Electrochemical oxidation of phytic acid-polypyrrole/carbon fiber composite material and its preparation method and application

A fiber composite material and composite material technology, applied in the field of supercapacitor electrode materials, can solve the problems of few surface active sites, high price of metal mesh, and difficulty in forming chemical bonds, etc., to achieve enhanced chemical adsorption, improved structural stability, and improved affinity. water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

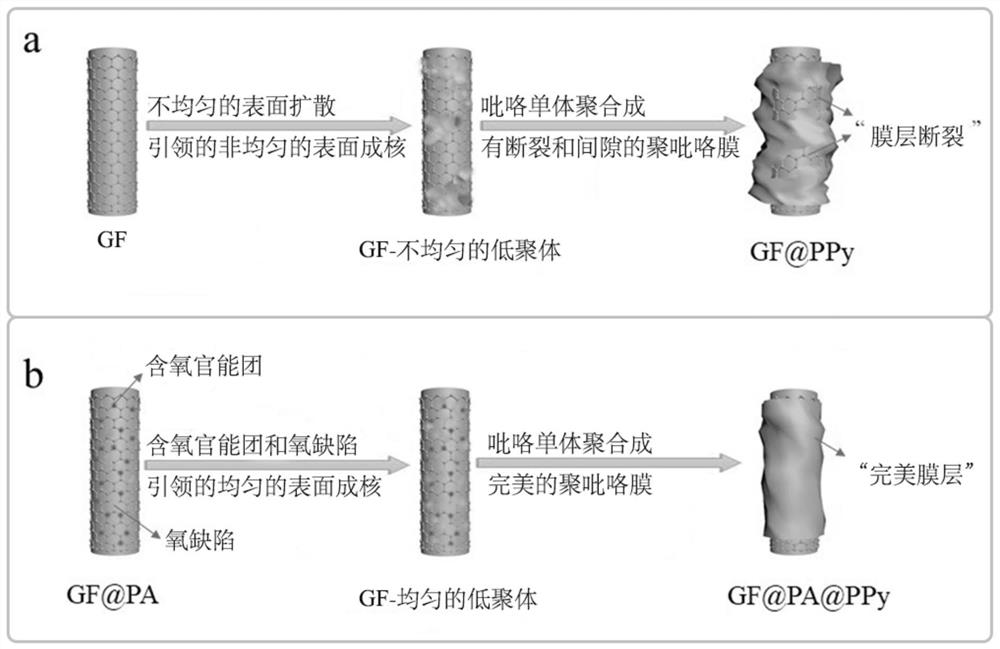

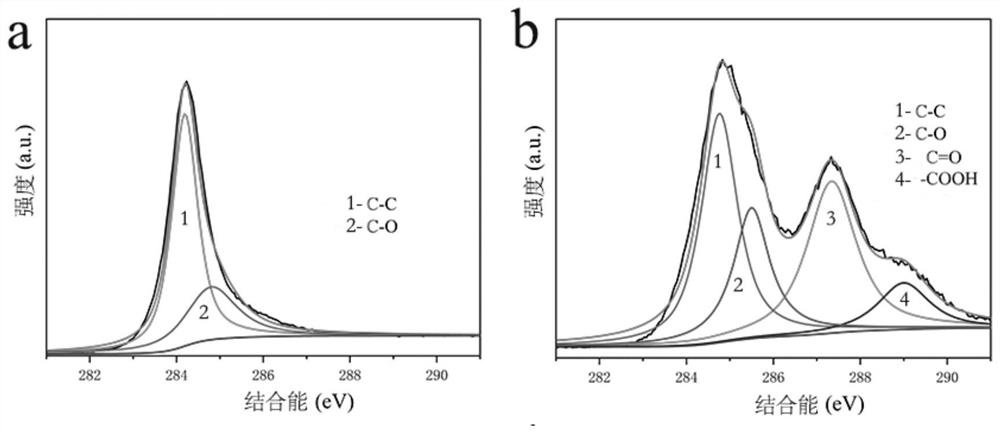

[0051] A phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material, including a modified carbon fiber composite material, the surface of the carbon fiber in the modified carbon fiber composite material is covered with a polypyrrole film, wherein the modified carbon fiber composite material is made of carbon fiber composite material. It is prepared after electrochemical oxidation, and the mass ratio of the polypyrrole film and the modified carbon fiber composite material is 3:10.

[0052] In this embodiment, the carbon fiber composite material is a carbon fiber felt, that is, in this embodiment, the phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material is specifically a phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material.

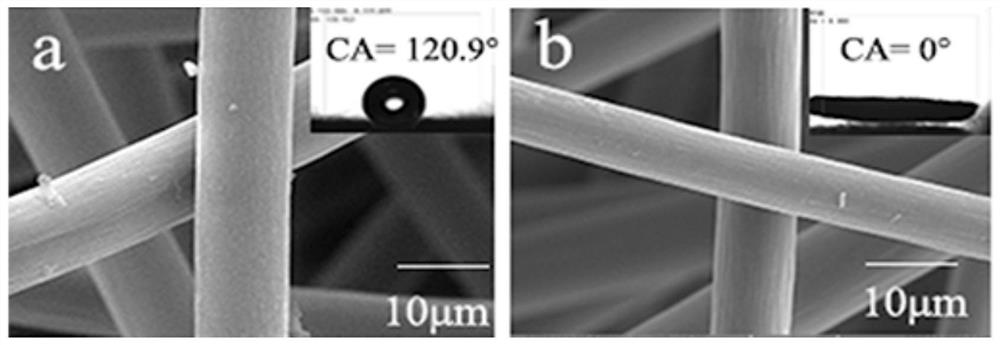

[0053] In this embodiment, the polypyrrole film uniformly covers the surface of the carbon fiber; the film layer on the surface of the carbon fiber is very perfect, there is no ...

Embodiment 2

[0077] A phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material, which is basically the same as Example 1, except that the polypyrrole film and the modified carbon fiber in the phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material of Example 2 are composited The mass ratio of the materials is 1:10.

[0078] A preparation method of the electrochemical oxidation of phytic acid-polypyrrole / carbon fiber composite material in the above-mentioned present embodiment is basically the same as that of embodiment 1, and the difference is only that: in the preparation method of embodiment 2, when the electrochemical polymerization reaction is performed, The reaction conditions were set to 0.8 V for 20 min.

[0079] The electrochemical oxidation of phytic acid-polypyrrole / carbon fiber composite material prepared in Example 2 is denoted as GF@PA@PPy-20.

Embodiment 3

[0081] A phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material, which is basically the same as Example 1, except that the polypyrrole film and the modified carbon fiber in the phytic acid electrochemical oxidation-polypyrrole / carbon fiber composite material of Example 3 are composited The mass ratio of materials was 2.2:10.

[0082] A preparation method of the electrochemical oxidation of phytic acid-polypyrrole / carbon fiber composite material in the above-mentioned present embodiment is basically the same as that of embodiment 1, and the difference is only that: in the preparation method of embodiment 3, when the electrochemical polymerization reaction is performed, The reaction conditions were set to 0.8 V for 30 min.

[0083] The electrochemical oxidation of phytic acid-polypyrrole / carbon fiber composite material prepared in Example 3 is denoted as GF@PA@PPy-30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com