Continuous extraction method and device of papermaking reconstituted tobacco

A technology of tobacco flakes and extraction devices, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve problems affecting the proportion of process formula, poor feeding, and affecting extraction efficiency, etc., to achieve good production flexibility, maintain uniformity, and improve The effect of extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

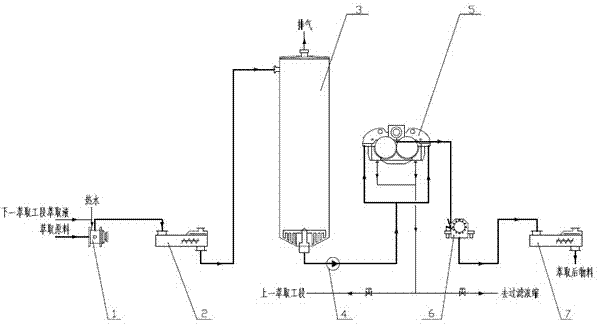

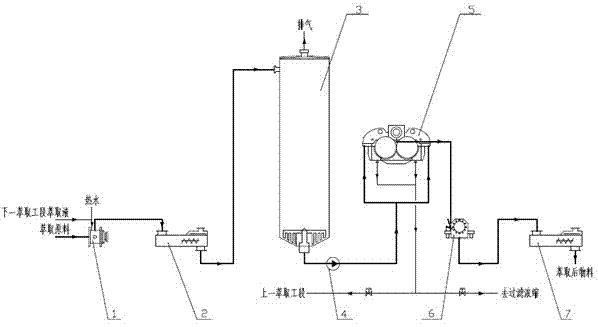

[0024] Such as figure 1 As shown, it is a schematic diagram of a continuous extraction device for paper-making tobacco sheets. The paper-making tobacco sheet continuous extraction device is composed of two extraction sections, and each extraction section is composed of a mixer 1, a first screw conveyor 2, a descending It consists of a flow extraction tower 3, a medium consistency pulp pump 4, a squeezer 5, a deflaker 6, and a second screw conveyor 7. The material outlet of the mixer 1 is connected with the material inlet of the first screw conveyor 2, the material outlet of the first screw conveyor 2 is connected with the top material inlet of the downflow extraction tower 3, and the bottom material outlet of the downflow extraction tower 3 is connected The material inlet of the thick stock pump 4, the material outlet of the medium thick stock pump 4 are connected to the material inlet of the squeezer 5, the concentrated material outlet of the squeezer 5 is connected to the ma...

Embodiment 2

[0037] Such as figure 1As shown, it is a schematic diagram of a continuous extraction device for paper-making tobacco sheets. The paper-making tobacco sheet continuous extraction device is composed of three extraction sections, and each extraction section consists of a mixer 1, a first screw conveyor 2, and a downflow extraction. It is composed of tower 3, medium-consistency pump 4, pulping machine 5, deflagging machine 6, and second screw conveyor 7. The material outlet of the mixer 1 is connected with the material inlet of the first screw conveyor 2, the material outlet of the first screw conveyor 2 is connected with the top material inlet of the downflow extraction tower 3, and the bottom material outlet of the downflow extraction tower 3 is connected The material inlet of the thick stock pump 4, the material outlet of the medium thick stock pump 4 are connected to the material inlet of the squeezer 5, the concentrated material outlet of the squeezer 5 is connected to the m...

Embodiment 3

[0054] Such as figure 1 As shown, it is a schematic diagram of a continuous extraction device for paper-making tobacco sheets. The paper-making tobacco sheet continuous extraction device is composed of a primary extraction section, and the primary extraction section is composed of a mixer 1, a first screw conveyor 2, a descending It consists of a flow extraction tower 3, a medium consistency pulp pump 4, a squeezer 5, a deflaker 6, and a second screw conveyor 7. The material outlet of the mixer 1 is connected with the material inlet of the first screw conveyor 2, the material outlet of the first screw conveyor 2 is connected with the top material inlet of the downflow extraction tower 3, and the bottom material outlet of the downflow extraction tower 3 is connected The material inlet of the thick stock pump 4, the material outlet of the medium thick stock pump 4 are connected to the material inlet of the squeezer 5, the concentrated material outlet of the squeezer 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com