Method for removing organic impurities in medium and heavy rare earth chloride solutions

A technology for organic impurities and heavy rare earths, applied in chemical instruments and methods, chemical/physical processes, and other chemical processes, can solve problems such as the inability to eliminate the enrichment of organic impurities, achieve the effect of ensuring adsorption capacity and enhancing the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

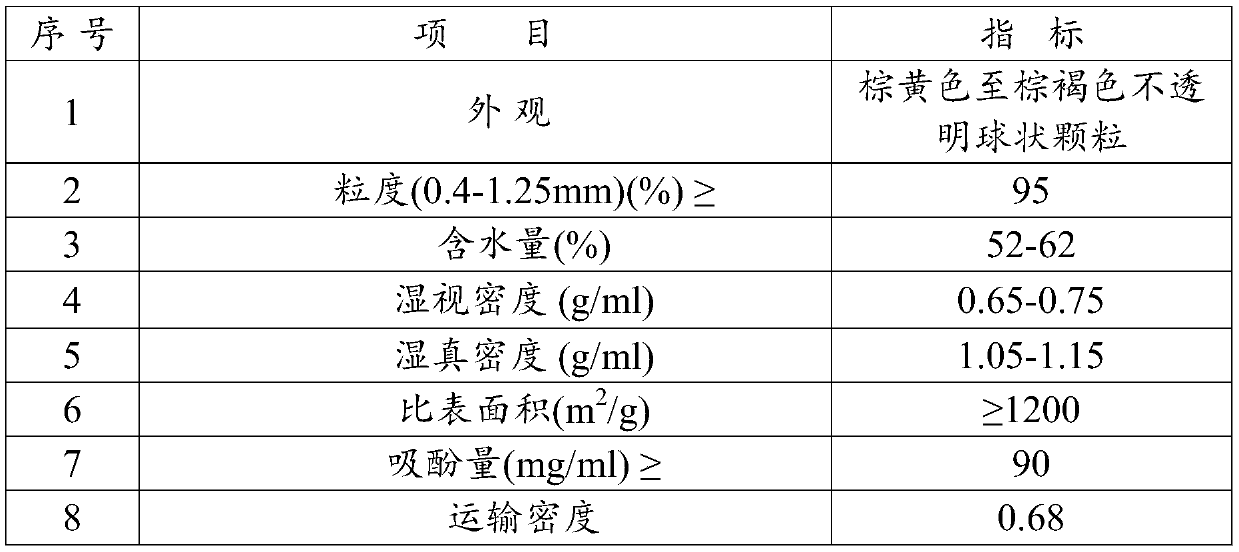

[0050] A cross-linked styrene-divinylbenzene polymer was loaded into the resin column. The resin column had a diameter of 0.3 meters and a height of 3 meters.

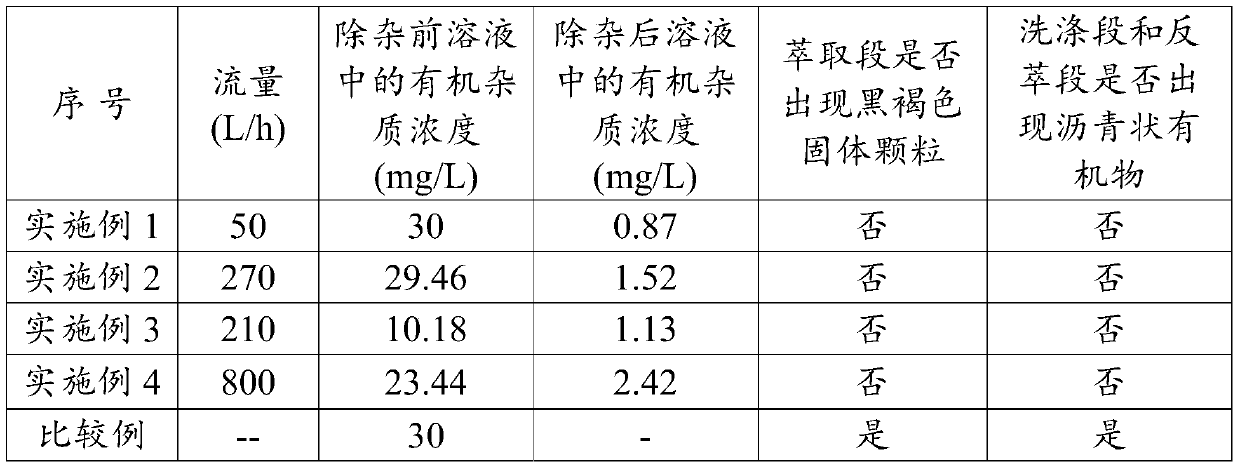

[0051] will contain (TbDy)Cl 3 solution (organic impurity concentration is 30mg / L, hydrogen ion concentration is 0.8mol / L, (TbDy)Cl 3 The concentration is 1.2mol / L) at room temperature, according to the flow rate of 50L / h, the organic impurities are removed through the resin column to obtain (TbDy)Cl after the removal of impurities 3 solution. (TbDy)Cl after removal of impurities 3 See Table 2 for solution properties.

[0052] The impurity-removed (TbDy)Cl 3 Solution, 2-ethylhexyl phosphate mono-2-ethylhexyl ester and kerosene are mixed in the mixing chamber of the extraction section, and the organic phase and the water phase are separated in the extraction section; the organic phase obtained in the extraction section first enters the washing section, and the washing section The washing liquid used is water, and ...

Embodiment 2

[0054] A cross-linked styrene-divinylbenzene polymer was loaded into the resin column. The resin column had a diameter of 0.3 meters and a height of 3 meters.

[0055] will contain (Eu-Dy)Cl 3 solution (organic impurities concentration is 29.46mg / L, hydrogen ion concentration is 0.2mol / L, (Eu-Dy)Cl 3 The concentration is 1.5mol / L) at room temperature, according to the flow rate of 270L / h, the organic impurities are removed through the resin column, and the (Eu-Dy)Cl after the removal of impurities is obtained 3 solution. (Eu-Dy)Cl after removal of impurities 3 See Table 2 for solution properties.

[0056] The impurity-removed (Eu-Dy)Cl 3 Solution, 2-ethylhexyl phosphate mono-2-ethylhexyl ester and kerosene are mixed in the mixing chamber of the extraction section, and the organic phase and the water phase are separated in the extraction section; the organic phase obtained in the extraction section first enters the washing section, and the washing section The washing liqu...

Embodiment 3

[0058] A cross-linked styrene-divinylbenzene polymer was loaded into the resin column. The resin column had a diameter of 0.3 meters and a height of 3 meters.

[0059] will contain (EuGd)Cl 3 solution (organic impurity concentration is 10.18mg / L, hydrogen ion concentration is 0.15mol / L, (EuGd)Cl 3 The concentration is 1.5mol / L) at room temperature, according to the flow rate of 210L / h, the organic impurities are removed through the resin column, and the (EuGd)Cl after the removal of impurities is obtained 3 solution. (EuGd)Cl after removal of impurities 3 See Table 2 for solution properties.

[0060] The impurity-removed (EuGd)Cl 3 Solution, 2-ethylhexyl phosphate mono-2-ethylhexyl ester and kerosene are mixed in the mixing chamber of the extraction section, and the organic phase and the water phase are separated in the extraction section; the organic phase obtained in the extraction section first enters the washing section, and the washing section The washing liquid use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com