High-efficiency rotational flow sewage purifier

A purifier and sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of small equipment maintenance, rapid continuous and efficient processing, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

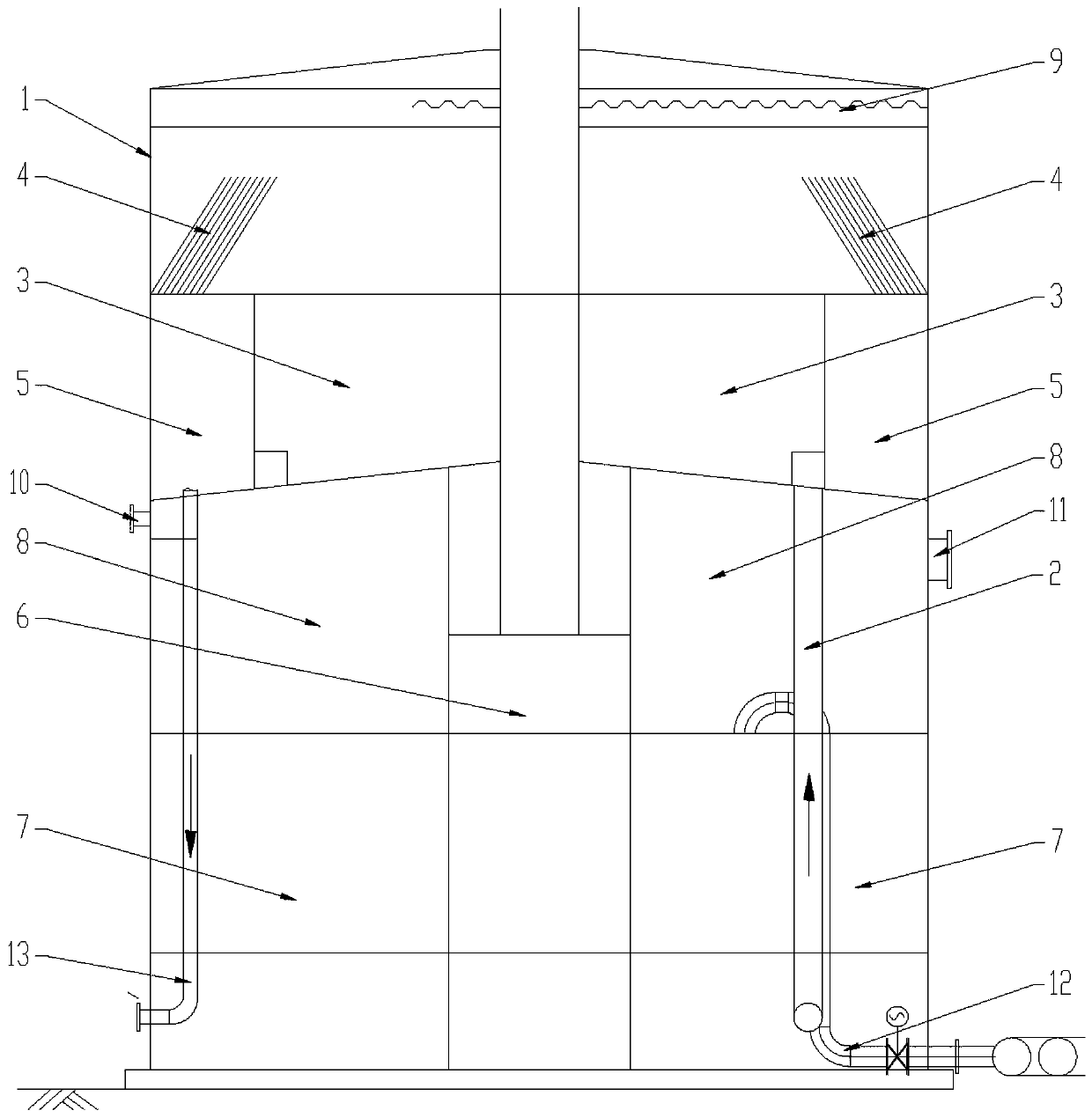

[0019] Such as figure 1 As shown: a high-efficiency cyclone sewage purifier, including a tank body 1, a cyclone centrifugal separation zone 3 connected with a sewage pipe 2 is provided on the upper part of the inner cavity of the tank body 1, and the sewage pipe 2 is connected with a mixer so that The sewage entering the tank body 1 has been dosed with medicine. A dynamic sedimentation zone 4 is provided above the cyclone centrifugal separation zone 3 and a sludge concentration zone 5 located directly below the dynamic sedimentation zone 4 is provided on its outside. The cyclone centrifugal separation zone 3 The sewage in the sludge reaches the dynamic sedimentation zone 4 after cyclone separation, so that part of the sludge and sand reach the dynamic sedimentation zone 4 under centrifugal action and then enter the sludge concentration zone 5. The conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com