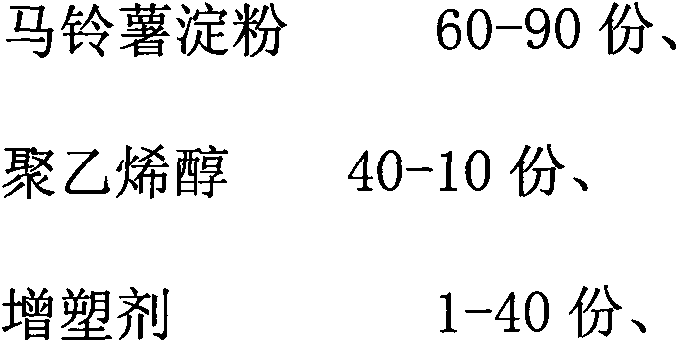

Method for preparing degradable mulching film by taking potato starch as raw material

A potato starch and raw material technology, applied in the direction of plant protection cover, can solve the problems of incomplete degradation, poor mechanical strength, polluted land, etc., and achieve the effects of low cost, high mechanical strength and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

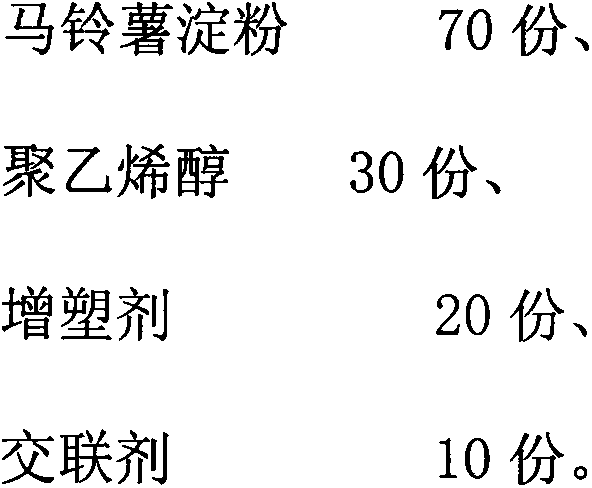

Embodiment 1

[0021] Example 1: Preparation of Potato Starch and Plasticizer Blends

[0022] Add 70 parts of potato starch, 7 parts of glycerin and 3 parts of urea to 10-50 parts of water, and stir at 80-95°C for 30-40 minutes at high speed to make it evenly mixed.

Embodiment 2

[0023] Embodiment 2: Preparation of polyvinyl alcohol and plasticizer blend

[0024] Add 3-6 parts of glycerin to 30 parts of polyvinyl alcohol and grind until there are no obvious particles, then add 10-30 parts of water and 3-6 parts of urea, and stir at 80-95°C for 30-40 minutes at high speed to make it evenly mixed.

Embodiment 3

[0025] Embodiment 3: Glutaraldehyde is used as the reaction condition of crosslinking agent

[0026] Mix potato starch / plasticizer solution and polyvinyl alcohol / plasticizer solution at a mass ratio of potato starch to polyvinyl alcohol of 7:3, stir at high speed for 30-40 minutes at 80-95°C, and add water appropriately during the period; mix evenly Finally, according to the proportion of 5-10% of the starch mass, 50% concentration of glutaraldehyde is added dropwise, and the cross-linking reaction is maintained at 80-95° C. for 30-40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com