Preparation method of earthworm liquid organic fertilizer

A technology of liquid organic fertilizer and earthworm liquid, applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment, etc., can solve the problems of easy nutrient loss and slow soil absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

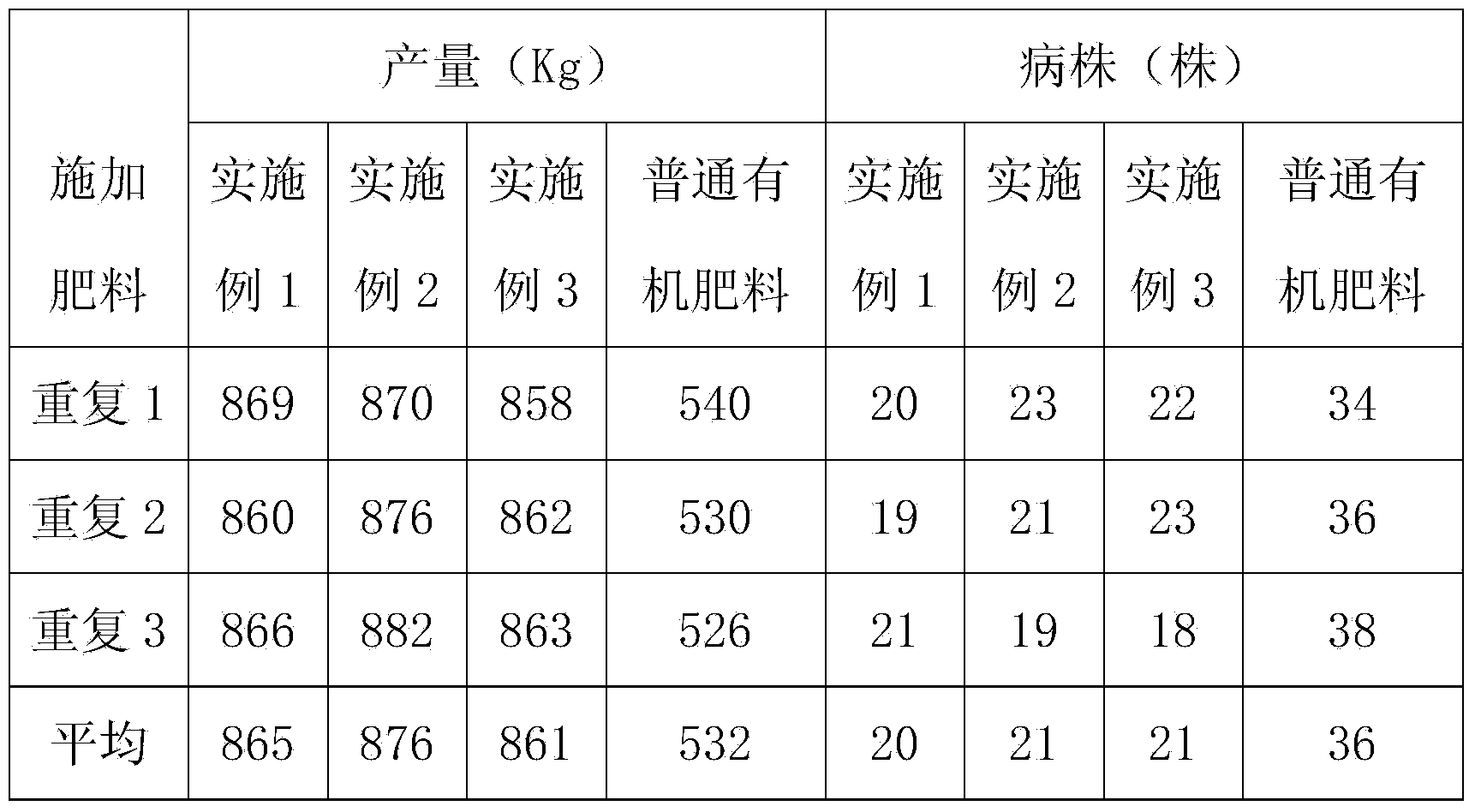

Examples

Embodiment 1

[0022] A preparation method of earthworm liquid organic fertilizer, comprising the following steps:

[0023] (1) Evenly beat 10Kg live earthworms in an electric mixer to obtain earthworm slurry;

[0024] (2) Put the earthworm slurry into the fermentation kettle, add 0.05Kg of EM bacteria, and ferment at 25°C for 24 hours;

[0025] (3) Filtrating the fermented earthworm slurry to obtain solid slag and earthworm liquid, and the solid slag is used as solid earthworm fertilizer;

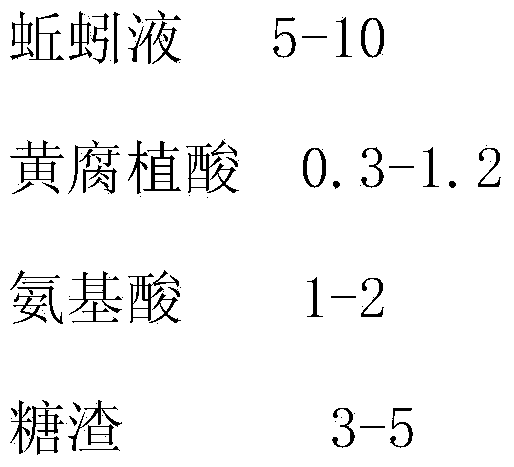

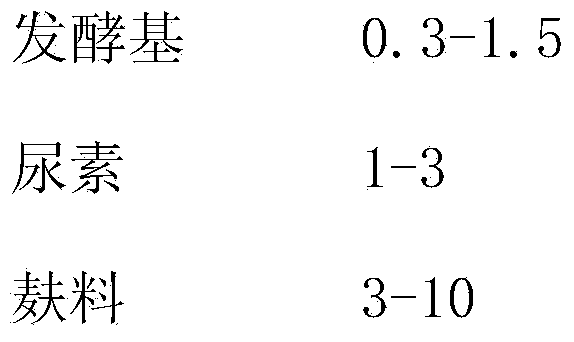

[0026] (4) Put 10Kg of the earthworm liquid obtained in step (3), 0.5Kg of fulvic acid, 1Kg of amino acid, 3Kg of sugar residue, 0.6Kg of HM fermentation base, 2Kg of urea and 5Kg of bran into the fertilizer mixing kettle, at 25°C Lower fermentation for 24 hours;

[0027] (5) After fermentation, filter the product and pack the filtrate.

Embodiment 2

[0029] A preparation method of earthworm liquid organic fertilizer, comprising the following steps:

[0030] (1) Evenly beat 10Kg live earthworms in a beater to obtain earthworm slurry;

[0031] (2) Put the earthworm slurry into the fermentation kettle, add 0.02Kg of EM bacteria, and ferment at 35°C for 24 hours;

[0032] (3) Filtrating the fermented earthworm slurry to obtain solid slag and earthworm liquid, and the solid slag is used as solid earthworm fertilizer;

[0033] (4) Put 7Kg of earthworm liquid obtained in step (3), 0.8Kg of fulvic acid, 1.2Kg of amino acid, 4Kg of sugar residue, 0.8Kg of HM fermentation base, 4Kg of animal manure, 3Kg of urea and 8Kg of bran into the fertilizer mixing kettle Fermentation at 35°C for 24 hours;

[0034] (5) After fermentation, filter the product and pack the filtrate.

Embodiment 3

[0036] A preparation method of earthworm liquid organic fertilizer, comprising the following steps:

[0037] (1) Evenly beat 10Kg live earthworms in a beater to obtain earthworm slurry;

[0038] (2) Put the earthworm slurry into the fermentation kettle, add 0.018Kg of EM bacteria, and ferment at 20°C for 24 hours;

[0039] (3) Filtrating the fermented earthworm slurry to obtain solid slag and earthworm liquid, and the solid slag is used as solid earthworm fertilizer;

[0040] (4) Put 9Kg of earthworm liquid obtained in step (3), 0.4Kg of fulvic acid, 0.8Kg of amino acid, 3Kg of sugar residue, 0.9Kg of fermentation base, 3Kg of animal manure, 2Kg of urea and 9Kg of bran into the fertilizer mixing kettle , fermented at 20°C for 24 hours

[0041] (5) After fermentation, filter the product and pack the filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com