Method for improving the freezing speed and quality of litchi chinensis through variable-frequency ultrasonic enhancement

A frequency conversion ultrasonic, freezing speed technology, applied in the preservation of fruits/vegetables by freezing/refrigeration, food preservation, preservation of fruits/vegetables by radiation/electrical treatment, etc., can solve the problem of slow freezing speed, damage to cell membrane and structure, and high energy consumption and other problems, to achieve the effect of increased freezing speed, reduced juice loss, and more consistent size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

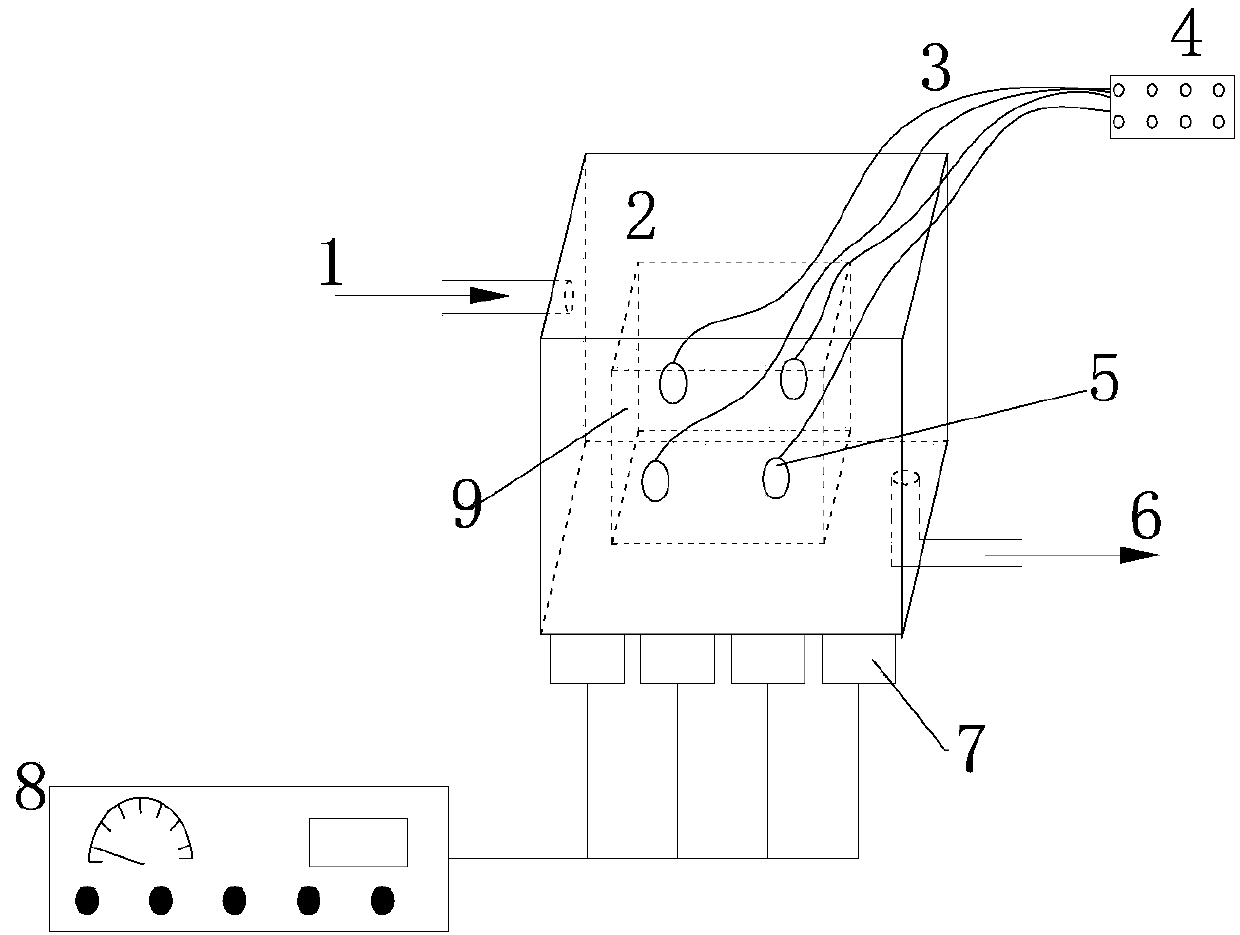

[0030] figure 1 It is a schematic diagram of the ultrasonic treatment device used in this embodiment. As shown in the figure, it includes an ultrasonic treatment tank 2, a T-type thermocouple 3, a multi-channel data recorder 4, a plurality of ultrasonic transducers 7, and an ultrasonic control panel 8. A circulating refrigerant inlet 1 is provided above the ultrasonic treatment tank 2 , there is a circulating refrigerant outlet 6 below, and a wire frame for holding the sample is arranged inside; the T-type thermocouple 3 is in contact with the sample 5 when in use, and is used to measure the freezing temperature change of the sample 5; multiple ultrasonic transducers Devices 7 are evenly distributed on the bottom of the ultrasonic treatment tank 2, and are respectively connected with the ultrasonic control panel.

[0031] The method for improving the freezing speed and quality of lychees by frequency-converting ultrasonic intensification in this embodiment includes the follow...

Embodiment 2

[0033]The ultrasonic processing device used in this embodiment is the same as that in Embodiment 1. The method for improving the freezing speed and quality of lychees by frequency-converting ultrasonic intensification includes the following steps: buy fresh lychees that have been picked for no more than 24 hours, wash them, and sort and remove them that have become corrupted. Frozen ingredients. Weigh 360g and pre-cool to 4°C. Take the pre-cooled concubine and insert a T-type thermocouple into the ultrasonic treatment tank. The temperature in the ultrasonic treatment tank is below -18°C, the refrigerant is 50% ethanol aqueous solution (v / v), and the ratio of solid to liquid is 1:40 , and began to record the core temperature of the concubine. When it drops to near the freezing point, change the ultrasonic frequency to assist in freezing the lychees to -20°C. After the freezing is over, take out the lychees. The frequency conversion ultrasonic processing conditions are: the po...

Embodiment 3

[0035] The ultrasonic processing device used in this embodiment is the same as that in Embodiment 1. The method for improving the freezing speed and quality of litchi by frequency-converting ultrasonic enhancement includes the following steps: purchase fresh hanging green litchi that has been picked for no more than 24 hours, wash, and pick and remove unsuitable corrupted litchi. Frozen ingredients. Weigh 360g and pre-cool to 4°C. Take the pre-cooled hanging green and insert a T-type thermocouple into the ultrasonic treatment tank. The temperature in the ultrasonic treatment tank is below -18°C, the refrigerant is 50% ethanol aqueous solution (v / v), and the ratio of solid to liquid is 1:40. , start to record the core temperature of the hanging green. When it drops to near the freezing point, change the ultrasonic frequency to assist in freezing the litchi to -18°C. After the freezing is over, take out the hanging green. The frequency conversion ultrasonic processing conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com