Extraction method of direct coal liquefaction residues and application of extracts

A technology of direct coal liquefaction and coal liquefaction residue, which is applied in the field of coal deep processing, can solve the problems that it is difficult to fully, rationally and efficiently utilize coal liquefaction to liquefy heavy liquefied oil, and achieve improved overall oil yield, convenient and safe operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

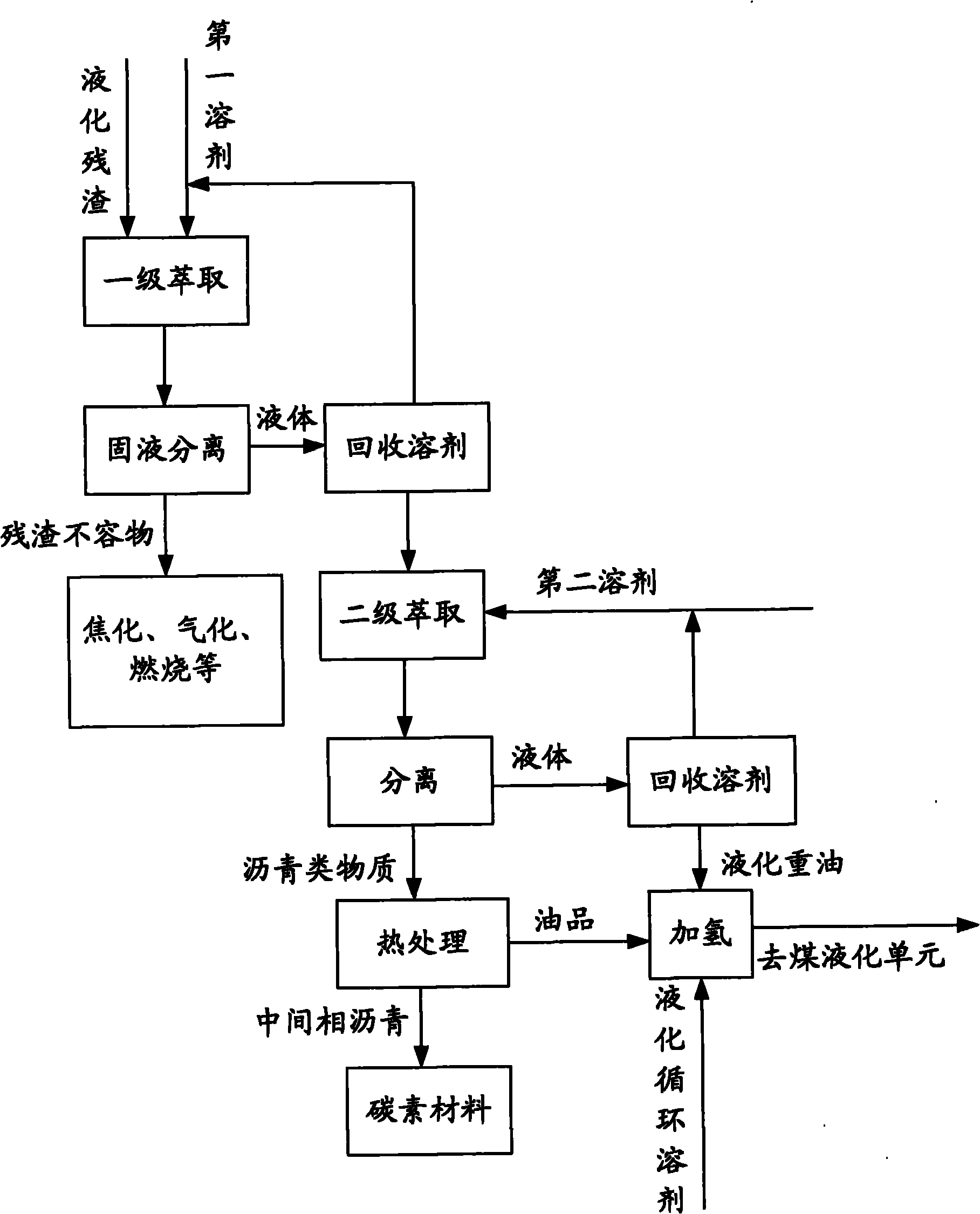

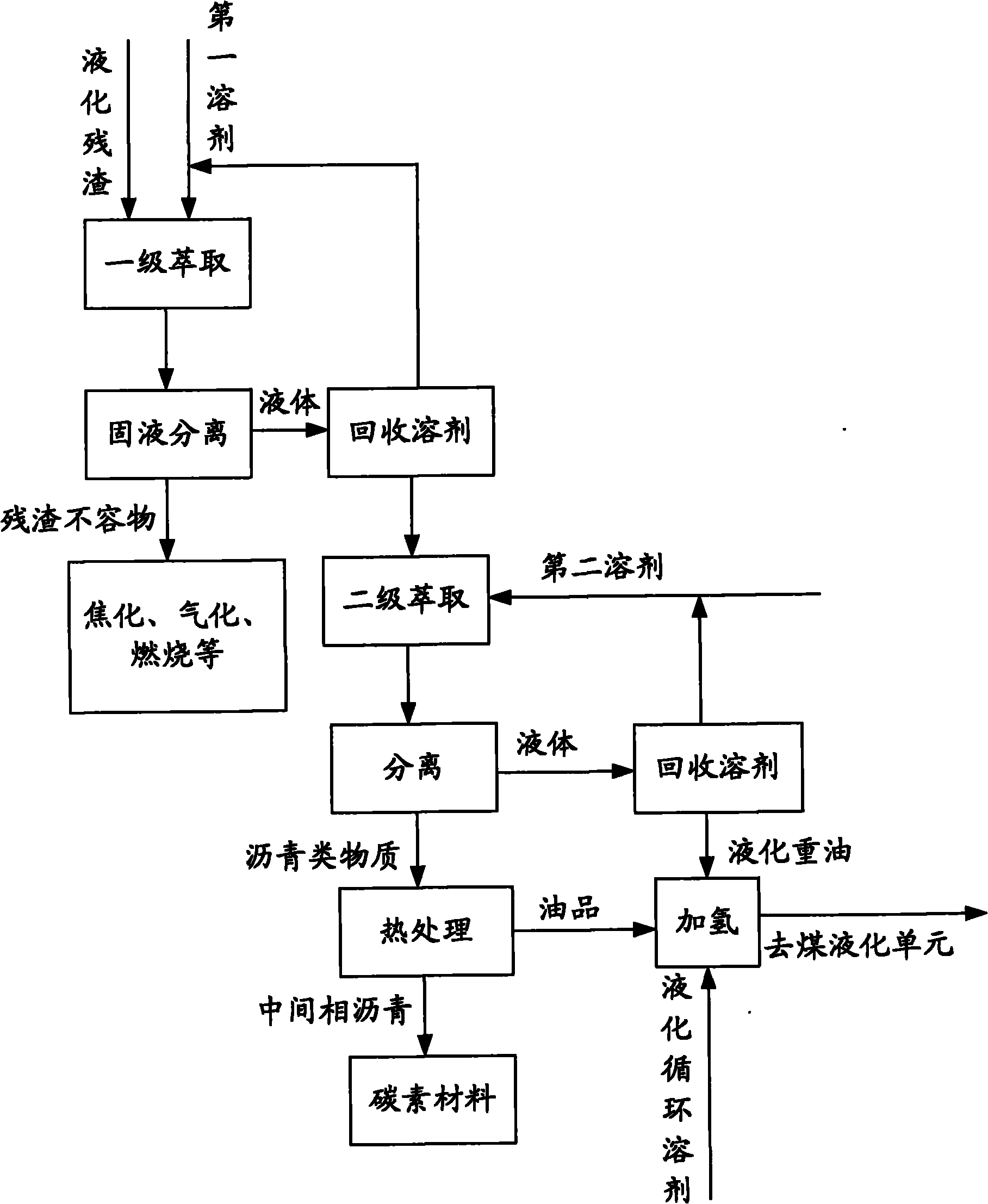

Method used

Image

Examples

Embodiment 1

[0069] Add 100kg of coal direct liquefaction residue and 400Kg of the first extraction solvent (distillation range 220-260°C) into the stirred tank, and then make them fully mixed. Charge N 2 Gas to 2.0MPa, heat up to 180°C, and stir at a stirring speed of 200r / min for 30 minutes to obtain a mixture. Then pressurize and heat filter to obtain the extract mixture, send it to the atmospheric distillation tower, cut the fraction at 220-260°C, recover the first extraction solvent for recycling, and obtain 64.3Kg of the extract mixture at the bottom of the tower. The extract mixture was fully mixed with 300Kg of the second extraction solvent (distillation range 2 Gas to 0.5MPa, heat up to 140°C, stir at a stirring speed of 250r / min for 20 minutes to obtain the mixture, then perform cyclone centrifugation to obtain the upper layer extract mixture S2, send it to the atmospheric distillation tower, and cut out the -1 , gas-liquid ratio 700m 3 / t, the hydrogenation catalyst is Co-Mo / γ-...

Embodiment 2

[0072] 200kg of coal direct liquefaction residue and 600Kg of the first extraction solvent (distillation range 220-260° C.) were added into the stirred tank for thorough mixing. Charge N 2 Gas to 1.0MPa, heat up to 150°C, and stir at a stirring speed of 150r / min for 20 minutes to obtain a mixture. Then pressurize and heat filter to obtain the extract mixture, send it to the atmospheric distillation tower, cut the fraction at 220-260°C, recover the first extraction solvent for recycling, and obtain the extract mixture 112.1Kg at the bottom of the tower. The extract mixture and 300Kg of the second extraction solvent (distillation range 2 Gas to 1.5MPa, heat up to 100°C, stir at a stirring speed of 150r / min for 20 minutes to obtain the mixture, then conduct vacuum hot filtration and separation to obtain the extract mixture S2, send it to an atmospheric distillation tower, and cut off the distillate at -1 , gas-liquid ratio 900m 3 / t, the hydrogenation catalyst is Co-Ni-W / γ-Al 2...

Embodiment 3

[0075] Add 150kg of coal direct liquefaction residue and 500Kg of the first extraction solvent (distillation range 220-260°C) into the stirred tank, and thoroughly mix them. Charge N 2 Gas to 0.5MPa, heat up to 140°C, and stir at a stirring speed of 180r / min for 120 minutes to obtain a mixture. Then carry out pressurized hot filtration to obtain the extract mixture, send it to the atmospheric distillation tower, cut the fraction at 220-260°C, recover the first extraction solvent for recycling, and obtain 75.6Kg of the extract mixture at the bottom of the tower. The extract mixture and 250Kg of the second extraction solvent (distillation range 2 Gas to 1.5MPa, heat up to 110°C, stir at a stirring speed of 180r / min for 40 minutes to obtain the mixture, then pressurize and heat filter and separate to obtain the extract mixture S2, send it to the atmospheric distillation tower, and cut the -1 , gas-liquid ratio 1000m 3 / t, the hydrogenation catalyst is Co-Ni-W / γ-Al 2 o 3 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com