Fully-biodegradable material as well as preparation method and application thereof

A biodegradable material and whole biological technology, applied in the field of fully biodegradable materials and their preparation, can solve problems such as non-degradability, and achieve the effects of easy access, low environmental pollution, and good degradation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

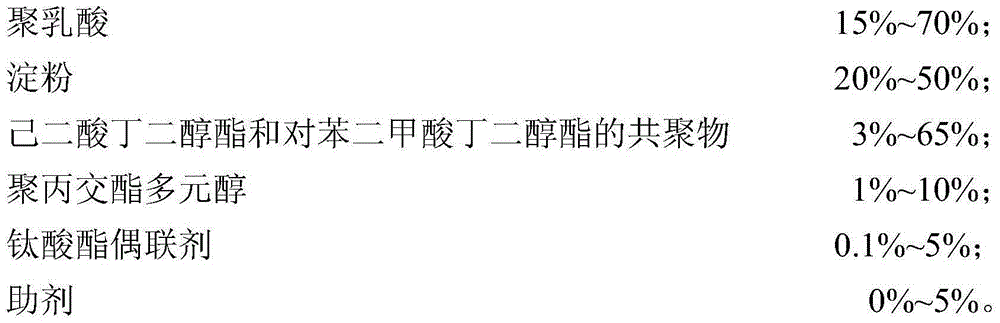

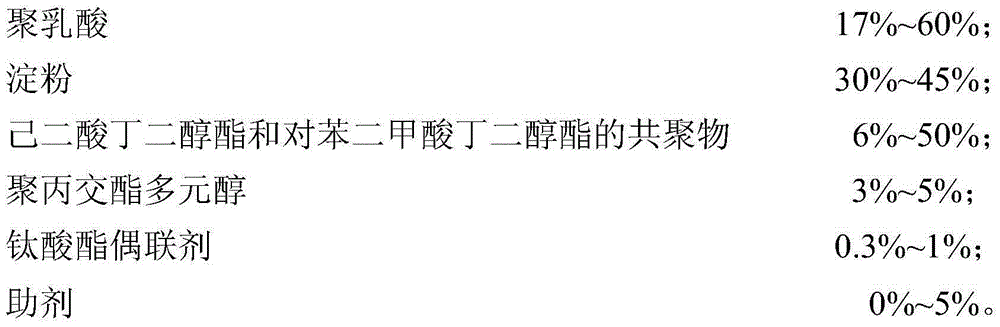

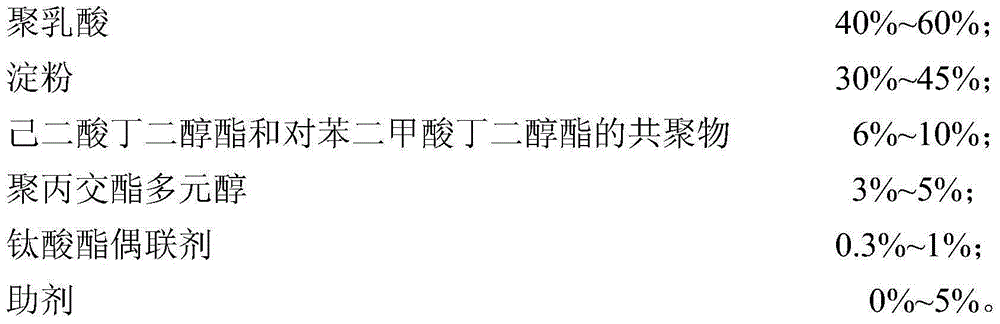

Method used

Image

Examples

Embodiment 1

[0042] At first, take the raw material of following weight part: polylactic acid (Natureworks4032D) 60 weight parts, cornstarch (national starch) 30.5 weight parts, the copolymer of butylene adipate and butylene terephthalate (Xin Fu Pharmaceutical) 6 parts by weight, polylactide polyol (Shenzhen Guanghua Weiye Industrial Co., Ltd., D-PLA220B) 3 parts by weight, titanate coupling agent (Nanjing Youpu Chemical Co., Ltd., UP-311W) 0.5 parts by weight share.

[0043] The preparation process is as follows: using high-speed mixing equipment, first dry the copolymer of polylactic acid, starch, butylene adipate and butylene terephthalate at 105°C for 30 minutes; then add polylactide polyol and titanic acid The ester coupling agent is mixed evenly to obtain a mixed material; the mixed material is added to a twin-screw extruder for melt blending; finally, it is air-cooled and granulated to obtain a fully biodegradable material. The screw length-to-diameter ratio of the twin-screw extrud...

Embodiment 2

[0045] First, take the following raw materials by weight: 40 parts by weight of polylactic acid (Natureworks4032D), 44.5 parts by weight of cornstarch (national starch), a copolymer of butylene adipate and butylene terephthalate (Xin Fu Pharmaceutical) 10 parts by weight, polylactide polyol (Shenzhen Guanghua Weiye Industrial Co., Ltd., D-PLA220B) 5 parts by weight, titanate coupling agent (Nanjing Youpu Chemical Co., Ltd., UP-311W) 0.5 parts by weight share.

[0046] The preparation process is as in Example 1.

Embodiment 3

[0048] First, take the following raw materials by weight: 17 parts by weight of polylactic acid (Natureworks4032D), 30 parts by weight of cornstarch (national starch), a copolymer of butylene adipate and butylene terephthalate (Xin Rich Pharmaceutical) 49.5 parts by weight, polylactide polyol (Shenzhen Guanghua Weiye Industrial Co., Ltd., D-PLA220B) 3 parts by weight, titanate coupling agent (Nanjing Youpu Chemical Co., Ltd., UP-311W) 0.5 parts by weight share.

[0049] The preparation process is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com