A method for advanced treatment of natural gas recovery jelly liquor containing foaming agent

An advanced treatment, natural gas technology, applied in mining wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., which can solve the problems of difficult separation and removal, inability to remove the treatment cost of foaming and discharging agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

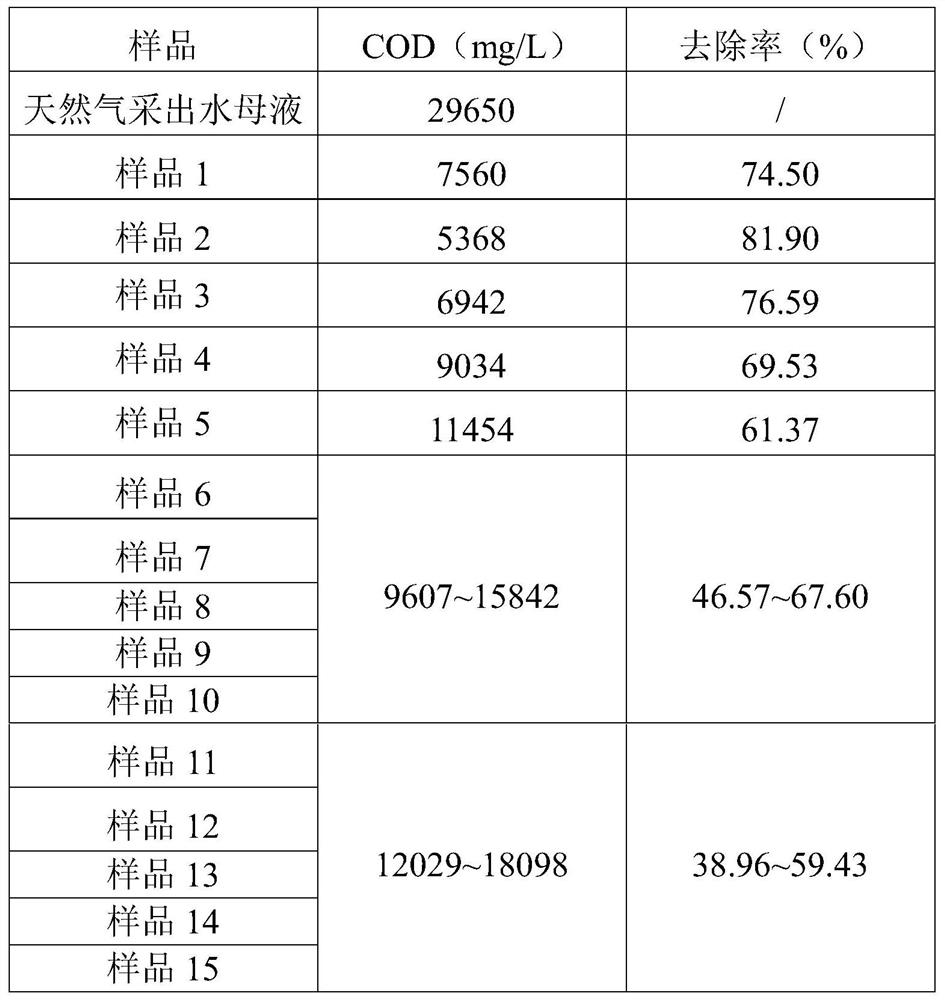

Embodiment 1

[0023] Adjust the pH value of the natural gas production water to 7, and install it in the flow type electroflocculation equipment with a surface area of 170mm 2 Aluminum plates with a spacing of 20mm, the connection mode of the electrodes is the double pole connection mode, and the cathode and anode plates are distributed in multiple groups in the electrolytic cell at intervals. Turn on the pump to pump the wastewater into the electrocoagulation equipment, start the pulse power supply, adjust the current intensity to 9A, then start the electrocoagulation reaction, set the reaction time to 10min; after the reaction is completed, the wastewater is left to settle for 20min, and then the plate and frame filter press After filtering, the obtained filtrate is subjected to multi-effect evaporation until the foaming agent content is 28,000-32,000 mg / L, so as to obtain the natural gas recovery water mother liquor.

[0024] Take 200ml of natural gas recovery jellyfish liquid after mu...

Embodiment 2

[0026] Adjust the pH value of natural gas produced water to 7, and install aluminum plates with a surface area of 170mm2 in the flow-type electroflocculation equipment, with a plate spacing of 20mm. In the electrolytic cell, there are multiple groups distributed at intervals. Turn on the pump to pump the wastewater into the electrocoagulation equipment, start the pulse power supply, adjust the current intensity to 9A, then start the electrocoagulation reaction, set the reaction time to 10min; after the reaction is completed, the wastewater is left to settle for 20min, and then the plate and frame filter press After filtering, the obtained filtrate is subjected to multi-effect evaporation until the foaming agent content is 28,000-32,000 mg / L, so as to obtain the natural gas recovery water mother liquor.

[0027] Take 200ml of natural gas extraction jellyfish liquor after multi-effect evaporation, add an appropriate amount of dilute hydrochloric acid to adjust the pH to 2, add...

Embodiment 3

[0029] Adjust the pH value of natural gas produced water to 7, and install aluminum plates with a surface area of 170mm2 in the flow-type electroflocculation equipment, with a plate spacing of 20mm. In the electrolytic cell, there are multiple groups distributed at intervals. Turn on the pump to pump the wastewater into the electrocoagulation equipment, start the pulse power supply, adjust the current intensity to 9A, then start the electrocoagulation reaction, set the reaction time to 10min; after the reaction is completed, the wastewater is left to settle for 20min, and then the plate and frame filter press After filtering, the obtained filtrate is subjected to multi-effect evaporation until the foaming agent content is 28,000-32,000 mg / L, so as to obtain the natural gas recovery water mother liquor.

[0030] Take 200ml of natural gas production jelly liquor after multi-effect evaporation, add appropriate amount of dilute hydrochloric acid to adjust the pH to 2, add 5.5ml ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com