Microfiltration machine with backwashing device, and microfiltration and precipitation integration machine

A technology of backwashing and microfiltration, which is applied in the direction of fixed filter element filter, filtration separation, filtration circuit, etc. It can solve the problems of high backwashing intensity, complicated operation, large area of sedimentation tank, etc., and meet the requirements of the control system Low, increased filter area, good backwashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

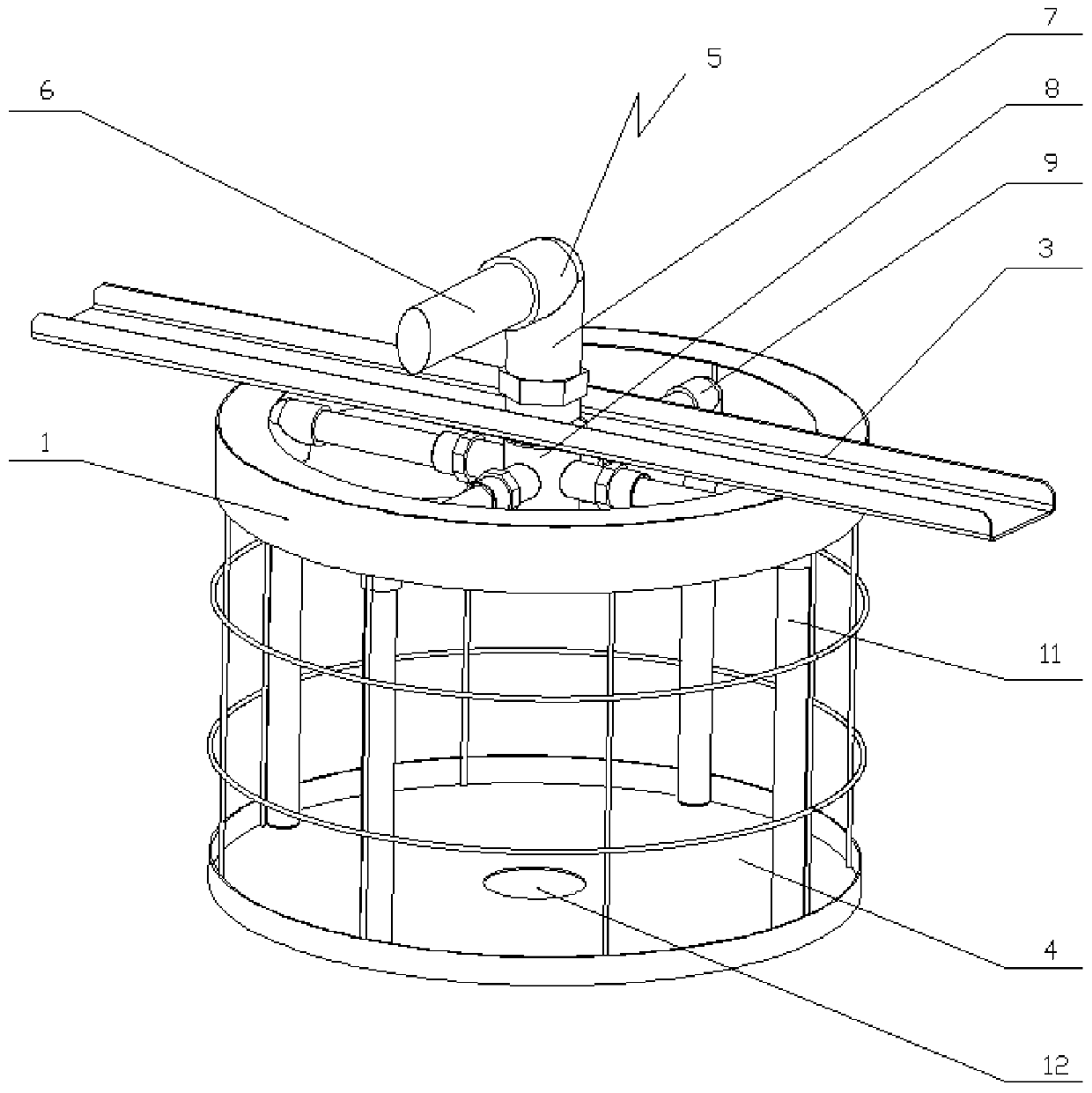

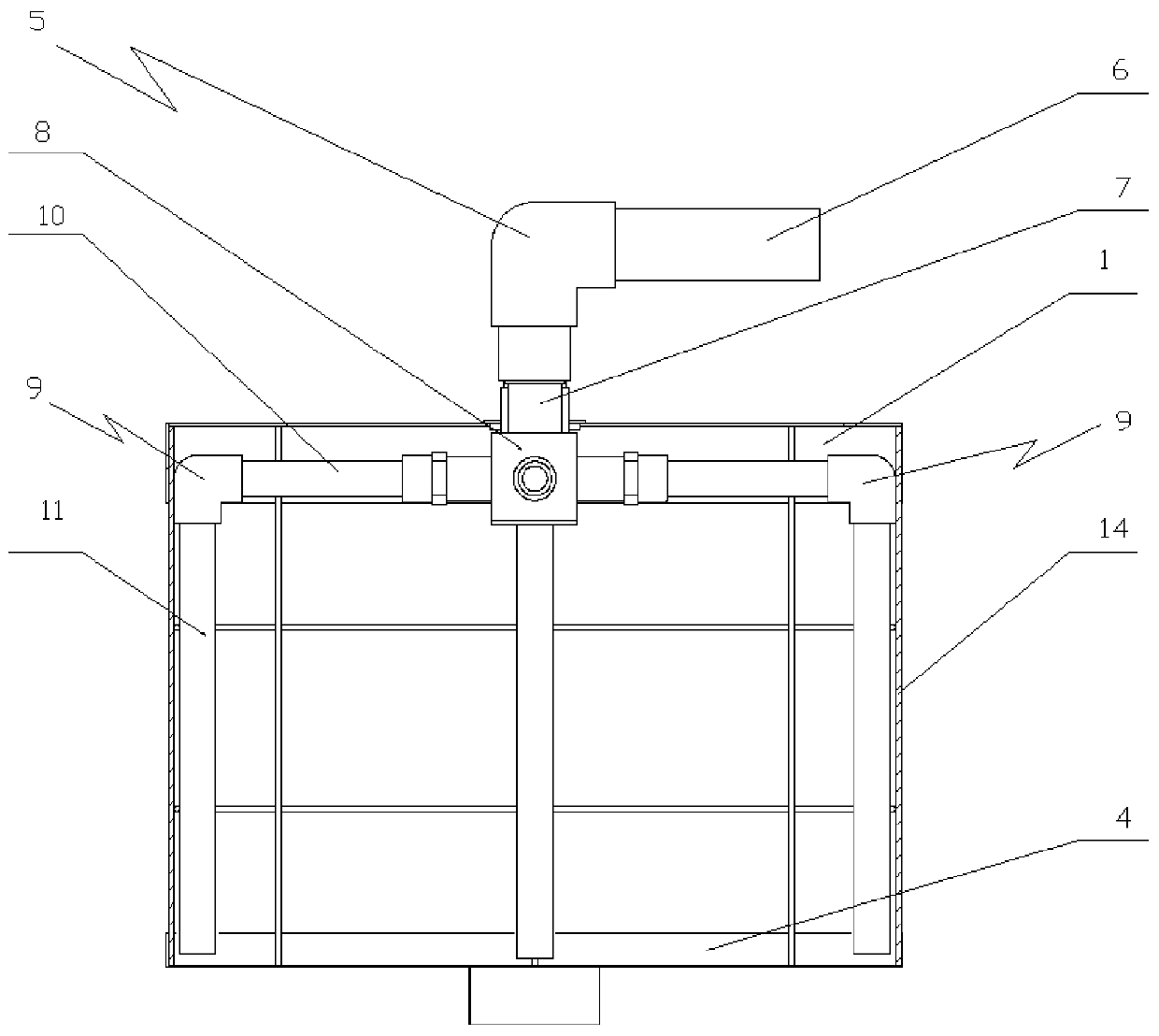

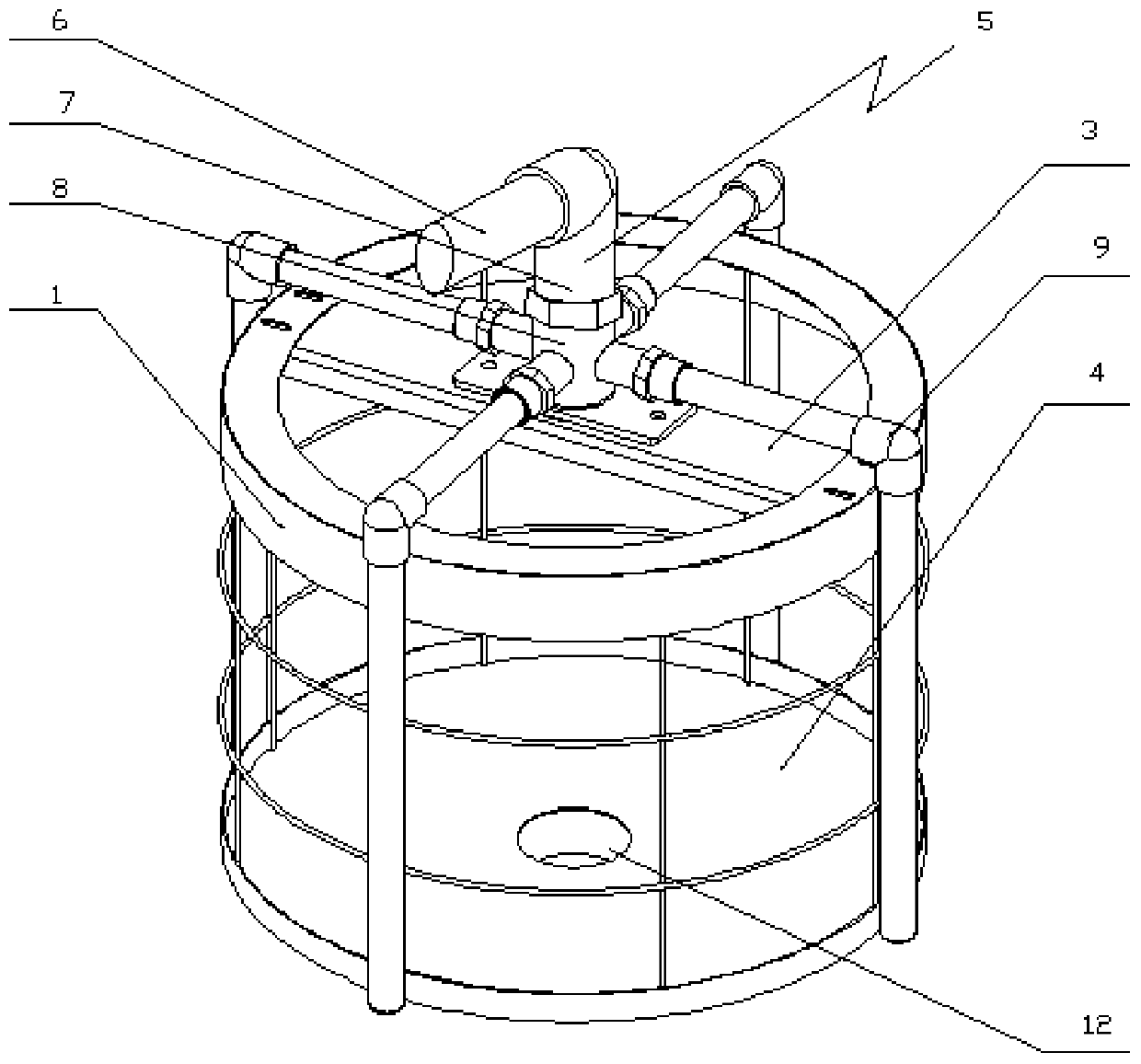

[0036] As shown in the figure, the present invention provides a microfilter with a backwashing device, which includes a filter screen support frame 1 with a filter screen 14 and a backwashing device 5, and the backwashing device 5 includes a backwashing water inlet pipe 6 And at least two backwash outlet pipes 9, the water outlet of the backwash inlet pipe 6 communicates with the upper end of the backwash outlet pipe 9, the lower end of the backwash outlet pipe 9 is distributed along the circumference of the filter screen support frame 1, the The filter screen 14 is set up vertically, and a rotating mechanism is provided between the backwash outlet pipe 9 and the backwash inlet pipe 6 to automatically rotate the lower end of the backwash outlet pipe 9 around the filter screen support frame 1 circle. The advantage is that the placement direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com