Constituent member of bearing, process for production of same, and ball-and-roller bearing provided with the constituent member

A component and bearing technology, applied in the direction of manufacturing tools, bearing components, bearings, etc., can solve problems such as hindering smooth rotation, and achieve the effect of ensuring static load capacity, sufficient static load capacity, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

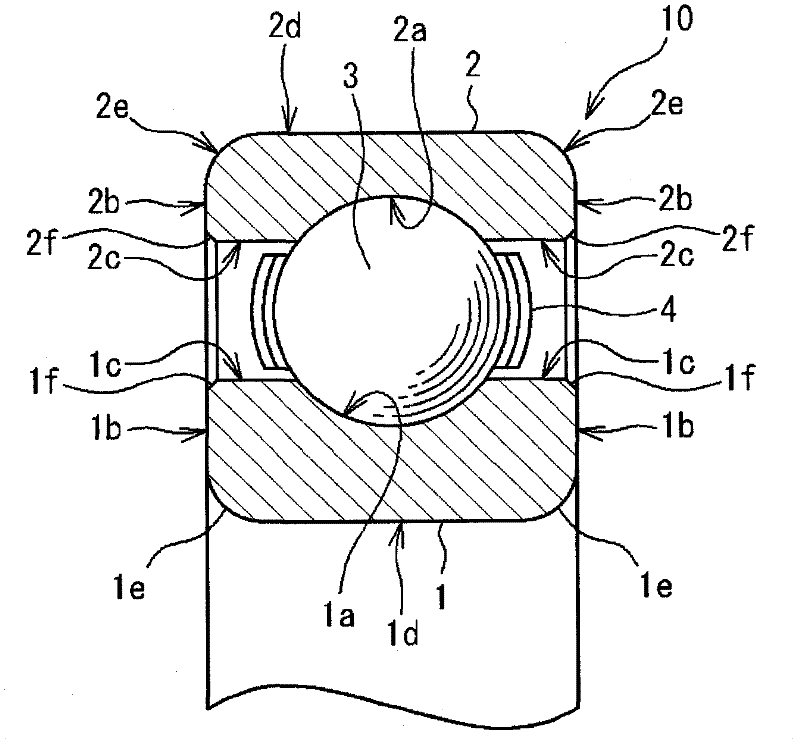

[0101] Next, a bearing component according to a first embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic explanatory diagram showing a ball bearing which is a rolling bearing including an inner ring, an outer ring, and balls as an example of bearing components according to the first embodiment of the present invention.

[0102] The ball bearing 10 includes: an inner ring 1 having a raceway portion 1a on its outer peripheral surface; an outer ring 2 having a raceway portion 2a on its inner peripheral surface; The balls 3 as a plurality of rolling elements and the cage 4 retain the plurality of balls 3 at predetermined intervals in the circumferential direction.

[0103] The surfaces of the raceway portion 1a, the end surface 1b, the shoulder surface 1c, and the inner peripheral surface 1d of the inner ring 1 are ground portions that have been finely ground. On the other hand, the chamfer 1e on the inner peripheral s...

no. 2 approach

[0155] [Bearing Components and Rolling Bearings Equipped with the Bearing Components]

[0156] Next, an outer ring as a bearing component according to a second embodiment of the present invention will be described with reference to the drawings. Regarding the second embodiment, similarly to the example of the rolling bearing of the first embodiment, the figure 1 Be explained. That is, using the same reference numerals for the same parts, below, based on figure 1 Be explained. figure 1 It is a schematic explanatory diagram showing the structure of a ball bearing as a rolling bearing including a bearing component (outer ring) according to a second embodiment of the present invention.

[0157] Like the first embodiment, the ball bearing 10 of the second embodiment includes an outer ring 2 having a raceway portion 2a on the inner peripheral surface, an inner ring 1 having a raceway portion 1a on the outer peripheral surface, and disposed on the inner and outer rings 1, Balls 3...

Embodiment 1-1~1-3 and comparative example 1-1~1-7

[0219] Two types of steel materials A and B having the compositions shown in Table 1 were used respectively, processed into predetermined shapes, and respective molding materials for the inner and outer rings of ball bearings (type 6206) with grinding allowances at the parts forming the raceway surfaces were manufactured. Steel material B in Table 1 is JIS SUJ2 which is a bearing steel. In addition, the diameter of the rolling elements is 9.525mm.

[0220] [Table 1]

[0221]

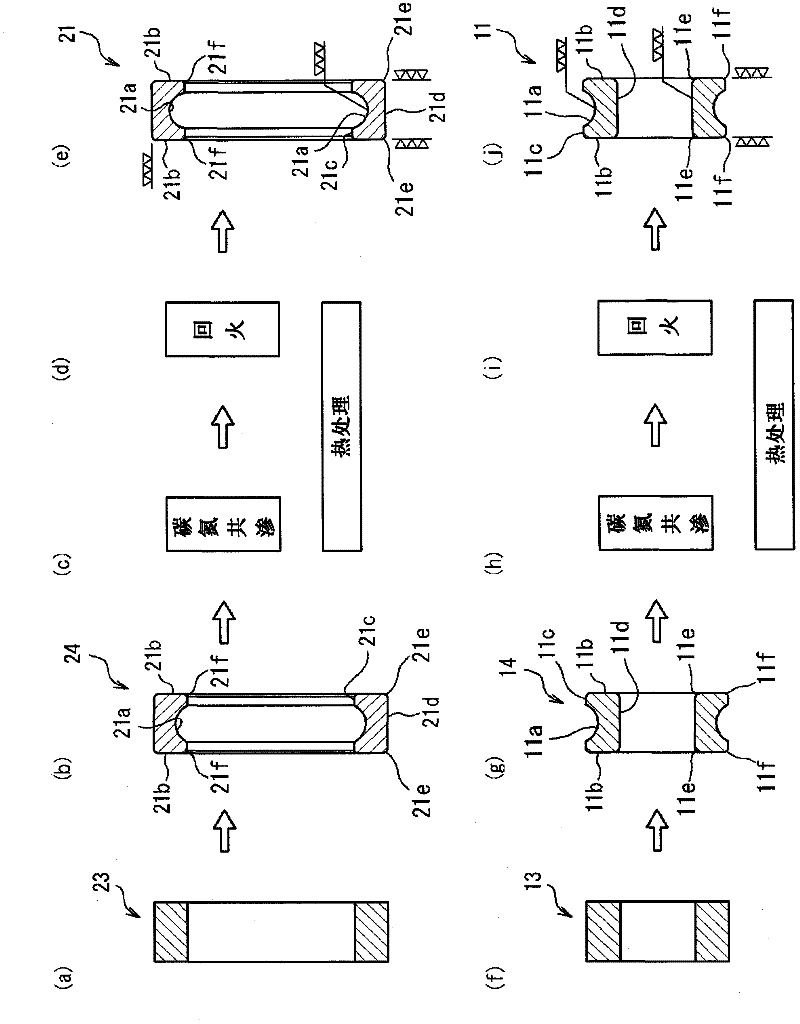

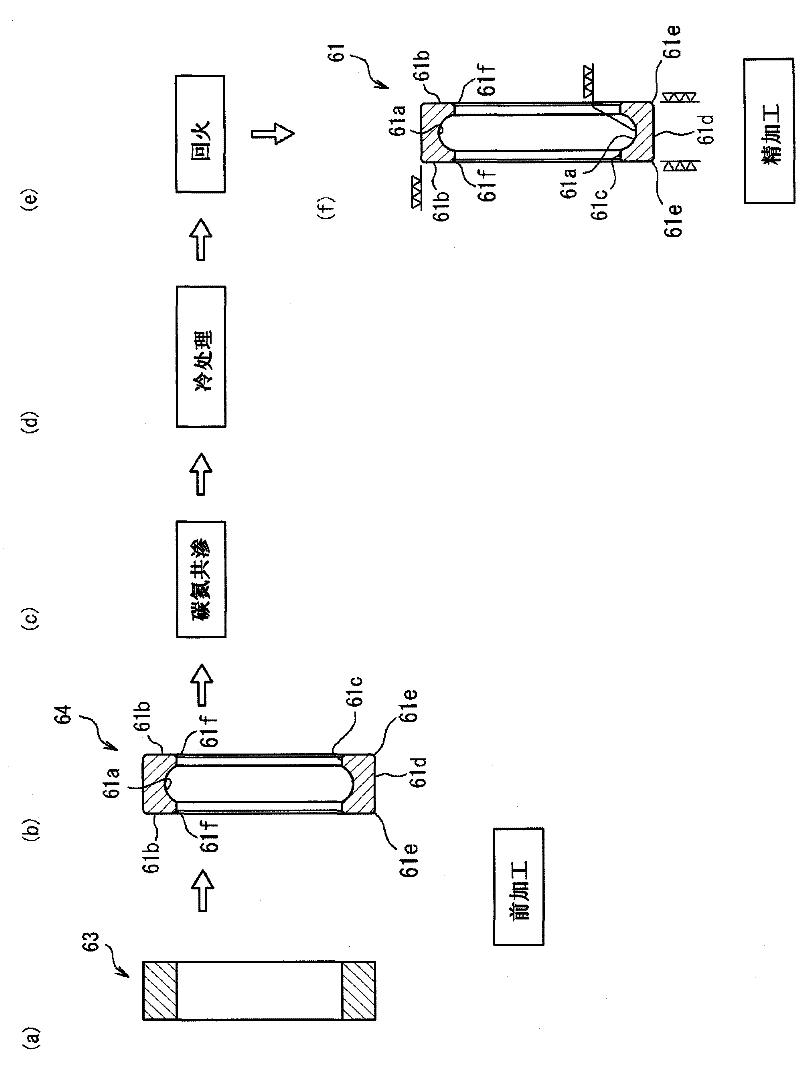

[0222] Next, for the obtained molding raw material, in Figure 3 ~ Figure 12 Heat treatment was performed under the heat treatment conditions shown, and the portion forming the above-mentioned raceway surface of the obtained heat-treated intermediate material was subjected to grinding processing to manufacture Examples 1-1 to 1-3 and Comparative Examples 1-1 to 1-7. The combination of inner and outer rings. Specifically, in the combinations of the inner and outer rings of Examples 1-1 to 1-3 and Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com