Heavy metal removing agent for crude oil

A technology for heavy metals and removing agents, which is applied in the petroleum industry, refining hydrocarbon oil, etc., can solve the problems of difficult separation of metal compounds, difficult to realize industrialization, and increase in the amount of extractants, so as to solve the harm of heavy metals such as nickel and vanadium. , easy to separate, simple to use the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

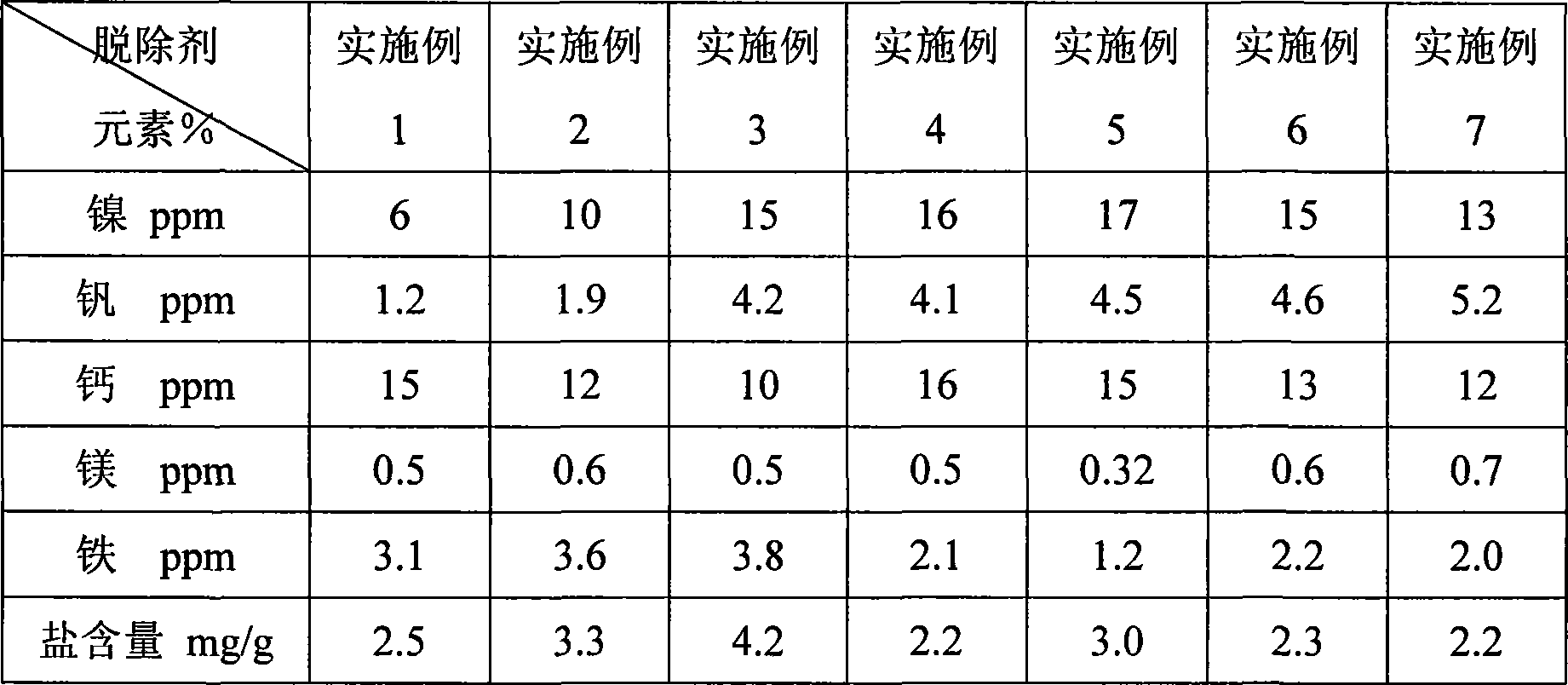

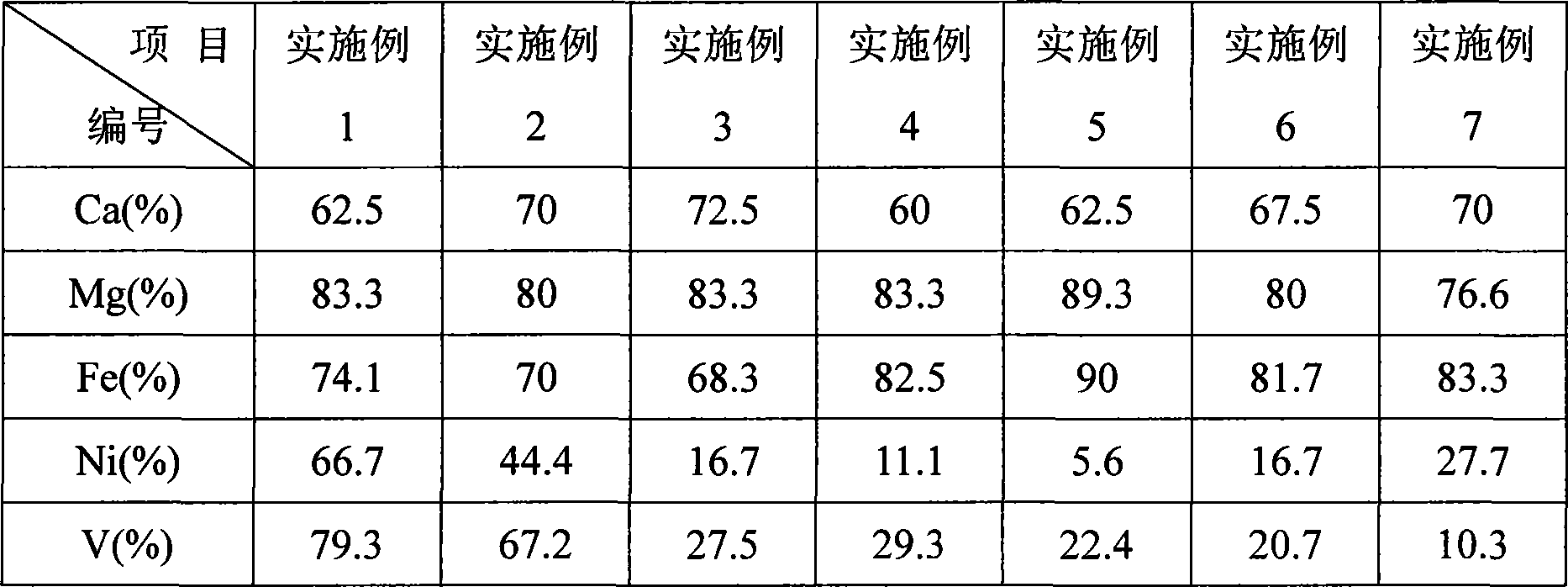

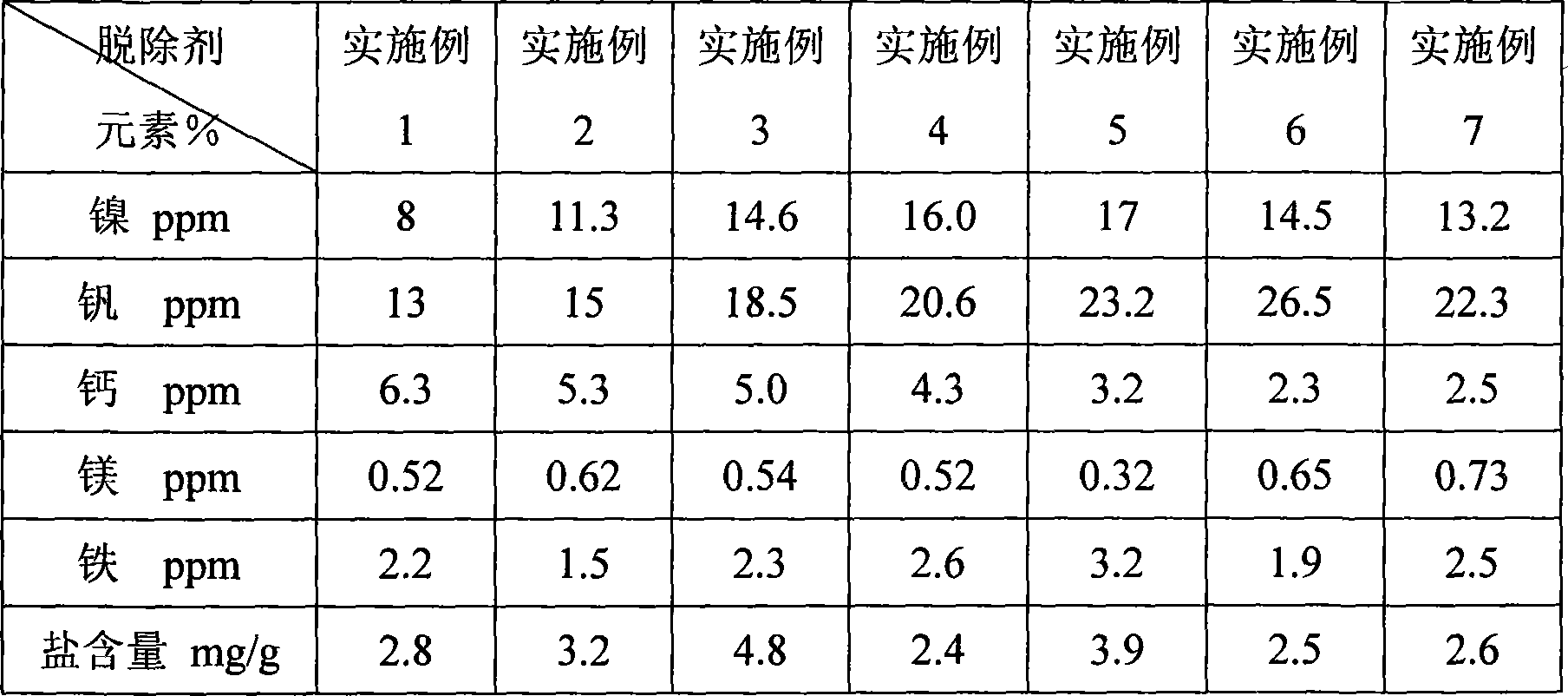

Embodiment 1-7

[0020] Embodiment 1-7: prepare heavy metal removing agent by following weight ratio:

Embodiment 1

[0021] Example 1 Ethylene carbonate 40%, polyoxypropylene polyoxyethylene ether 20%, polyoxyethylene ether glycerin phosphate 10%, thiourea 1%, alcohol water 9% (methanol: water = 1: 4)

Embodiment 2

[0022] Example 2 Ethylene carbonate 30%, polyoxypropylene polyoxyethylene ether 20%, polymaleic acid 15%, thiourea 1%, glycolic acid 25%, alcoholic water 9% (methanol: water=1: 4)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com