Granular-layer dust precipitator

A particle bed filtration and dust collector technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy deformation, material leakage and air leakage, and cannot be applied, and achieves good thermal deformation resistance. , The effect of uniform thermal expansion and cold contraction, reducing the filter load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

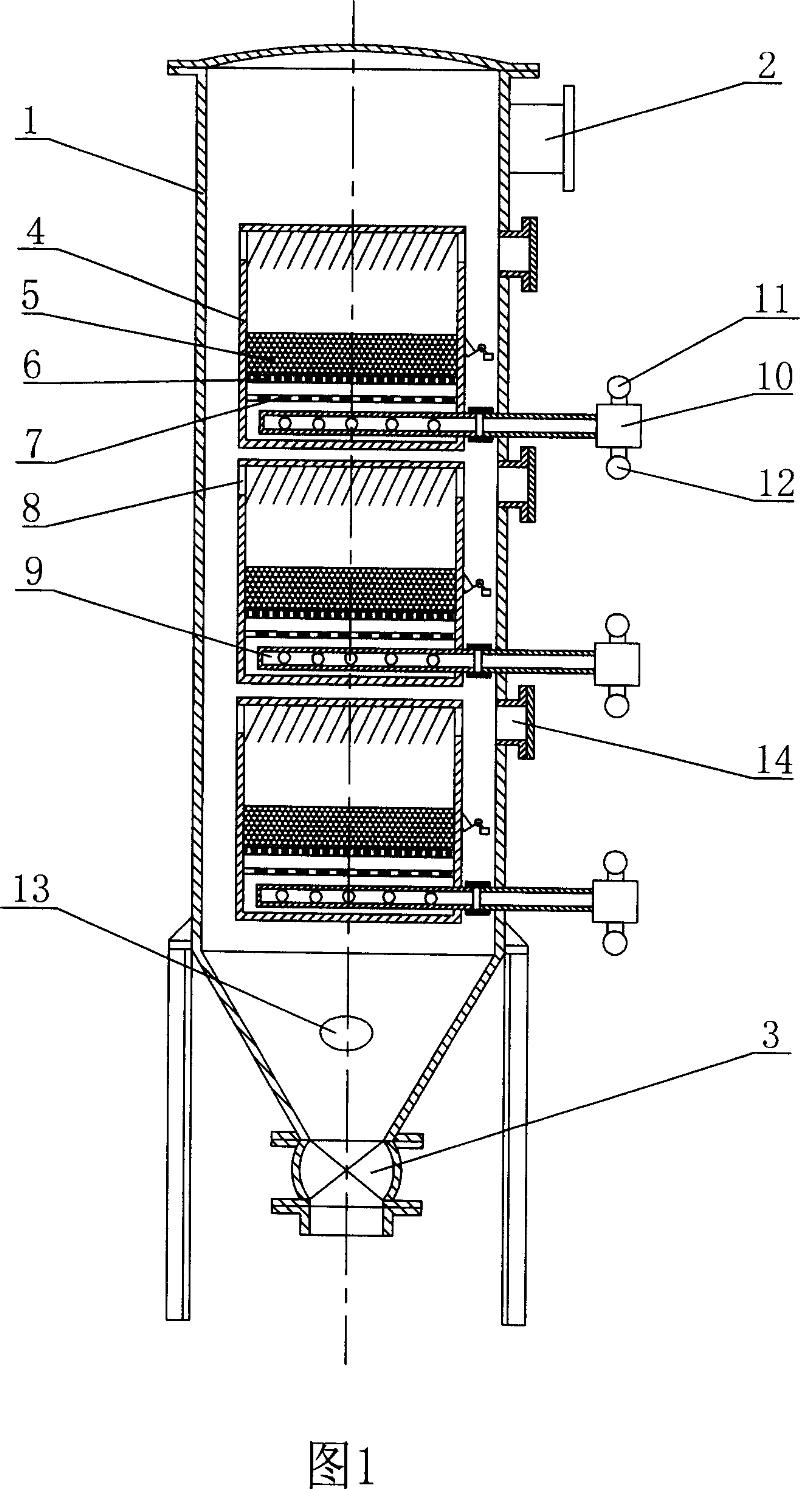

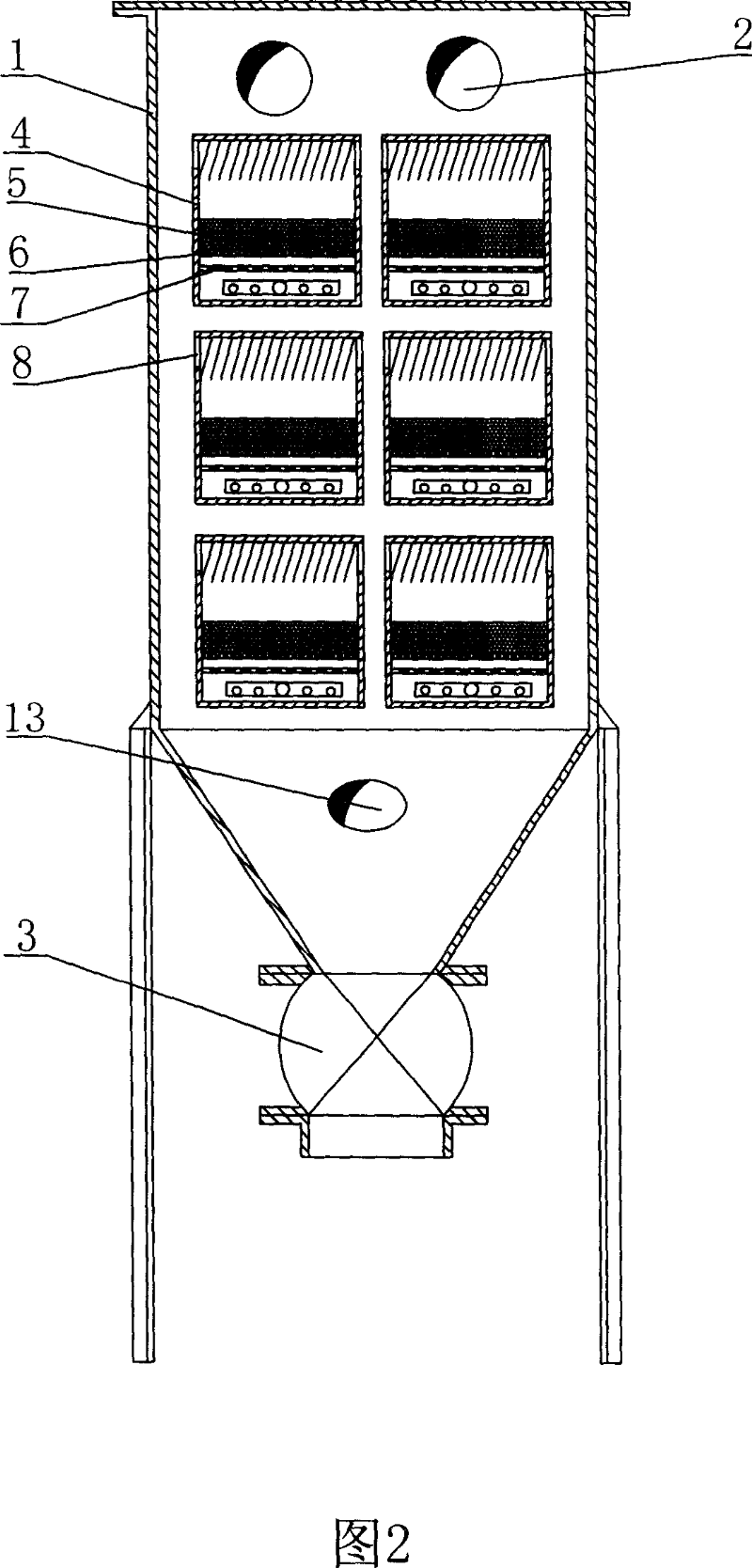

[0022] Embodiment 1: As shown in the figure, a particle bed filter and dust collector includes an outer shell 1, the upper part of the outer shell 1 is provided with a dust-containing gas inlet 2, and the lower end of the outer shell 1 is provided with a dust outlet 3, and the outer shell 1 There are two independent inner casings 4 arranged side by side on each layer along the height direction, and there are three layers in total. The inner casing 4 is provided with a granular layer 5 and an air distribution plate 6 below the granular layer 5. A pre-distribution perforated plate 7 is arranged under the air distribution plate 6, and an air vent 8 and an air pipe 9 are arranged on the inner shell 4. The air vent 8 is arranged above the particle layer 5, and the air pipe 9 is arranged on the pre-distributed porous plate 7. The lower side and laterally through the outer casing 1 are independently connected with a reversing valve 10, the reversing valve 10 is connected with the clea...

Embodiment 2

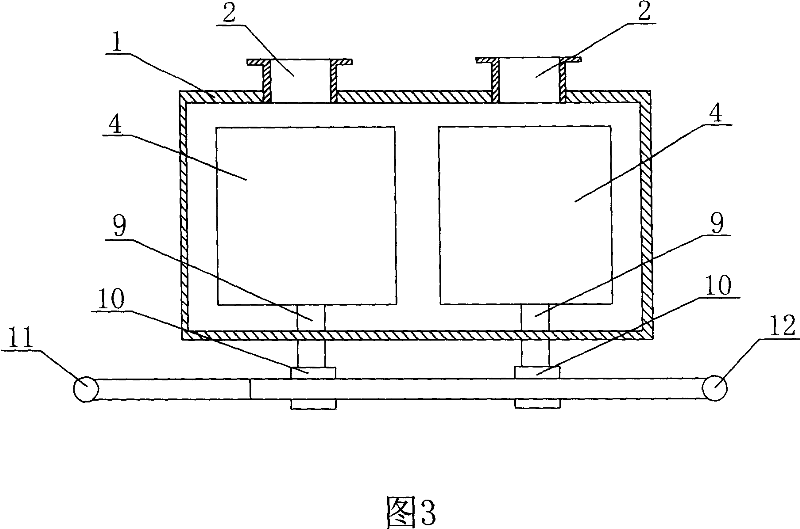

[0023] Embodiment two: as shown in the figure, other structures are the same as embodiment one, and the difference is that the two ventilation pipes 9 juxtaposed on the same layer are all connected with the ventilation branch pipe 15, and the ventilation branch pipe 15 is connected with an independent reversing valve 10, The reversing valve 10 is connected with the clean gas main pipe 11 and the back blow air main pipe 12 respectively.

[0024] In addition to the above-mentioned structure, the number of inner shells 4 in each layer of the outer shell 1 can be three, or four, but not less than one; when the number of inner shells 4 in each layer is more than two When more than two, the arrangement of the inner casing 4 can be a rectangular distribution, and can also be an annular distribution (when the cross section of the inner casing 4 is fan-shaped or trapezoidal); the outer casing 1 is provided with the number of layers of the inner casing 4 It can be two layers or four lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com