Acrylic acid emulsion and functional acrylic acid emulsion for unshadowed protective film

An acrylic emulsion and acrylate technology, applied in the direction of film/sheet adhesive, adhesive type, adhesive additive, etc., can solve the problems of poor applicability, gel, restriction, etc., to improve heat resistance and Corrosion resistance, high crosslink density and cohesive strength, shadow reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

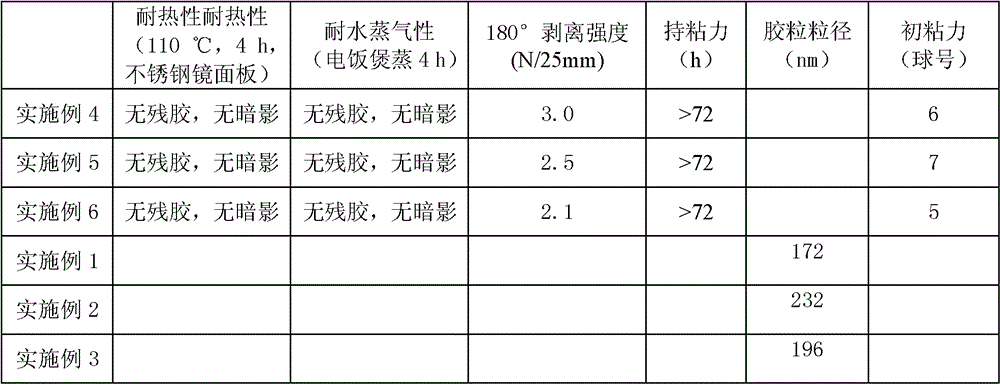

Examples

Embodiment 1

[0042] Weigh 35.2 parts of butyl acrylate, 39.8 parts of isooctyl acrylate, 6 parts of methyl methacrylate, 3 parts of hydroxyethyl acrylate, 10.1 parts of ethyl acrylate, 1.9 parts of methyl acrylate, and 2 parts of maleic acid. 2 parts of N-methylol acrylamide, 0.5 parts of ammonium persulfate, 2.0 parts of 2-acrylamido-2-methyl-propenesulfonic acid, 40 parts of deionized water, deionized water, 2-acrylamido- Add 2-methyl-propenesulfonic acid and ammonium persulfate to the pre-emulsification kettle and stir evenly; then add the weighed comonomer to the pre-emulsification kettle, and stir quickly for 0.5 hours to form a pre-emulsion solution, which is reduced for use. Add 85 parts of deionized water, 0.3 parts of 2-acrylamido-2-methyl-propenesulfonic acid, and 10% pre-emulsion into the reactor, start stirring, heat up to 82°C, keep for 30 minutes, and react to form seeds Emulsion, then drip the remaining pre-emulsion in about 5 hours, keep it for 30 minutes, and finally add 0....

Embodiment 2

[0044] Weigh 38 parts of butyl acrylate, 31 parts of isooctyl acrylate, 8 parts of lauryl acrylate, 6 parts of methyl methacrylate, 8 parts of ethyl acrylate, 4 parts of methyl acrylate, and 5 parts of maleic acid. 0.3 parts of hydrogen oxide, 0.3 parts of sodium formaldehyde sulfoxylate, 2.2 parts of allyloxy nonylphenol polyoxyethylene ether bisphosphonic acid, 40 parts of deionized water, deionized water, allyloxy nonylphenol polyoxygen Vinyl ether bisphosphoric acid and hydrogen peroxide, sodium formaldehyde sulfoxylate hydrogen sulfate are added to the pre-emulsification kettle and quickly stirred uniformly; then the weighed mixed monomer is added to the pre-emulsification kettle, and the pre-emulsion is formed after rapid stirring for 0.5h. Reduce speed for use, add 85 parts of deionized water, 0.2 parts of allyloxy nonylphenol polyoxyethylene ether bisphosphonic acid, 8% pre-emulsion to the reactor, start stirring, heat up to 82°C, keep for 30 minutes, and react to form s...

Embodiment 3

[0046] Weigh 10.3 parts of butyl acrylate, 40 parts of isooctyl acrylate, 8 parts of tridecyl acrylate, 9 parts of methyl methacrylate, 15 parts of hydroxypropyl acrylate, 8 parts of ethyl acrylate, and butyl methacrylate 4.7 parts, 3.2 parts of maleic acid, 1 part of N-methylolacrylamide, 0.8 parts of acrylamide, 0.4 parts of tert-butyl hydroperoxide, 0.3 parts of sodium formaldehyde sulfoxylate, allyloxynonyl 1.8 parts of phenol polyoxyethylene ether ammonium sulfate, 40 parts of deionized water, add deionized water, tert-butyl hydroperoxide, sodium formaldehyde sulfoxylate and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate to In the pre-emulsification kettle, quickly stir uniformly; then add the weighed mixed monomers to the pre-emulsification kettle, and quickly stir for 0.5h to form a pre-emulsion liquid, slow down for use, add 85 parts of deionized water and 0.4 parts of emulsification to the reactor 7% pre-emulsion liquid, start stirring, heat to 82℃, keep f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com