Method for preparingarbutus jamand prepared arbutus jam

A fruit-to-mass ratio technology, applied in food science and other directions, can solve the problems of uneven nutrient composition, short storage time, single species, etc., and achieve the effect of improving nutrient content, good quality of raw materials, and reducing damage and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] According to one aspect of the present invention, a kind of preparation method of red bayberry sauce is provided, and described preparation method comprises:

[0039] (a) providing bayberry stamens, bayberry leaves and bayberry fruit;

[0040] (b) mix bayberry stamens and bayberry leaves with mixed powder A according to the mass ratio of 1-3:3-8:0.5-1.5, carry out high-frequency resonance milling and pulverize to 0.2-1 μm, and obtain flower leaf micropowder;

[0041] Mixed powder A comprises serrapeptase, soybean lecithin powder and oat fiber powder;

[0042] (c) After removing the core and cleaning the red bayberry fruit, place it in the soaking solution B overnight, and the soaking solution B includes pineapple enzyme solution and glycerol monooleate; freeze-dry the soaked red bayberry fruit, and crush it at low temperature to obtain 150-200 mesh fruit powder; then crush the fruit powder to 0.6-2 μm by low-temperature supersonic airflow to obtain fruit powder;

[00...

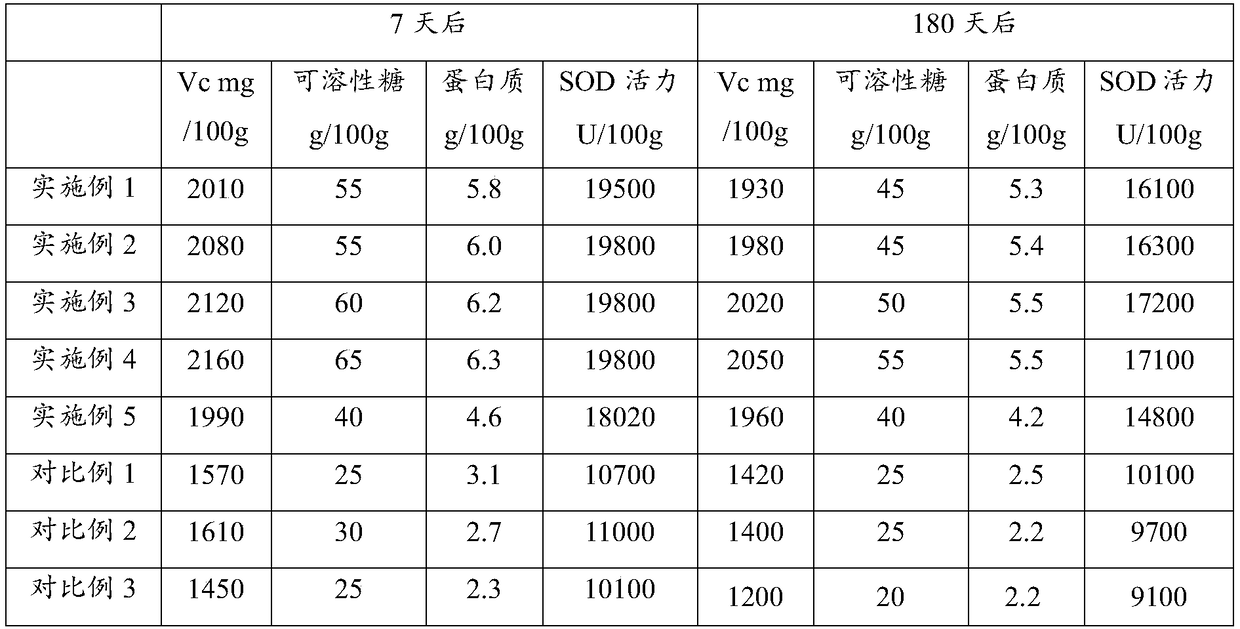

Embodiment 1

[0113] A preparation method of red bayberry sauce, comprising the following steps:

[0114] (a) providing bayberry stamens, bayberry leaves and bayberry fruit;

[0115] (b) Mix bayberry stamens and bayberry leaves with mixed powder A according to the mass ratio of 1:8:0.5, and carry out high-frequency resonance milling to pulverize to 0.2-1 μm to obtain flower leaf micropowder;

[0116] Mixed powder A includes serrapeptase, soybean lecithin powder and oat fiber powder at a ratio of 2:1:1; the temperature of high-frequency resonance mill grinding is 20°C; the vibration frequency is 40Hz; the amplitude is 5mm; the vibration intensity is 45G ;

[0117] (c) After removing the core and cleaning the red bayberry fruit, place it in the soaking solution B overnight. The soaking solution B includes pineapple enzyme solution and glycerol monooleate with a mass ratio of 10:5; the soaked red bayberry fruit is frozen Drying and crushing at low temperature to obtain coarse fruit powder of...

Embodiment 2

[0125] A preparation method of red bayberry sauce, comprising the following steps:

[0126] (a) providing bayberry stamens, bayberry leaves and bayberry fruit;

[0127] (b) Mix bayberry stamens and bayberry leaves with mixed powder A according to the mass ratio of 3:3:1.5, and carry out high-frequency resonance milling to pulverize to 0.2-1 μm to obtain flower leaf micropowder;

[0128] Mixed powder A includes serrapeptase, soybean lecithin powder and oat fiber powder with a ratio of 5:0.5:1.5; the temperature of high-frequency resonance mill grinding is -10°C; the vibration frequency is 50Hz; the amplitude is 1mm; the vibration intensity is 25G;

[0129] (c) After removing the core and cleaning the red bayberry fruit, place it in the soaking solution B overnight. The soaking solution B includes pineapple enzyme solution and glycerol monooleate with a mass ratio of 15:2; the soaked red bayberry fruit is frozen Drying and crushing at low temperature to obtain coarse fruit pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com