Efficient de-dusting gas box type bag dust collector

A bag type dust collector and air box type technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of bag damage, large filter load of filter bags, etc., to avoid damage, reduce filter load, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

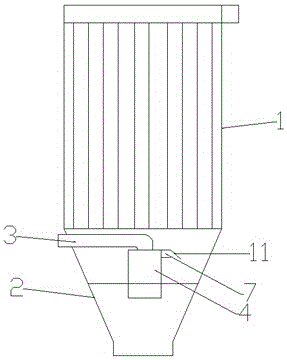

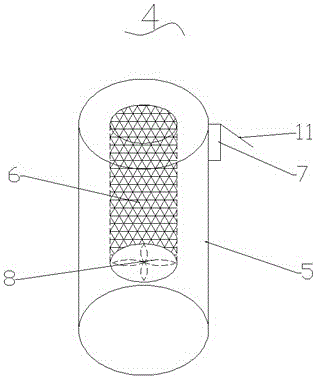

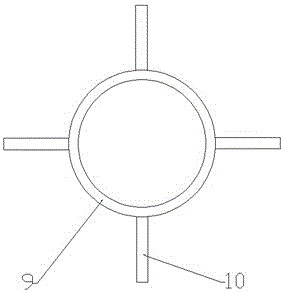

[0014] see Figure 1 to Figure 3 According to the present invention, a high-efficiency dust-removing air box bag filter includes a box body 1 and an ash hopper 2. The ash hopper 2 is provided with an air inlet pipe 3, and a centrifugal fan 2 is also provided in the ash hopper 2. Settling device 4, described centrifugal settling device 4 comprises outer cylinder 5 and inner cylinder 6 installed coaxially, the axes of described outer cylinder 5 and inner cylinder 6 coincide with the central axis of box body 1, the upper end of described outer cylinder 5 Closed and open at the lower end, the upper part of the side wall of the outer cylinder 5 is provided with an air outlet 7, the air inlet pipe 3 passes through the upper end of the outer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com