Technique for recycling cleaned coal from low-value gangue or tail coal of coal washery

A process method and coal washing plant technology, applied in the field of solid waste resource utilization, to achieve the effects of streamlined and simple process, low operating cost, and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

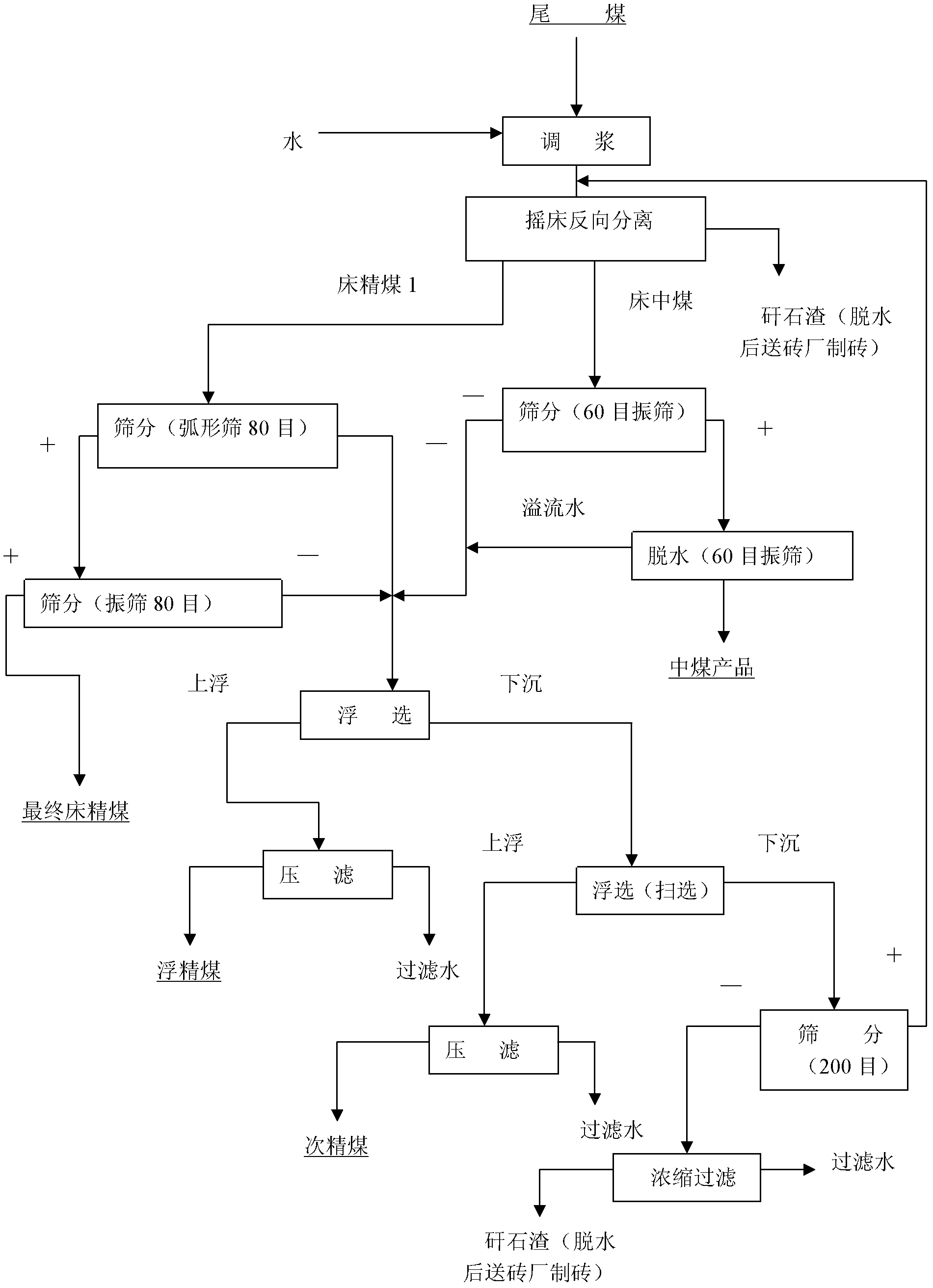

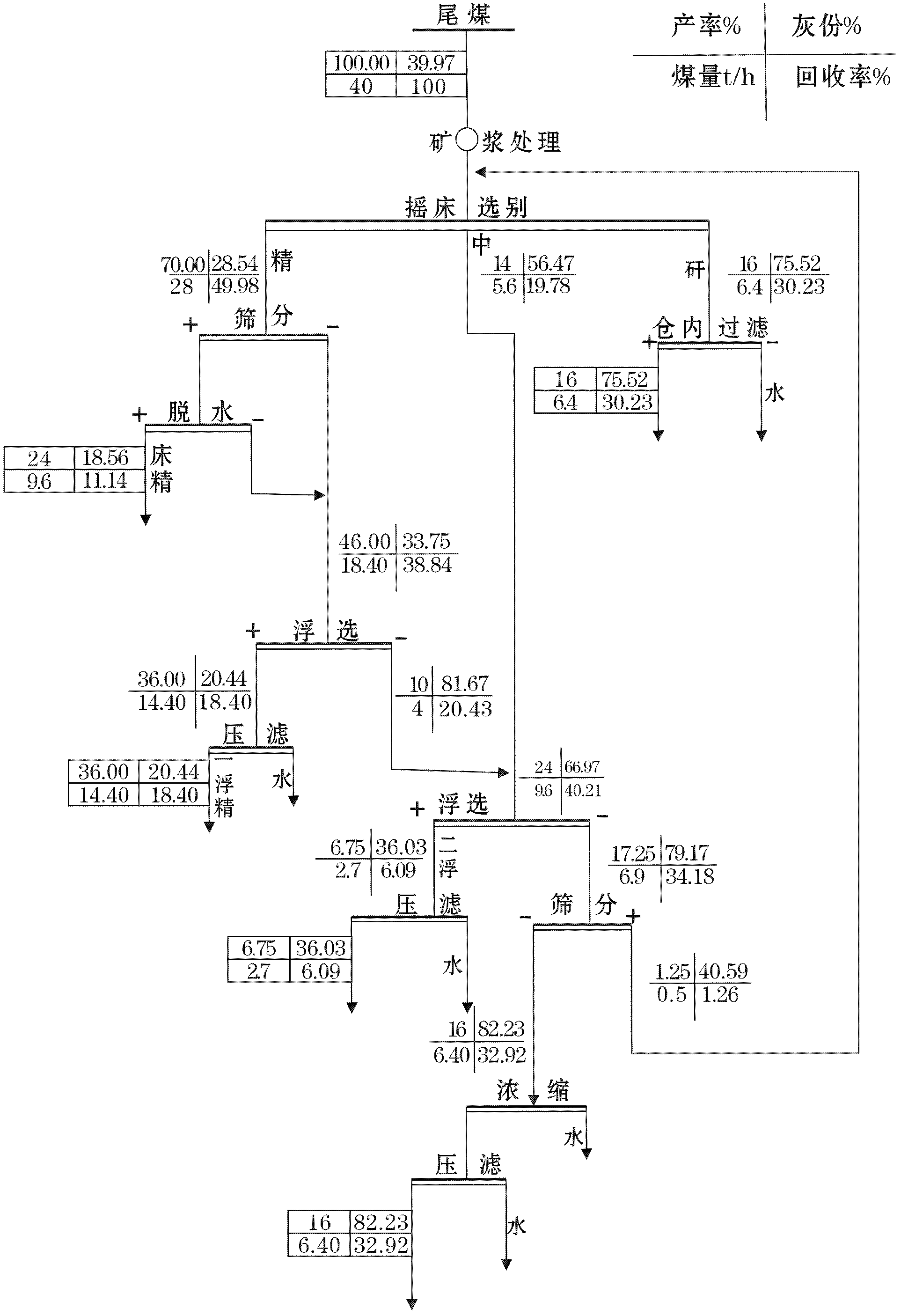

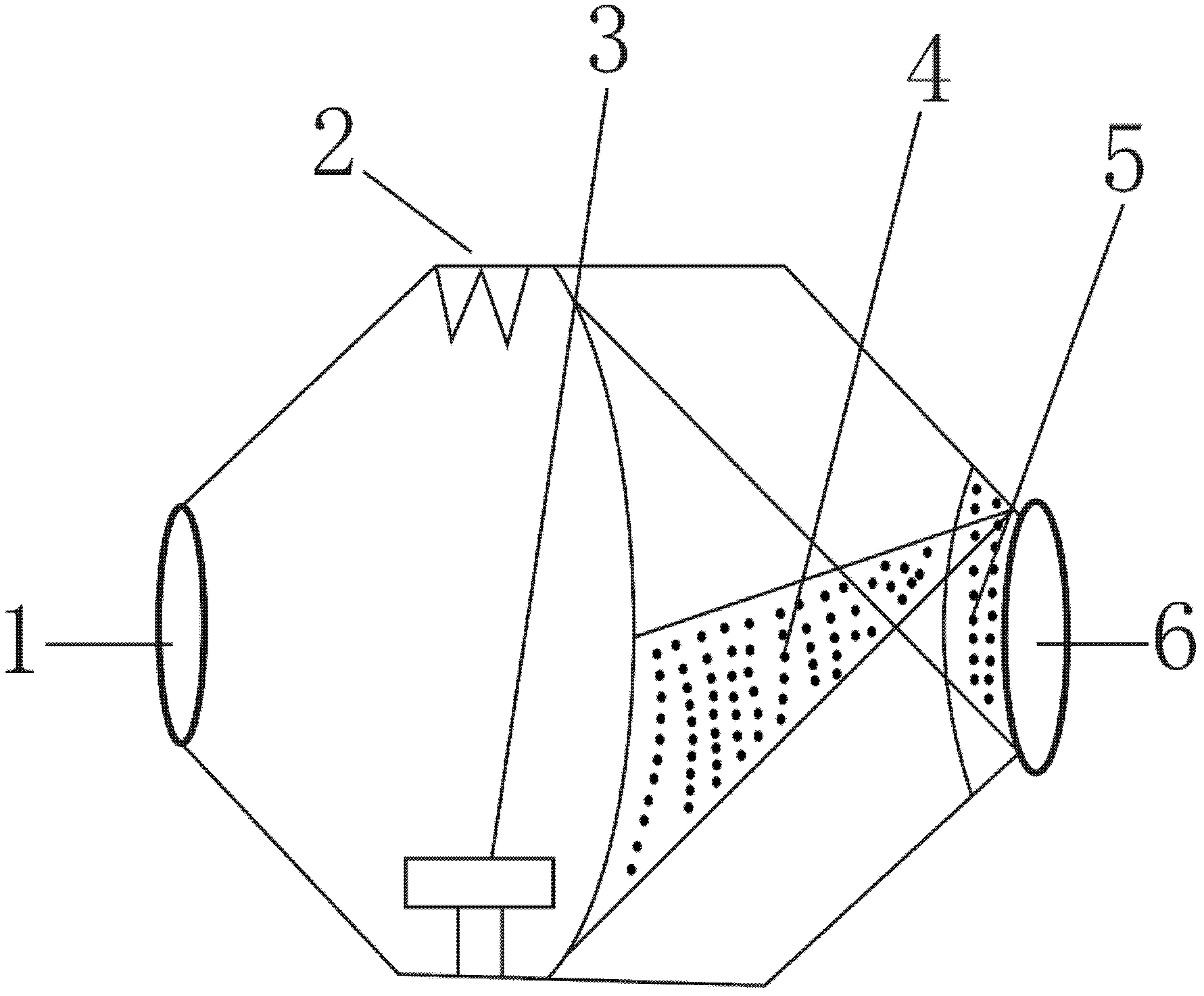

[0030] The positive technical effects of the present invention will be further described below in conjunction with the accompanying drawings and actual experimental conditions.

[0031] Example 1, such as Figure 1-3 It is requested that the tailing coal of a heavy medium plant contains 39.97% ash after testing. In the past, it was sold at a low price of 210 yuan / ton to some small honeycomb coal workshops or power plants for use. The degree of utilization is low and the economic benefits are poor. The present invention uses this as a raw material for advanced treatment. The specific method is: after pulping, control the concentration of ore pulp to 20-25%. In case of large pieces of material, it is first crushed to make the particle size less than 2mm before pulping. The pulp concentration can also be indirectly controlled by measuring the density to keep the plot at 1.2-1.3.

[0032] The tailing coal slurry after mixing is separated by a sieve with a mesh size of 2 mm to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com