Method for producing high-functional-trisaccharide-content isomaltooligosaccharide by using immobilized cells

A technology of isomaltose oligosaccharide, immobilized cells, applied in microorganism-based methods, biochemical equipment and methods, immobilized on/in organic carriers, etc., to achieve improved utilization, shortened process time, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

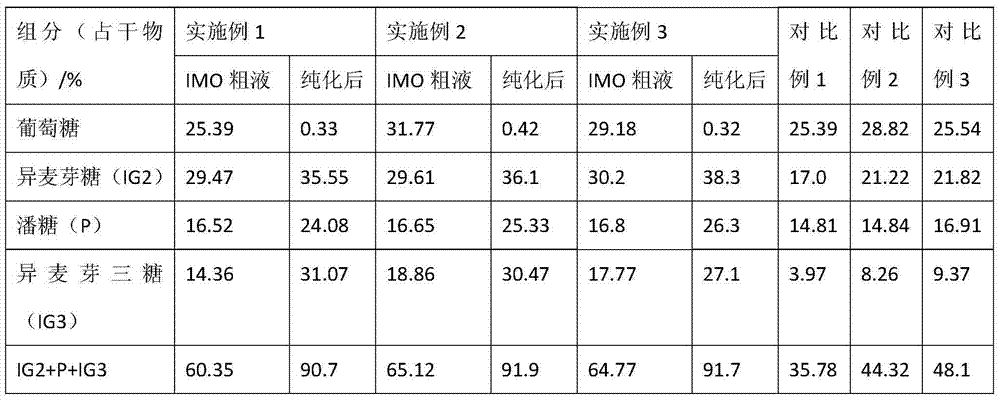

Embodiment 1

[0041] A method for immobilized cells to produce isomaltooligosaccharide with high functional trisaccharide content, the steps are as follows:

[0042](1) The seed liquid containing Aspergillus niger (Aspergillus niger) BLB‐28 strain was filtered out 10% by mass percentage of water, and then mixed with sodium alginate with a mass concentration of 3% in a volume ratio of 1:1, Then evenly drip it into a calcium chloride solution with a mass concentration of 3% for fixation for 4 hours, take out the immobilized rubber beads, wash them with water, and immerse them in pH 5‐7, containing 0.5% calcium chloride and 0.1% The mixed solution of chitosan is then soaked for 6h, and then the immobilized cells are loaded into the column by 20% of the column volume to obtain an immobilized cell column;

[0043] (2) Use cornstarch for pulping, the pulping concentration is 20% (mass concentration), and adjust the pH to 5.5, add high-temperature α-amylase, the addition amount is 0.2L per ton of ...

Embodiment 2

[0048] A method for immobilized cells to produce isomaltooligosaccharide with high functional trisaccharide content, the steps are as follows:

[0049] (1) The seed liquid containing Aspergillus niger (Aspergillus niger) BLB-28 strain was filtered out 40% of the water by mass percentage, and then mixed with sodium alginate with a mass concentration of 3% in a volume ratio of 1:5, Then evenly drop it into a calcium chloride solution with a mass concentration of 3% and fix it for 12 hours, take out the immobilized rubber beads, wash them with water, and immerse them in pH 5‐7, with a mass concentration of 3% calcium chloride and a mass concentration of 2%. The mixed solution of chitosan is then soaked for 12 hours, and then the immobilized cells are loaded into the column by 80% of the column volume to obtain the immobilized cell column;

[0050] (2) Use cornstarch for pulping, the pulping concentration is 40% (mass concentration), and adjust the pH to 6.5, add high-temperature ...

Embodiment 3

[0055] A method for immobilized cells to produce isomaltooligosaccharide with high functional trisaccharide content, the steps are as follows:

[0056] (1) The seed solution containing Aspergillus niger (Aspergillus niger) BLB‐28 strain was filtered out with a mass percentage of 20% water, and then mixed with sodium alginate with a mass concentration of 3% in a volume ratio of 1:2, Then evenly drip it into a calcium chloride solution with a mass concentration of 3% and fix it for 6 hours, take out the immobilized rubber beads, wash them with water, and immerse them in pH 5-7, with a mass concentration of 2% calcium chloride and a mass concentration of 1%. The mixed solution of chitosan is then soaked for 12h, and then the immobilized cells are loaded into the column by 70% of the column volume to obtain an immobilized cell column;

[0057] (2) Use cornstarch for pulping, the pulping concentration is 32% (mass concentration), and adjust the pH to 6.3, add high-temperature α-amy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com