A kind of hot-dip aluminum-zinc alloy containing rare earth and magnesium and preparation method thereof

A zinc alloy, hot-dip aluminum technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of poor surface appearance, poor blackening resistance of coating, poor processing formability, etc. Good wetness, improved blackening resistance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The material composition is:

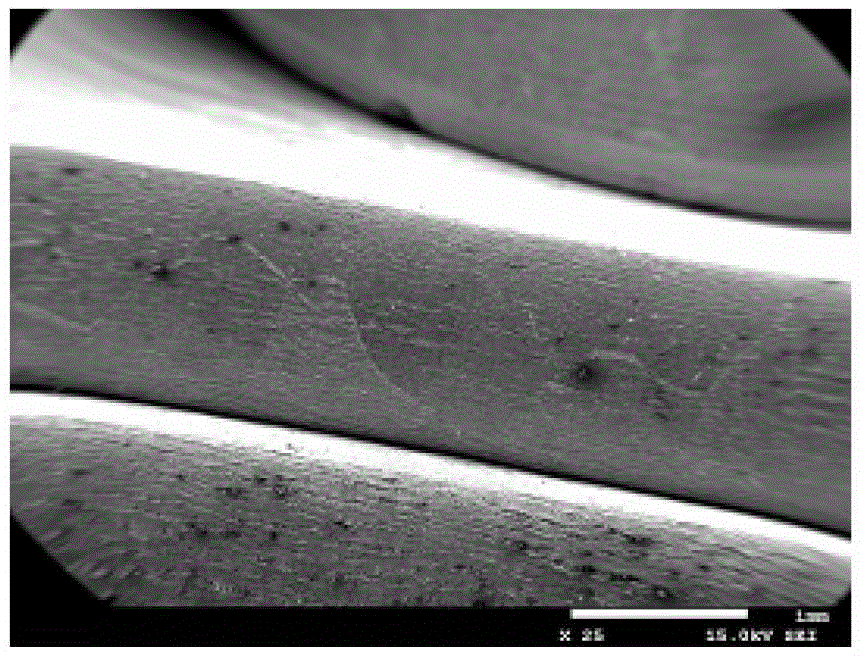

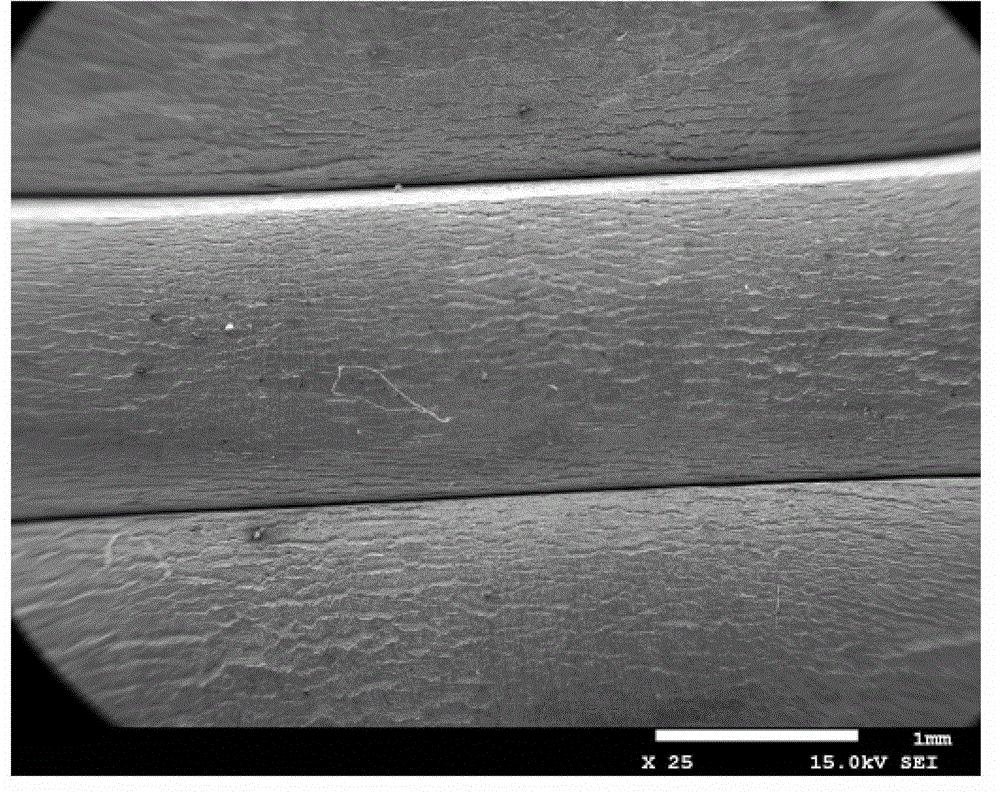

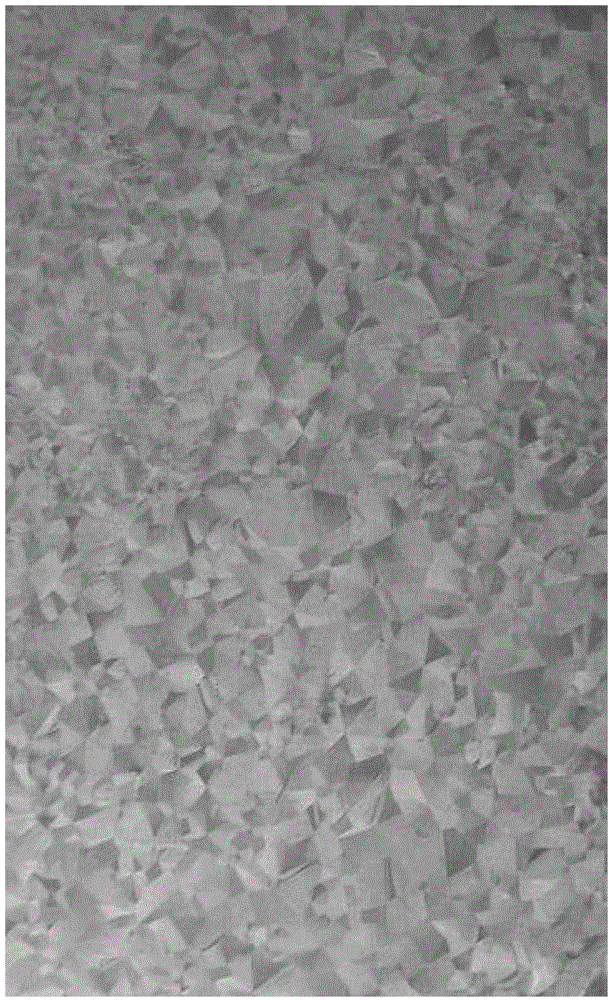

[0041] 55.0wt% Al, 1.5wt% Si, 0.07wt% La+Ce, the balance being Zn. Melt industrial pure aluminum, industrial pure zinc, industrial pure silicon, industrial pure rare earth Ce or La or La+Ce (or aluminum rare earth master alloy) in an intermediate frequency furnace (or industrial frequency furnace) according to the material composition, and pour it into the mold It is made into an alloy ingot for hot-dip plating, which is used in a continuous production line of hot-dip steel strip or a production line of hot-dip steel components. The hot-dip process used is the same as that of the original Galvalume alloy.

Embodiment 2

[0043] The material composition is:

[0044]55.0wt% Al, 1.5wt% Si, 0.12wt% La+Ce, the balance is Zn. According to the material composition, industrial pure aluminum, industrial pure zinc, industrial pure silicon, industrial pure rare earth Ce or La or La+Ce (or aluminum rare earth master alloy) are melted in the intermediate frequency furnace (or industrial frequency furnace) and poured into the mold It is made into an alloy ingot for hot-dip plating, which is used in a continuous production line of hot-dip steel strip or a production line of hot-dip steel components. The hot-dip process used is the same as that of the original Galvalume alloy.

Embodiment 3

[0046] The material composition is:

[0047] 55.0wt% Al, 1.5wt% Si, 0.07wt% La+Ce, the balance being Zn. According to the material composition, industrial pure aluminum, industrial pure zinc, industrial pure silicon, industrial pure rare earth Ce or La or La+Ce (or aluminum rare earth master alloy) are directly melted in the zinc pot or pre-melting pot on the hot-dip line , direct hot-dip production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com