Treatment method and treatment apparatus of oily sludge

A treatment method, oil sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problem of large amount of medicine, ideal treatment effect of fresh oil sludge, and inability of alkaline oil sludge Dealing with other problems, to achieve the effect of high crude oil recovery rate, low water content and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

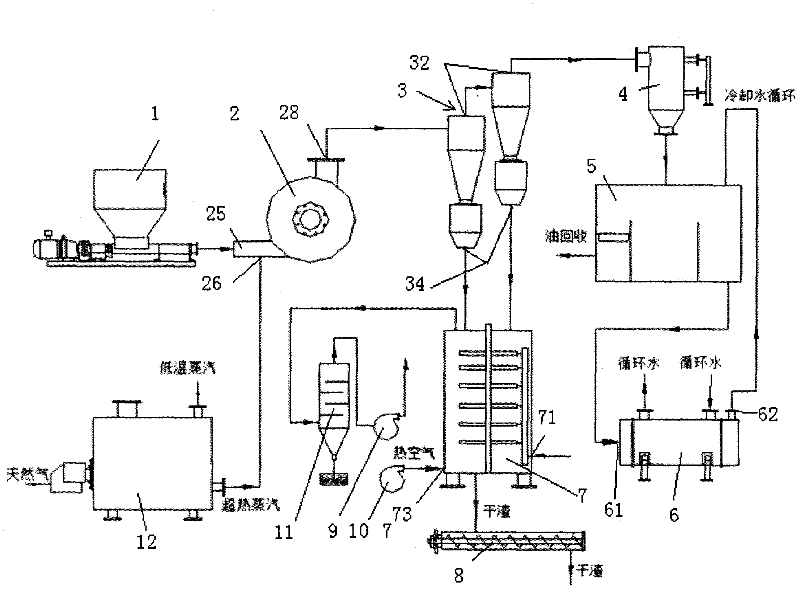

[0032] The oily sludge treatment method of the present invention and the oily sludge treatment equipment used in the method will be described below with reference to the accompanying drawings.

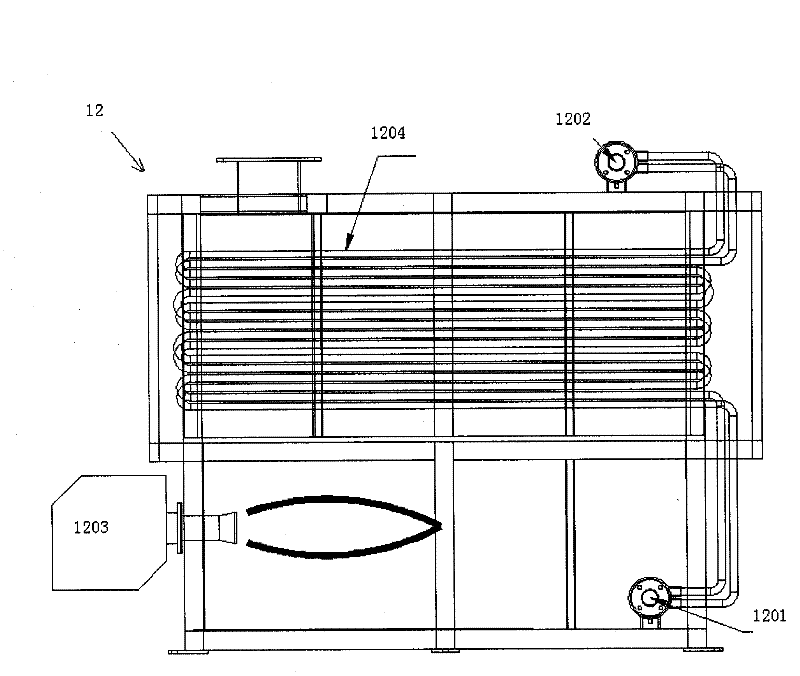

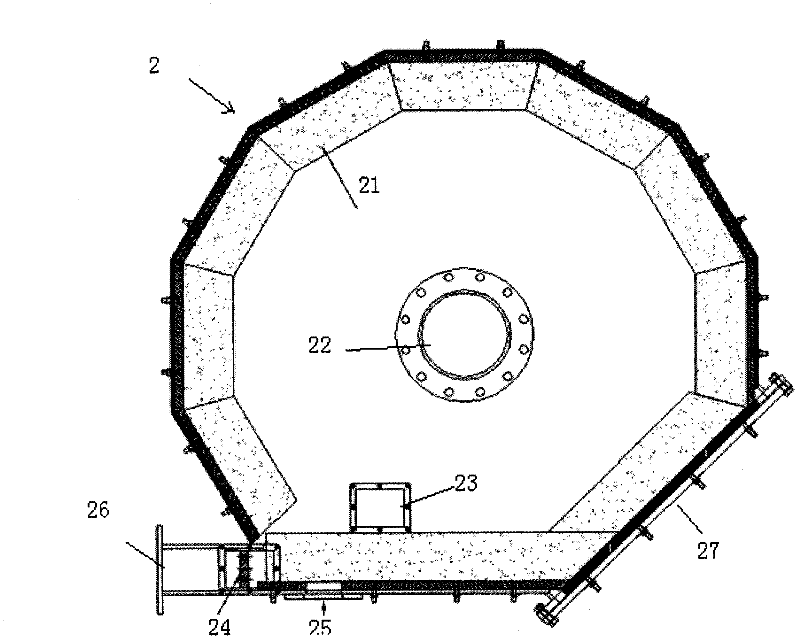

[0033] see figure 1 Describe the method for treating oily sludge of the present invention, which includes the following steps: (1) introducing superheated steam into a high-temperature treatment tank 2 to bake the oily sludge, so that the liquid including oil and water in the oily sludge is evaporated into gas; (2) The solid particles from the oily sludge contained in the gas are separated in the gas-solid separator 3, and then the separated solid particles are sent to the drier 7 for drying and combustion and then discharged; (3) The gas separated from the gas-solid separator 3 is condensed in the condenser 4 to generate liquid oil and water, and the liquid oil and water are separated in the oil-water separator 5 and recovered respectively. In step (1): the oily sludge is introduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com