Automotive urea production equipment and process

A technology for production equipment and urea for vehicles, which is applied in the field of chemical production equipment and technology, can solve the problems of production personnel's physical damage, strong pungent smell, production environment pollution, etc., and achieve the effect of good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

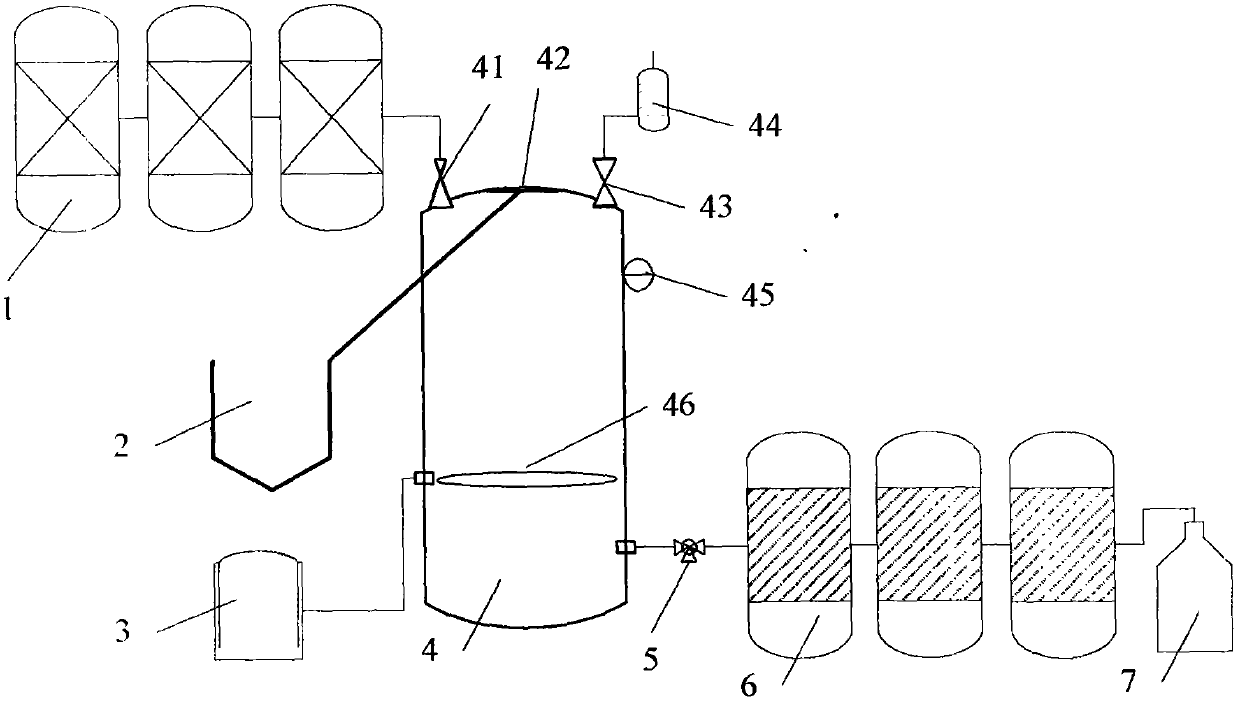

[0028] The urea used in vehicles is an aqueous solution of urea with a certain concentration. In the production of the solution provided in this example, industrial water is used to filter through the three-stage water filtration system (1) of physical filtration + ion exchange + electrodialysis, and the online water quality detection system dynamically monitors the water quality at any time, and adds qualified purified water to the dissolution tank. (4). The urea in this embodiment uses agricultural urea as the raw material, and is added to the dissolving tank (4) through the feeding system (2). The dissolving tank is provided with an air jet system (46), which can be distributed in a single-ring ring or a multi-ring ring or a spiral ring. Weakly alkaline; the gas storage system (3) is composed of an air compressor, a gas storage tank, a blowing system arranged in the dissolving tank and a connecting pipeline, and is connected with the gas storage system. When the urea soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com