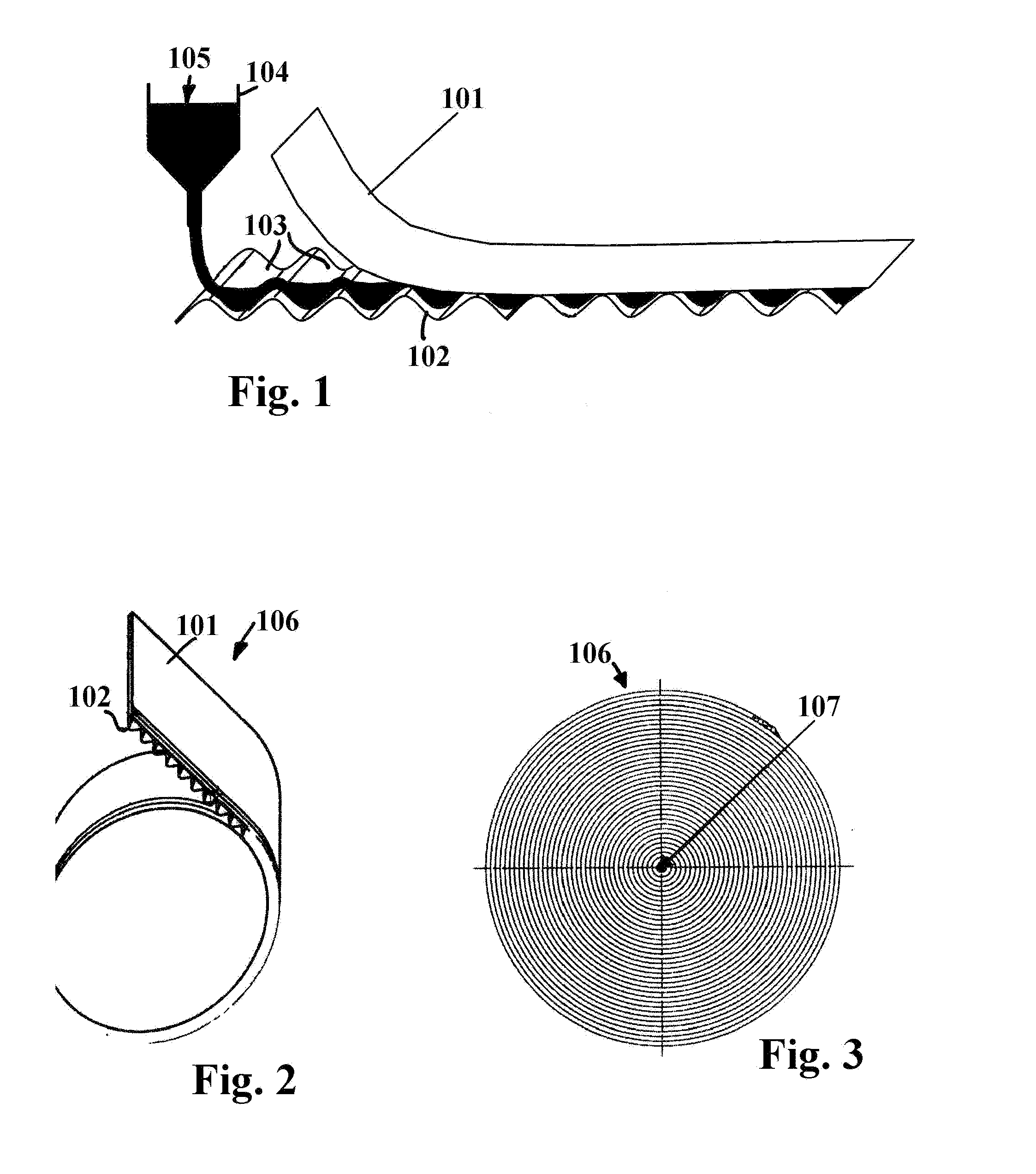

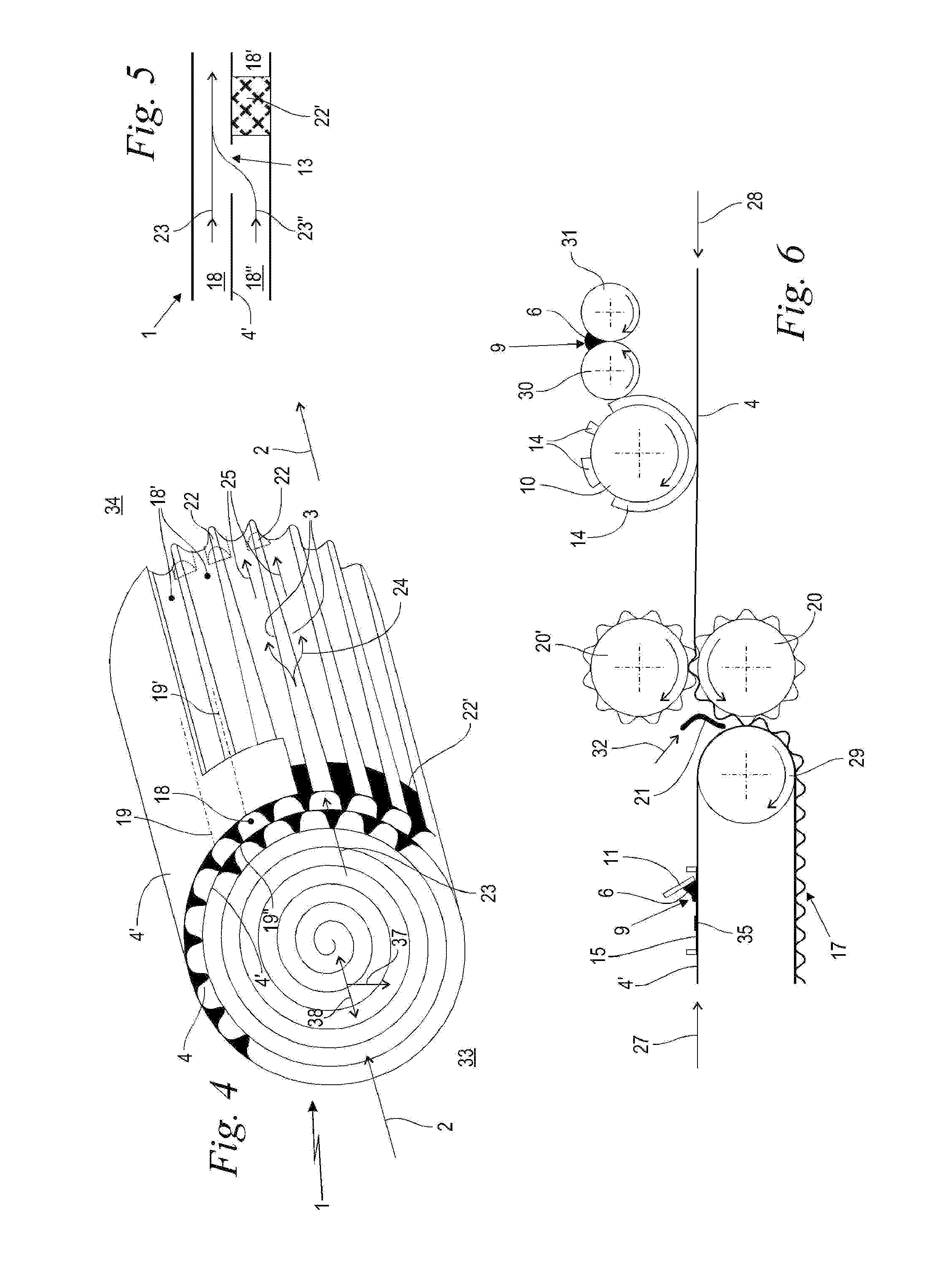

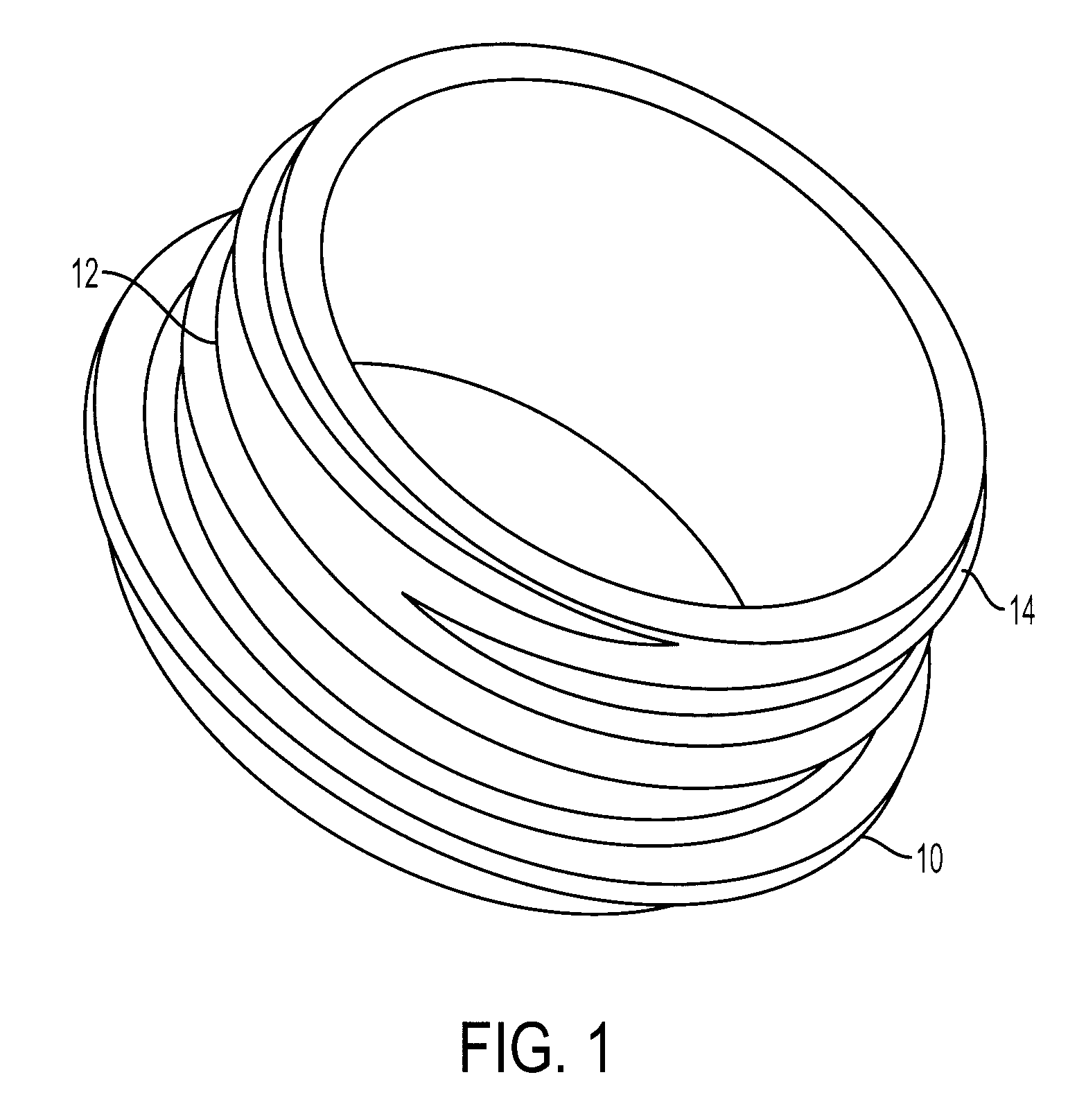

Ceramic filter element and method of manufacture

A method of manufacturing a ceramic diesel particle filter (DPF) and a DPF manufactured by the method, the DPF having a ceramic filter body (1) including gas channels (18, 18′) with planar and porous filter segments (3), which are provided for the exhaust gas stream (2) to flow through them transversely to the face of the filter segments (3). The filter body (1) is formed by sintering at least one ceramic-impregnated fiber web (4) in a firing step under heat such that fibers (5) of the fiber material are burned off and the ceramic material (6) is sintered together to form the porous filter segment (3) between its two surfaces (7, 8). At least one fiber web (4) is corrugated to form the gas channels (18, 18′) and rolled up to form the filter body (1), and the cross section of at least a portion of the gas channels (18, 18′) changes from an inlet end (33) to a discharge end (34).

Owner:MANN HUMMEL GMBH

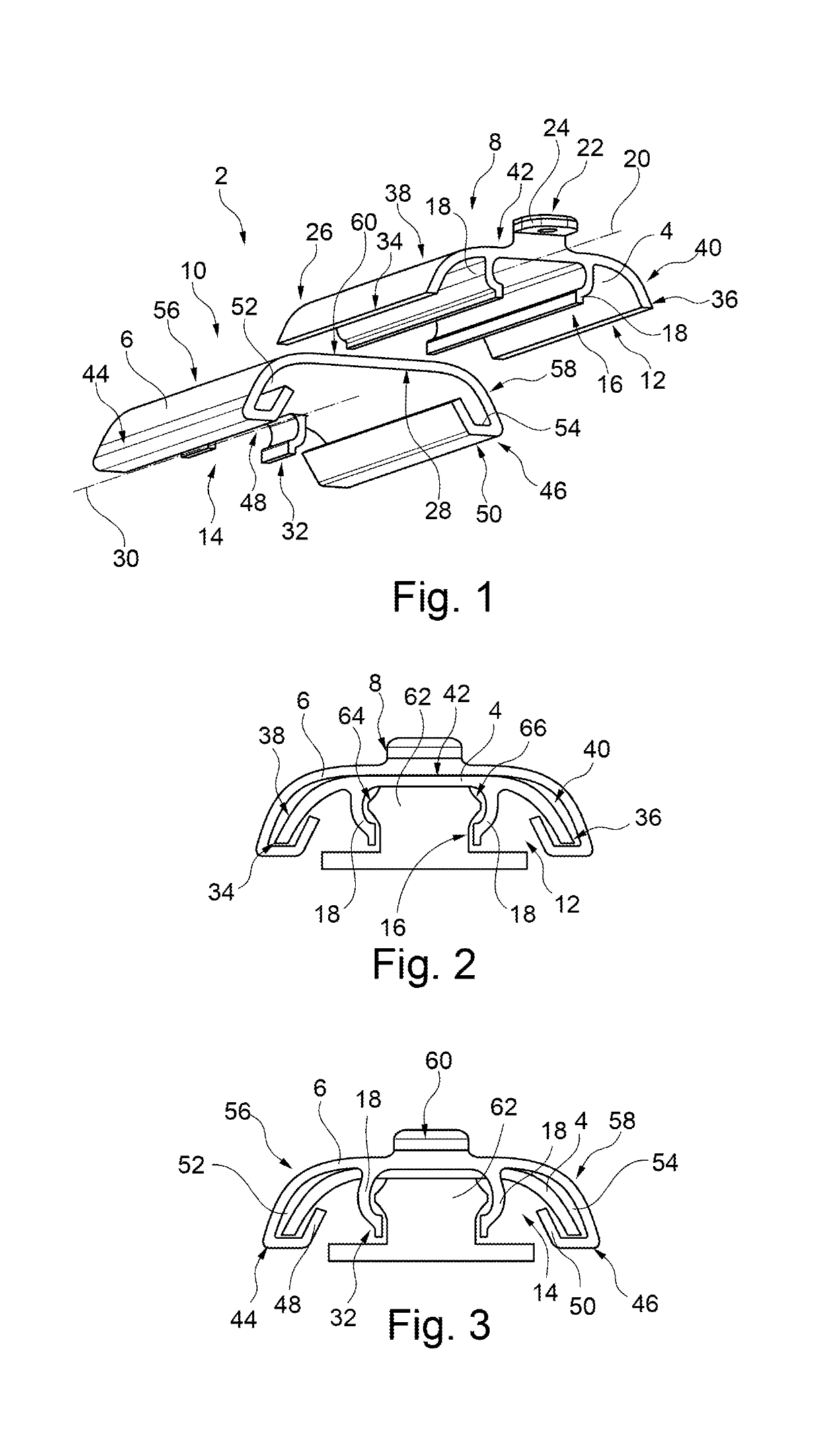

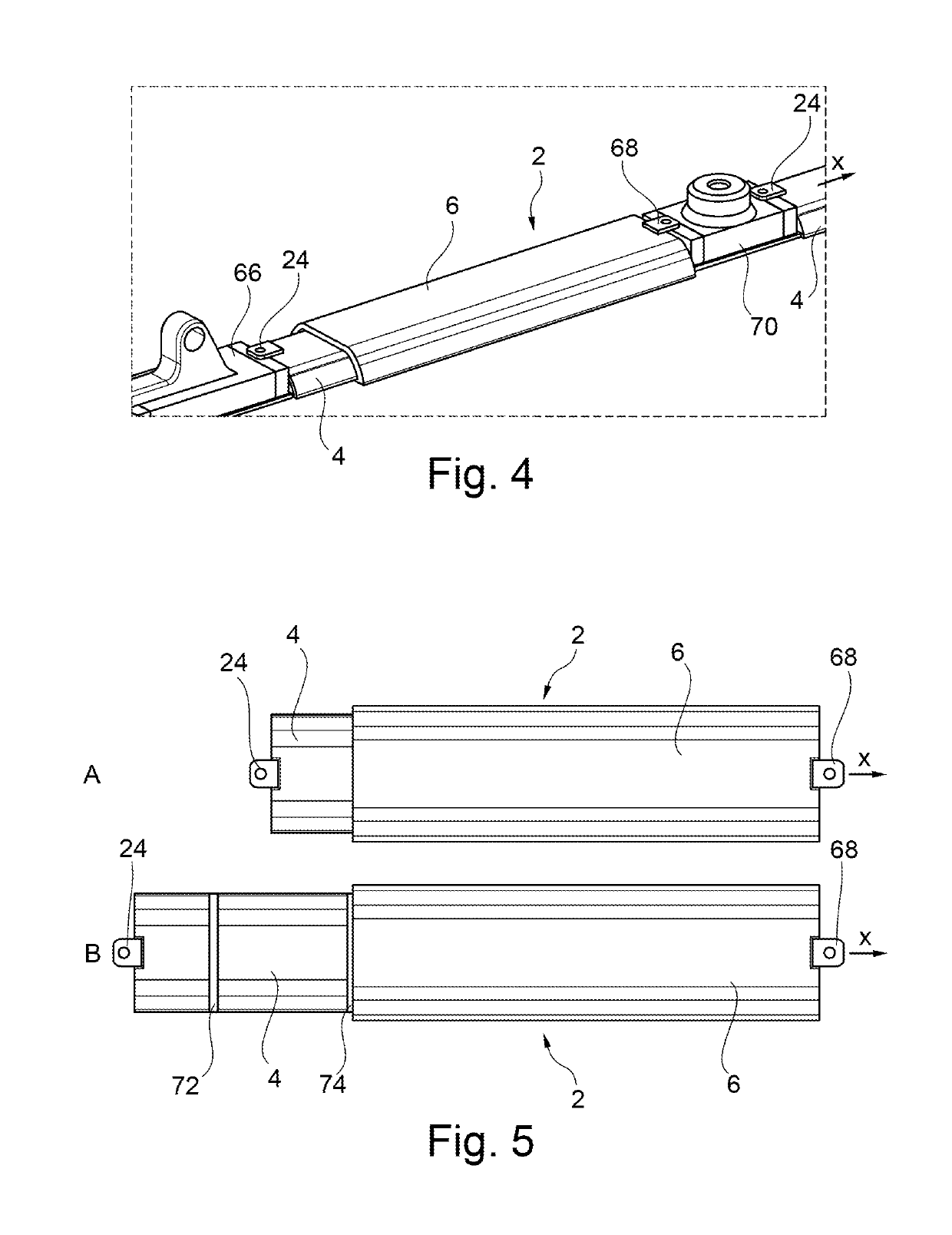

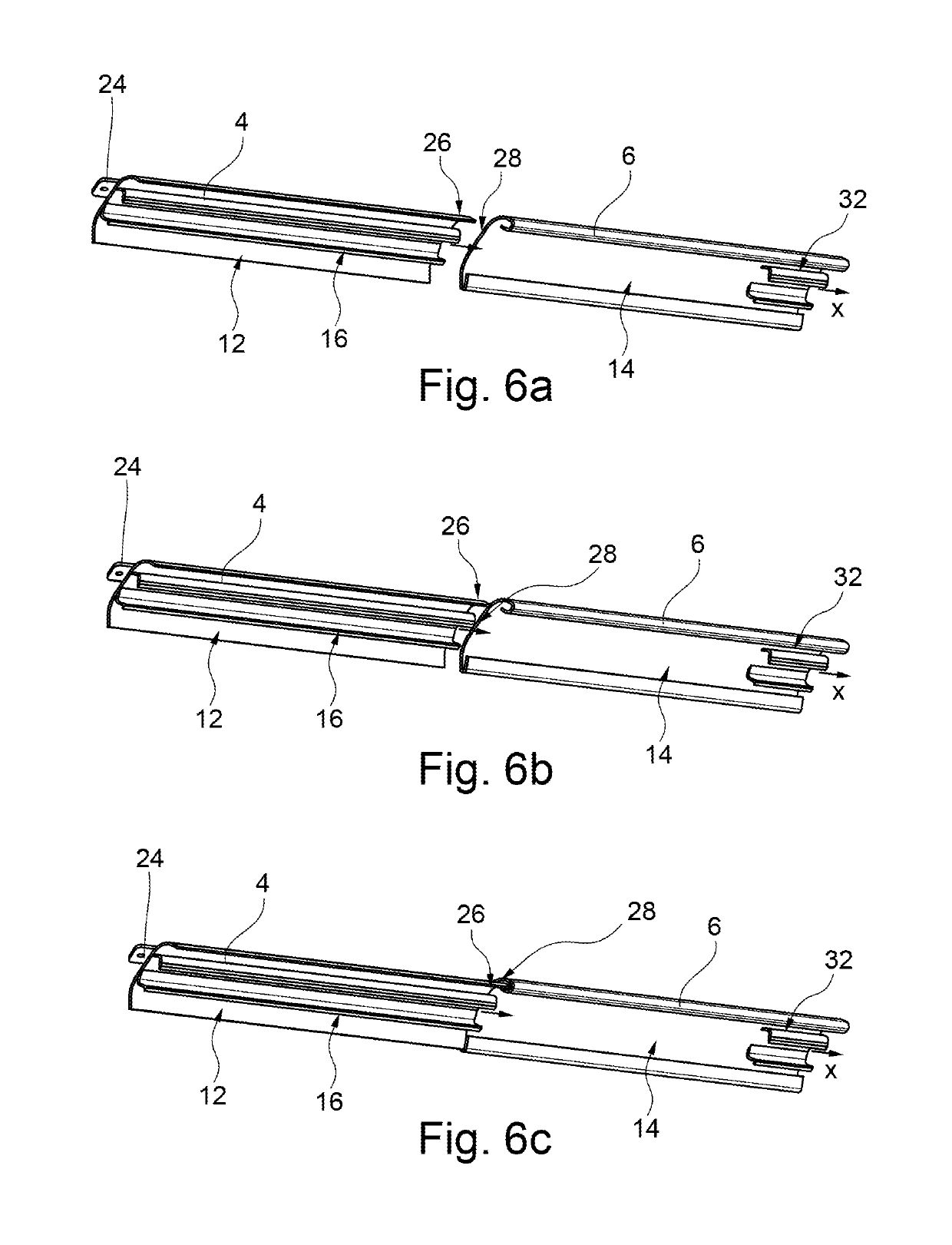

Rail covering for a sliding seat rail between two passenger seats in a cabin of a vehicle

ActiveUS20190308526A1Sufficient dimensional stabilityHigh tread resistanceSeating arrangementsMovable seatsEngineeringMechanical engineering

Owner:AIRBUS OPERATIONS GMBH

Plunger piston made from plastic for an air spring

InactiveUS20090160110A1Sufficient dimensional stabilityProduced cost-effectivelySpringsGas based dampersVehicle frameAir spring

A plunger piston for an air spring. The air spring being active between a component which is to be cushioned by springs, in particular the vehicle frame, and a sprung component, in particular the axle carrier of a motor vehicle. The plunger piston is configured as a hollow piston which is connected to the sprung component at the lower plunger-piston end and to a pneumatic-spring bellows which can be loaded with compressed air at an upper plunger-piston head. The pneumatic-spring bellows is connected on the other side to the component which is cushioned by springs, and rolls on the outside of the plunger-piston skirt during suspension movements. The lower plunger-piston end has an open configuration and has a reinforcing element which encircles the edge region of the opening.

Owner:LKH KUNSTWERK

Travel limiting element in a brake servo device and brake servo device

InactiveUS8505435B2Sufficient dimensional stabilityLighter and noise-dampingBraking action transmissionServomotorsMechanical engineeringVehicle brake

Owner:LUCAS AUTOMOTIVE GMBH

Recycled rubber backed cushioned vinyl

ActiveUS9340970B2Sufficient massSufficient weightCovering/liningsGlass/slag layered productsEngineeringSurface cover

Owner:ECORE INT

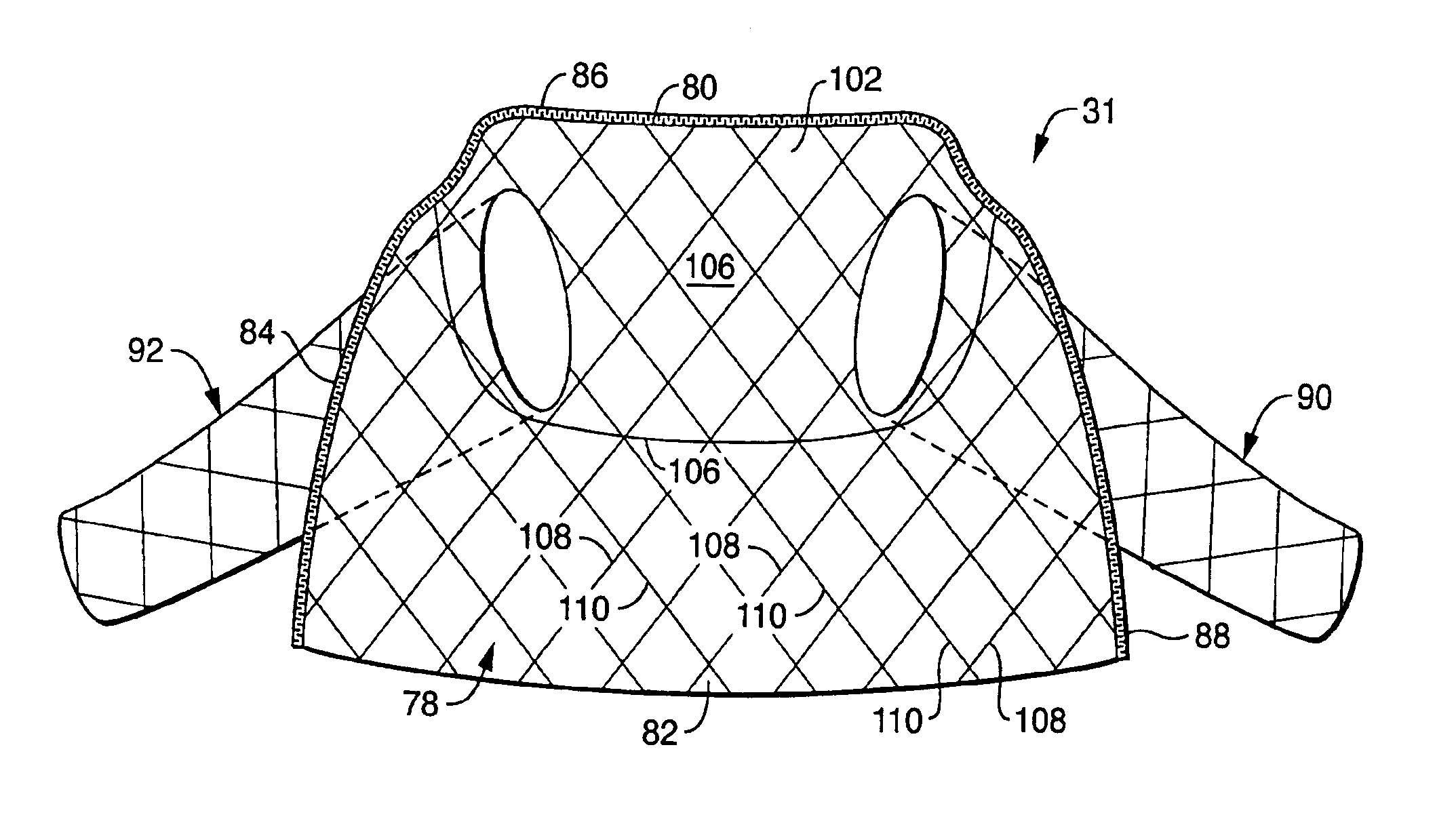

Crumple resistant lining and outerwear for use therewith

InactiveUS6898803B1Good dimensional stabilityReduce coefficient of frictionOvergarmentsProtective garmentEngineeringCoefficient of friction

A detachable lining for outerwear comprises a bodice, which includes an inner substantially full layer composed of a relatively rough fabric, an outer substantially full layer composed of a relatively smooth fabric, and an overlay partial layer composed of a relatively smooth fabric. The partial layer is superposed on the inner layer at an upper region of the bodice. The inner layer and outer layer are quilted together for enhancing dimensional stability and preventing bunching. The overlay partial layer has a relatively low coefficient of friction for encouraging sliding and preventing catching.

Owner:BLAUER MFG

Lightweight finish for hot-fill container

ActiveUS7866496B2Less materialSufficient dimensional stabilityCapsBottlesEngineeringMechanical engineering

A lightweight finish for a hot-fill container uses less material compared to existing hot-fill container finishes. The lightweight finish yields a cost savings while still providing adequate dimensional stability to allow the container to maintain its shape during the hot-fill process.

Owner:STOKLEY VAN CAMP INC

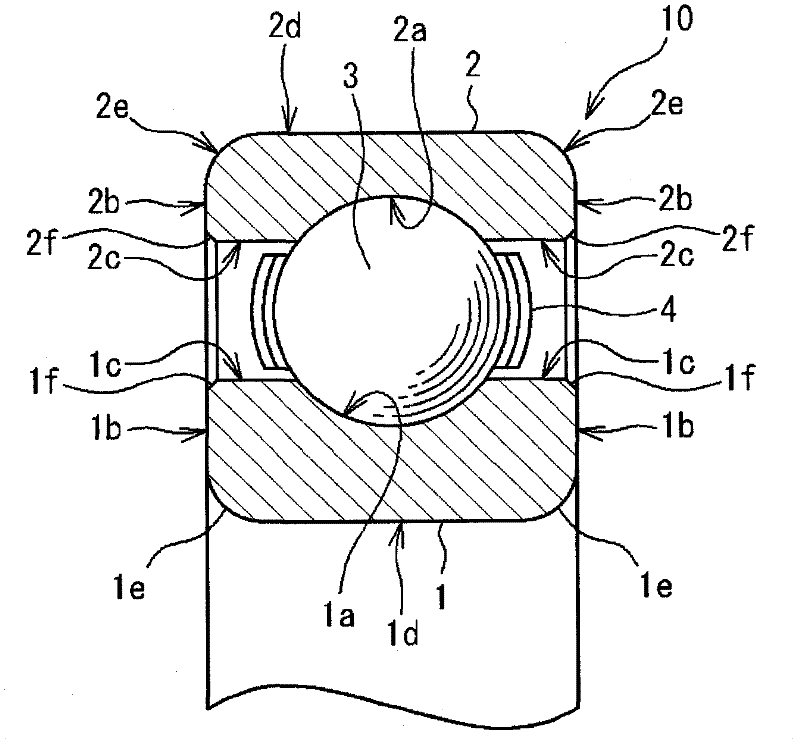

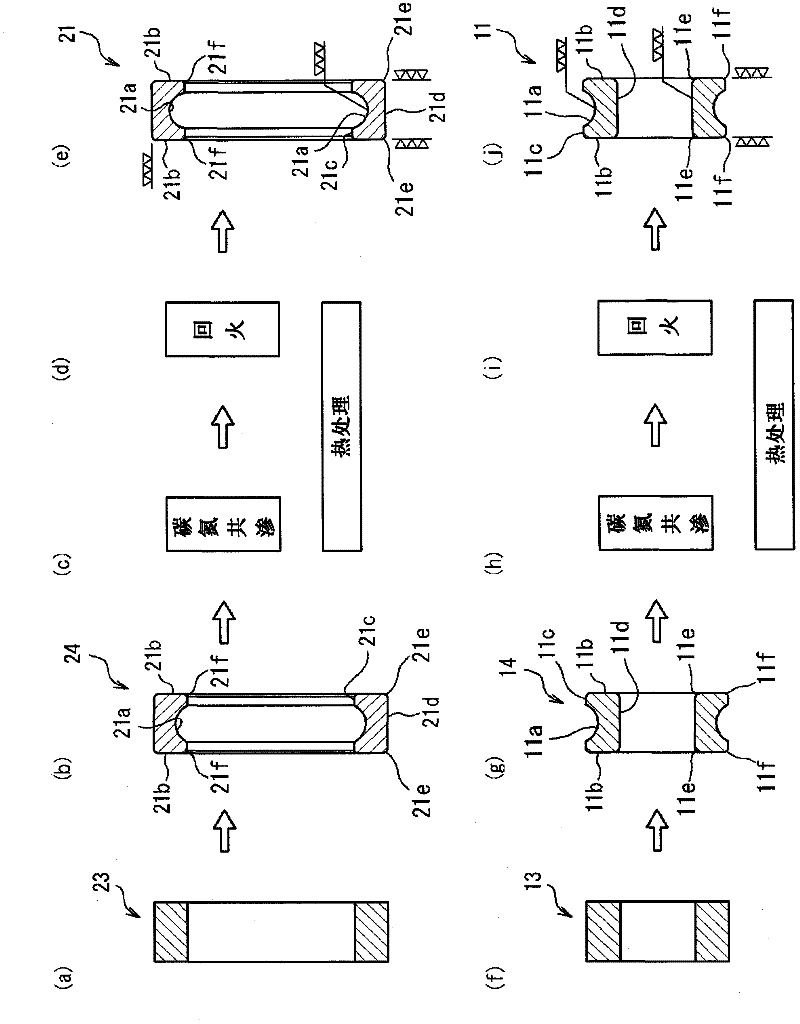

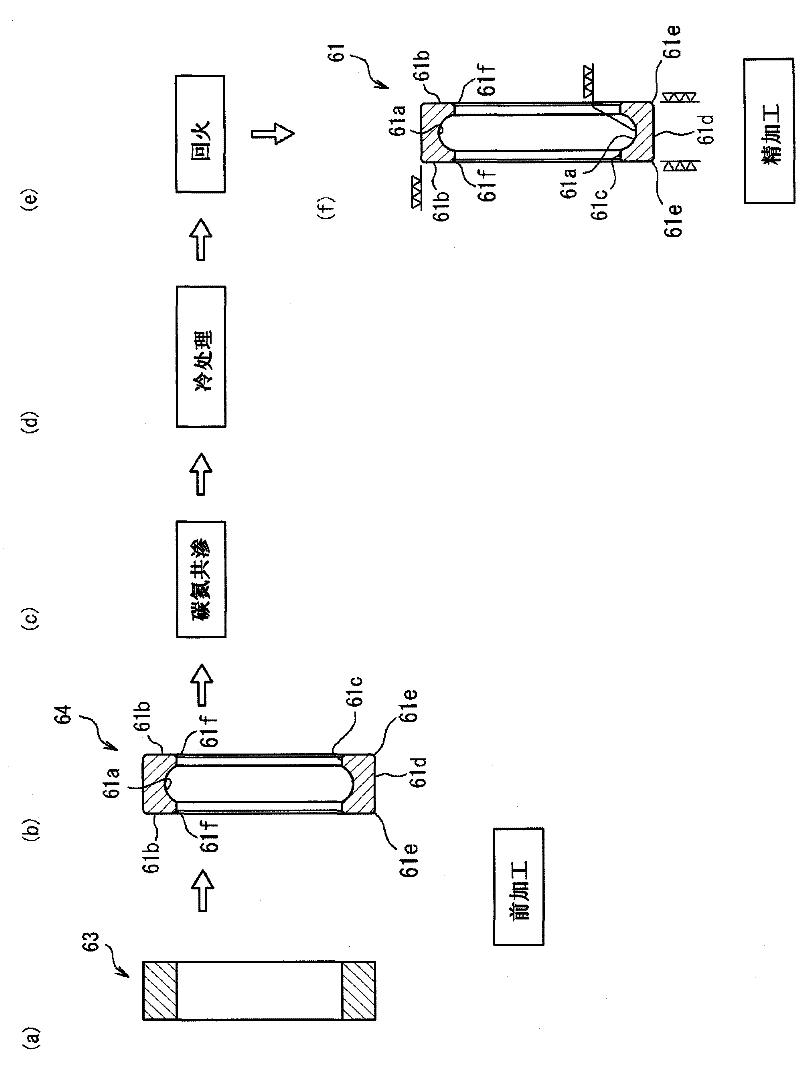

Constituent member of bearing, process for production of same, and ball-and-roller bearing provided with the constituent member

InactiveCN102245793AAchieve long lifeFull static load capacityShaftsBall bearingsCarrying capacitySurface layer

The present invention provides a constituent member of a bearing, which can prolong the life of a ball-and-roller bearing and can ensure sufficient static load carrying capacity and dimensional stability; a process for production of the constituent member; and a ball-and-roller bearing which has a long life and exhibits sufficient static load carrying capacity and dimensional stability. A workpiece obtained by shaping a steel containing 3.2 to 5.0 mass% of Cr and 0.05 to less than 0.5 mass% of V is subjected to heat treatment such as carbonitriding, whereby a constituent member of a ball-and-roller bearing is produced. In the constituent member thus produced, the contents of C and N in the surface layer extending from the surface of the member to a depth of 10[mu]m fall within the ranges of 1.1-1.6 mass% and 0.1-1.0 mass% respectively; the Vickers hardness at a depth of 50[mu]m from the surface falls within the range of 740 to 900 (62-67 in terms of Rockwell C hardness); the content of gamma-iron at a depth of 10[mu]m from the surface falls with the range of 20-55 vol%; vanadium nitride particles having particle diameters of 0.2-2[mu]m and / or vanadium carbonitride particles having particle diameters of 0.2-2[mu]m are made present in the surface layer extending from the surface to a depth of 10[mu]m; and the area fraction of the particles in the surface layer extending from the surface to a depth of 10[mu]m falls within the range of 1-10%.

Owner:JTEKT CORP

Breathing mask with individual adaptation to the shape of the face

InactiveUS7726313B2Rigidity of the sealing frame can be setEvenly distributedBreathing filtersBreathing masksMetal stripsPlastic materials

Owner:DRAGERWERK AG

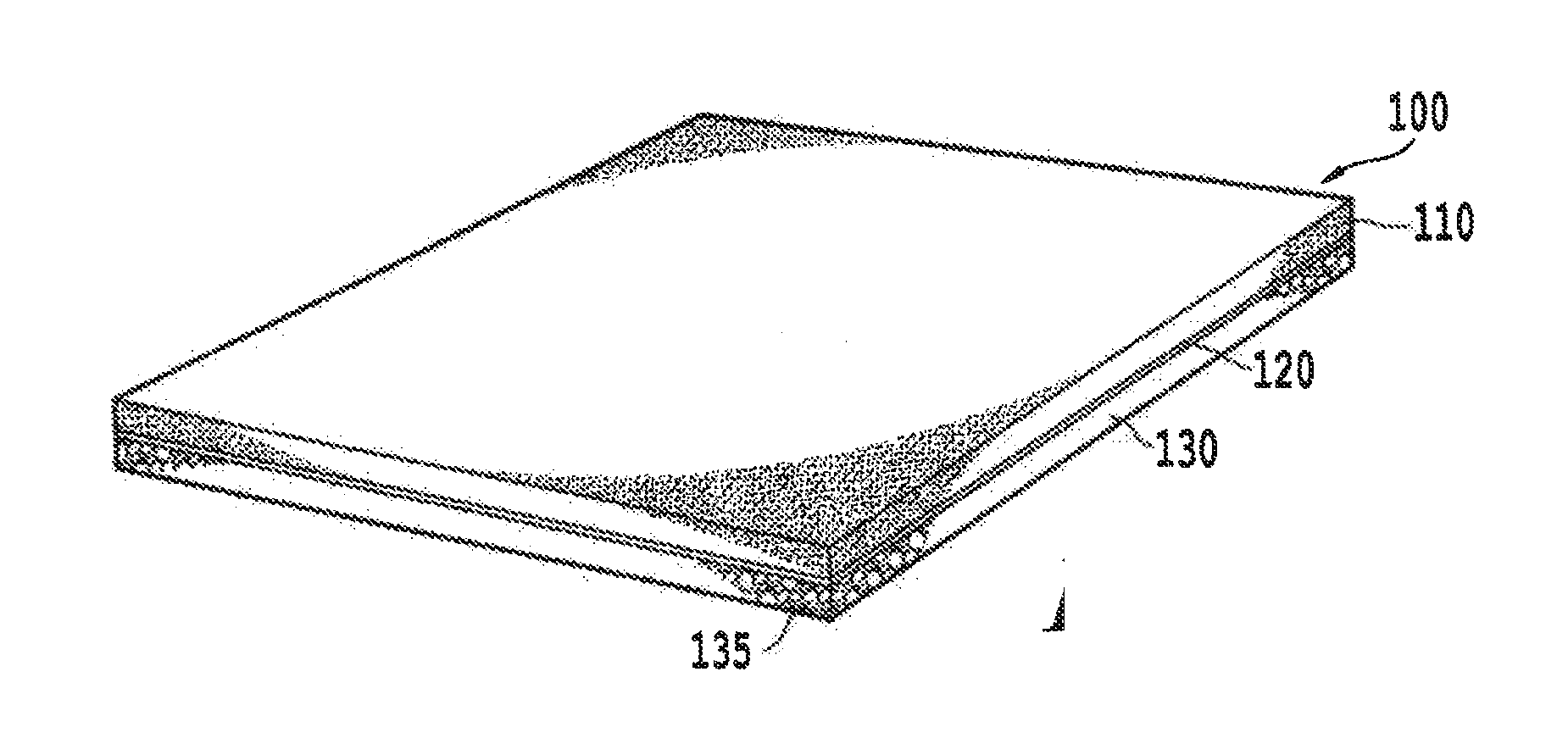

Metal-clad laminate and manufacturing method of the same

PendingUS20200404782A1Low melting pointImprove adhesionNon-macromolecular adhesive additivesDielectric materialsPolymer scienceMetal foil

A metal-clad laminate is provided. The metal-clad laminate includes:a dielectric layer, which has a first reinforcing material and a dielectric material formed on the surface of the first reinforcing material, wherein the dielectric material includes 60 wt % to 80 wt % of a first fluoropolymer and 20 wt % to 40 wt % of a first filler;an adhesive layer, which is disposed on at least one side of the dielectric layer and includes an adhesive material, wherein the adhesive material has 60 wt % to 70 wt % of a second fluoropolymer and 30 wt % to 40 wt % of a second filler; anda metal foil, which is disposed on the other side of the adhesive layer that is opposite to the dielectric layer,wherein the melting point of the second fluoropolymer is lower than the melting point of the first fluoropolymer.

Owner:TAIWAN POWDER TECH CO LTD

Base material for the preparation of vitreous or vitrocrystalline type pieces, process for preparing the base material and method for manufacturing the pieces

InactiveUS20030216239A1Sufficient dimensional stabilityImprove propertiesGlass shaping apparatusFritDecomposition

Base material for the manufacturing of baked vitreous or vitrocrystalline pieces, characterized in that it is a granulated material with granules with a particle size with a diameter smaller than 2,000 mum that comprises, at least, 60% and 99.89% by weight of a first component selected among a frit composition, an enamel composition, glass, or mixtures thereof, 0.1% and 5% by weight of an organic binding agent that has a decomposition temperature lower than the end of sintering temperature of the base material; and in that said material is formed of granules with a humidity content lower than 3% by weight.

Owner:ESMALGLASS SA

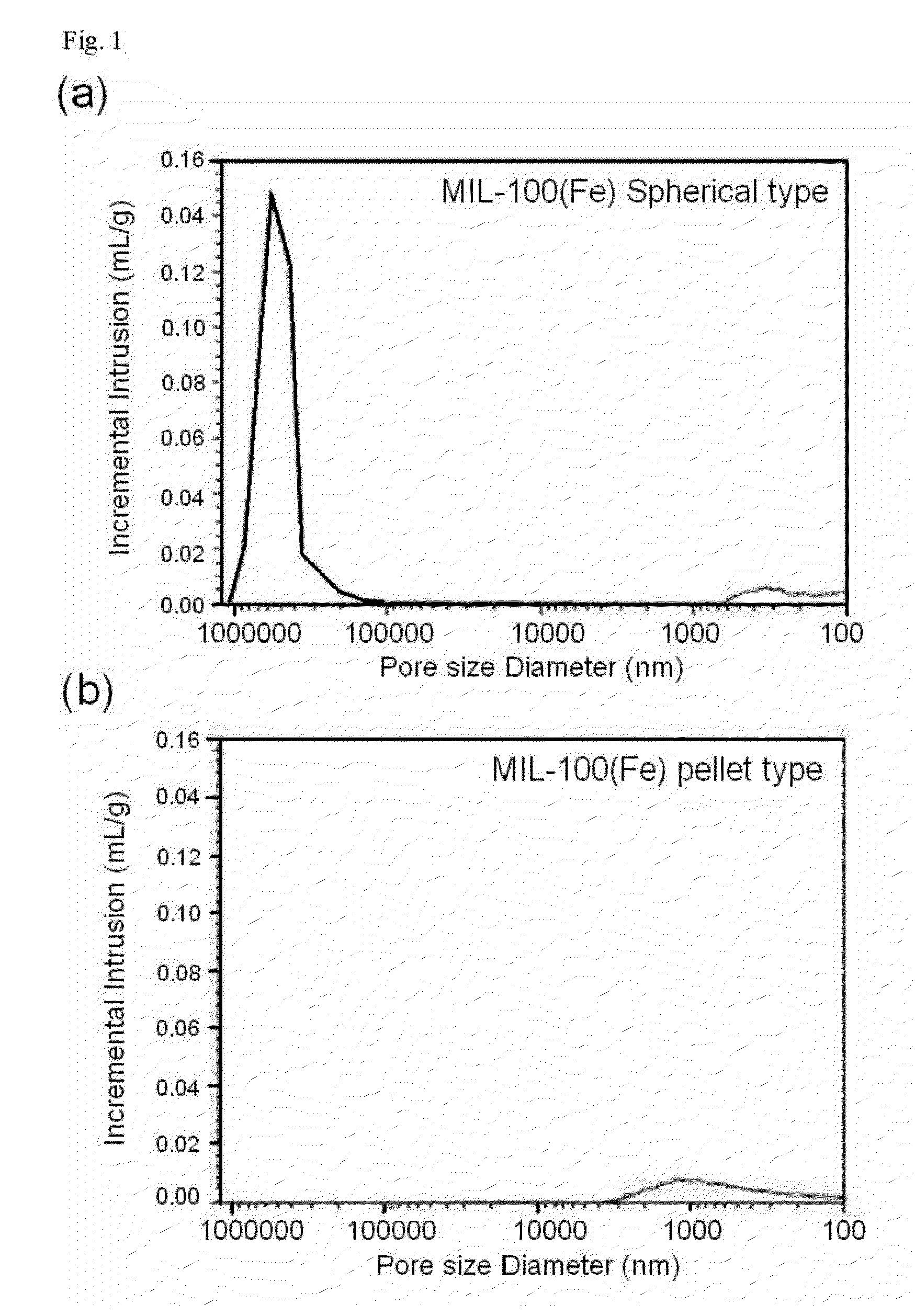

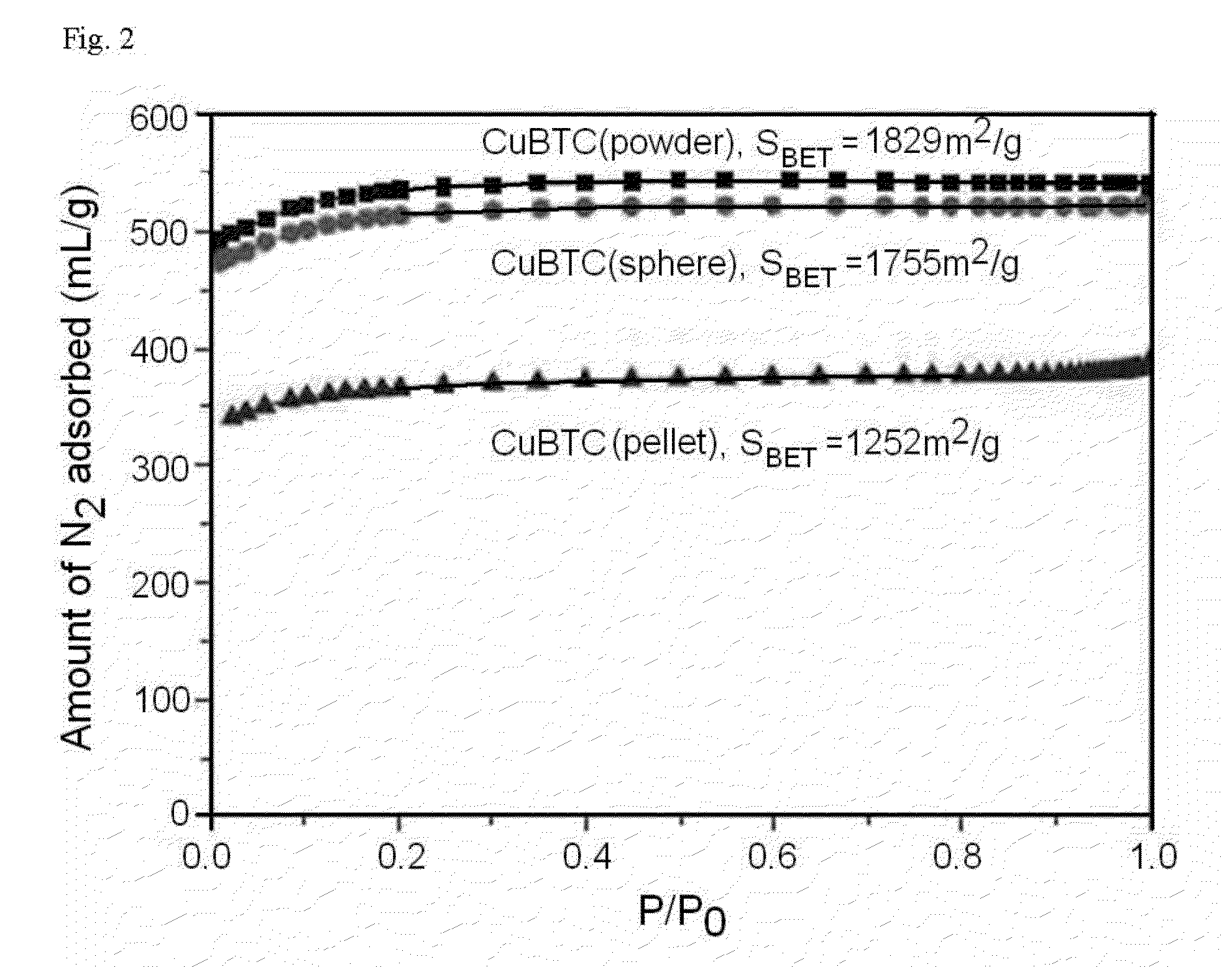

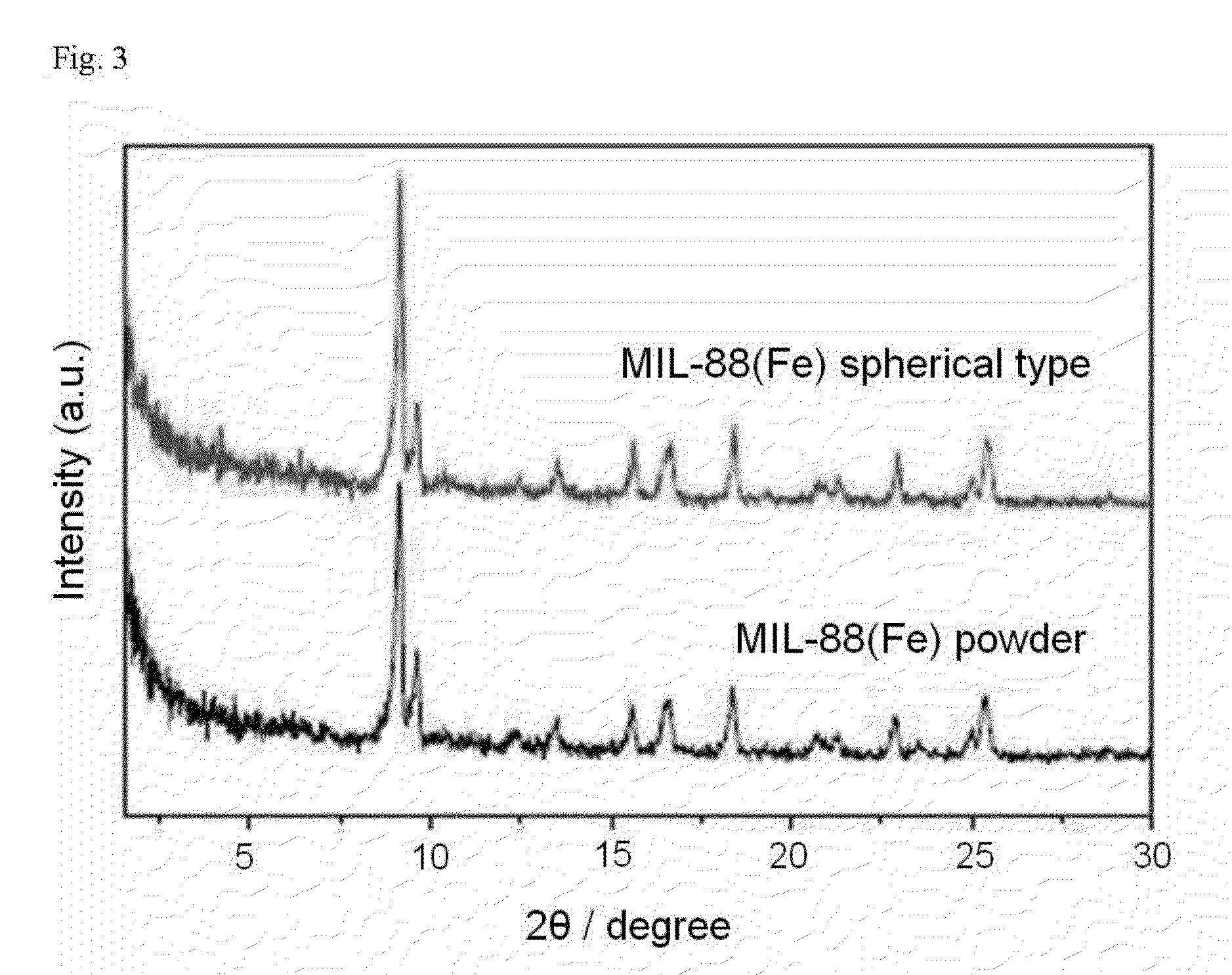

Complex comprising crystalline hybrid nanoporous material powder

ActiveUS9302258B2Stay flexibleImprove performanceOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsIon clustersCoordination complex

Owner:KOREA RES INST OF CHEM TECH

Recycled rubber backed cushioned vinyl

ActiveUS10759149B2Sufficient massSufficient weightCoatingsThin material handlingPolymer sciencePolymer chemistry

A laminated surface covering including a facing material made of vinyl and a backing material comprising a rubber component. The rubber component comprising at least a matrix of bonded rubber granules. A bonding material disposed between the facing material and the backing material. The facing material configured to melt at a temperature between 165° F. and 248° F. infiltrating the backing material thereby essentially encasing the rubber granules of the matrix and providing fire retardation and smoke suppression qualities.

Owner:ECORE INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com