Patents

Literature

47results about How to "No change in color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite fruit and vegetable crisp chip and manufacturing method thereof

The invention relates to a composite fruit and vegetable crisp chip and a manufacturing method thereof, especially to a composite fruit and vegetable crisp chip manufactured by using combined microwave vacuum freeze drying technology and vacuum low temperature frying technology, belonging to the field of food processing technology. The manufacturing method for the composite fruit and vegetable crisp chip comprises the following steps: preparation of condensed fruit and vegetable pulp; batching; batch mixing; die molding; microwave vacuum freeze drying; vacuum low temperature frying; etc. With the manufacturing method, generation of harmful substances like acrylamide and trans-fatty acids is reduced in the process of manufacturing, and the manufactured composite fruit and vegetable crisp chip has the advantages of crisp taste, a bright color, small nutrient loss, etc.

Owner:宁夏虹桥有机食品有限公司

Method for improving the freezing speed and quality of litchi chinensis through variable-frequency ultrasonic enhancement

ActiveCN103168828ASame sizeFast freezingFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingLoss ratePre treatment

The invention discloses a method of improving the freezing speed and quality of litchi chinensis through variable frequency ultrasonic enhancement. The method comprises the following steps: pretreating fresh litchi chinensis, precooling, adding refrigerating fluid for impregnating, and conducting variable-frequency ultrasonic treatment, namely treating for 20-60s under the frequency of 20-40kHz by adopting the ultrasonic wave with the power of 40-300W, and then increasing the frequency to 40-80kHz for treating for 20-60s under the equal power. With the method, the freezing speed of the litchi chinensis can be increased, the freezing time can be shortened, and unfrozen juice loss rate can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Pigment without lead for glass, and preparation method

Owner:淄博华为颜料有限公司

Quick-frozen daylily making method

InactiveCN102599233AMaintain structural propertiesMaintain nutrientsFruits/vegetable preservation by freezing/coolingBrowningProcess engineering

The invention belongs to the technical field of vegetable freezing and freshness preservation, and specifically relates to a quick-frozen daylily making method. The quick-frozen daylily making method comprises the steps of raw material screening, cleaning, scalding, color protecting, water draining, packaging, precooling, quick-freezing and freezing storage. According to the invention, a liquid immersion type quick-frozen technology is applied to the freshness preservation of daylily for the first time, therefore, the structure characteristics and nutritional components of daylily are kept maximumly; and through combining the scalding and the color protecting with the liquid immersion type quick-frozen technology, the problem that the previous daylily after being defrosted is easy to brown is solved; and in addition, equipment adopted in the invention is easy to control, and the method is low in energy consumption and suitable for the mass production of frozen daylily, therefore, the method creates a new way for the development of the daylily industry.

Owner:GUANGDONG KEQI SUPER QUICK FREEZING TECH

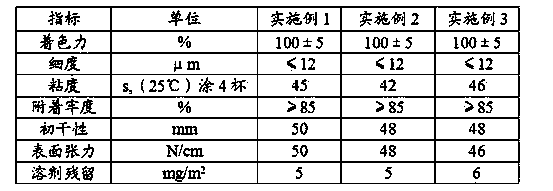

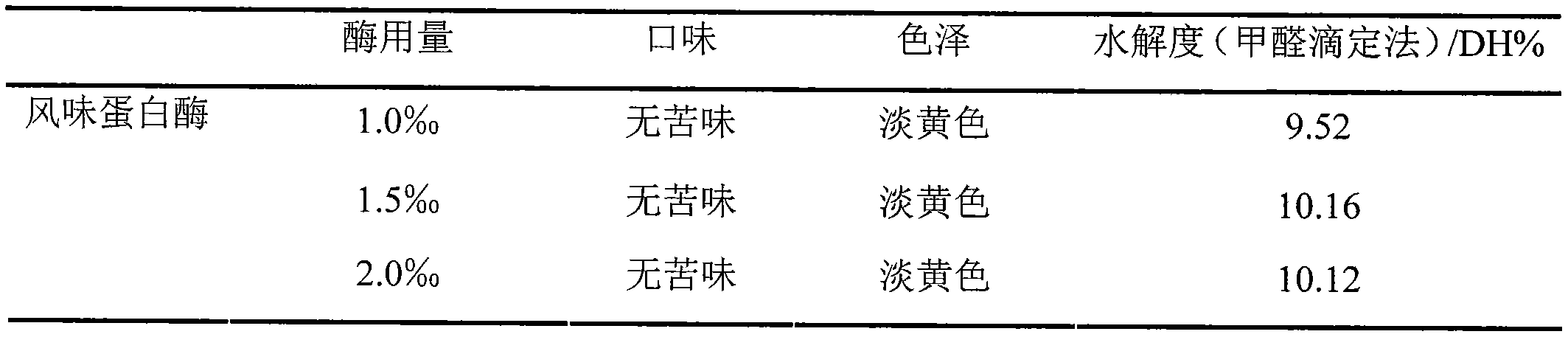

Benzene and ketone free high temperature resistant table printing ink

The invention discloses a benzene and ketone free high temperature resistant table printing ink. The benzene and ketone free high temperature resistant table printing ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-10 parts of a delustering agent, 0.3-0.6 parts of an antifoaming agent, 0.3-0.8 parts of a high temperature resistant assistant, and 1-2 parts of a curing agent. The adoption of a double liquid design increases the hardness and the adhesion of an ink film, effectively prevents offsetting or ink falling, realizes excellent high temperature and boiling resistances, and increases the shelf life of the printing ink.

Owner:SUZHOU ZHONGYA INK

Preparation method of pickled pepper type poultry product

The invention discloses a preparation method of pickled peppery type poultry product, comprising the following steps: sterilizing and disinfecting a multi-stage GMP (Good manufacturing practice) workshop, then washing, unfreezing, selecting and slitting poultry raw materials, washing again, then boiling the cleaned raw materials, washing the raw materials after being boiled, cooling, putting the raw materials into pre-prepared material water added with compound fresh-keeping color fixative, then taking out for vacuum packaging, and finally, radiating and sterilizing the materials. The pickledpeppery type poultry product prepared by the method is rich in nutrition, keeps the special mouthfeeling and flavor of the poultry product, the nutrition content and the flavor of the pickled pepperytype poultry product can be kept to the greatest degree, the shelf life of the product is prolonged, and as for the method, the process is simple and the investment cost is low.

Owner:ANHUI TRUELOVE FOODS

Cigarette paper

ActiveCN103362033AGood uniformityStable aroma componentsFlexible coversWrappersPaper sheetSmoke paper

The invention discloses a cigarette paper. Aroma extracts are prepared into microcapsules with sustained-release functions, then the microcapsules are applied to cigarette paper for addition of aroma, and the cigarette paper is obtained. The cigarette paper has advantages of stable aroma components, difficult volatilization and long aroma time. The cigarette paper is suitable for popularization and application in the cigarette paper manufacturing field.

Owner:GUANGZHOU AOJIAN PERFUME

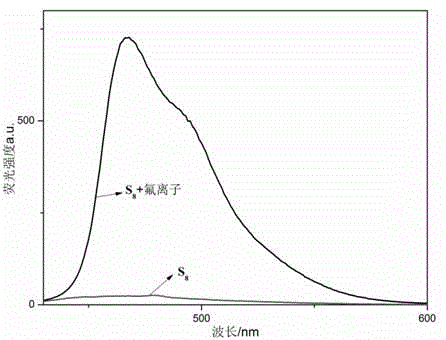

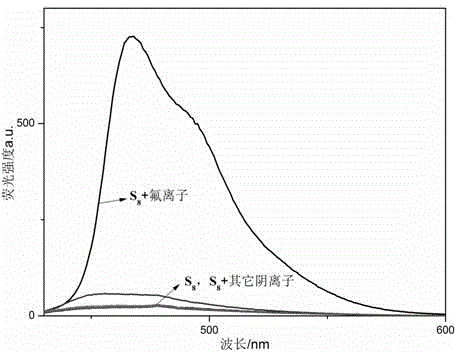

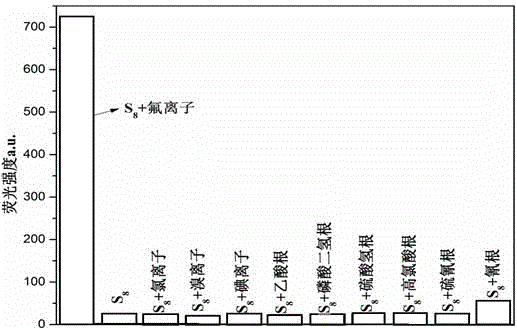

Double-schiff-base based on naphthol, synthesis thereof and application thereof as fluorinion sensor molecular

InactiveCN103822916ANo change in colorUndisturbedMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsUv absorbanceFluorescence

The invention relates to double-schiff-base based on naphthol, synthesis thereof and application thereof as a fluorinion sensor molecule. The invention provides the fluorinion sensor molecule, namely the double-schiff-base based on naphthol, wherein the double-schiff-base is faint yellow and almost free of fluorescence in a dimethyl sulfoxide solution; when fluorinions are added into the solution, the solution emits stronger blue fluorescence at the position of 467 nm immediately, the ultraviolet absorption spectrum of the solution has a red shift of 20 nm, and meanwhile the solution becomes deep yellow immediately; when other negative ions are added in, the fluorescence and color of the solution with the sensor molecule are not changed almost, so that the sensor molecule can identity fluorinions through single fluorescence, and the identification process cannot be disturbed by the other negative ions. Through titration experimental determination, the minimum detection line of the sensor molecule to the fluorinions can reach 1.4*10<-8> mol / L, which is far lower than the detection standard of fluorinions in drinking water, thus the double-schiff-base can be used for detecting the content of the fluorinions in the drinking water.

Owner:NORTHWEST NORMAL UNIVERSITY

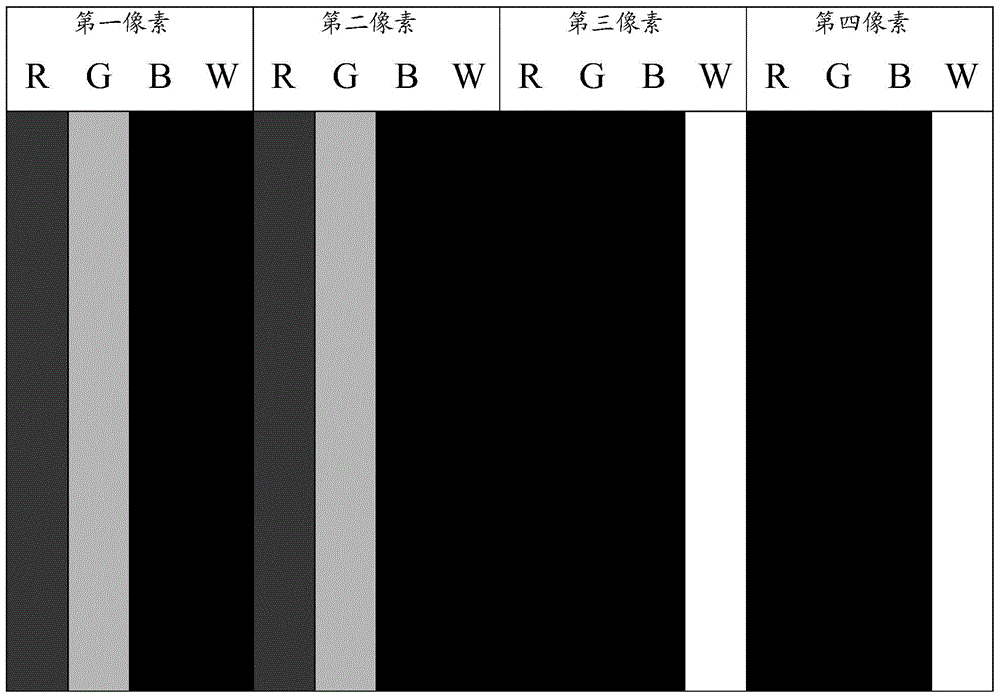

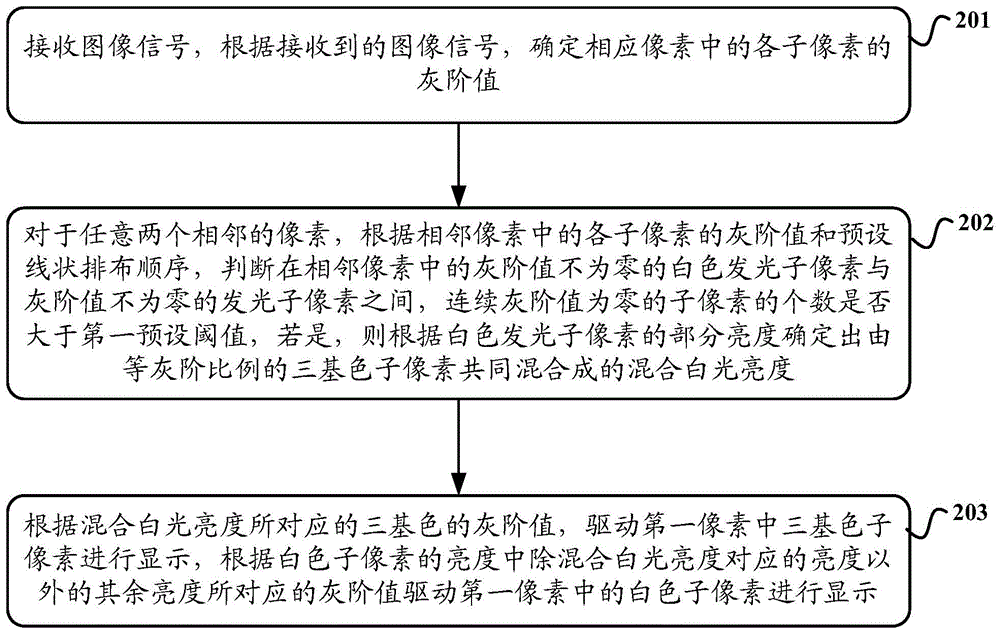

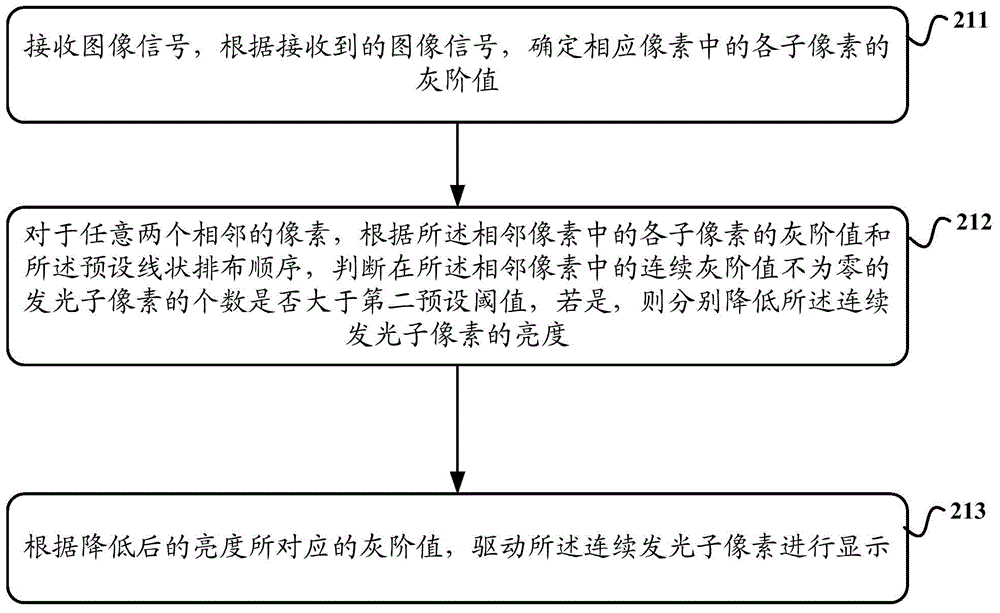

Image display driving method, image display driving device and image display driving equipment

ActiveCN104795015AReduce areaImprove displayCathode-ray tube indicatorsWhite lightBrightness perception

An embodiment of the invention discloses an image display driving method, an image display driving device and image display driving equipment, relates to the field of image processing, and aims to improve image display effect. The image display driving method includes according to gray-scale values and preset linear arrangement sequences of sub pixels in adjacent pixels, judging whether the number of the sub pixels, with the continuous gray-scale values being zero, between the white luminous sub pixels with the gray-scale values not being zero and the luminous sub pixels with the gray-scale values not being zero in the adjacent pixels is larger than a preset threshold value; if yes, determining mixed white light brightness formed by mixing of the three primary colors of sub pixels in equal gray-scale proportion according to partial brightness of the white luminous sub pixels; according to the gray-scale values of the three primary colors corresponding to the mixed white light brightness, driving the three primary colors of sub pixels in a first pixel to be displayed, and according to the gray-scale values corresponding to other brightness, except brightness corresponding to the mixed white light brightness, in the brightness of the white sub pixels, driving the white sub pixels in the first pixel to be displayed.

Owner:HISENSE VISUAL TECH CO LTD

Seleniferous film coating agent for fresh preservation of large cherry

ActiveCN103478241AExtended storage timeNo change in tasteFruits/vegetable preservation by coatingVitamin CPolyphenol

A seleniferous film coating agent for fresh preservation of a large cherry comprises 0.5-1.5% of chitosan, 0.1-0.3% of sodium alginate, 0.01-0.5% of tea polyphenol, 1-3% of calcium chloride, 1-3% of vitamin C, 3-8% of fructose, 1-5% of sodium chloride, 3-8% of alcohol, 2% of acetic acid, 30-50% of sponge gourd water and the balance of water. With the adoption of the agent for the fresh preservation of the large cherry, the large cherry is not required to be cleaned any longer and can be directly eaten; the cherry is directly rich in selenium and delicious in taste and supplements a microelement, namely selenium, simultaneously; the storage and fresh preservation time of the large cherry is prolonged and can be up to 2.5-3.5 months without flavor reversion, that is, a color, brittleness and taste of the large cherry are not changed basically; after the large cherry is soaked, fly maggots concealed in the cherry can be thoroughly soaked out; the long-term problems of the industry are solved; and the agent is harmless to a body and can even be directly drunk.

Owner:湖州优研知识产权服务有限公司

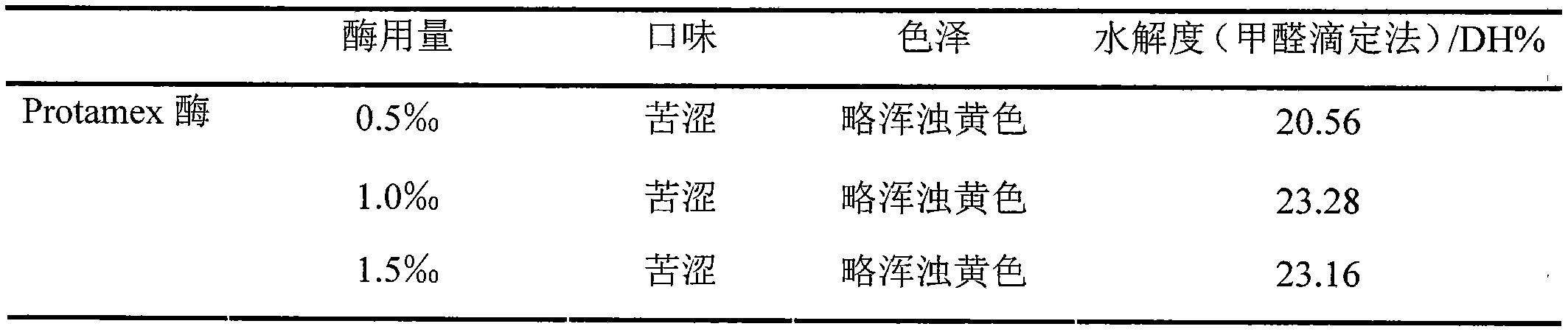

Chia seed polypeptide and preparation method thereof

ActiveCN104388507AIncrease the degree of hydrolysisNo change in colorPeptidesFermentationFlavorDissolution

The invention provides a chia seed polypeptide and a preparation method thereof. The preparation method comprises the following steps of (1) crushing chia seeds; (2) dissolving; (3) performing enzymolysis; (4) concentrating and drying to obtain the chia seed polypeptide, wherein the enzymolysis manner in the step (3) is adding protamex enzyme and flavourzyme. According to the chia seed polypeptide and the preparation method thereof, the content of the prepared polypeptide is more than 70%, the prepared polypeptide is solid powder, the luster is not changed, the product is not bitter and does not have off-flavor, the prepared polypeptide is easy to dissolve, and the dissolution speed is higher than the self dissolution speed of the chia seed.

Owner:INNER MONGOLIA QITE JINSHENG BIOTECH CO LTD +2

Cordyceps sinensis freeze-drying method for retaining cordyceps polysaccharide and SOD activity

InactiveCN108931109AThere is no change in appearanceNo change in colorDrying solid materials without heatPlant ingredientsFreeze-dryingAdditive ingredient

The invention discloses a cordyceps sinensis freeze-drying method for retaining cordyceps polysaccharide and SOD activity. Cordyceps sinensis is newly picked. The freeze-drying method specifically comprises the following steps that (1) raw materials are subjected to impurity removal and screening; (2) the raw materials are cleaned; (3) pre-freezing is carried out with the freezing temperature being -30 DEG C to -45 DEG C and the freezing time being 2-5 hours; (4) vacuum freeze drying is carried out, wherein the sublimation drying temperature is -25 DEG C to -30 DEG C, the freezing pressure is12-30 Pa, the drying time is 12-15 hours, the resolving temperature is 15-20 DEG C, the pressure is 18-30 Pa, and the time is 3-6 hours; (5) ozone sterilization is carried out; (6) finished cordycepssinensis products are obtained; and (7) the finished cordyceps sinensis products are subjected to vacuum packaging and normal-temperature storage. By means of the freeze-drying mode, internal molecular structures and nutrition ingredients of cordyceps sinensis can be completely retained, and the full shape and golden color of cordyceps sinensis can also be maintained.

Owner:重庆戴贺李生物科技有限公司

Preparation method of halogen-free flame retardant non-melting nylon66 fabric

InactiveCN103898744AImprove flame retardant performanceNo change in colorFibre typesHalogenCombustion

The invention relates to a manufacturing method of a halogen-free flame retardant non-melting nylon66 fabric, and belongs to the fields of flame retarding and modifying of fabrics. Firstly, the fabric is pretreated, then the fabric undergoes the processes of sufficient steeping and conventional steeping pressing with a nitrogen-phosphorus flame retardant containing PNF, AS and HEDP, and baking is carried out to firmly combine the flame retardant with the fabric so as to achieve the aims of retarding flame and preventing molten drop. The manufacturing method of the halogen-free flame retardant non-melting nylon 66 fabric is capable of overcoming the abuses that halogen is contained and the molten drop is serious in the prior art. Through the manufacturing method, the treated fabric has favorable flame retardance, and the color and the hand feel of the fabric have no obvious change; experiments show that the oxygen index value of the treated chinlon sample is improved from 21.1% to 26.0%; the vertical combustion results show that the damaged length of the treated chinlon fabric sample is reduced from 14.0cm to 10.6cm, the after flame time is shortened from 68.9s to 1.3s, the molten drop number during the combustion is decreased, the carbonization of the fabric is favorable, the dosage of the flame retardant is less, the process is simple and the cost is low, so that the method is an efficient flame retarding method.

Owner:BEIJING UNIV OF CHEM TECH

Benzene-free and ketone-free surface printing high temperature resistant ink

The invention discloses a benzene and ketone free high temperature resistant table printing ink. The benzene and ketone free high temperature resistant table printing ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-10 parts of a delustering agent, 0.3-0.6 parts of an antifoaming agent, 0.3-0.8 parts of a high temperature resistant assistant, and 1-2 parts of a curing agent. The adoption of a double liquid design increases the hardness and the adhesion of an ink film, effectively prevents offsetting or ink falling, realizes excellent high temperature and boiling resistances, and increases the shelf life of the printing ink.

Owner:SUZHOU ZHONGYA INK

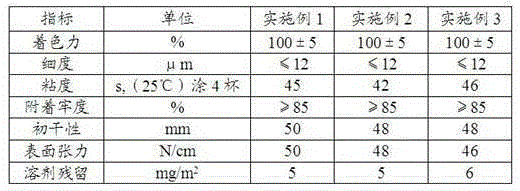

Moringa oleifera leaf drying method

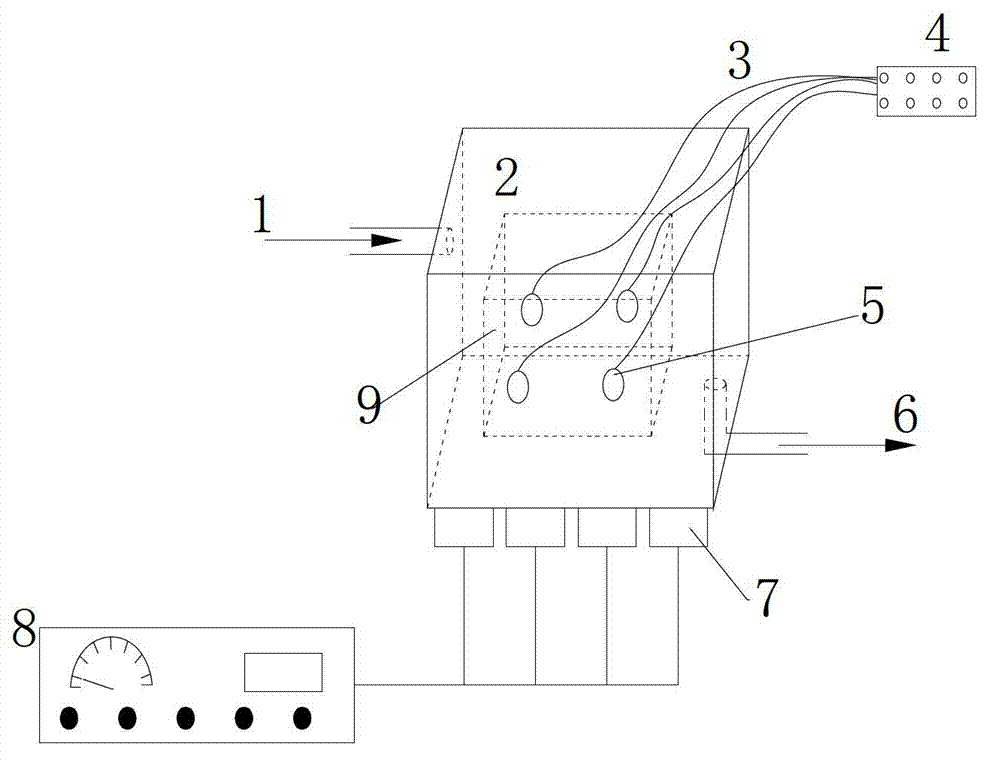

InactiveCN105660824AShort drying cycleSimple processFruits/vegetable preservation by dehydrationMicrowave cavityMORINGA OLEIFERA LEAF

The present invention discloses a moringa oleifera leaf drying method. The method comprises the following steps: (1) fresh moringa oleifera leaves are sent into a material distributing bin of a microwave drying device to conduct mechanical material distribution, and the moringa oleifera leaves are spread horizontally on a conveyor belt of the microwave drying device; (2) the distributed moringa oleifera leaves are transferred into a microwave cavity of the microwave drying device, the microwave is used to conduct drying, and at the same time, a dehumidifier is used to discharge moisture in the cavity of the microwave drying device; and until the moringa oleifera leaves are dried into a water content of 0.5%-3%, and the materials can be discharged at a material discharge temperature of 45-55 DEG C; and (3) the treated moringa oleifera leaves by the step (2) are sent into an ultrafine crusher to conduct crushing, and then the crushed materials are inspected and the inspected materials are packaged to obtain dried moringa oleifera leaf finished products. The drying method is short in time, simple in processes and high in efficiency. The dried moringa oleifera leaf finished products have basically unchanged color, are pure in color and luster, and less in nutritional active ingredient damage, and the obtained moringa oleifera leaf powder is high in nutritional quality.

Owner:HENAN BODA MICROWAVE EQUIP

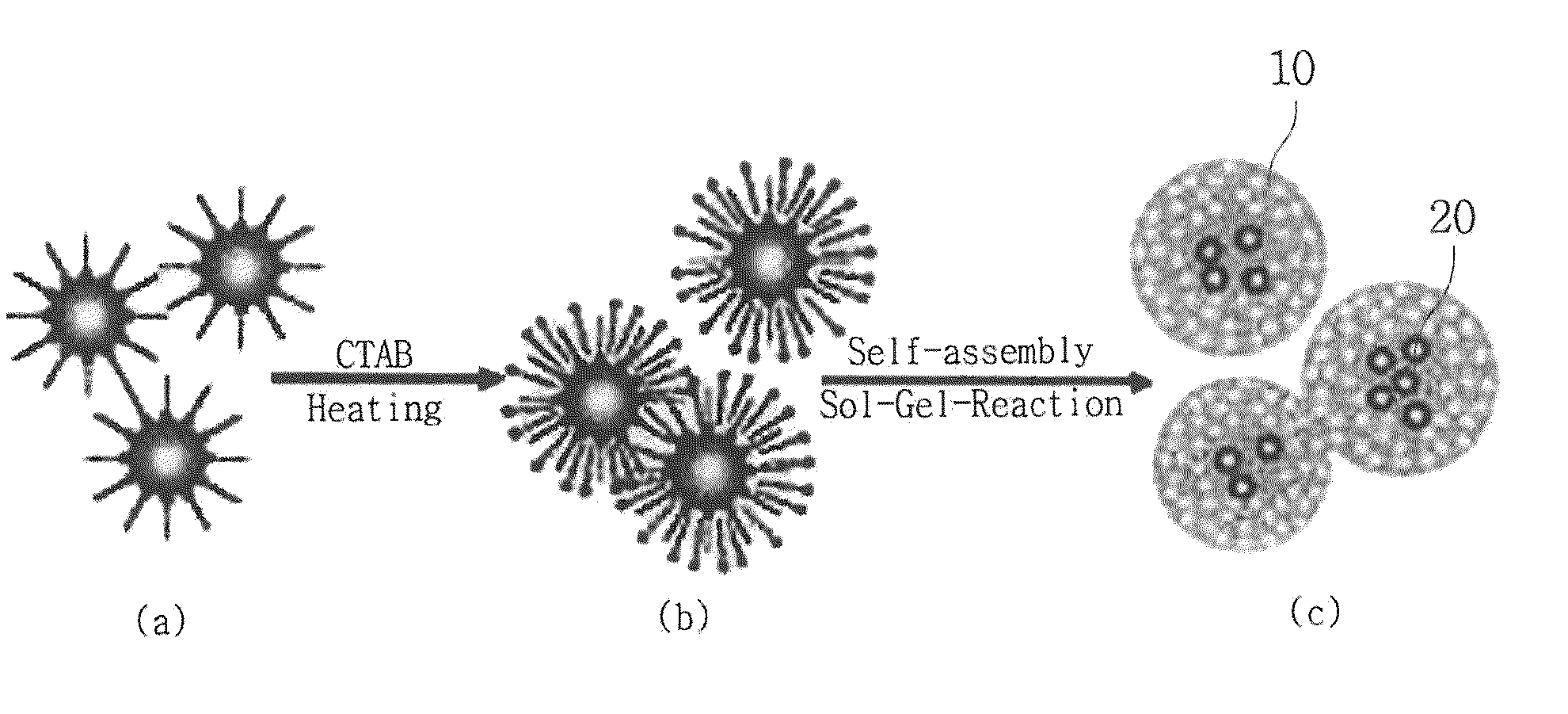

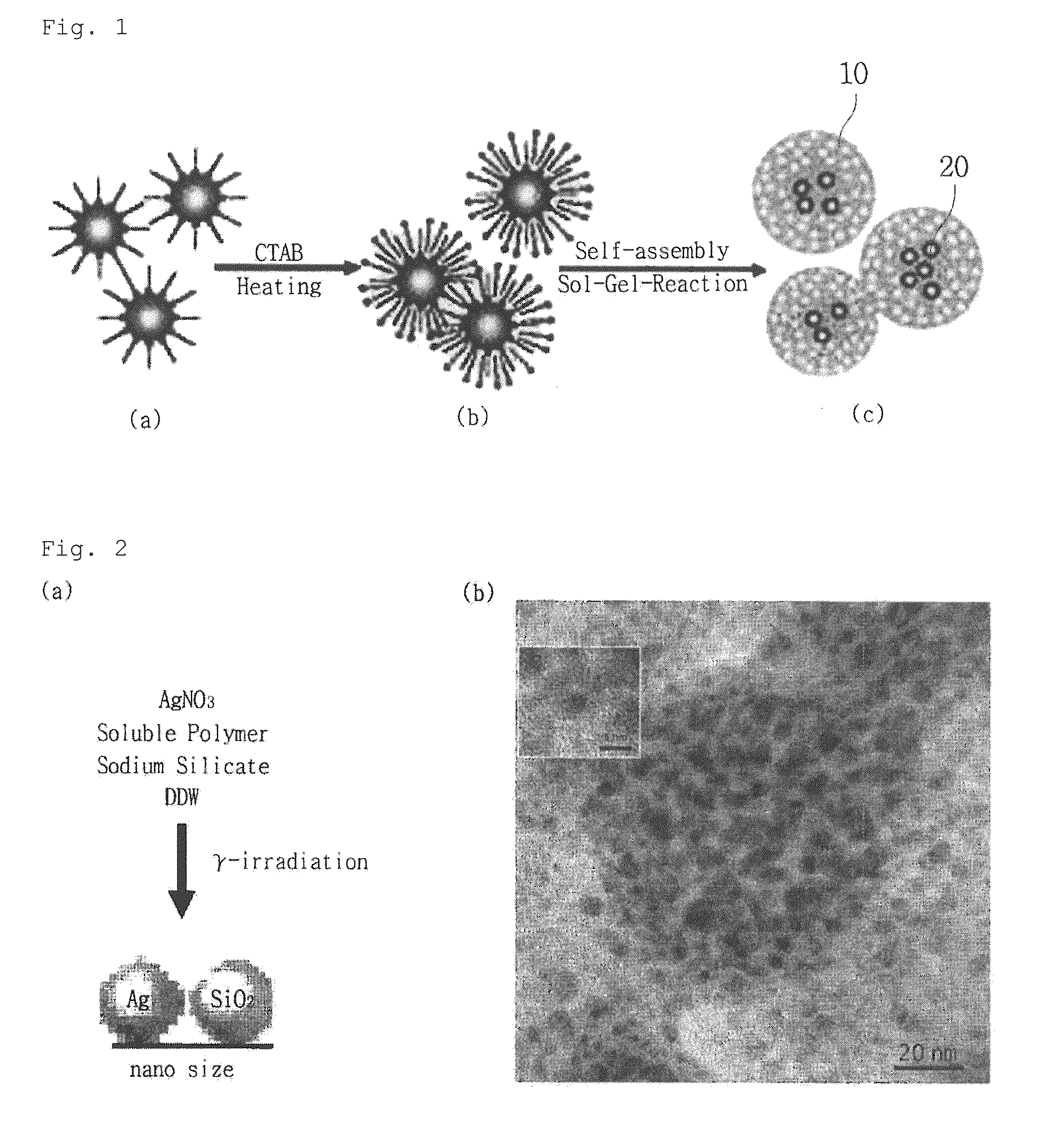

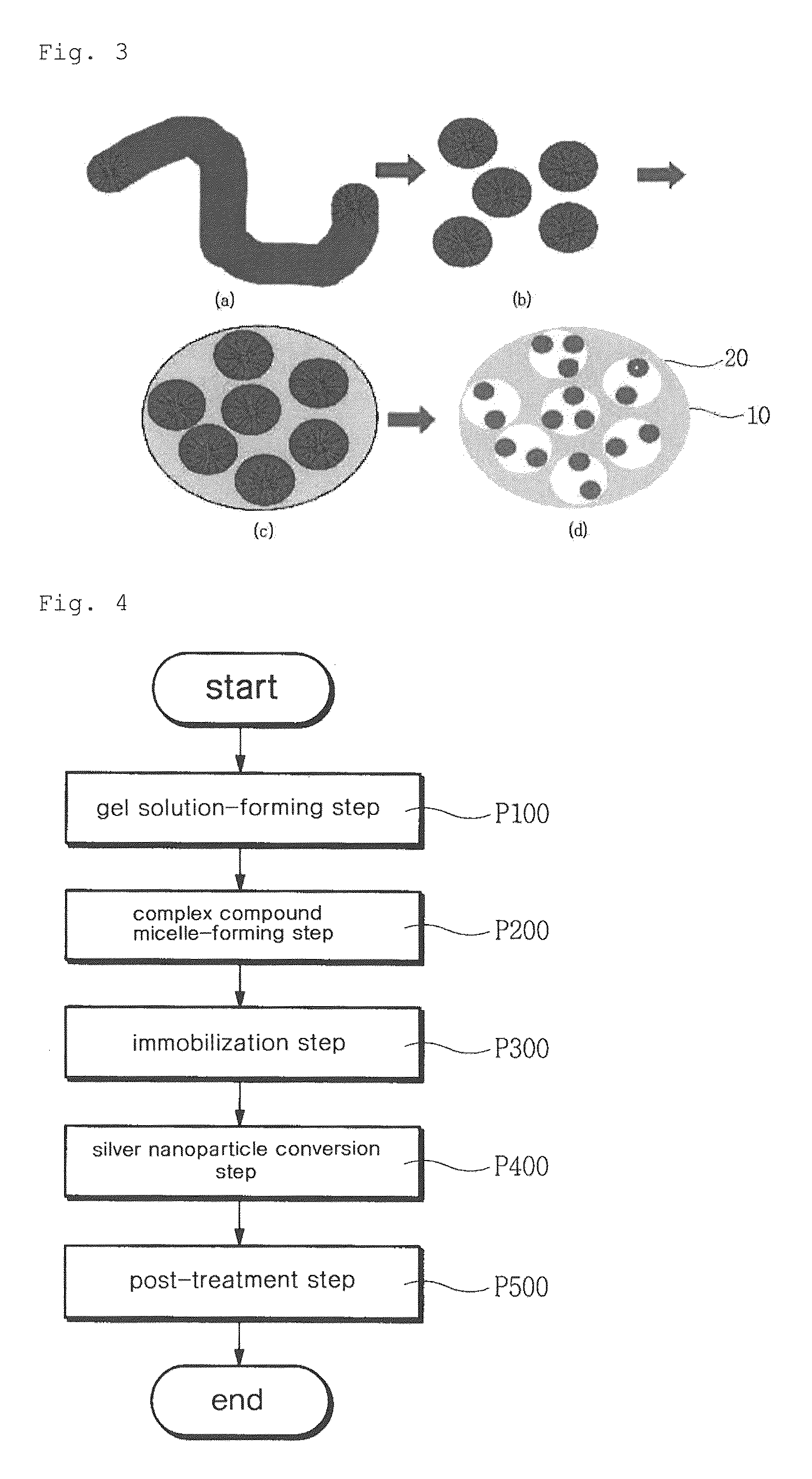

Method of manufacturing spherical mesoporous silica containing dispersed silver nanoparticles, and spherical mesoporous silica manufactured by said method

ActiveUS9040448B2No change in colorChange odorMaterial nanotechnologySilicaChange colorMesoporous silica

Owner:THERMOLON KOREA

PE whitening-resistant transparent priming paint

The invention discloses a PE whitening-resistant transparent priming paint. The PE whitening-resistant transparent priming paint comprises the following components in parts by weight: 30-70% of air-dried unsaturated polyester resin, 3-10% of acrylic acid ester, 0.01-2% of an antifoaming agent, 0.01-2% of a dispersant, 10-35% of a filling material, 0-2% of a wetting agent, 0.01-2% of a rheological auxiliary agent, 0.01-2% of a wax auxiliary agent, 0.01-2% of a hand feeling auxiliary agent, 0.01-2% of a thickening agent, and 5-10% of a solvent. The PE transparent priming paint makes a paint film to have better fullness, hardness, high chemically-resistant performance, strong whitening resistance, and excellent transparency. VOC volatilization is far lower than a national standard 420 mg / l, the PE transparent priming paint has low excitant smell, can effectively solve the problem that the product is severely influenced by whitening of a woodwork at anaphase, the PE transparent priming paint has excellent greening on a light color wood base material, and can satisfy the high environmental protection, low smell, and low pollution requirements for consumers.

Owner:HUIZHOU CHANGRUNFA PAINT

Dyeing and finishing method of all-cotton plain fabric

ActiveCN109594357ABright colorHigh glossMercerising of indefinite length fabricsBiochemical treatment with enzymes/microorganismsFormazanVinyl sulfone

The invention discloses a dyeing and finishing method of all-cotton plain fabric. The dyeing and finishing method comprises three processes: pretreatment, dyeing and after-finishing in sequence, wherein the pretreatment process comprises the following steps: singeing of gray fabric, enzyme pad steaming and desizing, boiling off, bleaching, mercerizing and polishing; the after-finishing process comprises the following steps: soft shaping and calendering; in the dyeing process, active dye with more than two active groups is adopted for dyeing, a parent structure of the active dye is anthraquinone, azobenzene, formazan or phthalocyanine; each of the active groups is selected from one or more of monochlorotriazine, monofluorintriazine, vinyl sulfone or difluoro monochloropyridine. The all-cotton plain fabric produced by adopting the dyeing and finishing method is bright in color and has better gloss; the color has no obvious change after the fabric is washed repeatedly.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

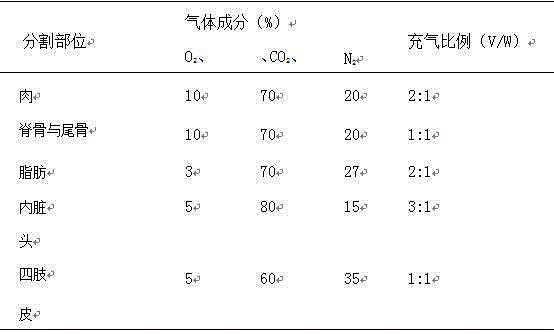

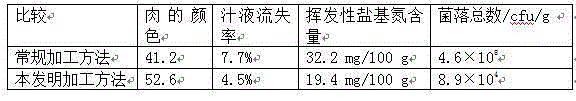

Preservative method of andrias davidianus chilled fresh cut meat through ternary-mixed modified atmosphere

ActiveCN105123886ANo significant change in smellNo change in colorMeat/fish preservation using chemicalsAfter treatmentMass ratio

The invention discloses a preservative method of andrias davidianus chilled fresh cut meat through ternary-mixed modified atmosphere. The method includes following steps: 1) performing after treatment of the steps of washing andrias davidianus and the like, cutting meat, claw and ribs into pieces being 1-10 cm in size, and soaking the cut meat into a sterilizing and disinfecting agent being 5-70 mg / l in concentration for 2-30 min; 2) treating the cut meat at -5 - 12 DEG C for 5-40 min; 3) packaging the treated andrias davidianus cut meat into plastic boxes and bags with water-absorbing and anti-bacterial paper placed under the meat; 4) performing gas-filled packaging with the gas including 5-50% of O2, 10-90% of CO2 and 50-70% of N2, wherein the mass ratio of filling amount to the meat is 0.2:1-10:1 (V / W); and 5) storing and transporting the packaged andrias davidianus cut meat at 0-4 DEG C. A test result proves that the smell, color and appearance of the andrias davidianus cut meat after preservation for 20 days does not changed obviously, wherein the total microbial count is lower than 5*10<5> cfu / g.

Owner:胡云峰

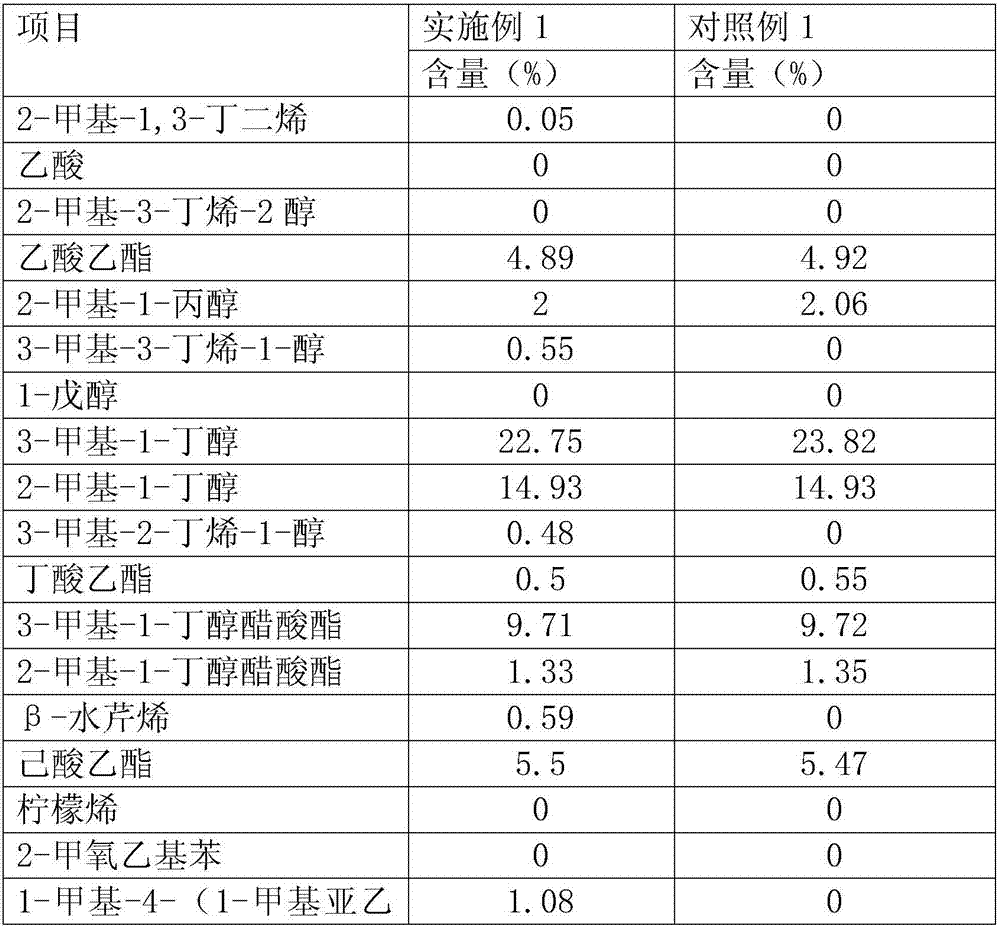

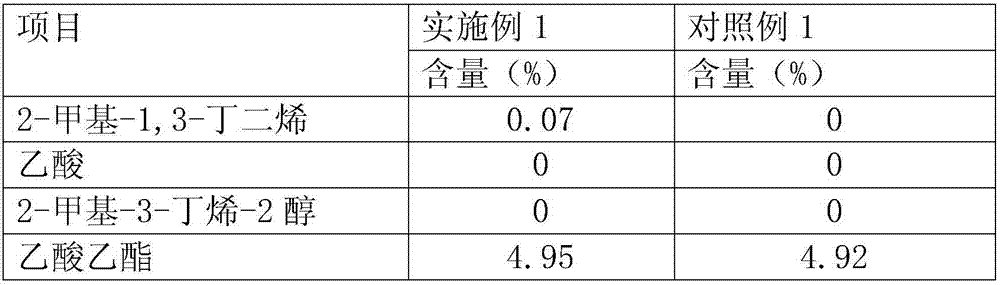

Fragrance enhancement method of litchi liquor

The invention discloses a fragrance enhancement method of litchi liquor. The fragrance enhancement method comprises the following steps of 1, shelling and stoning litchis, taking pulp and adding water to conduct pulping; 2, adjusting the pH value of litchi pulp, adding pectinase to conduct enzymolysis, and filtering enzymatic hydrolysate, wherein the filter liquid is litchi juice; 3, adjusting the sugar degree of the litchi juice to 16%-18%, inoculating active dry yeast, and conducting fermentation for 6-8 days to obtain primary liquor; 4, adjusting the pH value of the primary liquor to 4.0-5.0, adjusting the sugar degree to 6%-8%, inoculating the active dry yeast, and continuing to conduct fermentation for 2-3 days to obtain secondary liquor; 5, adjusting the pH value of the secondary liquor to 4.0-5.0, adjusting the sugar degree to 16%-18%, inoculating the active dry yeast, and continuing to conduct fermentation for 6-8 days to obtain tertiary liquor; 6, conducting centrifugal filtration on the tertiary wine, and conducting aging, so that the litchi liquor is obtained. According to the fragrance enhancement method, the fragrance can be enhanced, the alcoholic strength of the fermentation broth is not influenced, the wine fragrance of the fermentation broth is stronger, and the color of the liquor is not obviously changed.

Owner:GUANGXI YUNHENG WINERY

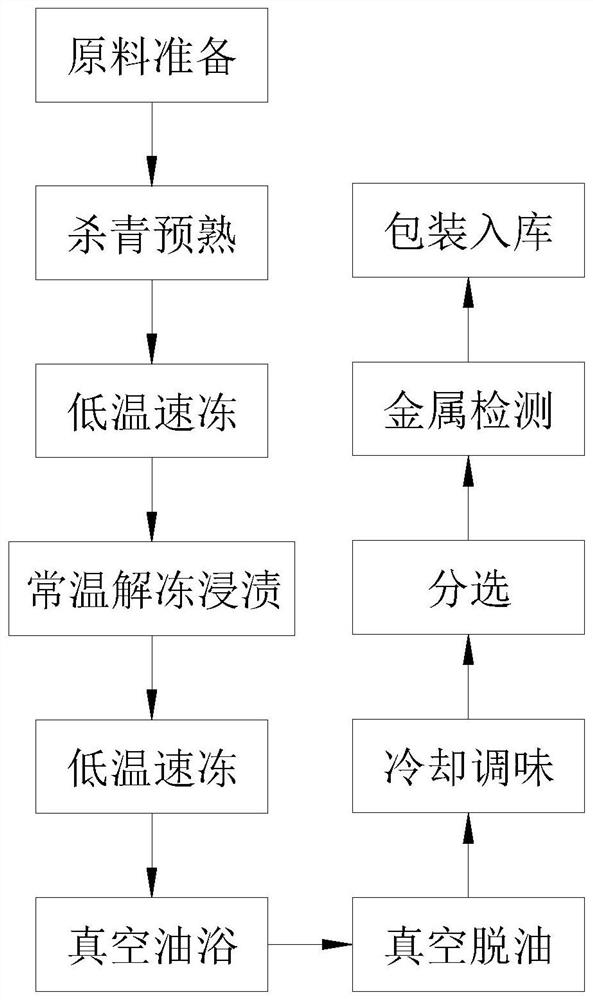

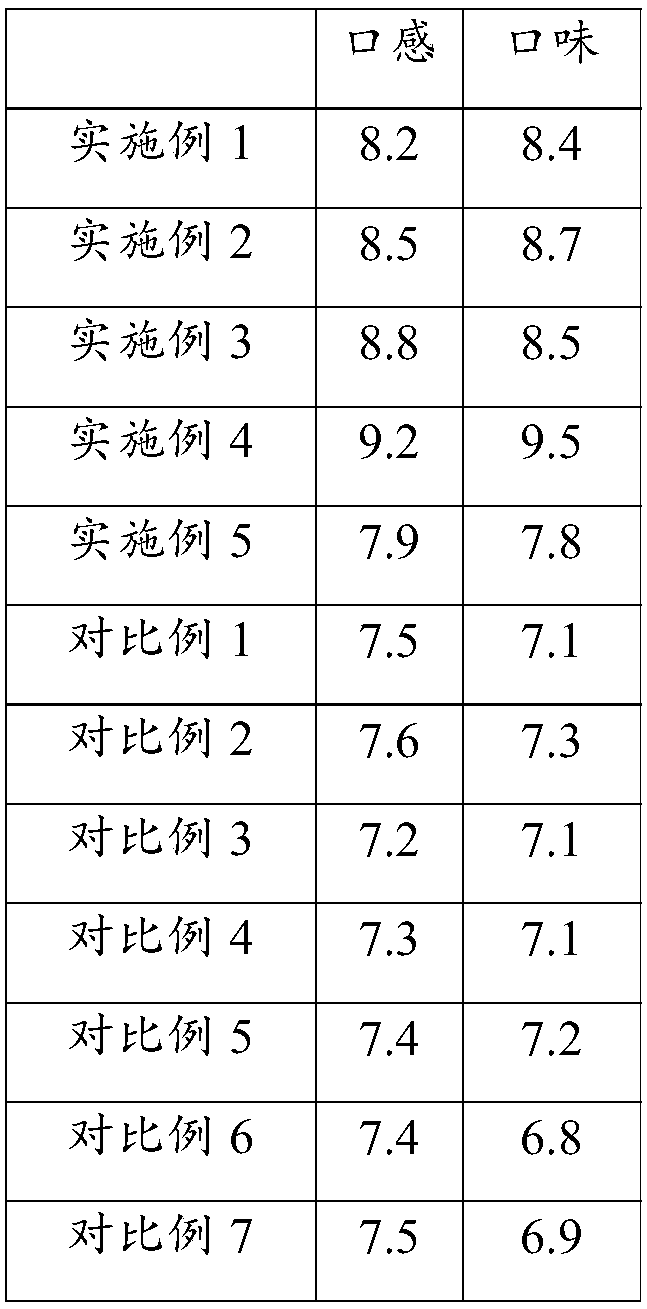

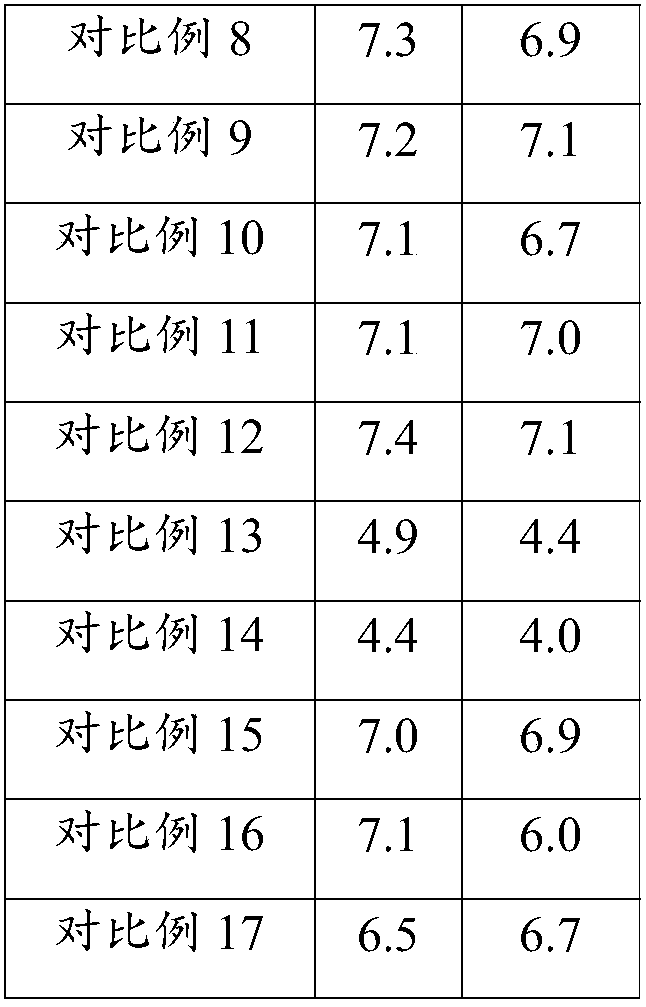

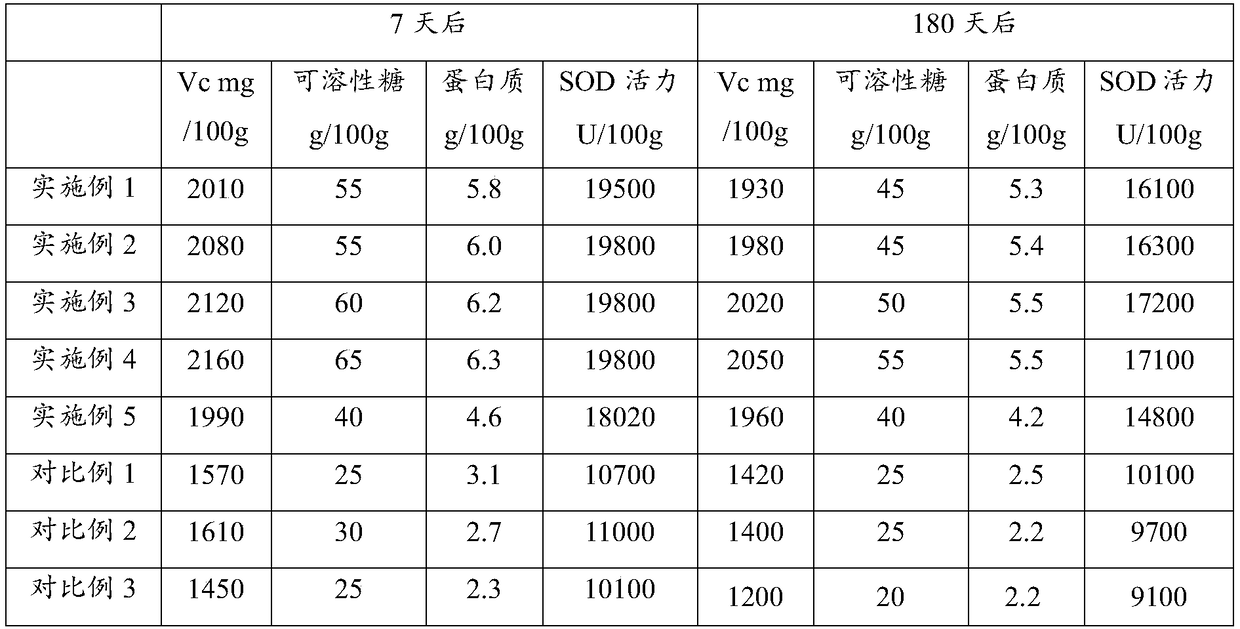

Processing method of instant tricholoma matsutake

PendingCN113519827AThe taste is crispy, sweet and deliciousNutrients are not lostFood freezingFood thermal treatmentTricholoma matsutakeNutrition

The invention is suitable for the technical field of food processing, and provides a processing method of instant tricholoma matsutake, which comprises the following steps: step 1, preparing raw materials; step 2, performing fixation and pre-cooking; step 3, performing low-temperature quick freezing; step 4, unfreezing and dipping under normal pressure; step 5, performing low-temperature quick-freezing; step 6, carrying out vacuum oil bath; step 7, deoiling in vacuum; step 8, cooling and seasoning; step 9, sorting; step 10, carrying out metal detection; and step 11, packaging and warehousing. The raw materials are treated in a root cutting and cleaning manner, and the frozen product is fluffy in internal tissue structure and forms reticular crystals through a flow-state low-temperature quick-freezing tunnel, so that the original shape and color of the product can be better maintained, and the purposes of keeping fresh at low temperature and preventing nutrition loss are achieved. And normal-temperature running water is adopted for slow thawing and unfreezing in a normal atmospheric pressure environment, so that the internal organization structure of the product cannot be damaged. The red tricholoma matsutake tastes crisp, sweet and delicious, the nutrition of the red tricholoma matsutake is greatly reserved, the nutrient components are basically not lost, more than 90% of the nutrient components are reserved, and the color, taste and shape of the red tricholoma matsutake are not changed.

Owner:涿州秋实农业科技有限公司 +1

Method for processing candied jujubes with quick-frozen jujubes

InactiveCN102342319AReduce processing timeLess nutrient lossClimate change adaptationFruits/vegetable preservation by freezing/coolingSucroseSaccharum

The invention discloses a method for processing candied jujubes with quick-frozen jujubes. The method is characterized by comprising the following steps: washing the selected red jujubes until the red jujubes are clean, denucleating and slotting the red jujubes and then quickly freezing the red jujubes, putting the red jujubes in a material box of a vacuum impregnation tank, completing thawing and first-step sugar soaking of the quick-frozen jujubes in mixed liquor of cane sugar with mass concentration being 20-30% and salt with mass concentration being 0.5-1% simultaneously, then sucking 30-40% of sugar liquor, carrying out vacuum impregnation for 2-2.5 hours, taking out and draining the impregnated red jujubes and carrying out vacuum drying at a pressure of 50-600Pa and temperature of 30-50 DEG C for 1.5-2 hours, thus obtaining the candied jujubes. The method has the following beneficial effects: the quick-frozen jujubes are adopted as the raw materials, thus prolonging the processing time of the candied jujubes to a great degree and realizing production all year round; and vacuum thawing and vacuum impregnation are carried out simultaneously, thus shortening the processing time and furthest maintaining the original flavors, quality and nutrients of the original fruits and vegetables.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparingarbutus jamand prepared arbutus jam

The invention provides a method for preparing arbutus jam and preparedarbutus jam, and relates to the technical field of jam preparation, and the method includes providing arbutus stamens, arbutus leaves and arbutus fruits; the arbutus stamens andarbutus leaves are mixed with powder including salepeptidase, soybean phospholipid powder and oat fiber powder and are pulverized by a high-frequency resonance mill to obtain floral leaf micro powder. The arbutus fruitsare placed in an immersion solution B including pineapple enzyme solution and glycerol monooleate for one night, and then freeze-dried, pulverized at a lowtemperature and pulverized at a lowtemperature by using supersonic airflow to obtain fruit micro powder. Mixture E is obtained by mixing the floral leaf micro powder and fruit micro powder with apple mud, adding lemon juice and sugar, introducing nitrogen, and carrying out high-voltage pulsed electric field treatment and magnetic field treatment. The arbutus jam is obtained byadding a thickener. The arbutus jam has natural aroma of fruits and rich nutrition,has a health-care function, and has little nutrient loss after a long time.

Owner:徐丽琴

A kind of preparation method of halogen-free flame-retardant non-melting nylon 66 fabric

InactiveCN103898744BImprove flame retardant performanceNo change in colorFibre typesCooking & bakingHalogen

The invention relates to a manufacturing method of a halogen-free flame retardant non-melting nylon66 fabric, and belongs to the fields of flame retarding and modifying of fabrics. Firstly, the fabric is pretreated, then the fabric undergoes the processes of sufficient steeping and conventional steeping pressing with a nitrogen-phosphorus flame retardant containing PNF, AS and HEDP, and baking is carried out to firmly combine the flame retardant with the fabric so as to achieve the aims of retarding flame and preventing molten drop. The manufacturing method of the halogen-free flame retardant non-melting nylon 66 fabric is capable of overcoming the abuses that halogen is contained and the molten drop is serious in the prior art. Through the manufacturing method, the treated fabric has favorable flame retardance, and the color and the hand feel of the fabric have no obvious change; experiments show that the oxygen index value of the treated chinlon sample is improved from 21.1% to 26.0%; the vertical combustion results show that the damaged length of the treated chinlon fabric sample is reduced from 14.0cm to 10.6cm, the after flame time is shortened from 68.9s to 1.3s, the molten drop number during the combustion is decreased, the carbonization of the fabric is favorable, the dosage of the flame retardant is less, the process is simple and the cost is low, so that the method is an efficient flame retarding method.

Owner:BEIJING UNIV OF CHEM TECH

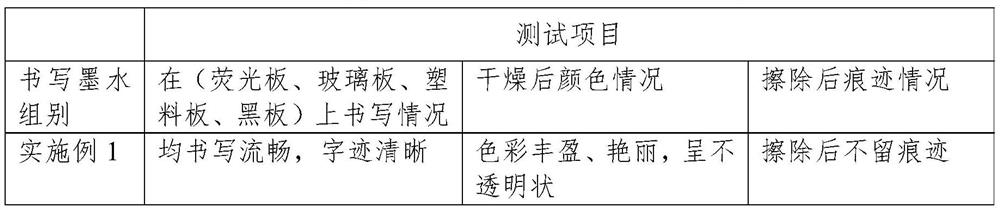

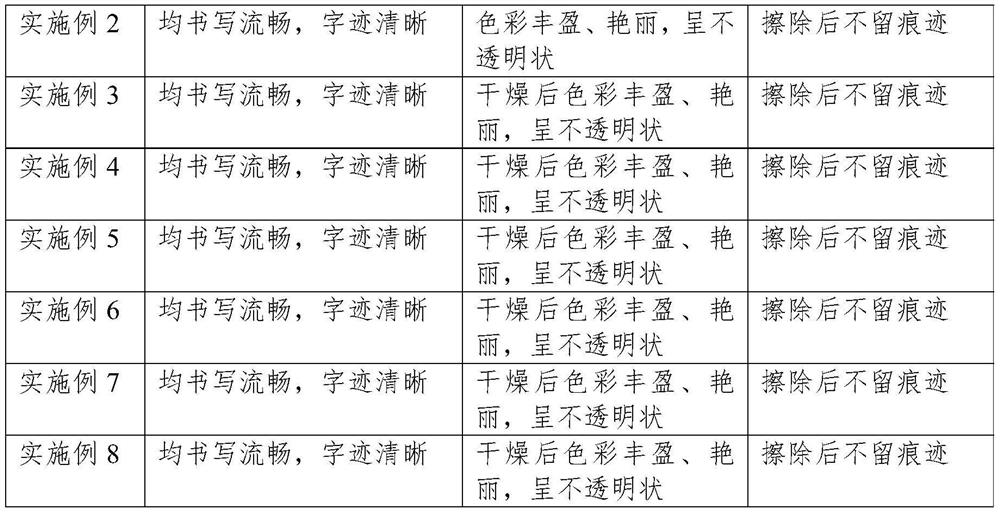

Special water-based fluorescent ink for fluorescent screen and preparation method of ink

The invention discloses special water-based fluorescent ink for a fluorescent screen and a preparation method of the special water-based fluorescent ink, and the special water-based fluorescent ink comprises the following components in percentage by weight: 15-35% of a fluorescent color paste, 2-8% of a wetting dispersant, 10-20% of a covering, 0.5-5% of an anti-settling assistant, 0.03-0.1% of bactericide, 2-8% of film-forming resin, 1-5% of a wetting leveling agent and the balance of deionized water. The preparation method of the water-based fluorescent ink comprises the following steps: adding the wetting dispersant and the deionized water into a reaction kettle at the same time, then stirring for 1-2h at room temperature, and adding the fluorescent color paste; and under the conditionof stirring, sequentially adding the covering and the anti-settling additive, and finally adding the bactericide, the film-forming resin and the wetting leveling agent. The formula is reasonable in design, writing on the fluorescent screen can be smooth and smooth, the color is bright, handwriting is clear, and no trace is left after erasing; and the ink is also suitable for writing on smooth surfaces of glass plates, plastic plates, blackboards and the like with various colors, and the dried color is rich and bright.

Owner:SHANGHAI NNW NEW MATERIALS TECH

Method for processing mellow-thick green tea

InactiveCN106031395APromote dissolutionNo change in colorPre-extraction tea treatmentMicrowaveHigh power density

The invention discloses a method for processing mellow-thick green tea, and relates to a tea processing method. The method aims at achieving the aim that on the basis of keeping the quality of traditional tea, the concentration of tea soup of upscale green tea is increased. The processing method includes the following steps that fresh leaves are fixed through a fixing machine, then tissue cracking is conducted through microwaves, the cracked tea is quickly frozen and cooled, the quickly-frozen tea is shaped, and finally refiring is carried out till the tea is adequately dry. The method has the advantages that the fixed leaves are heated through the high-power-density microwaves, moisture contained in cells of the fixed leaves is rapidly heated and gasified, cell walls are broken through gasifying, tea cell contents can be conveniently dissolved out during brewing, and therefore the effect of increasing the concentration of the tea soup is achieved.

Owner:孙永华

Brewing method of litchi wine

The invention discloses a brewing method of litchi wine. The method includes the steps of: 1) removing peel and pits from litchis, taking the litchi flesh and adding water for beating; 2) adjusting the pH value of the litchi pulp to 4.0-5.0, also adjusting the sugar content to 16-18%, inoculating active dry yeast that is 0.01-0.02% of the weight of the litchi pulp, and conducting fermentation at 20-25DEG C for 6-8d so as to obtain raw wine; 3) adjusting the pH value of the raw wine to 4.0-5.0, adding pectinase, and performing enzymolysis at 40-45DEG C for 20-30min so as to obtain enzymatic hydrolysate; 4) adjusting the pH value of the enzymatic hydrolysate to 4.0-5.0, and further conducting fermentation at 20-25DEG C for 1-3d, thus obtaining secondary wine; and 5) carrying out centrifugal filtration and ageing on the secondary wine, thus obtaining the litchi wine. The fermentation method provided by the invention can retain the characteristic natural aroma of litchi, and the prepared litchi wine has harmonious wine aroma and fruity flavor, and no influence is produced on the alcohol content of the fermented matters, also the color of the wine liquid has no obvious change.

Owner:GUANGXI YUNHENG WINERY

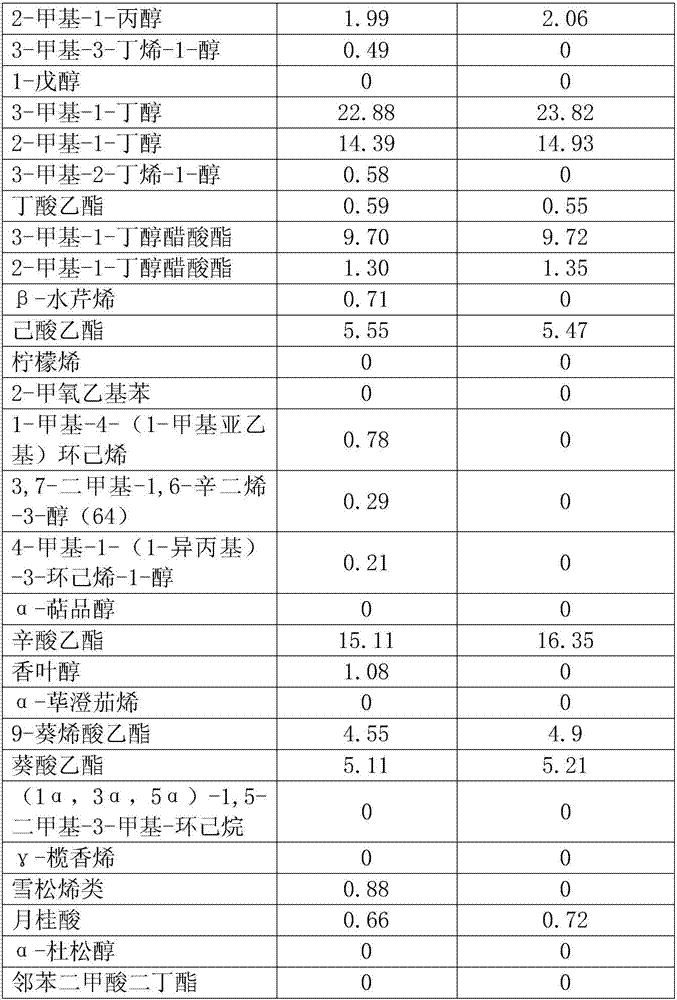

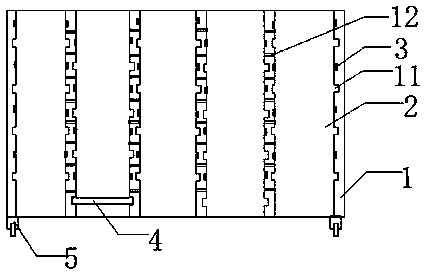

Storage and fresh keeping method of color peppers

InactiveCN107897347AImprove qualityNo change in colorFruit and vegetables preservationFood ingredientsLED lampComputer science

The invention belongs to the technical field of storage and fresh keeping of color peppers, and particularly relates to a storage and fresh keeping method of color peppers. The color peppers are stored in a constant-temperature constant-humidity room, the picked color peppers are stored in the constant-temperature constant-humidity room through storage frames, each storage frame is divided into aplurality of storage cavities through vertical baffles, a sliding chute is arranged at a position at the equal height with the opposite surface of every two adjacent partition boards, a placing boardis arranged in each sliding chute, a plurality of round through holes are uniformly formed in each placing board, a string bag is arranged in each round through hole, and a plurality of red LED lampsof which the wave length is 620nm are uniformly distributed on each vertical baffle above the corresponding sliding chute. Compared with the prior art, the storage and fresh keeping method has the following advantages that through the adoption of the method, the storage period can be prolonged based on avoiding secondary pollution, water losses in the fresh keeping process of the color peppers arelow, the nutrition maintaining degree is good, the stored color peppers are good in quality, basically unchanged in color, simple in operating method and low in energy consumption, and the fresh keeping quality of the color peppers is improved.

Owner:陈玉海

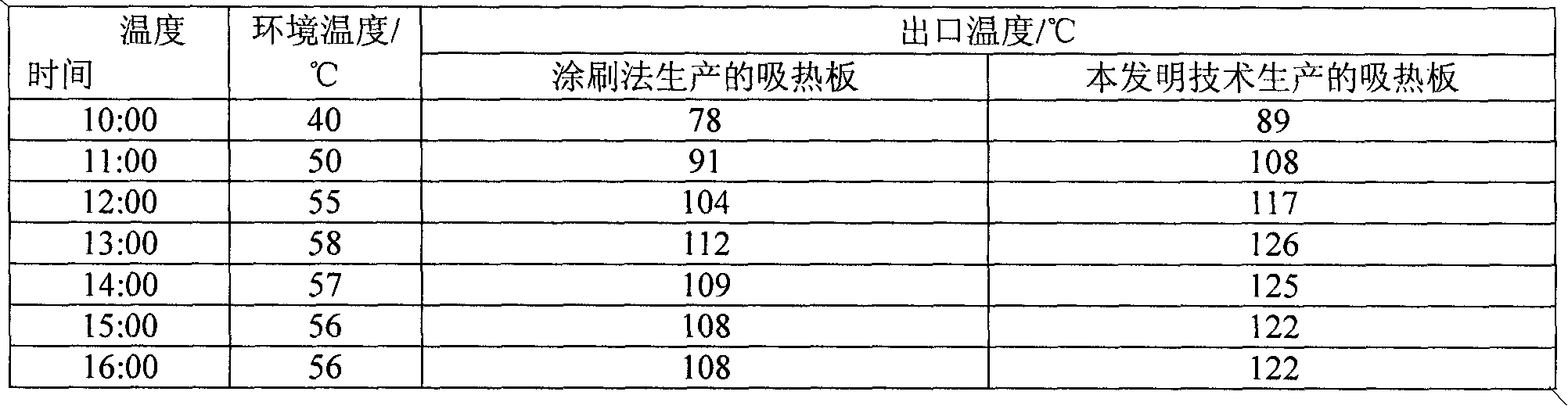

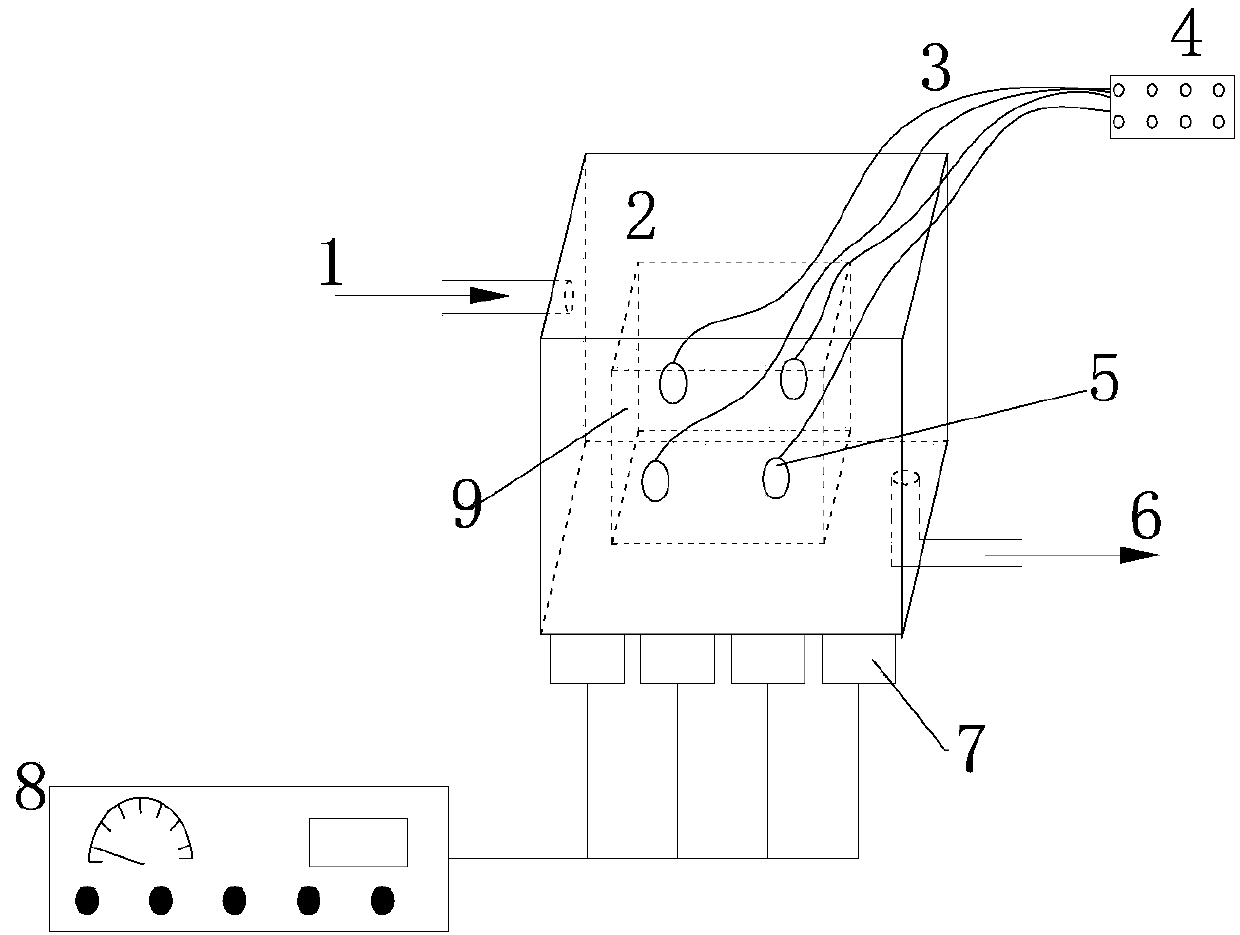

Production method of solar absorber plate

InactiveCN101818374AFast formingExtend the life cycleSurface reaction electrolytic coatingManganese sulphateSolar air collector

The invention discloses a production method of a solar absorber plate, which aims at solving the deficiency of the preparation process technology of the existing solar selective absorbing coating, difficult realization of preparation of large-area coating with the existing process technology, and high manufacturing cost. The production method comprises the following steps: taking a chrome-base alloy steel plate as a matrix material; pre-processing the plate such as de-oiling, polishing, activating, washing and the like; taking nitric acid, manganese sulphate, ammonium nitrate and the like as main coloring agents, and then coloring by chemical oxidation blackening; and finally performing chemical solidification and seal treatment to obtain the chrome-base alloy steel solar absorber plate with uniform bright-black conversion coating on the surface. The chrome-base alloy steel solar absorber plate has the characteristics of high thermal absorption rate and low emission rate, can be taken as the solar absorber plate for solar photo-thermal conversion, and can be widely applied to solar heat utilization equipment such as a flat-plate solar air collector, a solar water heater and the like.

Owner:GANSU JINSHI CHEM

Method for improving the freezing speed and quality of litchi chinensis through variable-frequency ultrasonic enhancement

ActiveCN103168828BSame sizeFast freezingFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingLoss ratePre treatment

The invention discloses a method of improving the freezing speed and quality of litchi chinensis through variable frequency ultrasonic enhancement. The method comprises the following steps: pretreating fresh litchi chinensis, precooling, adding refrigerating fluid for impregnating, and conducting variable-frequency ultrasonic treatment, namely treating for 20-60s under the frequency of 20-40kHz by adopting the ultrasonic wave with the power of 40-300W, and then increasing the frequency to 40-80kHz for treating for 20-60s under the equal power. With the method, the freezing speed of the litchi chinensis can be increased, the freezing time can be shortened, and unfrozen juice loss rate can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com