Preparation method of instant crisp okra slices

A production method and a technology for crispy chips, which are applied to the production field of okra ready-to-eat crispy chips, can solve the problems of low oil content of puffed food, affect product quality, easy fat oxidation, etc., and achieve less fat content, possibility of reduction, and oil content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

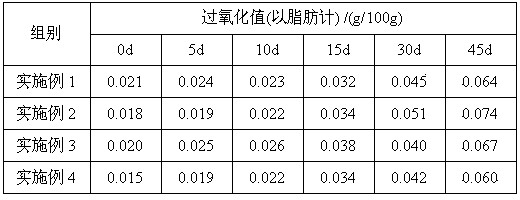

Embodiment 1

[0032] (1) Selection: select 20 kg of tender okra fruits with a length of 10 to 15 cm without pests and diseases and mechanical damage as raw materials;

[0033] (2) Blanching: Blanch the tender okra fruit in 80°C water for 10 minutes, then remove and drain the surface water;

[0034] (3) Slicing: Cut off the pedicles and tips of the two ends of the blanched okra tender pods, keep the uniform part in the middle for slicing, and control the slice thickness to 1-2cm;

[0035] (4) Quick-freezing: place the sliced okra at -18°C for 24 hours;

[0036] (5) Pre-puffing by vacuum frying: deep-fry the quick-frozen okra fruit slices at a vacuum degree of -90 to -96 kPa and a temperature of 70°C for 8 minutes;

[0037] (6) Vacuum deoiling: In the same vacuum frying equipment, under the condition of keeping the vacuum constant, deoil the fried okra slices for 10 minutes at a rotating speed of 100r / min to obtain 2.4kg of okra slices;

[0038] (7) Separation of fruit seeds and spraying ...

Embodiment 2

[0042] (1) Selection: select 20 kg of tender okra fruits with a length of 10 to 15 cm without pests and diseases and mechanical damage as raw materials;

[0043] (2) Blanching: Blanch the tender okra fruit in clean water at 100°C for 2 minutes, then remove and drain the surface water;

[0044] (3) Slicing: Cut off the pedicles and tips of the two ends of the blanched okra tender pods, keep the uniform part in the middle for slicing, and control the slice thickness to 1-2cm;

[0045] (4) Quick freezing: place the sliced okra at -50°C for quick freezing for 10 hours;

[0046] (5) Pre-puffing by vacuum frying: deep-fry the quick-frozen okra fruit slices at a vacuum degree of -90 to -96 kPa and a temperature of 85°C for 5 minutes;

[0047] (6) Vacuum deoiling: In the same vacuum frying equipment, under the condition of keeping the vacuum constant, deoil the fried okra fruit slices at a speed of 300r / min for 5min to obtain 2.5kg of okra fruit slices;

[0048](7) Separation of f...

Embodiment 3

[0052] (1) Selection: select 20 kg of tender okra fruits with a length of 10 to 15 cm without pests and diseases and mechanical damage as raw materials;

[0053] (2) Blanching: Blanch the tender okra fruit in steam at 100°C for 2 minutes, then remove and drain the surface water;

[0054] (3) Slicing: Cut off the pedicles and tips of the two ends of the blanched okra tender pods, keep the uniform part in the middle for slicing, and control the slice thickness to 1-2cm;

[0055] (4) Quick-freezing: place the sliced okra at -30°C for 16 hours;

[0056] (5) Pre-puffing by vacuum frying: deep-fry the quick-frozen okra fruit slices at a vacuum degree of -90 to -96 kPa and a temperature of 75°C for 7 minutes;

[0057] (6) Vacuum deoiling: In the same vacuum frying equipment, under the condition of keeping the vacuum constant, deoil the fried okra fruit slices at a speed of 200r / min for 7 minutes to obtain 2.2kg of okra fruit slices;

[0058] (7) Separation of fruit seeds and spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com