Low temperature dyeing technology for pure cotton fabrics

A technology for low-temperature dyeing and pure cotton fabrics, which is applied in the field of dyeing technology of pure cotton fabrics, can solve the problems of water, electricity, steam and process time, large consumption of water, electricity and steam energy, and cannot be used in the same bath with dyeing. Significant social and economic benefits, reduced energy consumption, and process time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

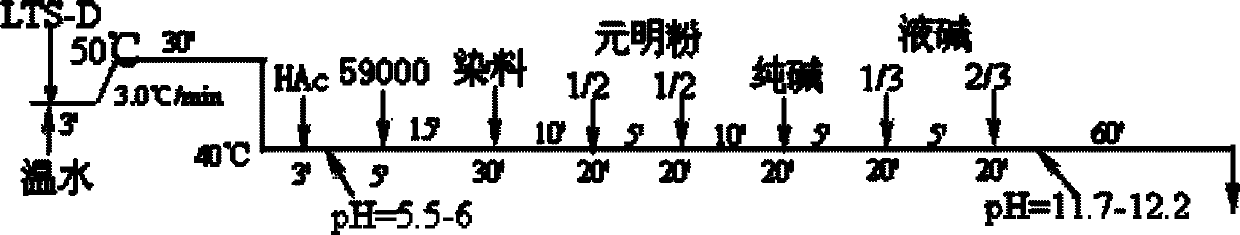

[0025] refer to figure 1 Shown, a kind of low-temperature dyeing process of pure cotton fabric comprises the steps:

[0026] (1) Low-temperature pretreatment: Add one-bath scouring and dyeing auxiliaries to the dyeing liquor with warm water and pure cotton fabrics in advance, the feeding time of one-bath scouring and dyeing auxiliaries is 3 minutes, adjust the concentration of one-bath scouring and dyeing auxiliaries to 1.5g / l, increase the temperature at 50°C at a rate of 3°C / min, and continue to react for 30 minutes (the feeding time is not included in this reaction time, and the reaction time that appears below is explained here). Agent is a kind of nonionic surfactant mixture, is specifically fatty alcohol polyoxyethylene ether mixture, and the present invention adopts the low-temperature refining and dyeing agent ForylLTS-D produced by Kekai Fine Chemical (Shanghai) Co., Ltd.;

[0027] (2) Polishing: Adjust the temperature to 40°C, add acetic acid to adjust the pH value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com