Solid and oil removal method and device for chilled water and washed water in MTO (methanol to olefin) process

A technology for methanol to olefins and quench water, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of incomplete catalyst recovery, paralysis of water treatment system, wear and blockage of pores and other problems, to achieve the effect of reducing the probability of forming large particles, increasing the operating cycle of the equipment, and reducing the cost of membrane replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

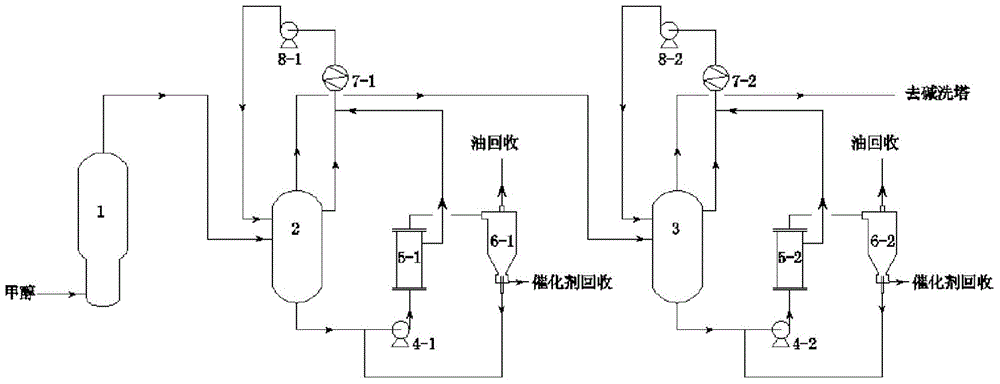

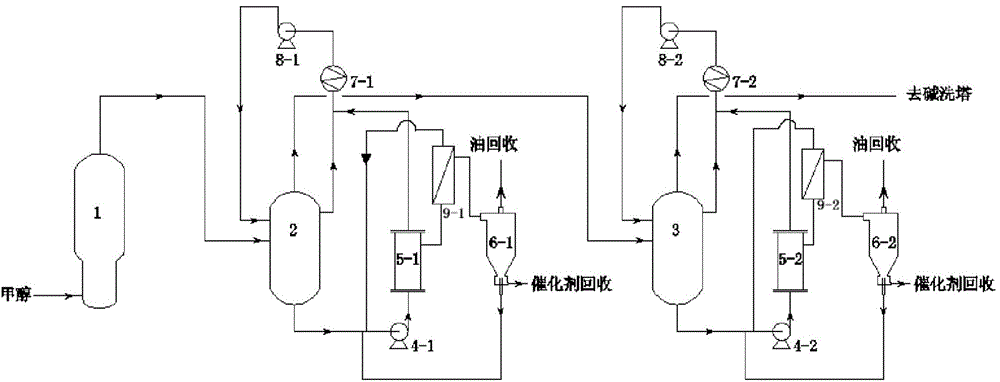

[0046] Such as figure 1 In the shown device flow, methanol enters the reactor 1, and reacts under the action of a catalyst to form products and by-products. Products and by-products entrain part of the catalyst in the form of gas and enter the quenching tower 2. The quenching water from the bottom of the quenching tower 2 has a temperature of 115° C., a catalyst content of 189 mg / L, and an oil content of 510 mg / L. Driven by the first ultrafiltration membrane feed pump 4-1, it enters the first ultrafiltration membrane assembly 5-1. The ultrafiltration membrane installed inside is a titanium oxide membrane. The ultrafiltration membrane works under different pressure conditions and also Back pressure can be added to form a transmembrane pressure difference. The membrane surface flow velocity is 5m / s, the pore size is 5nm, the temperature is 87°C, and the permeation side back pressure is 0.2MPa; the recoil condition is 0.8MPa, the recoil cycle is 45min, and the recoil time is 6s. ...

Embodiment 2

[0055] Such as figure 1 In the shown device flow, methanol enters the reactor 1, and reacts under the action of a catalyst to form products and by-products. Products and by-products entrain part of the catalyst in the form of gas and enter the quenching tower 2. The quenching water from the bottom of the quenching tower 2 has a temperature of 115° C., a catalyst content of 189 mg / L, and an oil content of 510 mg / L. Driven by the first ultrafiltration membrane feed pump 4-1, it enters the first ultrafiltration membrane assembly 5-1. The ultrafiltration membrane installed inside is a titanium oxide membrane. The ultrafiltration membrane works under different pressure conditions and also The transmembrane pressure difference can be formed by adding back pressure. The transmembrane pressure difference is 0.4Mpa, the pore size is 20nm, the temperature is 87°C, and the permeation side back pressure is 0.2MPa; the recoil condition is 0.8MPa, the recoil cycle is 45min, and the recoil t...

Embodiment 3

[0064] Such as figure 1 In the shown device flow, methanol enters the reactor 1, and reacts under the action of a catalyst to form products and by-products. Products and by-products entrain part of the catalyst in the form of gas and enter the quenching tower 2. The quenching water from the bottom of the quenching tower 2 has a temperature of 115° C., a catalyst content of 189 mg / L, and an oil content of 510 mg / L. Driven by the first ultrafiltration membrane feed pump 4-1, it enters the first ultrafiltration membrane assembly 5-1. The ultrafiltration membrane installed inside is a titanium oxide membrane. The ultrafiltration membrane works under different pressure conditions and also Back pressure can be added to form a transmembrane pressure difference. The transmembrane pressure difference is 0.4Mpa, the membrane surface flow rate is 3m / s, the temperature is 87°C, and the permeation side back pressure is 0.2MPa; the recoil condition is 0.8MPa, and the recoil cycle is 45min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com