Nanofiber composite membrane with base material and preparation method thereof

A nanofiber and nanofiber layer technology is applied in the field of nanofiber composite membrane with base material and its preparation, which can solve the problems of sacrificing filtration flux and flow rate, destroying the structure of electrospinning fiber, etc. The effect of large surface area and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

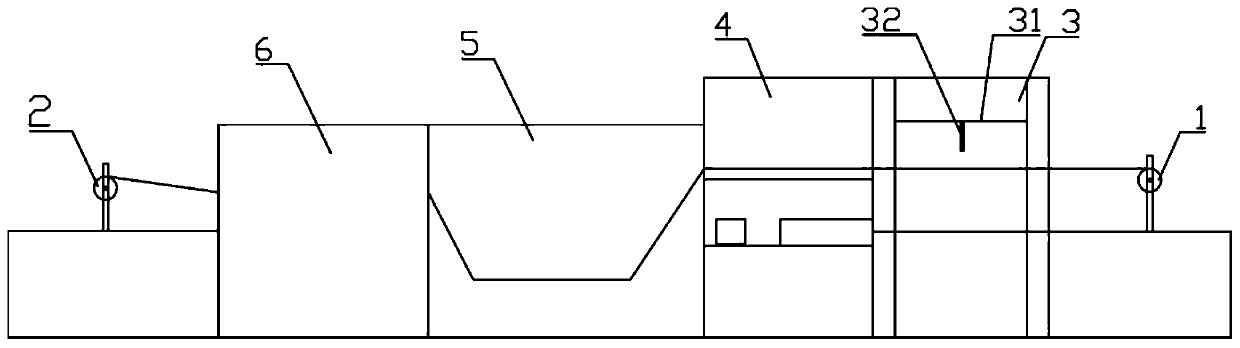

Method used

Image

Examples

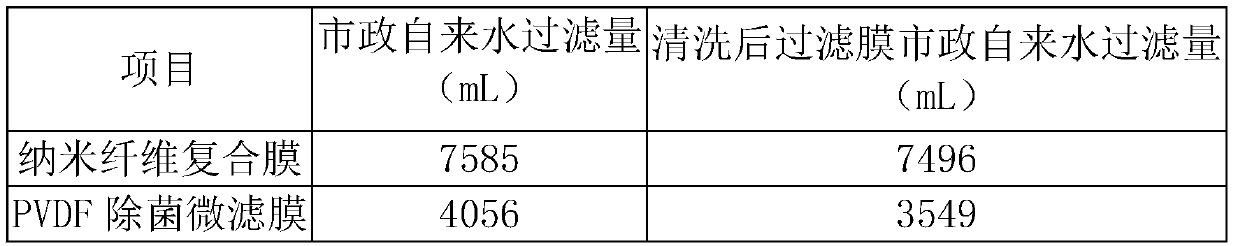

Embodiment 1

[0029] The nanofiber composite membrane of this embodiment uses a polyvinylidene fluoride microfiltration membrane with a filtration accuracy of 0.45 μm as a substrate, and a polyvinylidene fluoride nanofiber layer is compounded on its surface. The specific steps are as follows:

[0030] Pretreatment: on the substrate microfiltration membrane according to 12mL / m 2 The amount of spraying, through the high-pressure atomization nozzle to spray micro-nano-level N-methylpyrrolidone, let it stand for 5s, let N-methylpyrrolidone fully corrode the surface of the substrate microfiltration membrane, and obtain the pretreated substrate microfiltration membrane .

[0031] Preparation of spinning solution:

[0032] (1) Measure N,N-dimethylformamide and N,N-dimethylacetamide respectively according to the volume ratio of 8:2, stir and mix them evenly to obtain a formacetamide mixed solution.

[0033] (2) According to the ratio of volume ratio of 7:3, measure the formacetamide mixed solutio...

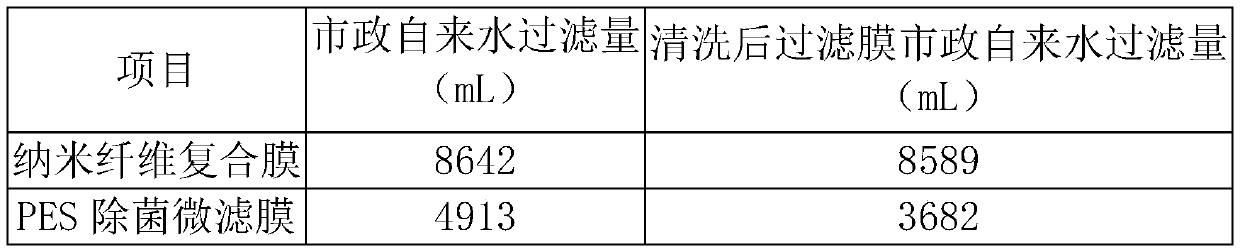

Embodiment 2

[0044] The nanofiber composite membrane of this example uses a polyethersulfone microfiltration membrane with a filtration accuracy of 0.45 μm as the substrate, and a layer of polyethersulfone nanofiber layer is compounded on its surface. The specific steps are as follows:

[0045] Pretreatment: on the substrate microfiltration membrane according to 15mL / cm 2 Spray the amount of spraying, spray micro-nano-scale N-methylpyrrolidone through the high-pressure atomizing nozzle, let it stand for 8s, let the N-methylpyrrolidone fully corrode the surface of the substrate microfiltration membrane, and obtain the pretreated substrate microfiltration membrane .

[0046] Preparation of spinning solution:

[0047] (1) Measure N,N-dimethylformamide and N,N-dimethylacetamide respectively according to the volume ratio of 8:2, stir and mix evenly to obtain a formacetamide mixed solution.

[0048] (2) Take formaldehyde mixed solution and acetone respectively according to volume ratio of 9:1,...

Embodiment 3

[0058] The nanofiber composite membrane of this example uses a polyvinylidene fluoride microfiltration membrane with a filtration accuracy of 0.22 μm as the substrate, and a layer of polyethersulfone nanofiber layer is compounded on its surface. The specific steps are as follows:

[0059] Pretreatment: to the substrate microfiltration membrane according to 10mL / m 2 The amount of spraying, through the high-pressure atomizing nozzle to spray micro-nano-level N-methylpyrrolidone, let it stand for 10s, let N-methylpyrrolidone fully corrode the surface of the substrate microfiltration membrane, and obtain the pretreated substrate microfiltration membrane .

[0060] Preparation of spinning solution:

[0061] (1) Measure N,N-dimethylformamide and N,N-dimethylacetamide respectively according to the volume ratio of 8:2, stir and mix evenly to obtain a formacetamide mixed solution.

[0062] (2) Measure the formaldehyde-acetamide mixed solution and acetone respectively according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com