Metal curtain wall assembling device

A technology for assembling device and metal curtain wall, applied in the direction of walls, building components, buildings, etc., can solve the problems of affecting the appearance of buildings, unable to release thermal expansion and contraction stress, etc., to reduce the appearance of spalling, practicability and aesthetics enhancement , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

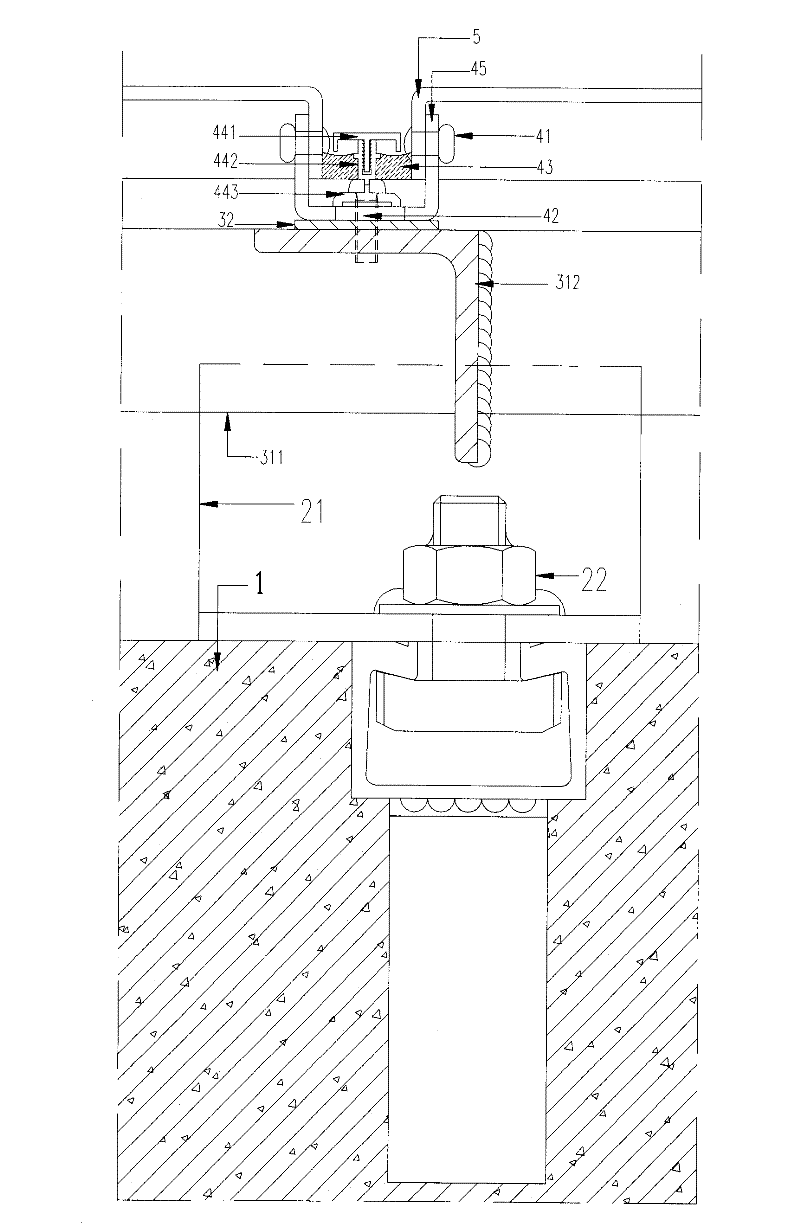

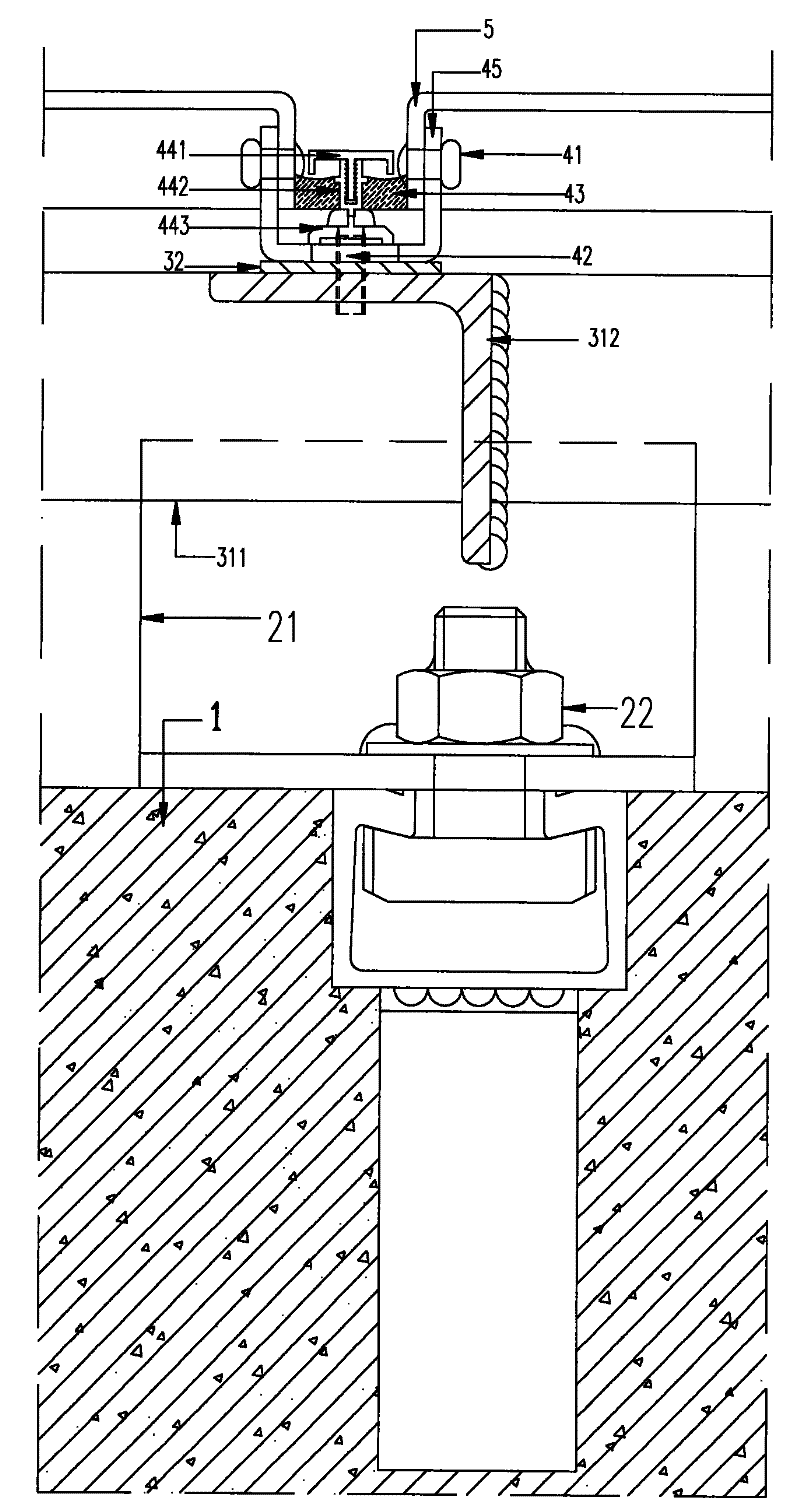

[0016] Such as figure 1 As shown, a metal curtain wall assembly device includes a main keel assembly, a secondary keel assembly, an aluminum veneer sealing and fixing assembly, and an aluminum veneer 5. The main keel assembly includes a first angle steel 21, a Hafen groove embedded part 22. The secondary keel component includes a second angle steel and a gasket 32, the second angle steel includes a second transverse angle steel 311, and a second longitudinal angle steel 312, and the aluminum veneer sealing and fixing component includes a core-pulling rivet 41. Pan head screws 42, silicone sealant 43, angle aluminum 45, PVC components; the first angle steel 21 is fixed on the building concrete structure 1 through the Hafen groove embedded parts 22, and the second angle steel Welded on the first angle steel 21, the aluminum veneer 5 is connected to the angle aluminum 45 through a core-pulling rivet 41, the second longitudinal angle steel 312 is connected to the angle aluminum 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com