Patents

Literature

36results about How to "Good production flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of intermediate fractional oil from Fischer-Tropsch synthetic oil

ActiveCN1854265ADifferent performanceLow priceTreatment with hydrotreatment processesHydrogenNaphtha

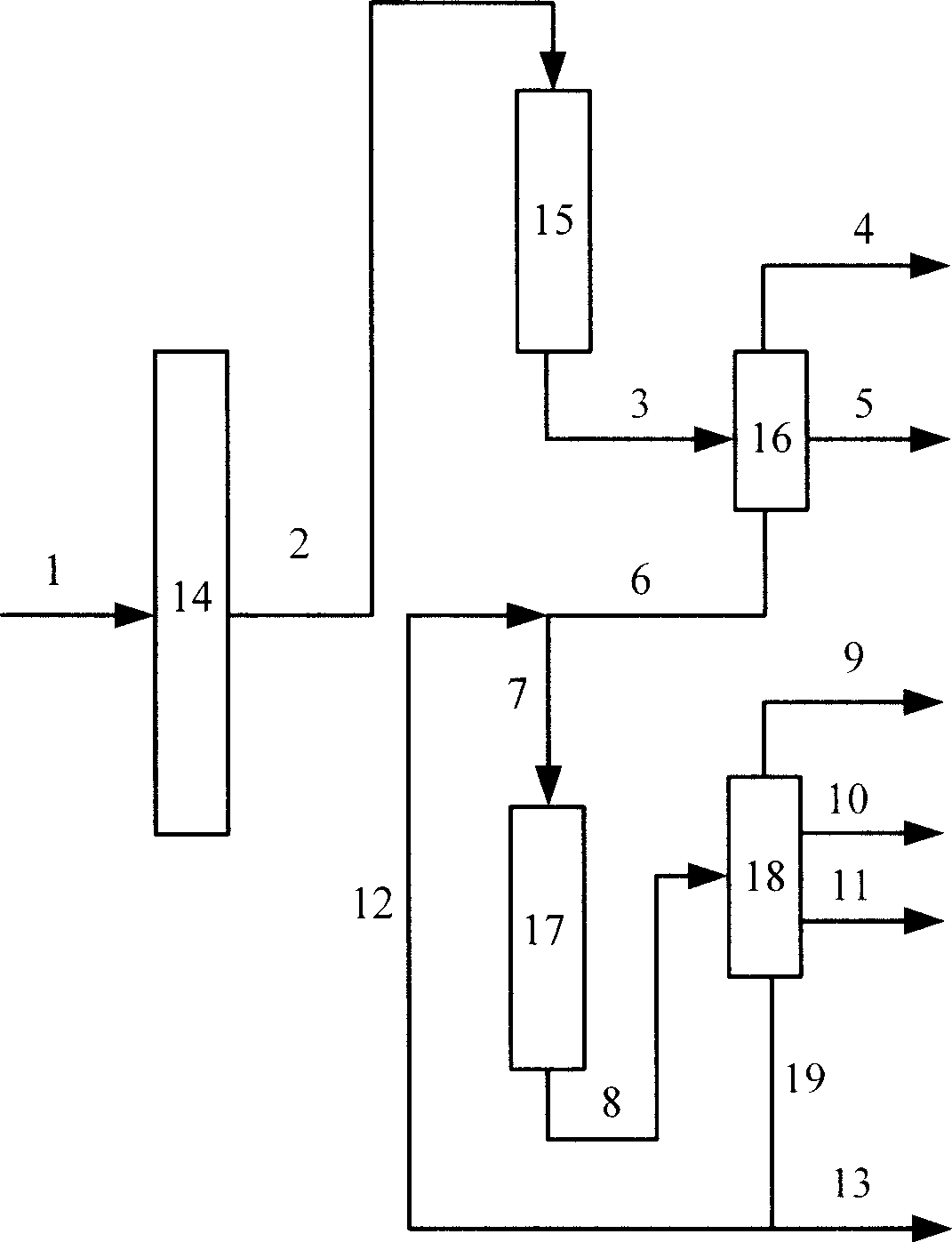

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation purifying combined process for Fischer-Tropsch synthetic substance

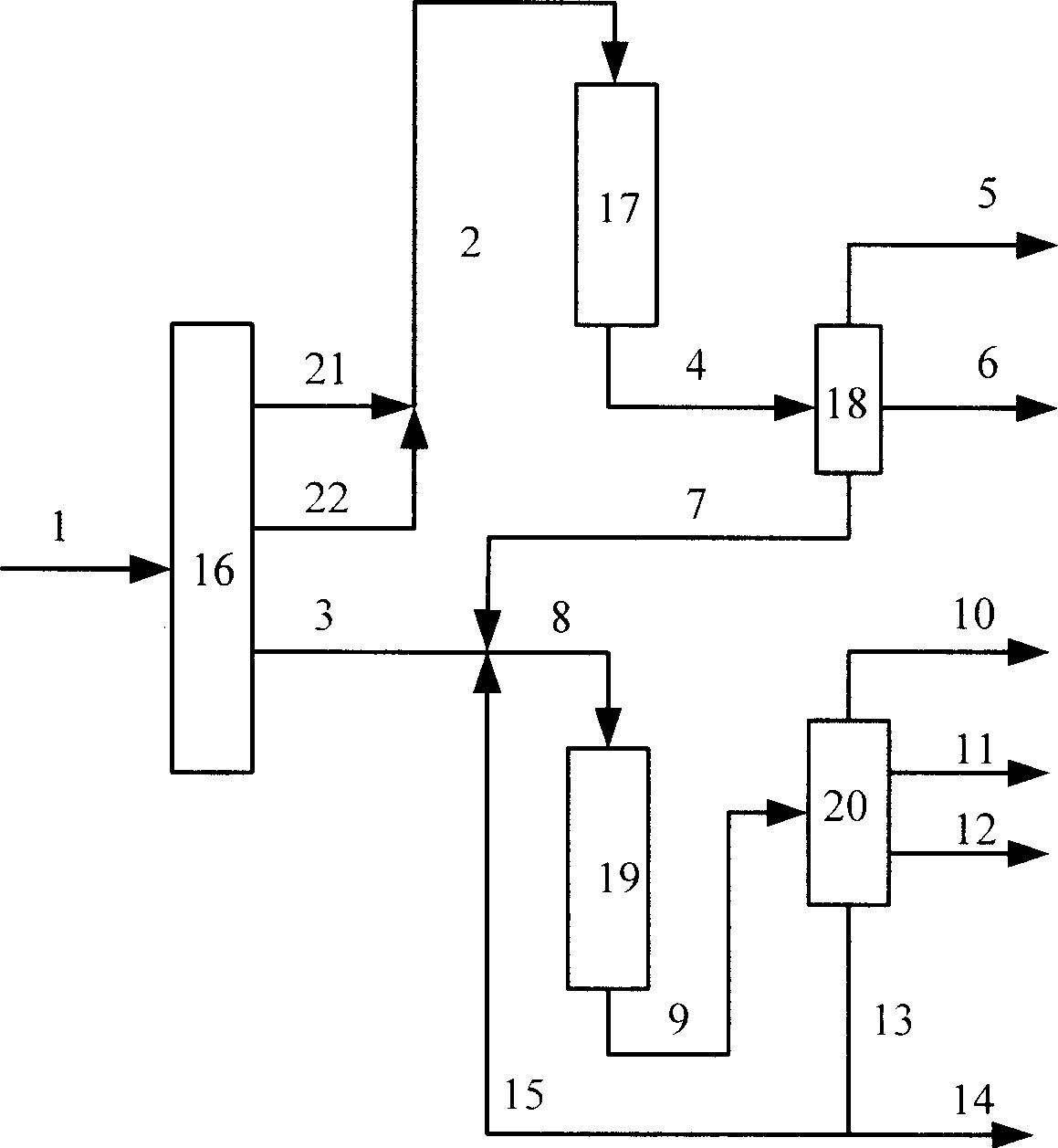

A kind of combined technology method to hydrogenate and improve quality of the product from Fishcher-Tropsch synthesis process, condensate and synthetic wax can be gained by natural isolation of the product from Fishcher-Tropsch synthesis process, and the condensate will contact with hydrogen and hydrofining catalyst, then the tail oil produced by the isolation of the hydrofining reactant liquor will contact with the synthetic wax, hydrogen, and hydrocracking and isocracking catalyst, the middle oil fraction product can be gained after the isolation of the hydrocracking reactant liquor at last. The yield of the diesel oil is more than 80% by the method, the cetane number will be more than 80, and sulfur, nitrogen and aromatic hydrocarbon can barely found in the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated Fischer-Tropsch synthetic oil hydrogenation purification

ActiveCN1854264AAvoid enteringImprove overall utilizationTreatment with hydrotreatment processesHydrogenNaphtha

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

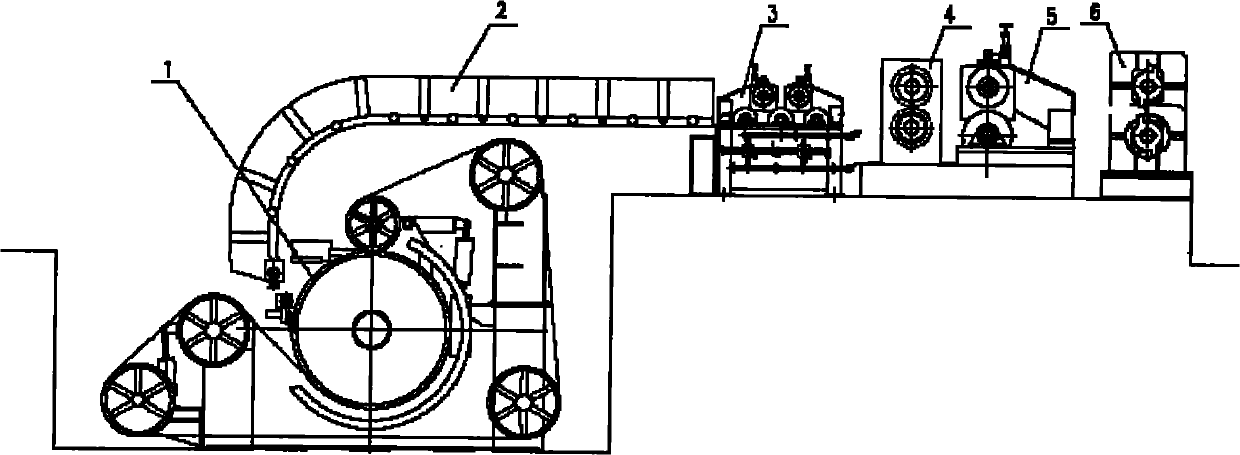

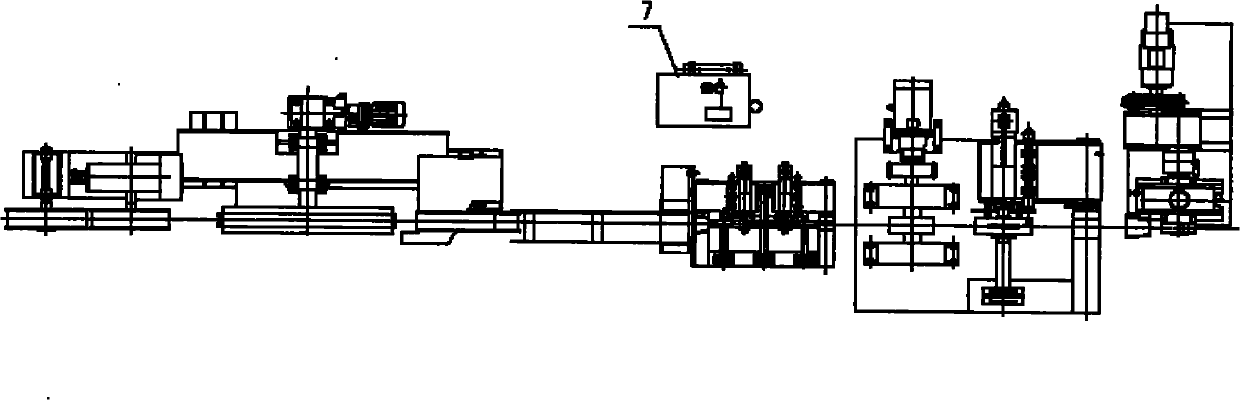

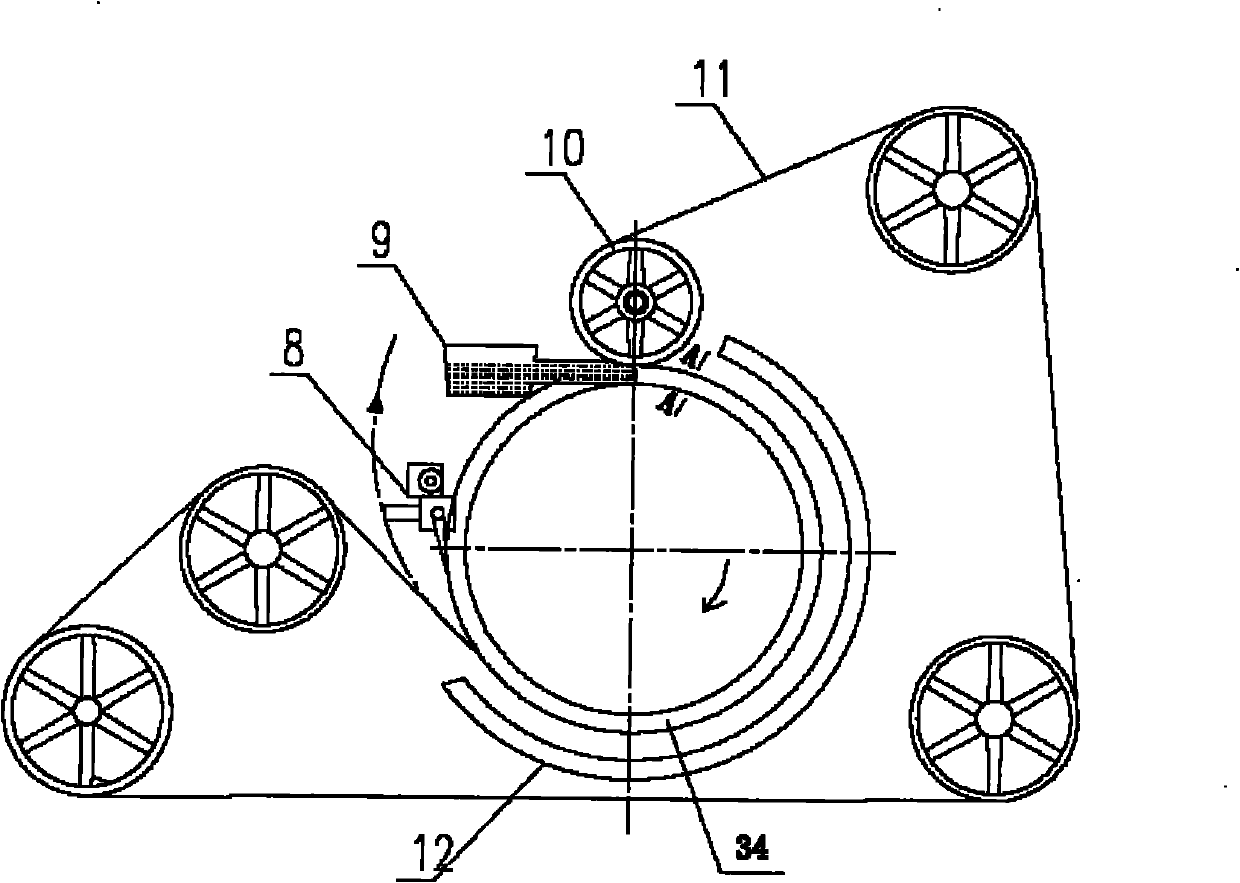

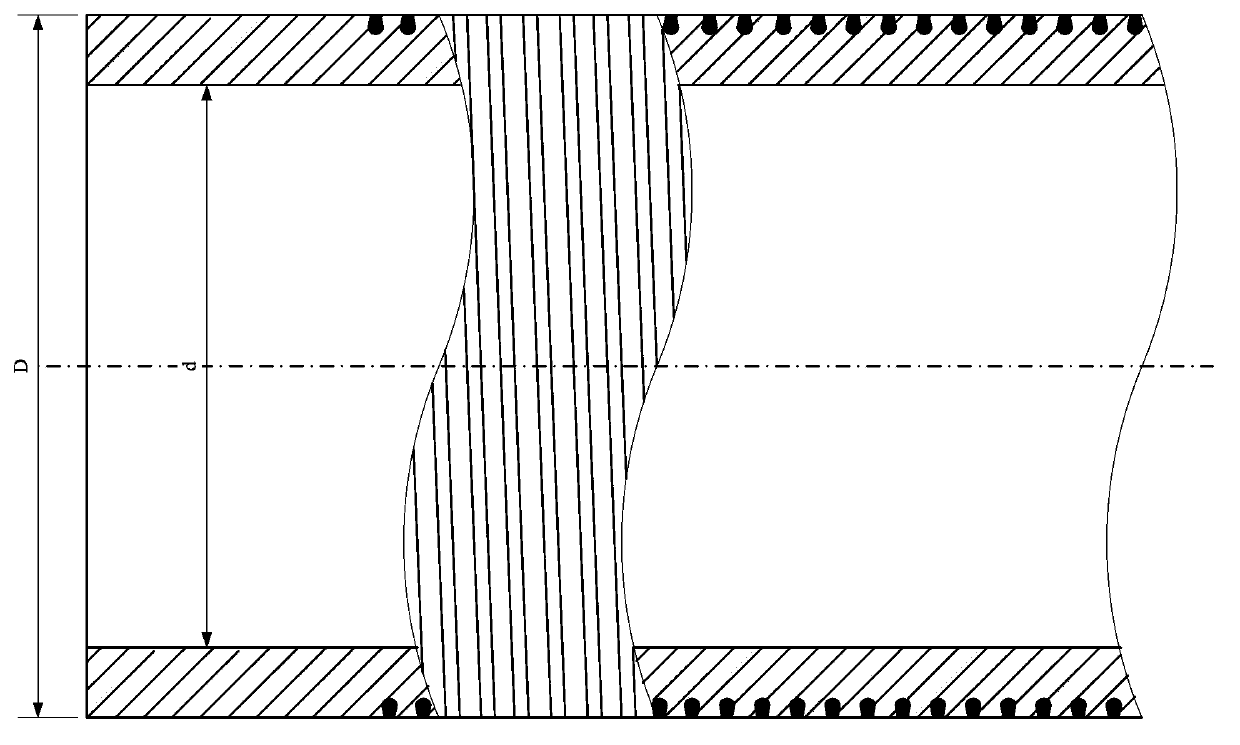

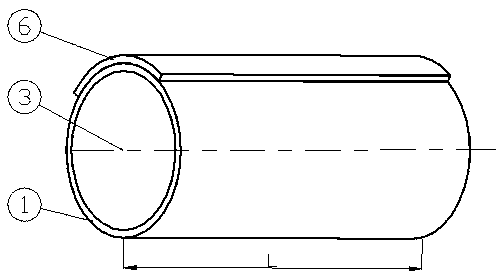

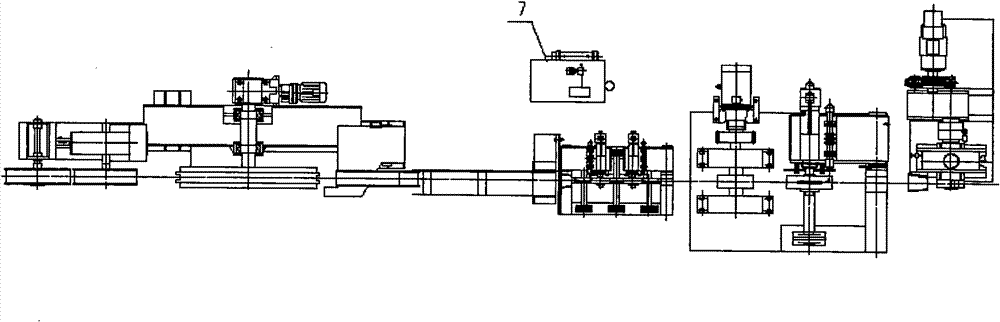

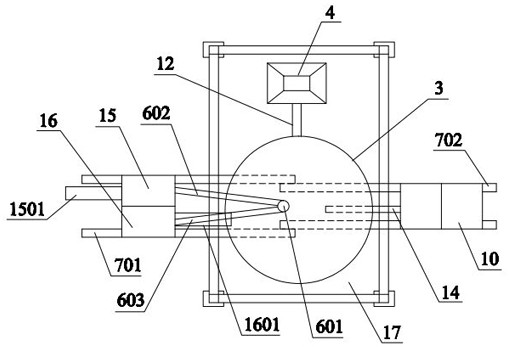

Method and device for producing A356 aluminum alloy by belt casting

The invention discloses a method and a device for producing A356 aluminum alloy by belt casting. The prepared A356 aluminum alloy liquid is subjected to furnace refining and on-line degassing filtration, and then is continuously poured into a crystallizer of a casting machine; and the periphery of the crystallizer is continuously filled with cooling water for crystallization. A crystalline region is divided into five sections from the higher temperature to the lower temperature, and a cooling region is divided into twelve regions according to different flow rates of the cooling water distributed at the periphery of the crystallizer. The belt casting machine comprises a casting machine, a straightening machine, a blank guiding machine, a rolling code machine, a roller shearing machine, and the like, which are arranged in turn; and an approach bridge is arranged between the casting machine and the straightening machine. Compared with the prior art, the method and the device have the advantages of simple production equipment, less investment, short production flow, low production cost, advanced technology, low gas-slag content in the products, low composition segregation, stable product quality, and excellent production flexibility, quickly adjustable product types, and safe working environment.

Owner:YUNNAN ALUMINUM

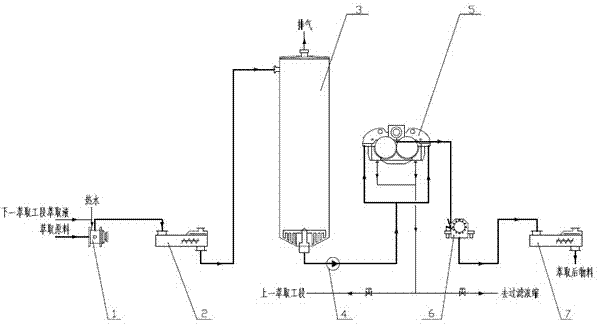

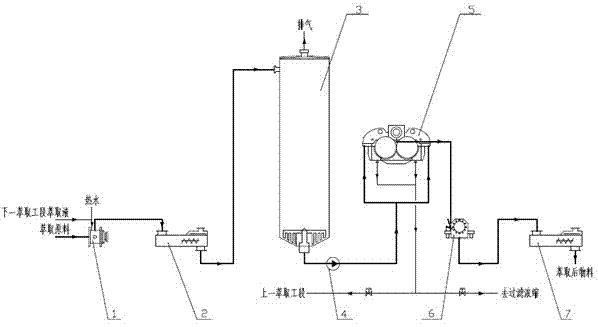

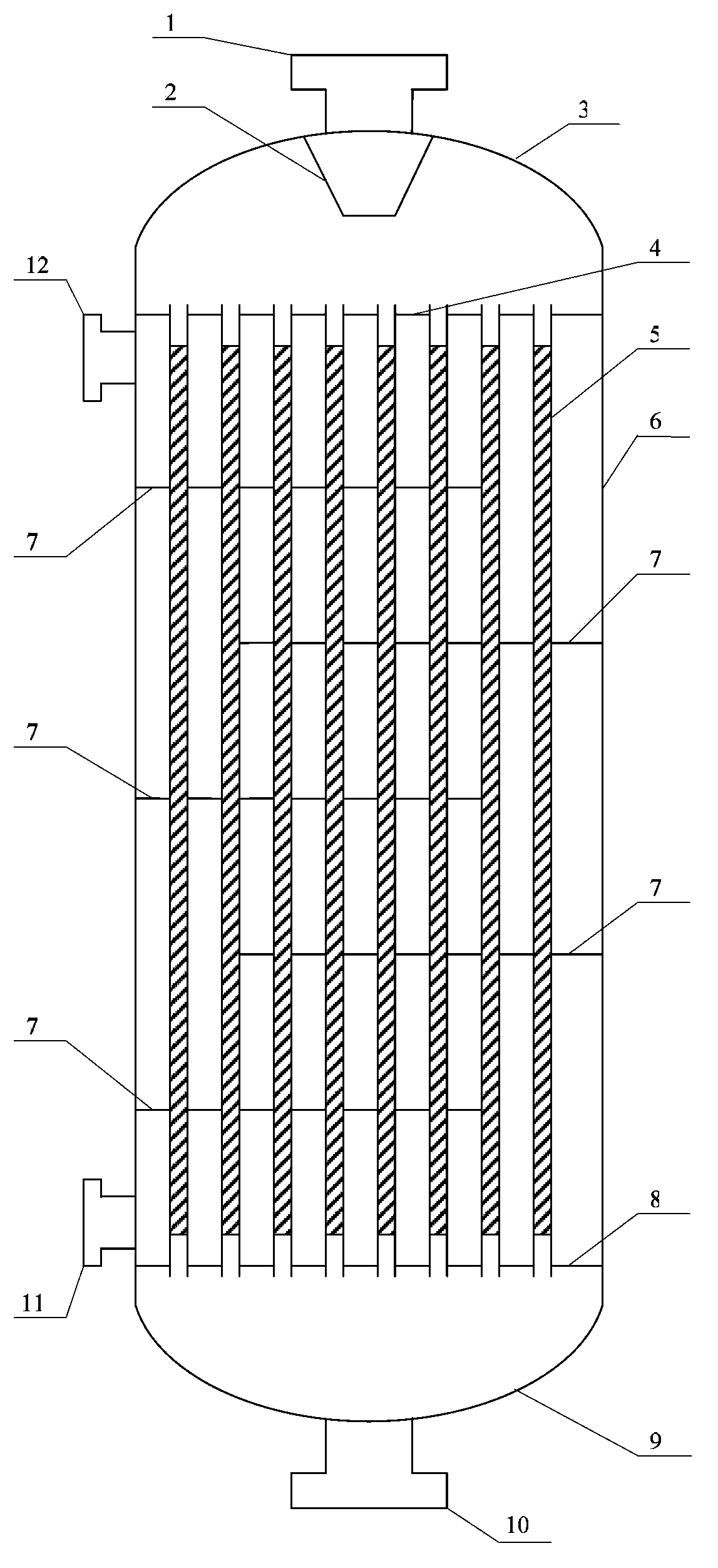

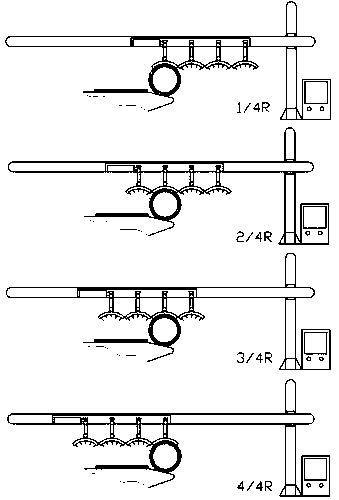

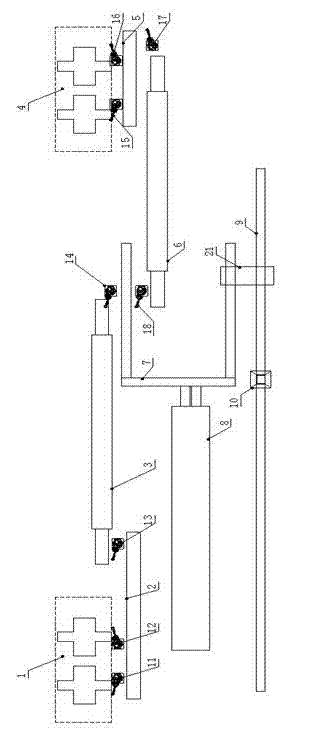

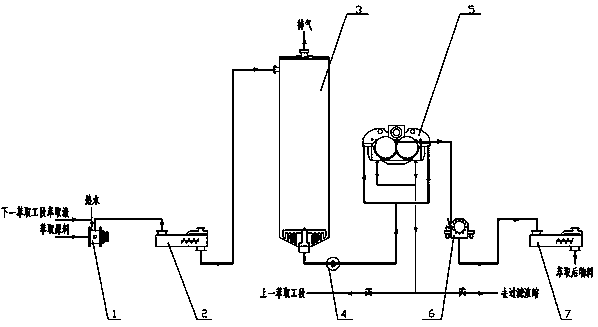

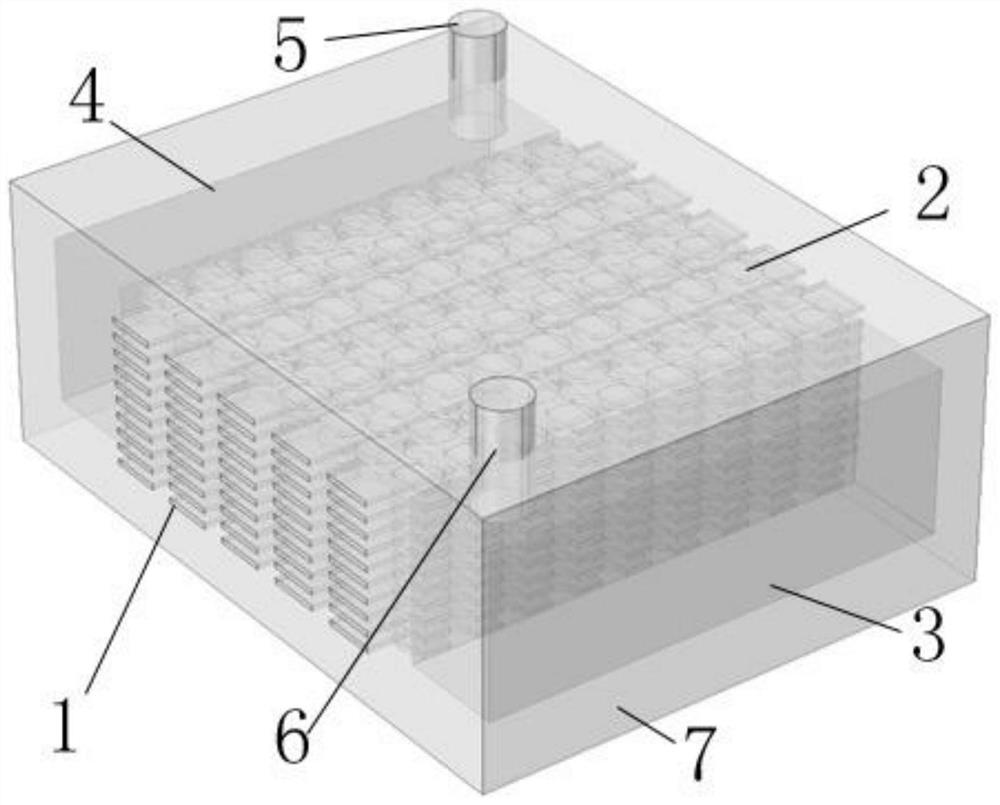

Continuous extraction method and device of papermaking reconstituted tobacco

ActiveCN102488319ARemain suspended on the surface of the liquidThere will be no suspension on the liquid surfaceTobacco treatmentScrew conveyorContinuous production

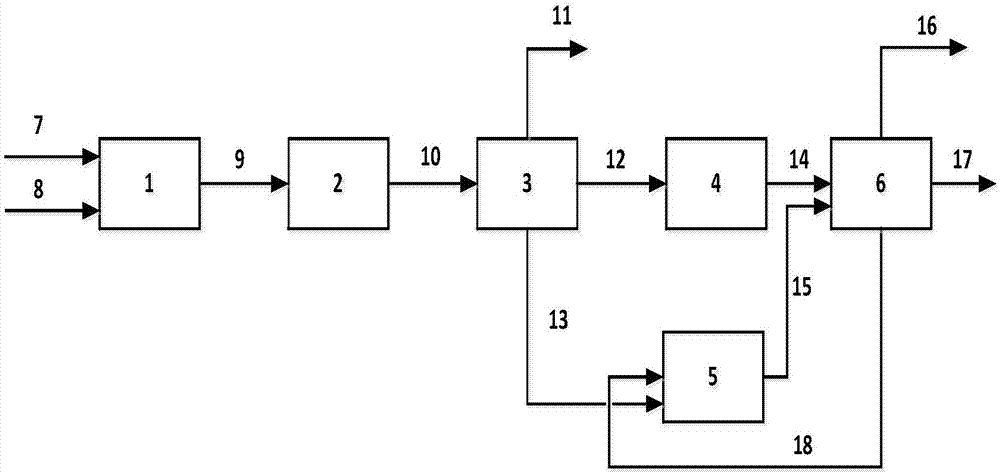

The invention discloses a continuous extraction method and device of papermaking reconstituted tobacco. The continuous extraction device of the papermaking reconstituted tobacco is characterized by comprising a mixer, a first spiral conveyor, a downflow extraction tower, a medium-consistency pulp pump, a press master, a fluffer and a second spiral conveyor, wherein the mixer, the first spiral conveyor, the downflow extraction tower and the medium-consistency pulp pump are orderly connected, a material discharge hole of the medium-consistency pulp pump is connected with a material feeding hole of the press master, a concentrated material discharge hole of the press master is connected with the fluffer, the fluffer is connected with the second spiral conveyor, a material discharge hole of the second spiral conveyor is connected to the next level of extraction section or pulping section, and an extract liquor discharge hole of the press master is connected to an extract liquor feeding hole of the mixer in a concentration section of the extract liquor or the last extraction section. The continuous extraction device of the papermaking reconstituted tobacco, disclosed by the invention, has the advantages of simple operation, good production flexibility, capability of continuously producing, low water consumption and high extraction rate.

Owner:CHINA HAISUM ENG

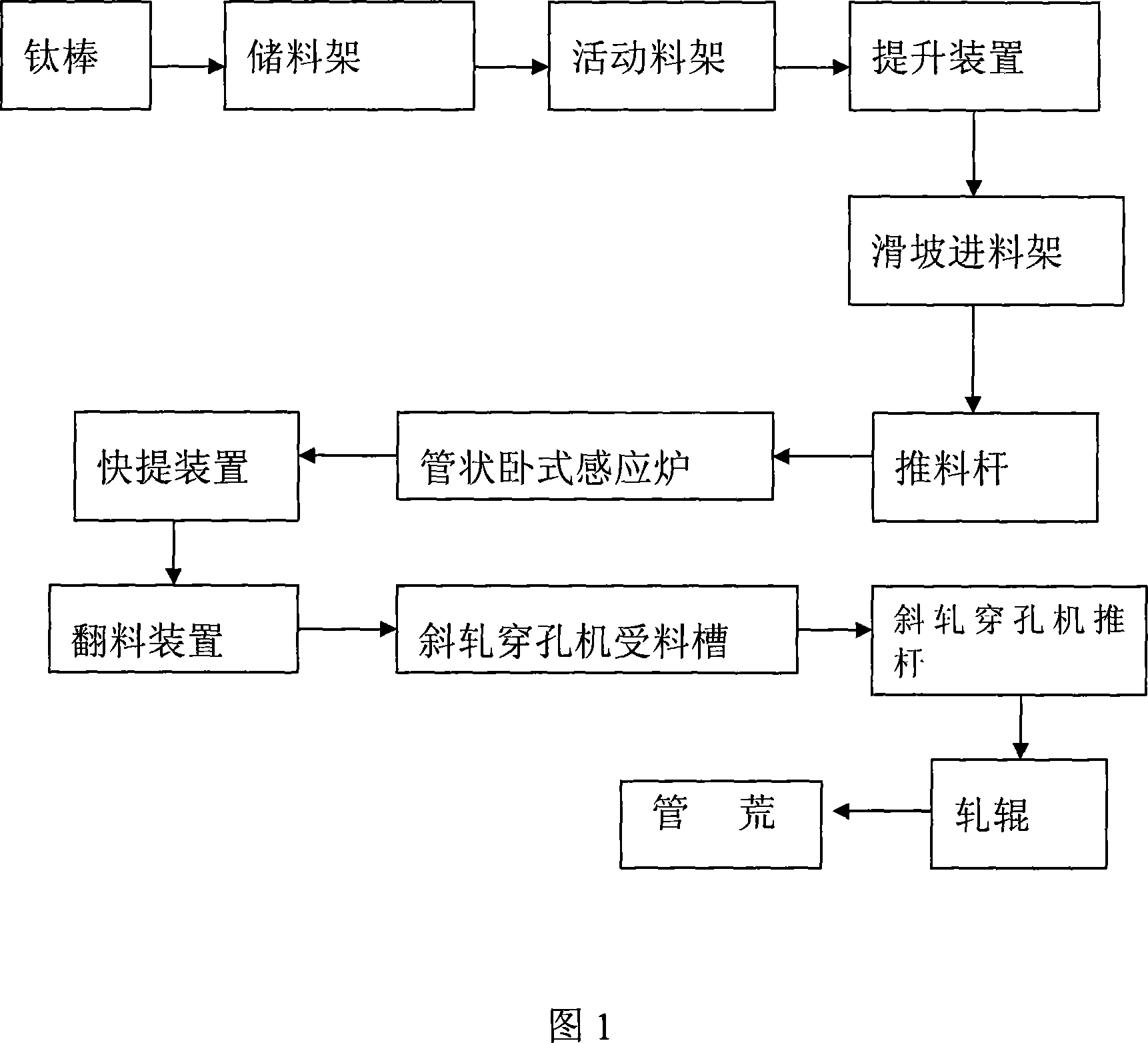

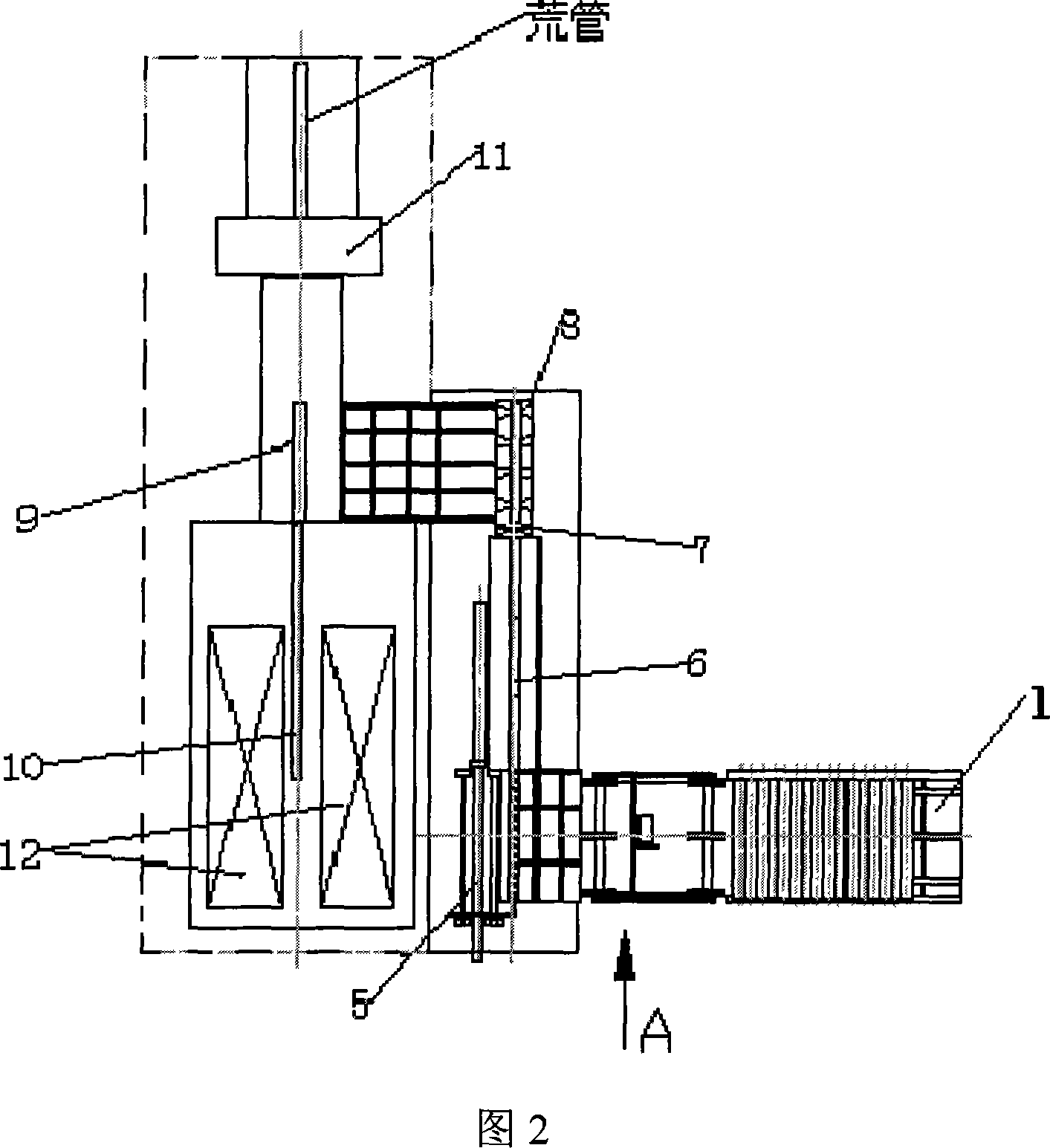

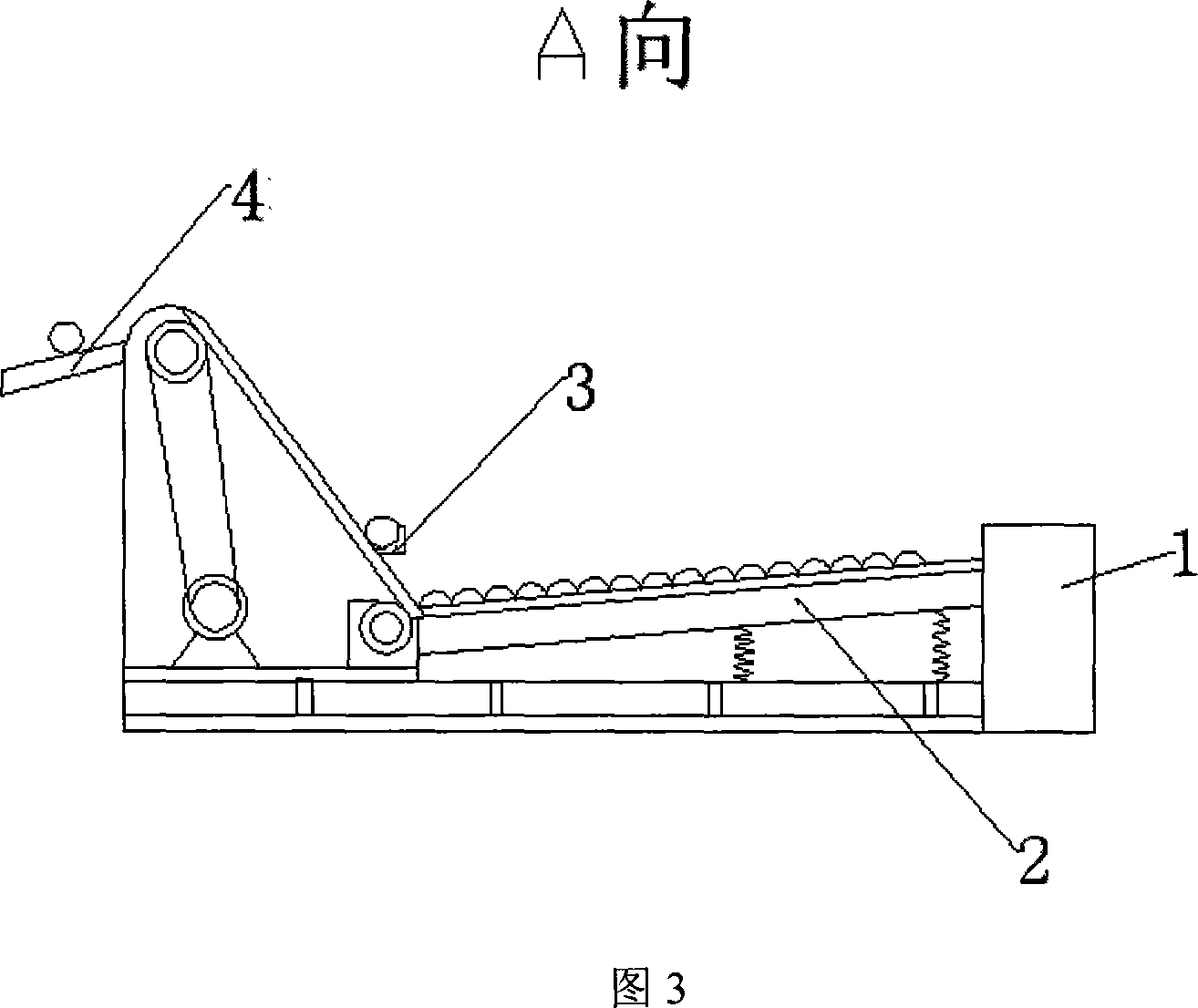

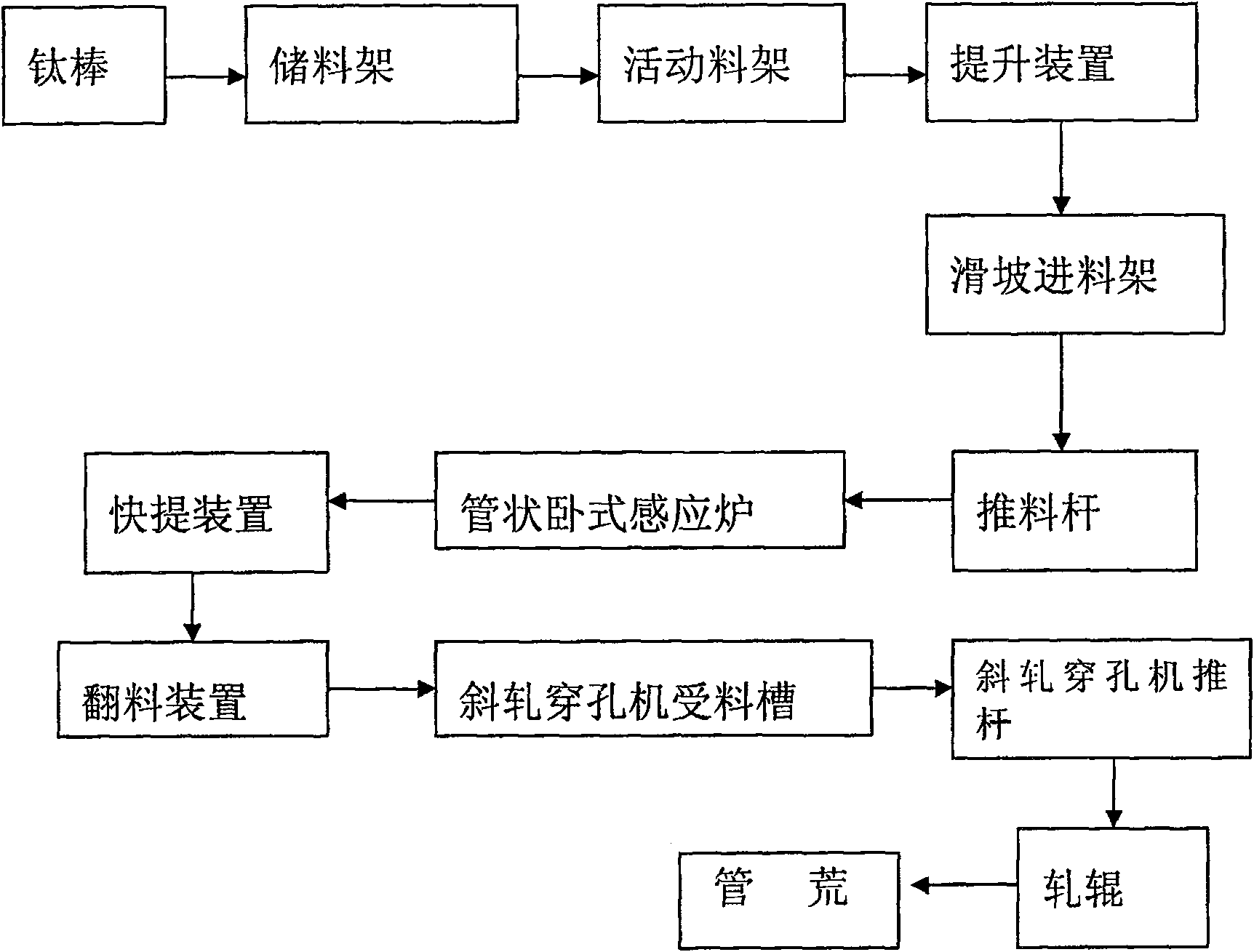

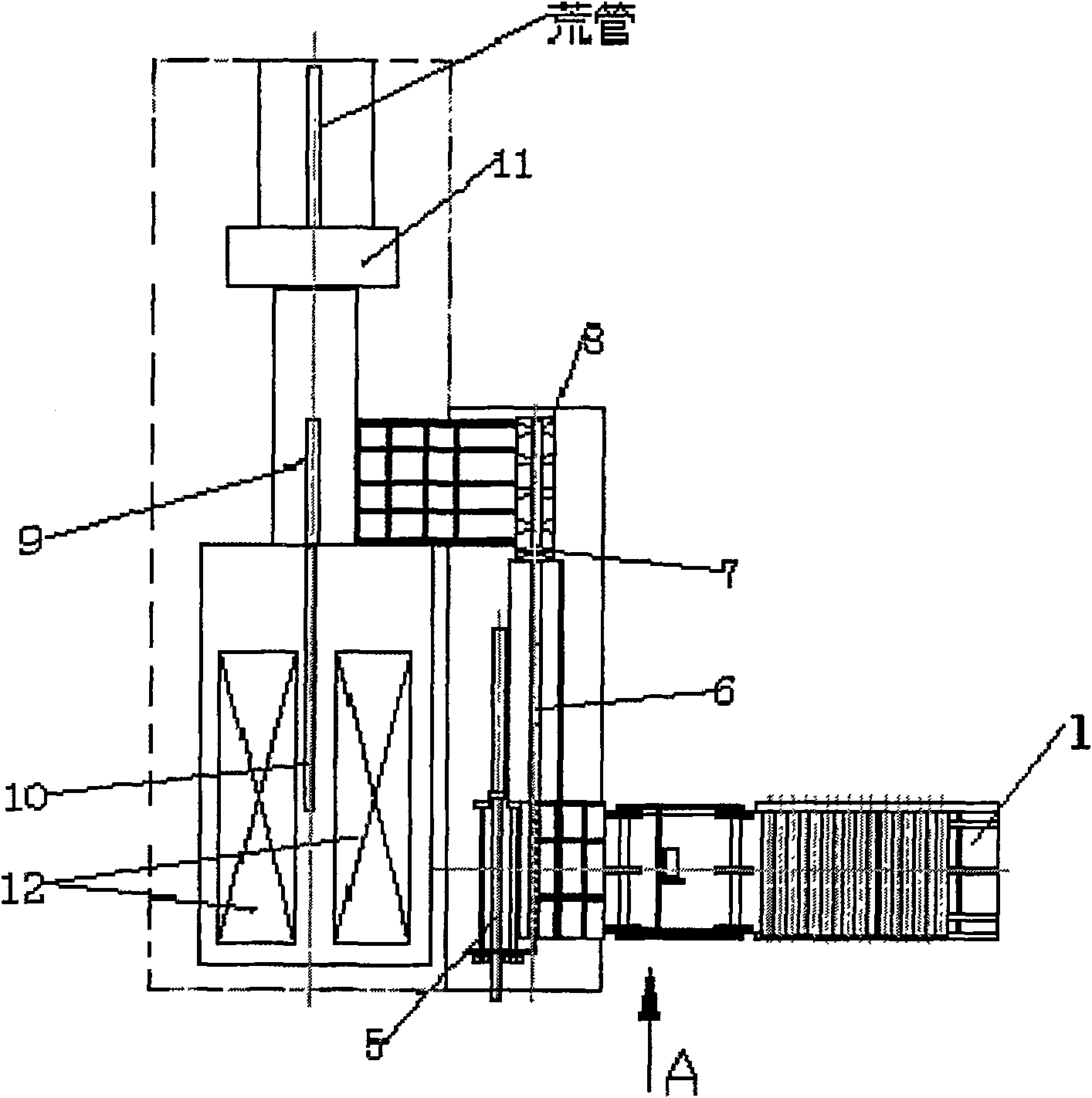

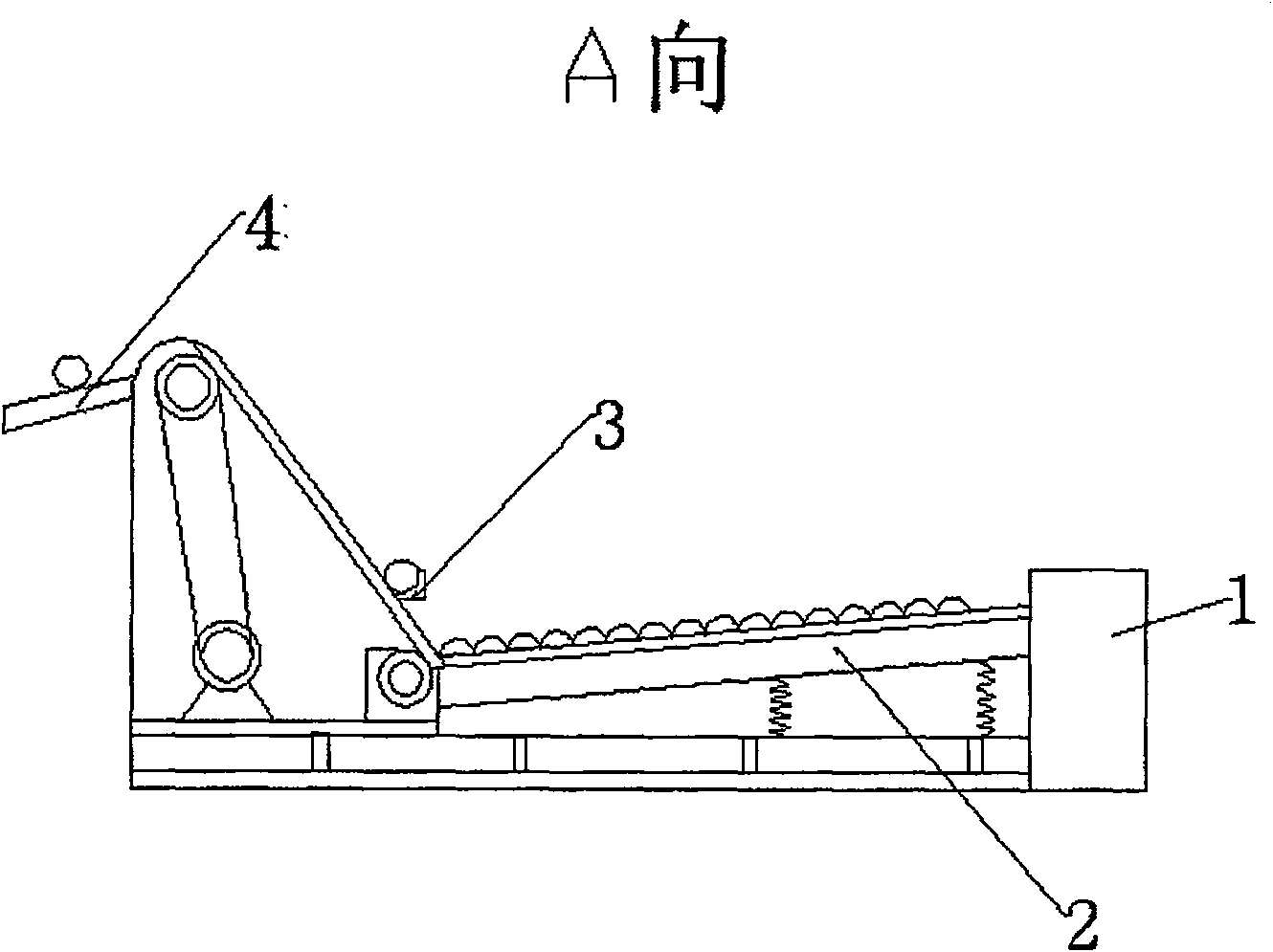

Process for heating titanium oblique perforating rod ingot

InactiveCN101029348AHeating fastReduce oxidationTemperature control deviceFurnace typesPunchingMonitoring system

Process for heating titanium-oblique rolling punch rod blank adopts horizontal step-by-step medium-frequency induction heating finance as tool. The heating furnace consists of automatic skip mechanism, core-watch temperature differential monitoring system and fast-extraction discharge mechanism. The process is carried out by hoisting titanium rod onto bedding rack by overhead traveling crane, arranging on movable bedding rack paralleled, lifting titanium-rod onto charge rack on slop by production beat, entering into horizontal step-by-step medium-frequency induction heating furnace successively, moving titanium-rod forwardly by step-by-step mode, raising temperature while homogeneous heating, discharging, entering into blow tank of oblique-rolling punch, nipping and punching to raw pipe. It's simple, safe and cheap and has no environmental pollution.

Owner:WESTERN TITANIUM TECH

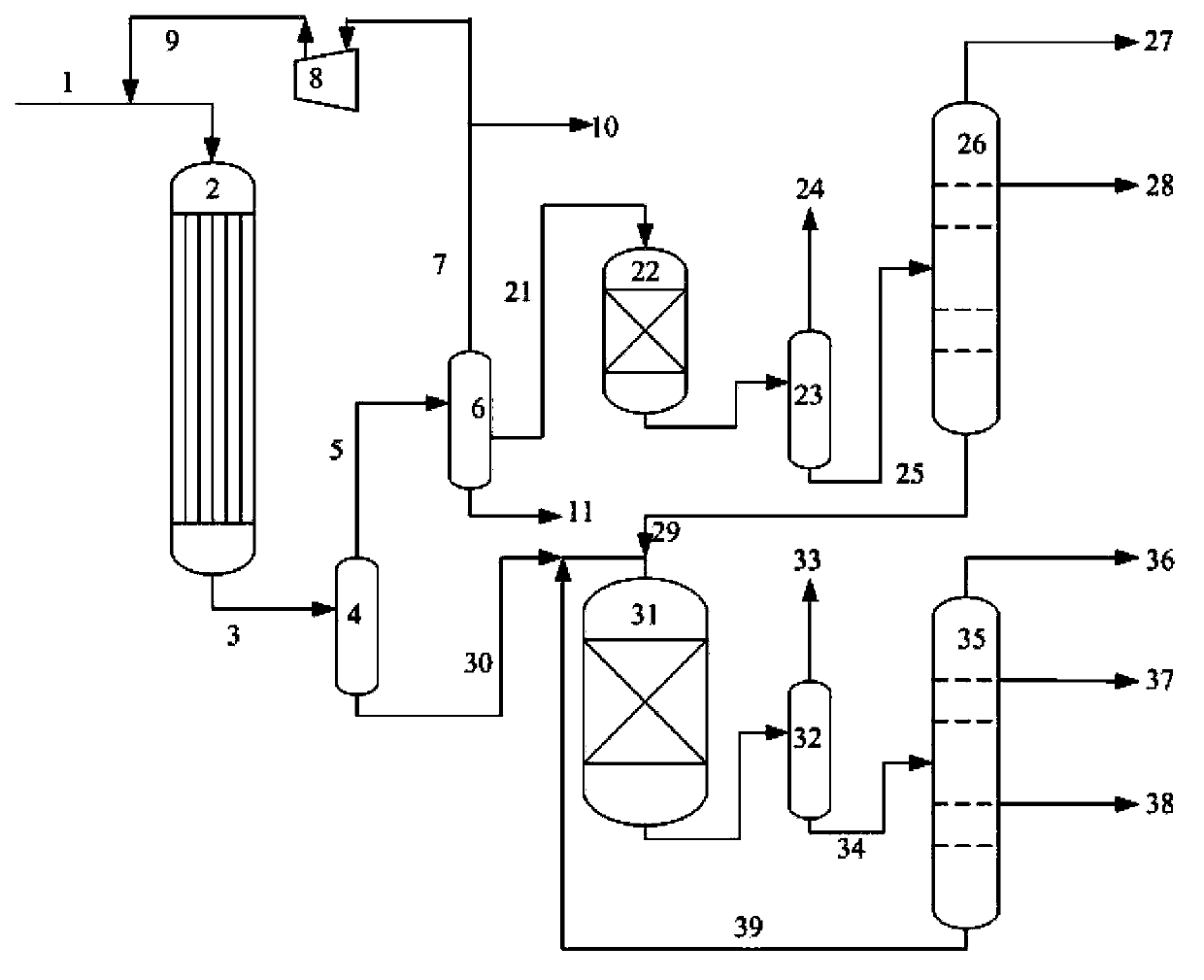

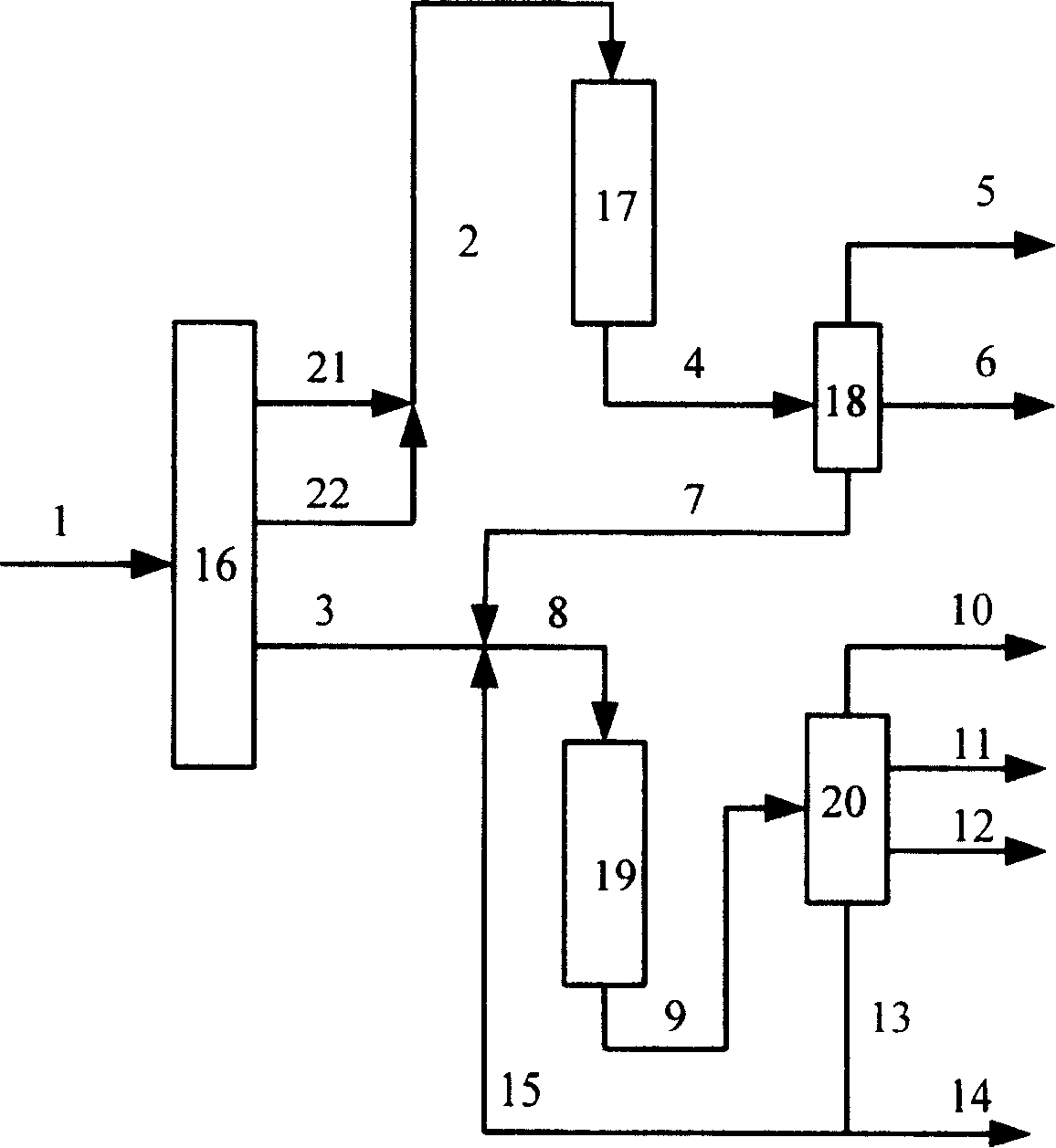

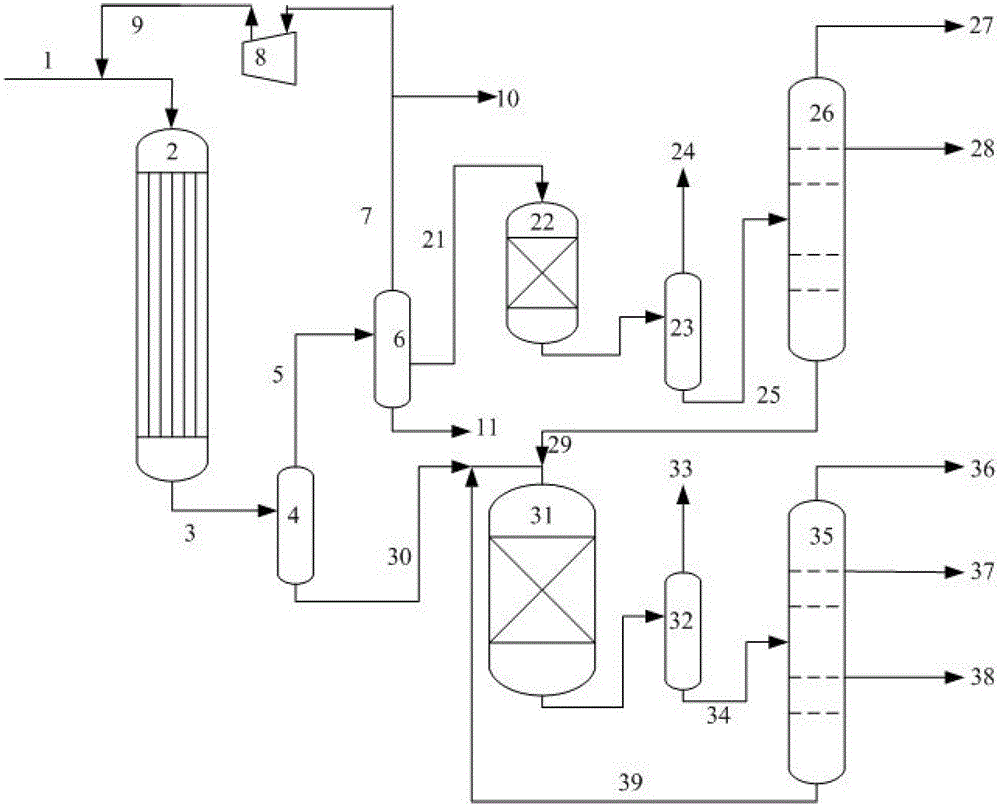

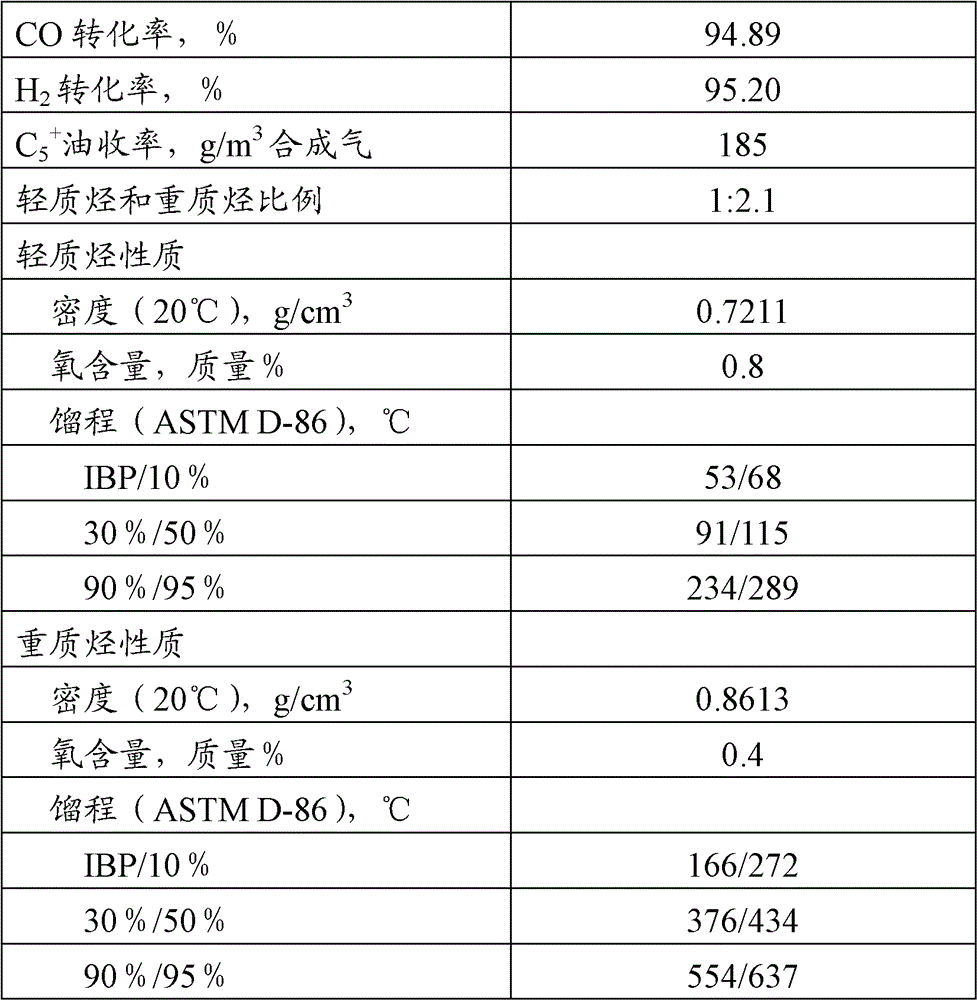

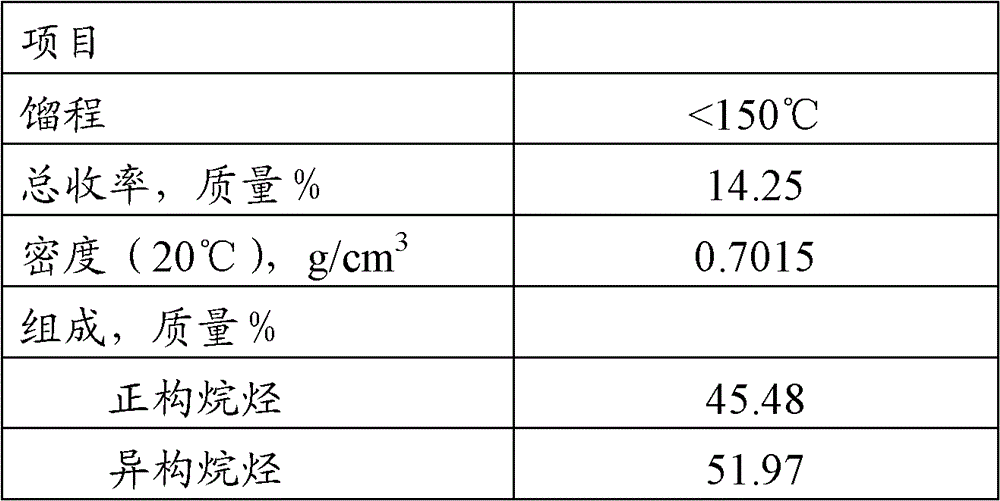

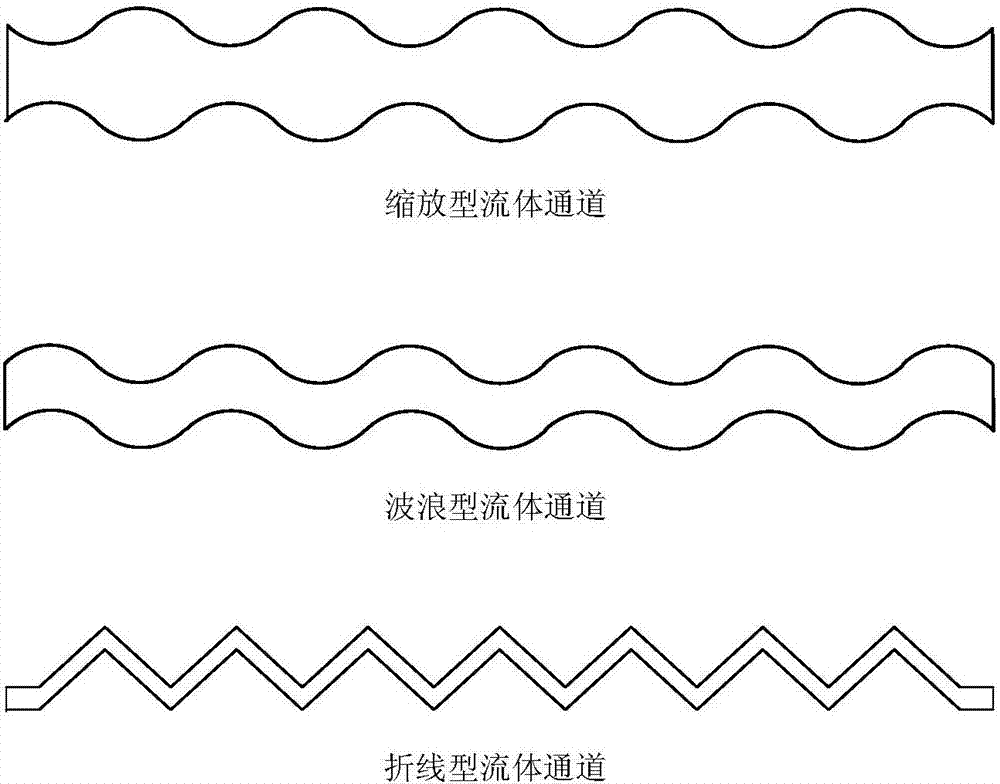

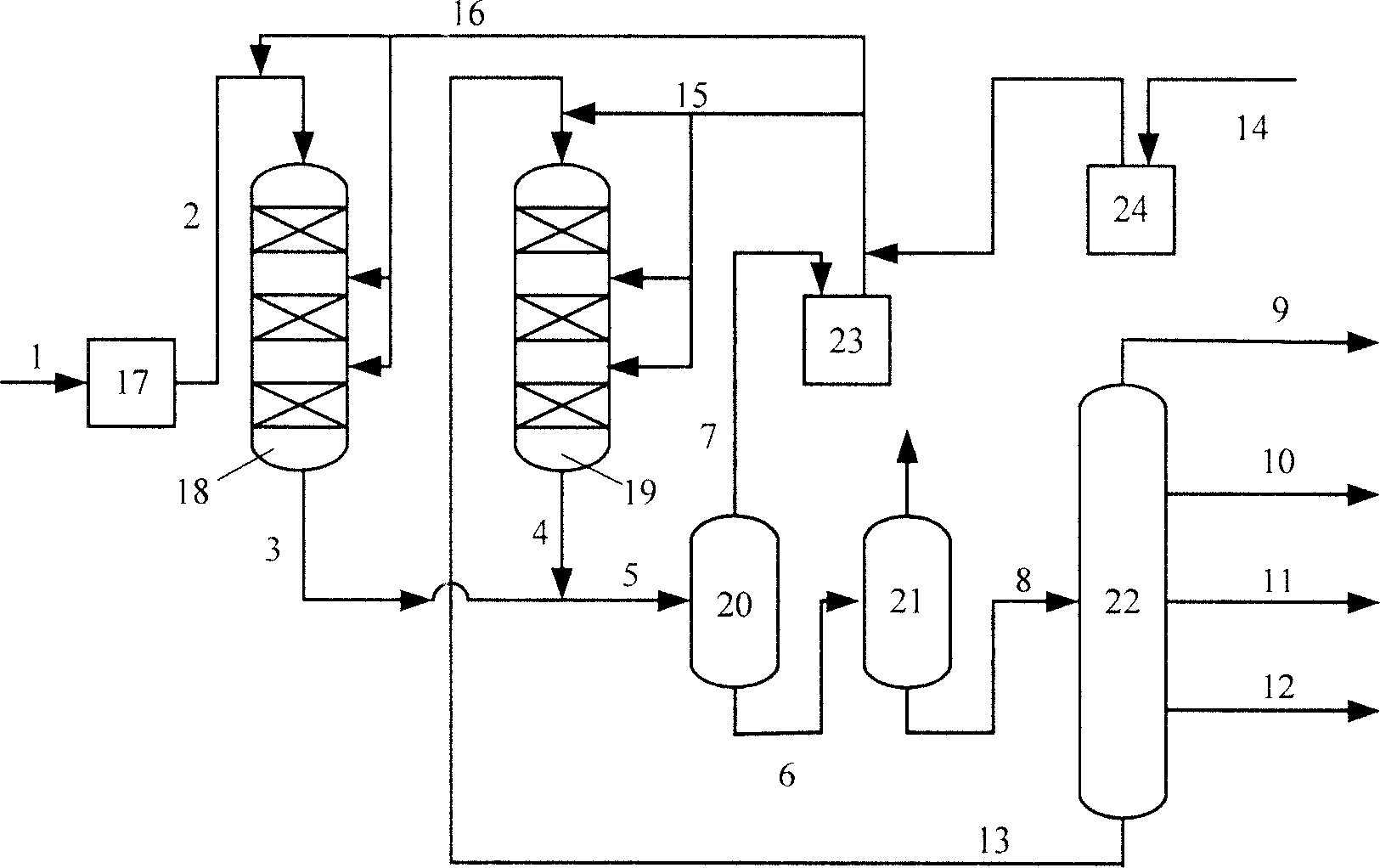

Method for producing clean diesel oil from synthetic gas

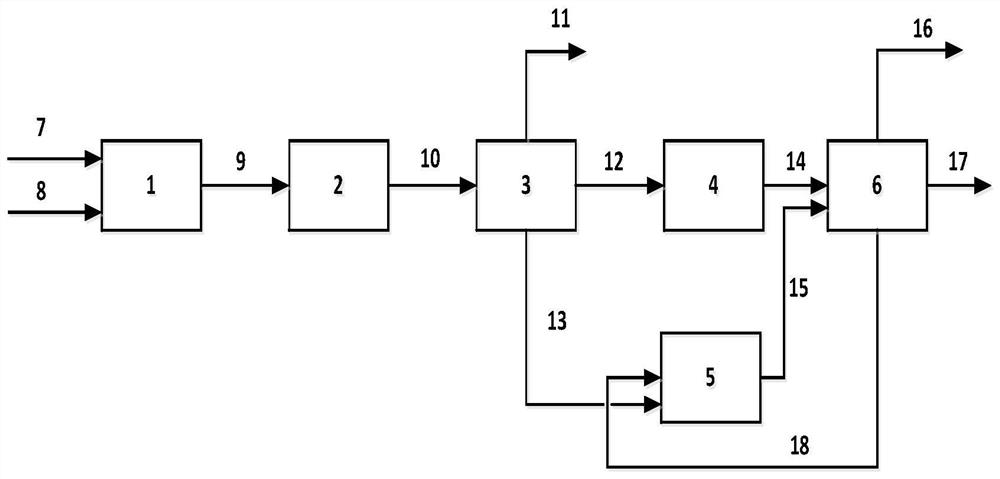

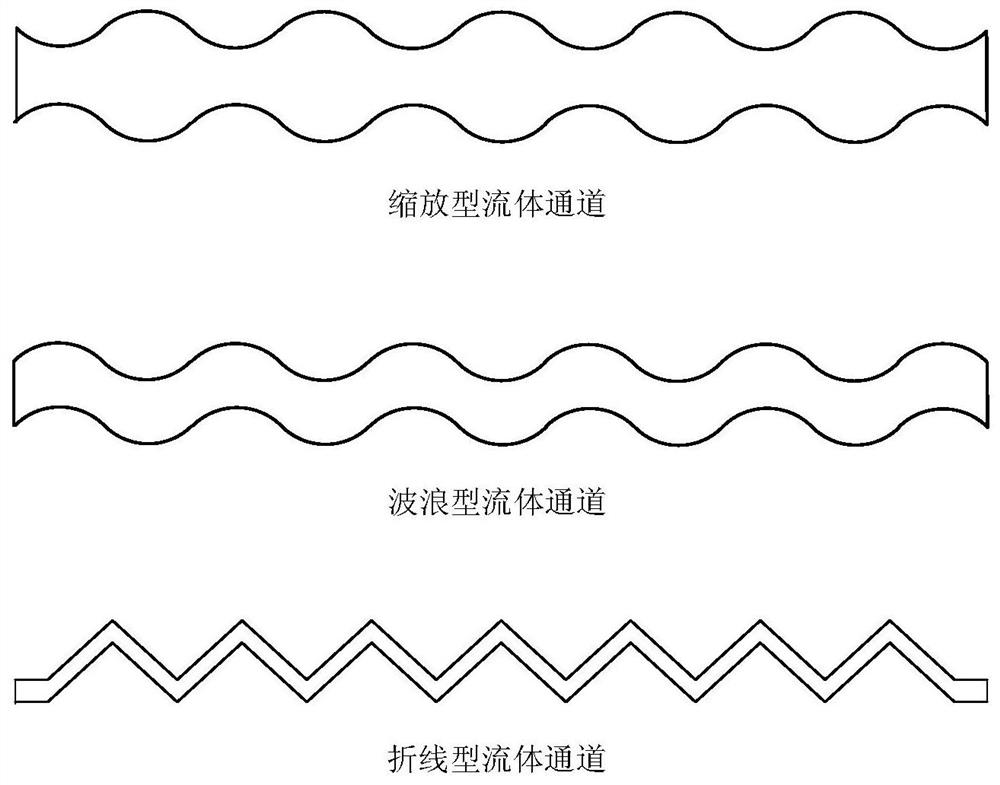

ActiveCN103965941ASolve axialSolve temperature problemsLiquid hydrocarbon mixture recoveryTreatment with hydrotreatment processesHydrogenSeparation system

The invention provides a method for producing clean diesel oil from synthetic gas. The method comprises the following steps: allowing synthetic gas to enter a tubular fixed bed reactor and contact with a catalyst for a Fischer-Tropsch synthesis reaction, wherein the interior surface of a reaction tube is smooth, and the exterior surface of the reaction tube has a groove; separating heavy hydrocarbon and light hydrocarbon out from a synthetic product; mixing light hydrocarbon with hydrogen, allowing an obtained mixture to enter a hydrorefining reactor and contact with a catalyst for a hydrogenation saturation reaction and a hydrogenation deoxidation reaction; and allowing a hydrorefining reaction product to enter a separation system, mixing separated tail oil with heavy hydrocarbon, allowing an obtained mixture to enter a hydrogenation isocraking reactor and allowing a product to enter the separation system so as to obtain an intermediate distillate oil product. The method provided by the invention overcomes the problems of hardly controllable reaction heat and difficult heat transfer and hot spots of a reactor during the Fischer-Tropsch synthesis reaction and realizes economic and effective production of the clean diesel oil directed at the characteristic that hydrocarbons are produced in the process of production.

Owner:CHINA PETROLEUM & CHEM CORP +1

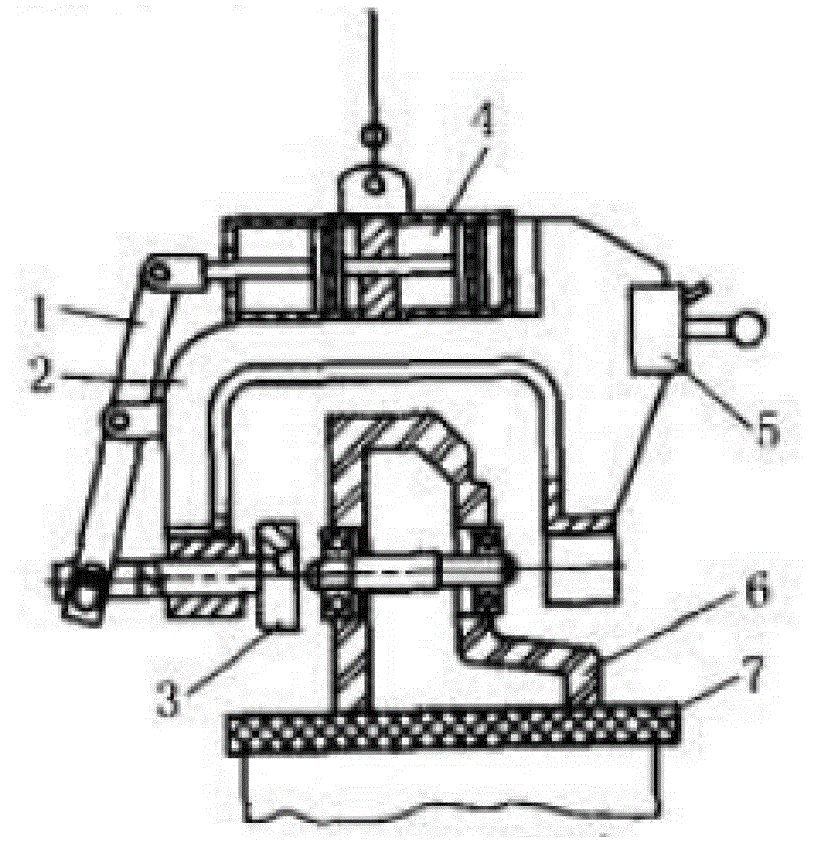

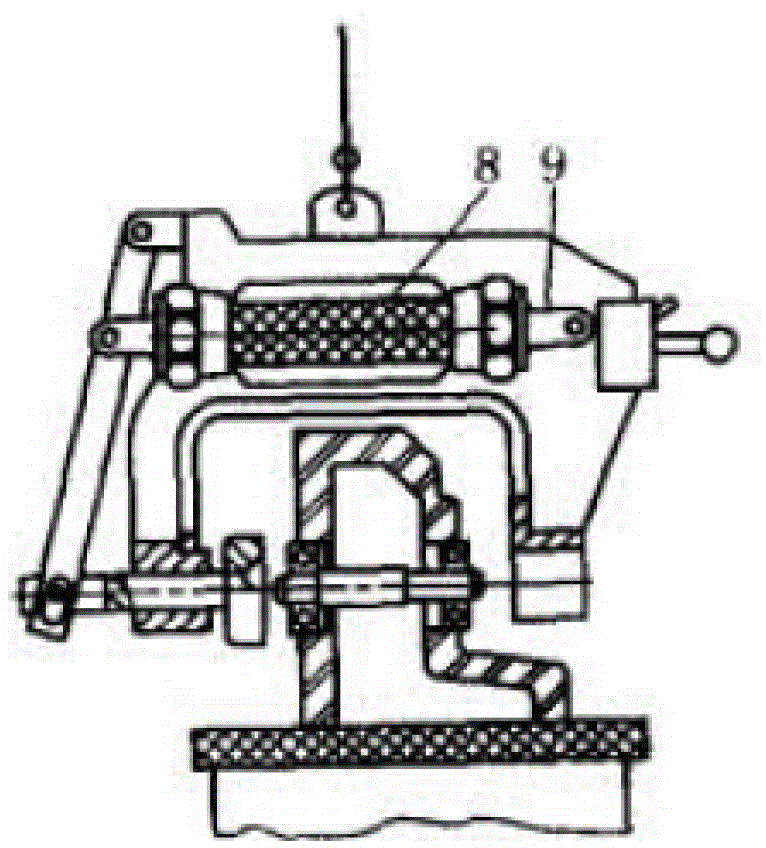

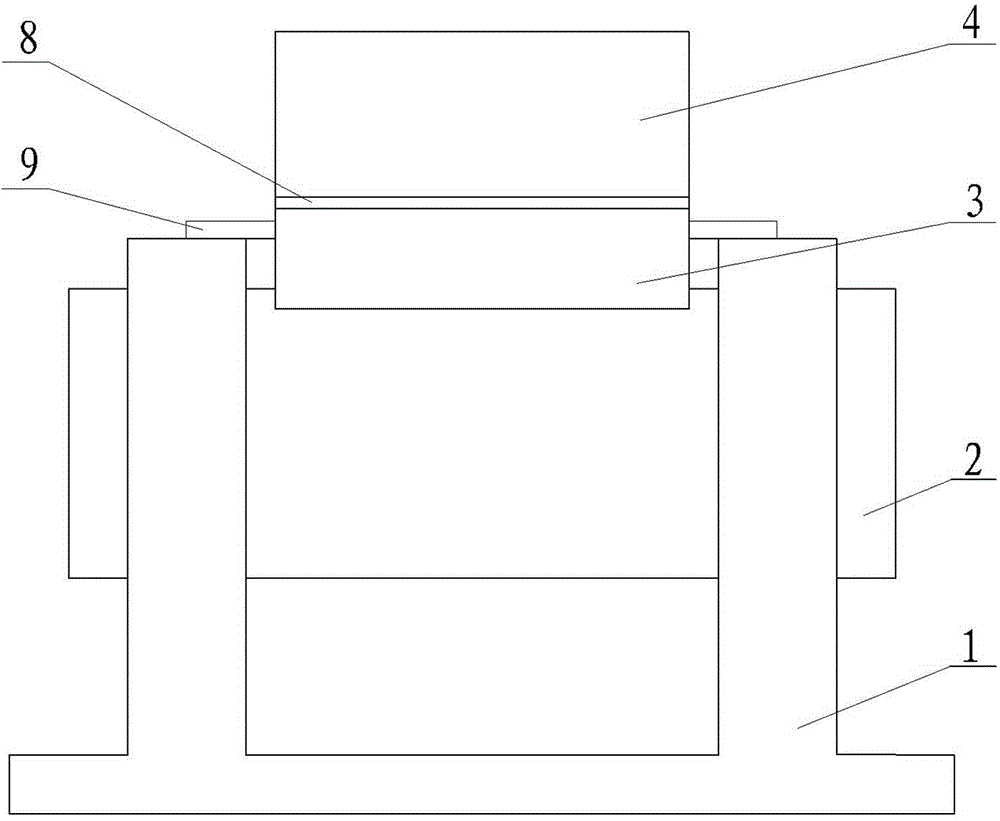

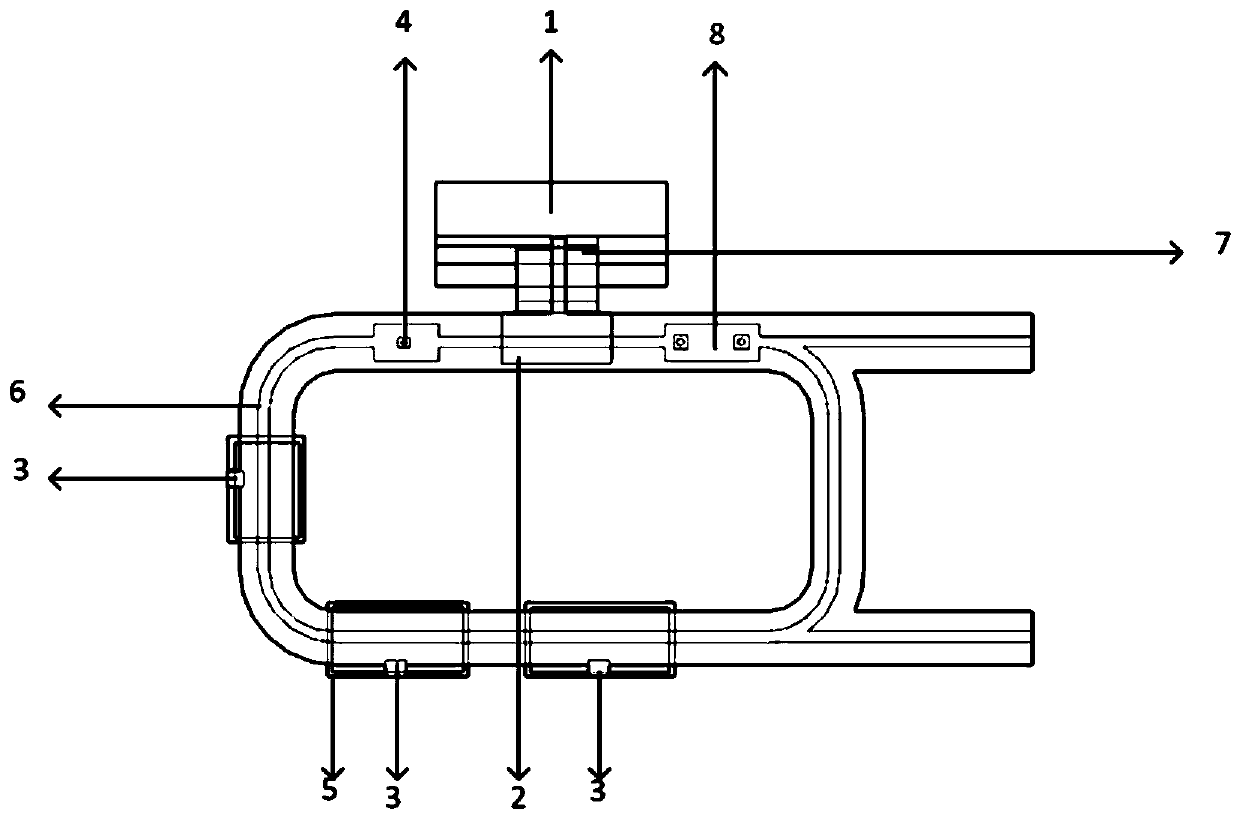

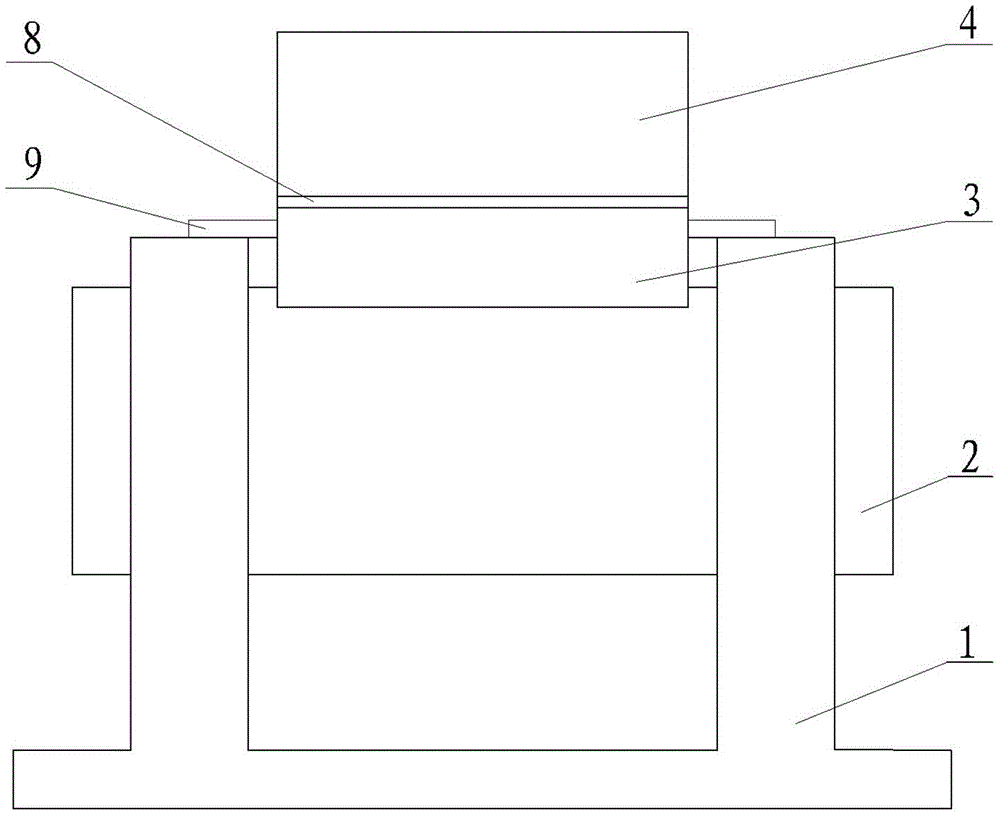

Mobile type pneumatic pressing device

The invention discloses a mobile type pneumatic pressing device. The device comprises a C-shaped frame, a connecting rod, a pressure plate, a pneumatic drive device, a lever and a control switch for controlling a steam cylinder or pneumatic muscle, wherein a strip-shaped hole is formed in one end of the lever, a connecting pin connected with the connecting rod is arranged in the strip-shaped hole, and the other end of the lever is hinged with a power output end of the pneumatic drive device; a hoisting connecting part is further arranged on the C-shaped frame. According to the mobile type pneumatic pressing device, the lever transfers power to the connecting rod under the drive of the steam cylinder or the pneumatic muscle, the connecting rod transfers power to the pressure plate, press fitting of a workpiece is realized, the pressing force is large, press fitting of a large workpiece can be realized, the hoisting connecting part is arranged on the C-shaped frame, the pneumatic pressing device can be conveniently transferred and moved in a workshop by means of hoisting equipment and can perform press fitting production in different places, and the production flexibility is good.

Owner:CHONGQING FUXIN GLASS

Landfill sludge treatment method

ActiveCN107628737ADisposal realizedSolve the problem of odor pollutionSludge treatment by oxidationSocial benefitsHorizontal distribution

The invention relates to a landfill sludge treatment method. The method comprises the following steps: sampling and analyzing sludge, determining the pH value, the type of smelly pollutants, the landfill depth and the horizontal distribution of the sludge, preparing an oxidation preparation, injecting the oxidation preparation into underground sludge by virtue of in-situ mixing and stirring equipment, and simultaneously stirring the oxidation preparation and the sludge underground by virtue of an impeller stirring head of the in-situ mixing and stirring equipment; after uniform stirring, carrying out standing reaction for 3.5-5.5 hours, and putting a curing agent into sludge by using an engineering machine, and stirring continuously by using the in-situ mixing and stirring equipment; afteruniform stirring, standing for 24-48 hours, carrying out open type excavation and transfer on the solidified sludge. By sequentially carrying out in-situ treatment and excavation, the construction operability is strong, the investment cost of the equipment is low, the treatment period is short, the treatment is thorough, the secondary pollution is avoided, the problem of stink pollution in the excavation process of the sludge is solved, and meanwhile, the treatment of the sludge is realized; and the method has relatively good economic and social benefits.

Owner:中节能大地(杭州)环境修复有限公司

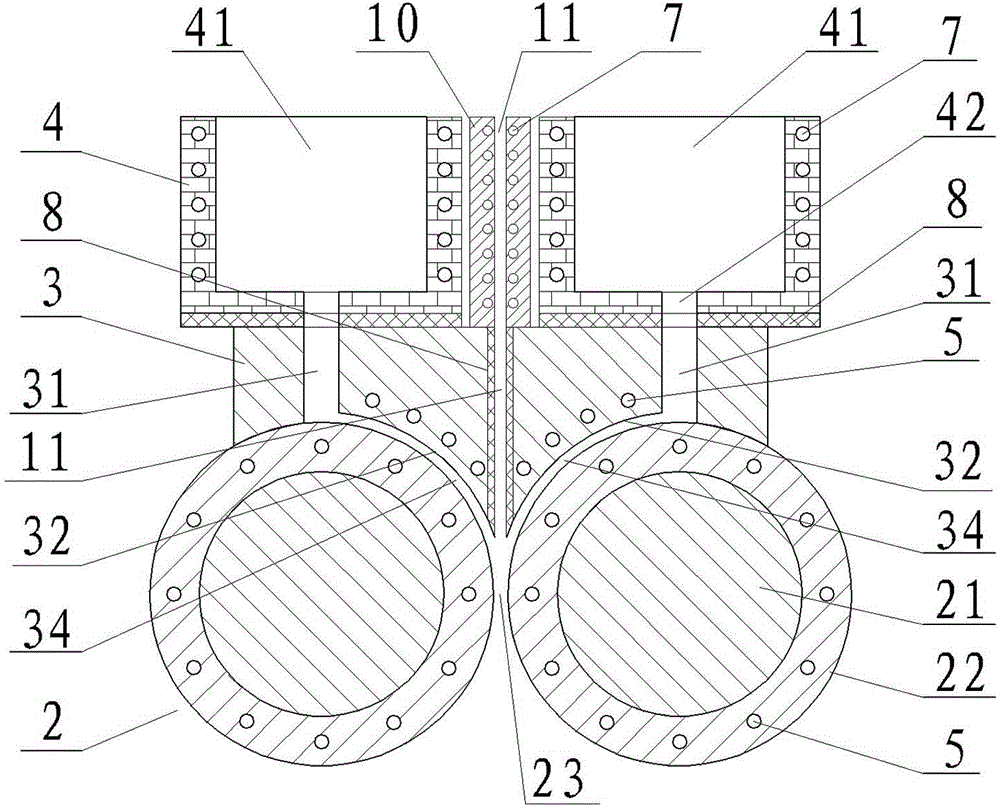

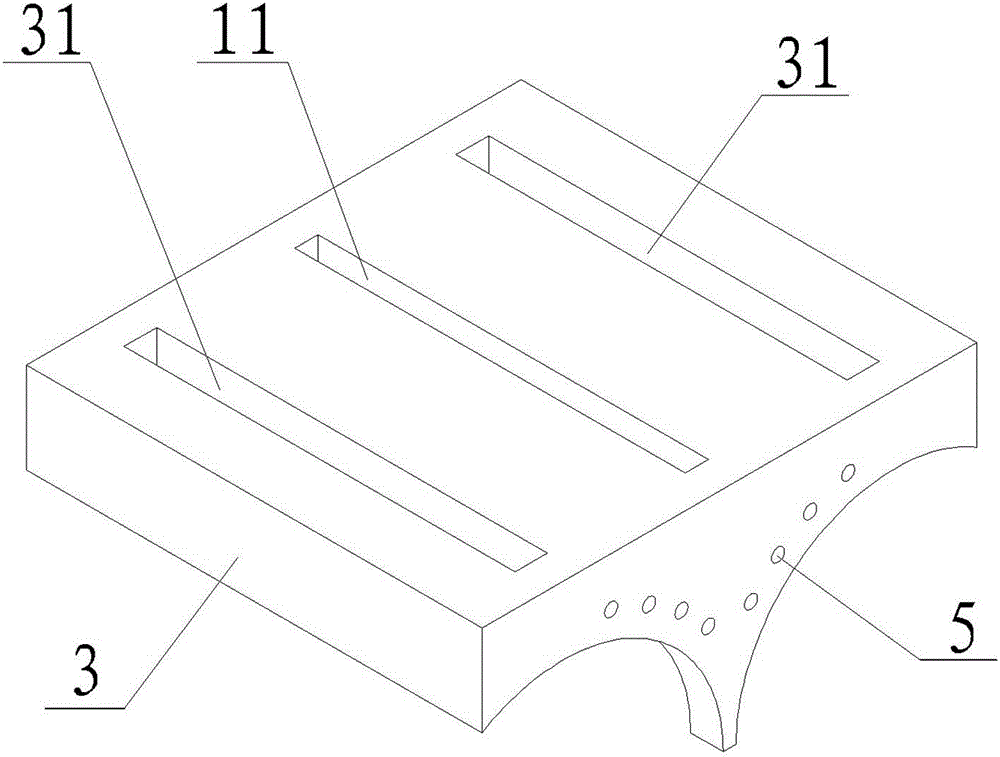

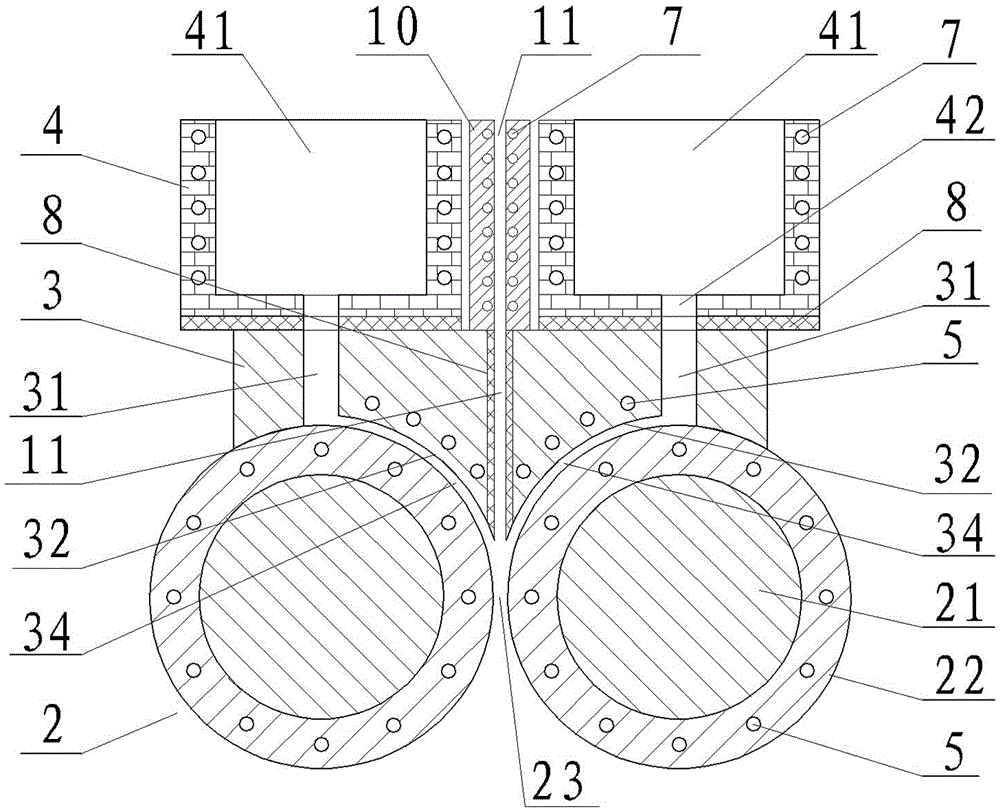

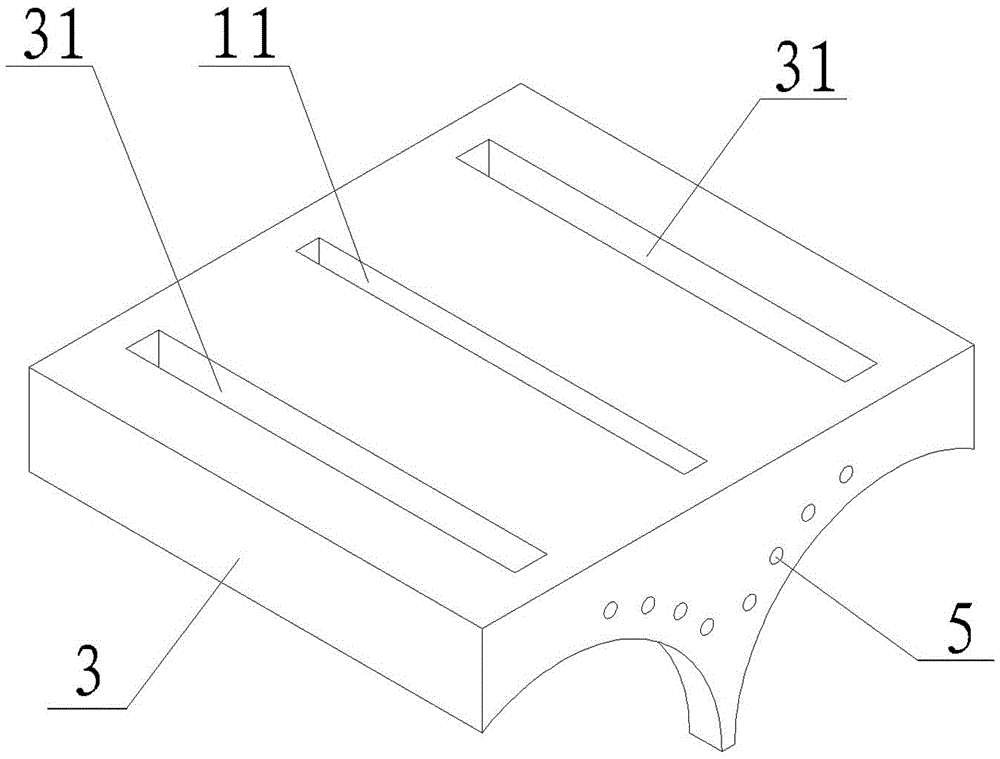

Three-layer metal clad plate short process roll forming device and method

ActiveCN104525564ARealize integrationImprove continuityMetal rolling arrangementsSemi solidEngineering

The invention discloses a three-layer metal clad plate short process roll forming device and method. The device comprises a rack, two rollers, a crystallizer, two tundishes and a preheating device, wherein the two rollers are horizontally mounted on the rack in parallel; the crystallizer is mounted on the two rollers; the two tundishes are mounted on the top of the crystallizer; the preheating device is mounted on the middle position of the crystallizer and between the two tundishes; a rectangular channel through which a core layer metal plate passes is formed in the center of the crystallizer and the center of the preheating device. According to the invention, structures that two crystallizing cavities are formed between the crystallizer and the two rollers and the rectangular channel through which the core layer metal plate passes is formed in the center of the crystallizer are adopted, so that after two kinds of cladding layer molten metal are continuously cooled and stirred to form a semi-solid state sizing agent in the two crystallizing cavities, the sizing agent and the core layer metal plate are directly compounded and rolled into a three-layer metal clad plate. Therefore, the three-layer metal clad plate produced by using the device and the method has the advantages that the production process flow is short, the quality is excellent and the like.

Owner:GUANGDONG INST OF NEW MATERIALS

Hydrogenation purifying combined process for Fischer-Tropsch synthetic substance

A kind of combined technology method to hydrogenate and improve quality of the product from Fishcher-Tropsch synthesis process, condensate and synthetic wax can be gained by natural isolation of the product from Fishcher-Tropsch synthesis process, and the condensate will contact with hydrogen and hydrofining catalyst, then the tail oil produced by the isolation of the hydrofining reactant liquor will contact with the synthetic wax, hydrogen, and hydrocracking and isocracking catalyst, the middle oil fraction product can be gained after the isolation of the hydrocracking reactant liquor at last. The yield of the diesel oil is more than 80% by the method, the cetane number will be more than 80, and sulfur, nitrogen and aromatic hydrocarbon can barely found in the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

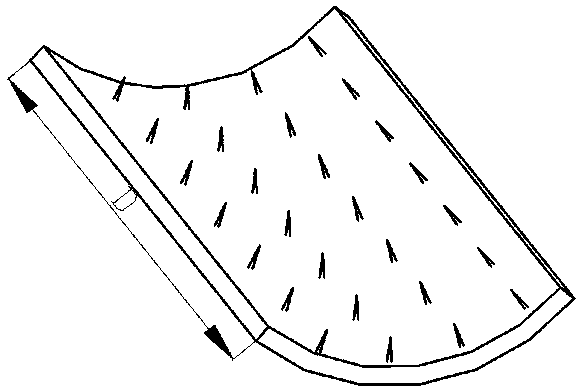

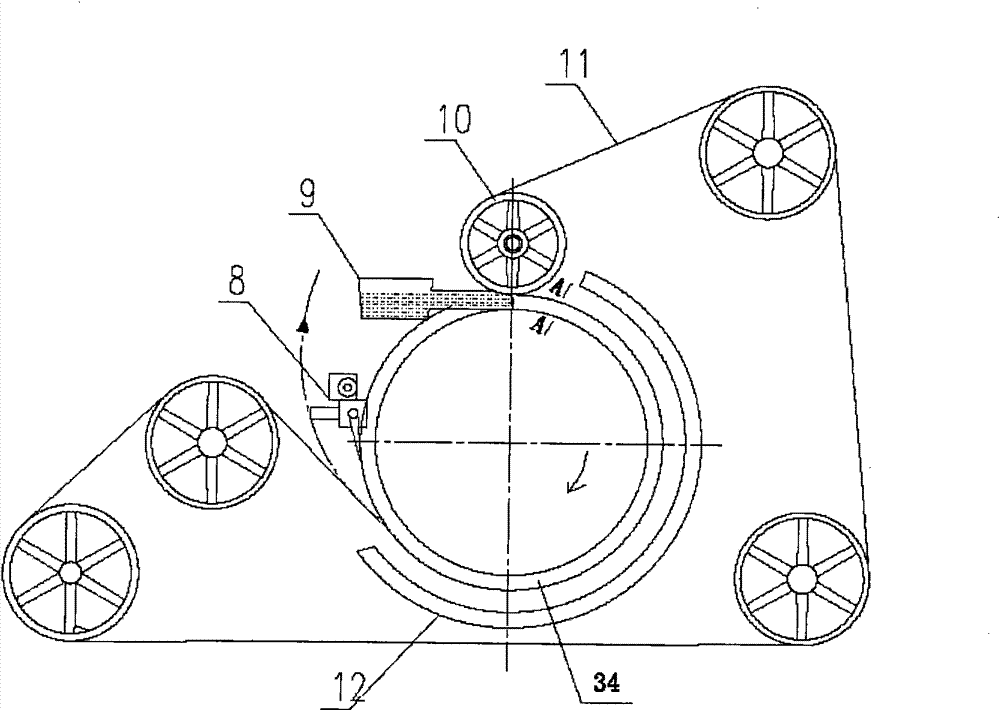

Method and device for improving interlayer bonding force of fiber reinforced building plate

PendingCN111283848AImprove bindingFully automatedAuxillary shaping apparatusUniversal jointControl system

The invention discloses a method and a device for improving interlayer bonding force of a fiber reinforced building plate. The method comprises the following basic steps of a, adding slurry to a forming cylinder layer by layer by rotating to form a wet blank; b, when the wet blank reaches a certain thickness, enabling array needles on a plurality of arc-shaped acupuncture tiles above the forming cylinder to be in contact with and inserted into the wet blank gradually, and generating corresponding array holes; c, continuing receiving the slurry by the array holes so that the array holes are filled to form array rivets, and stripping the array rivets after the wet blank reaches the thickness; and d, pulling the arc-shaped acupuncture tiles to a starting side, and repeating the process aboveto realize continuous production. The device comprises the forming cylinder, the plurality of the arc-shaped acupuncture tiles, hinges, the array needles, an elliptical closed orbit, universal joints,hanging rods, a pulling motor, a control system, a lifting system and the like. The method and device disclosed by the invention are easily combined to a conventional copying method or slurry flowingmethod production line at present, and do not have limitation on components, thickness and the like of materials; and the performance of the obtained fiber reinforced building plate with improved interlayer bonding force is greatly improved.

Owner:山东鲁泰建筑产业化材料有限公司

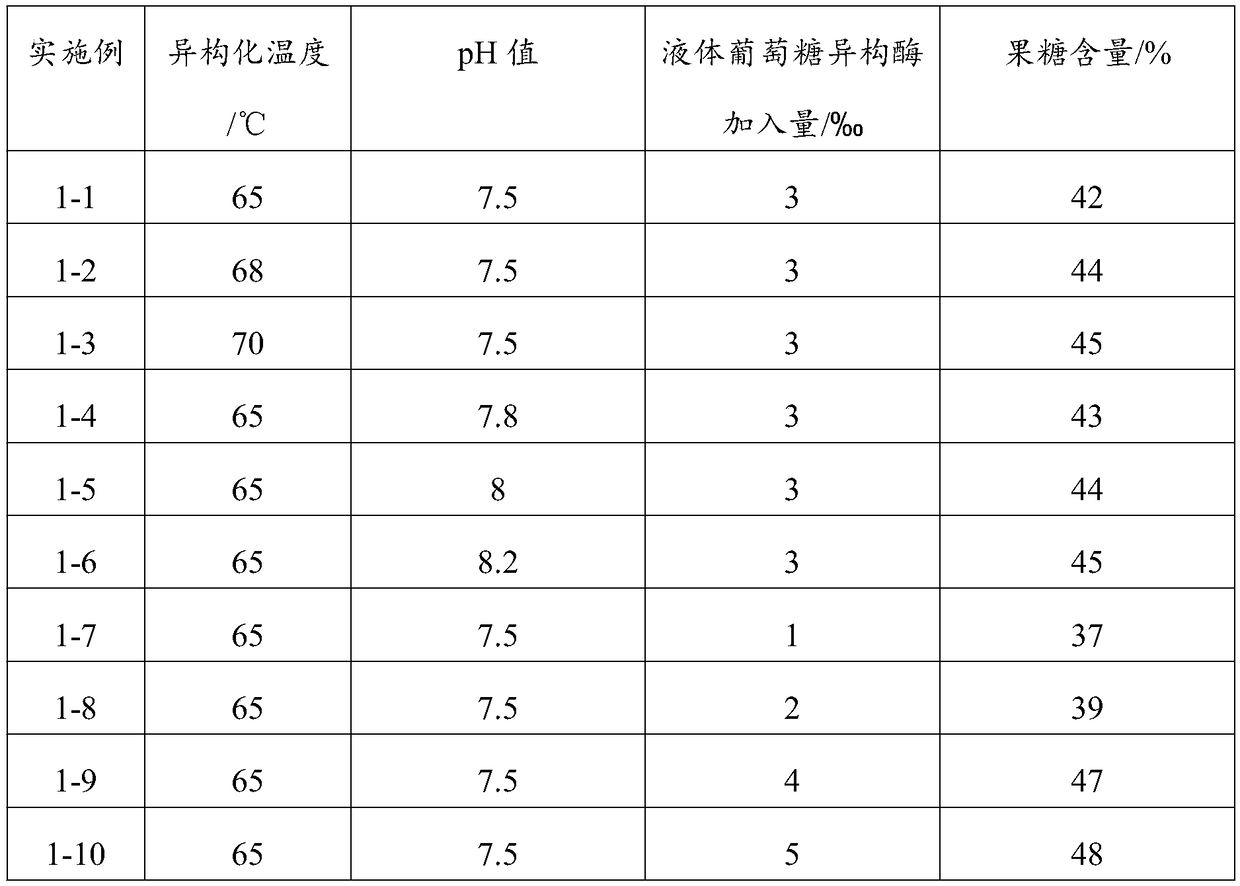

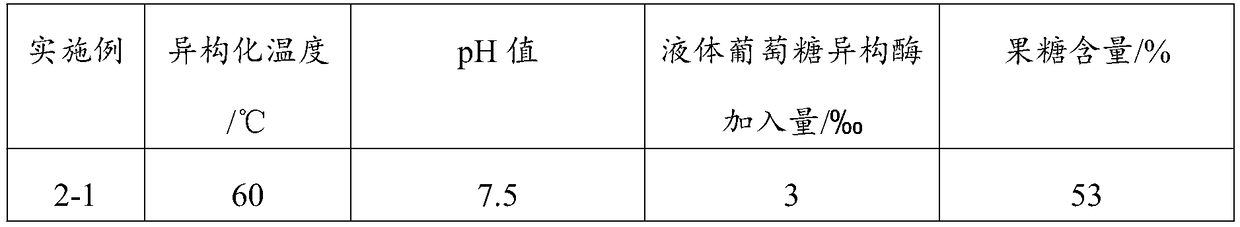

Preparation method of fructose syrup

InactiveCN108841900ASimple production processReduce energy consumptionFermentationChromatographic separationLiquid glucose

The invention provides a preparation method of fructose syrup. The preparation method comprises the following steps: adding magnesium sulfate and sodium metabisulfite into glucose liquid with the content of glucose being more than 93%, regulating the pH value of the mixture to 7.0-8.5, heating the mixture to 60-80 DEG C and adding liquid glucose isomerase into the mixture; performing a thermal reaction for 10-30h after uniform mixing, so as to obtain rough fructose syrup; then, regulating the pH value to below 4.0, performing decoloration and removing impurities, so as to obtain the fructose syrup. Compared with the prior art, the method is simple in production process and less in investment on production equipment; in addition, equipment such as an isomerism column, chromatographic separation equipment and the like are not needed, so that the method is convenient in operation, high in flexibility of production scheduling and relatively low in energy consumption, therefore, the methodis beneficial for environmental protection.

Owner:ANHUI NEW SIMON BIOTECH CO LTD

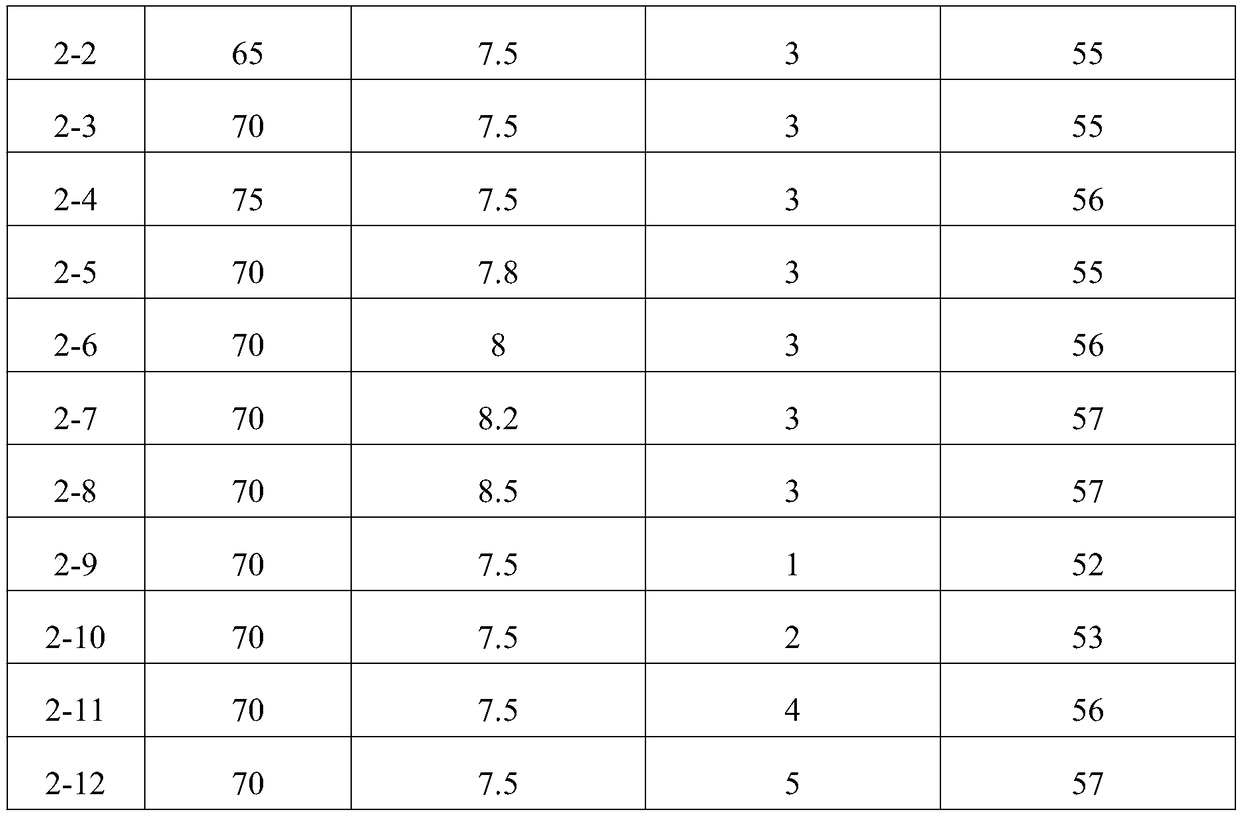

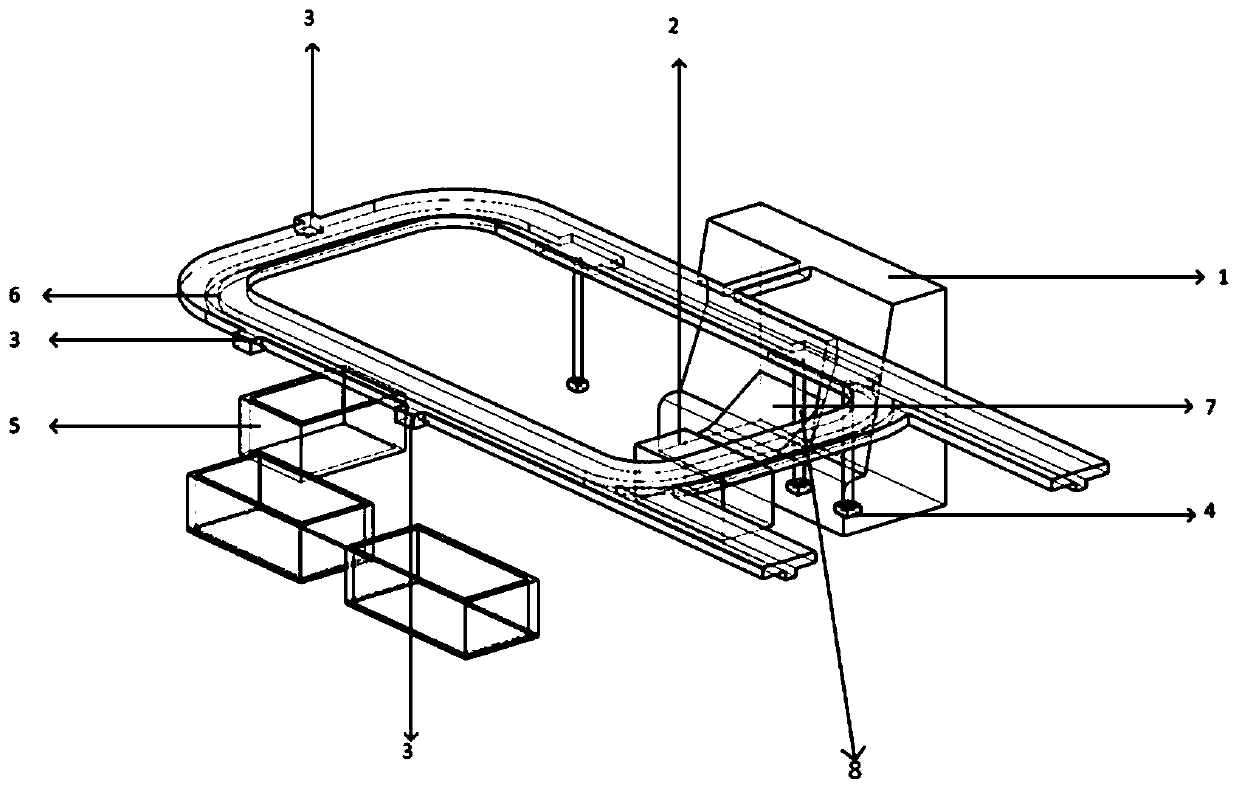

Rebar bending machine discharged material automatic transferring and classifying system and method

ActiveCN110947871AImprove the intelligent production level of processingEfficient transportWire articlesConveyor partsEngineeringMachine

The invention discloses a rebar bending machine discharged material automatic transferring and classifying system and method. The system comprises a bending machine, a receiving table, sensors, electromagnets, loading and transporting groove boxes, a rail, a discharging outlet and fixtures; the electromagnets are installed over the receiving table and under the rail and fixed by the fixtures, andthe motion trail is stipulated through the rail; a discharging outlet of the bending machine is located above the receiving table and below the rail, and machined rebar hoops can fall on the receivingtable under gravity action of the rebar hoops; and the loading and transporting groove boxes are arranged in the corresponding position and used for receiving the rebar loops falling from the electromagnets. According to the rebar bending machine discharged material automatic transferring and classifying system and method, various types of rebar hoops can be automatically sorted and transferred according to the kind, quantity, size and other information of the rebar hoops without manual intervention, the production efficiency is improved, and the safety accident risk is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

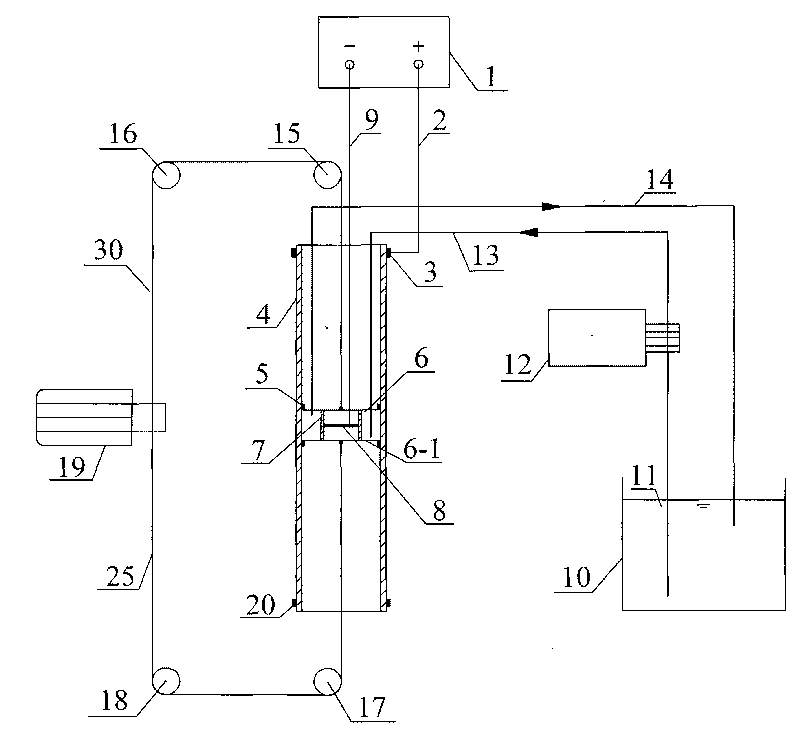

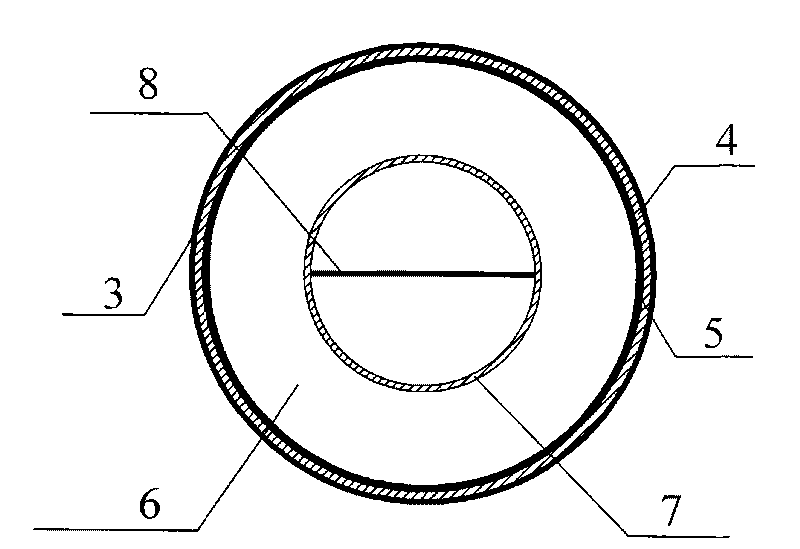

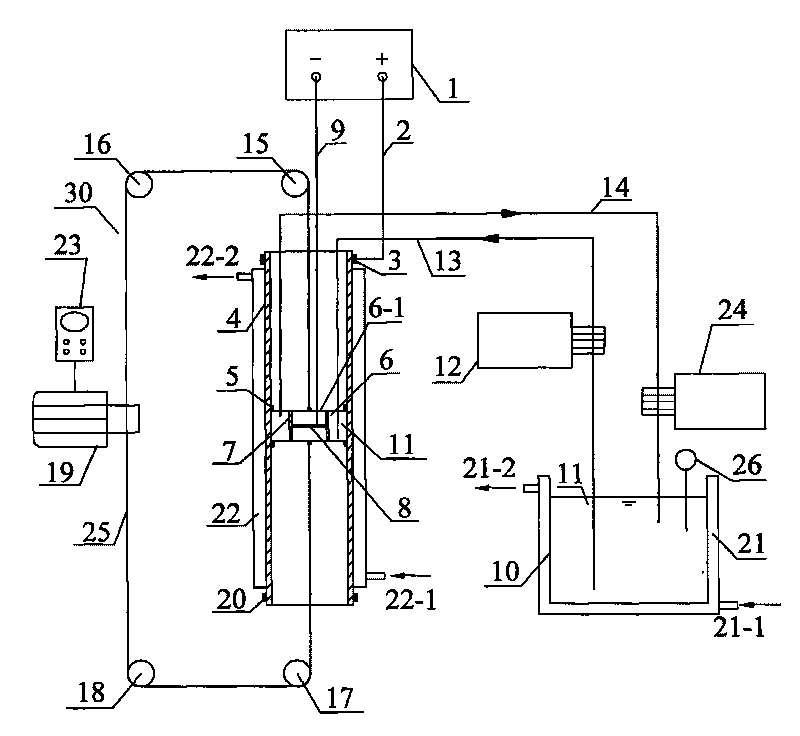

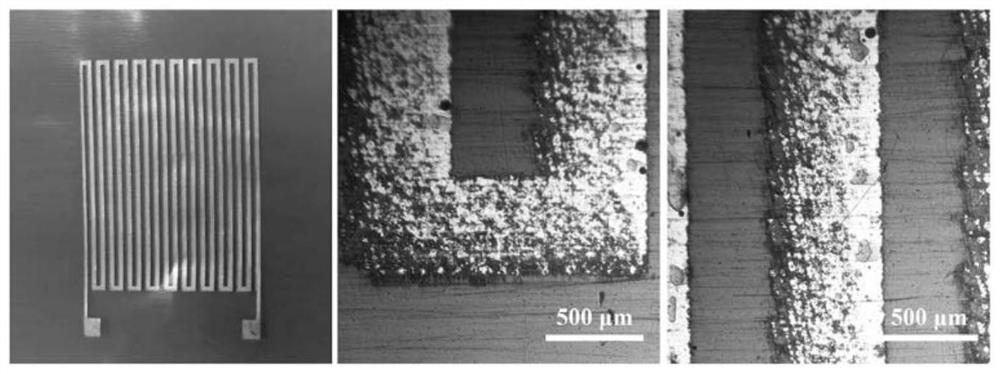

Preparation device of large-area titanium dioxide thin film catalyst and preparation method thereof

The invention provides a preparation device of a large-area titanium dioxide thin film catalyst and a preparation method thereof, relating to the preparation device and the method of a titanium dioxide catalyst and solving the problem that the continuous and high-efficiency preparation of the large-area titanium dioxide thin film catalyst is hardly realized under the condition of low-power power supply. The electrolyte in a reaction monomer tank is in contact with the side of an anode made of titanium and the side of a cathode synchronously, a driving mechanism is used for enabling the reaction monomer tank to make relative movement along the side of the anode made of the titanium. The preparation method mainly comprises the following steps of: circularly flowing the electrolyte between an electrolyte tank and the reaction monomer tank; applying voltage or current between the anode and the cathode, wherein the current density is below 200mA / cm2 and the voltage is below 300V; and enabling the reaction monomer tank to make relative movement along the side of the anode made of the titanium according to set requirements. The device can prepare the large-area titanium dioxide thin film catalyst under the condition of the low-power power supply by arranging the reaction monomer tank capable of moving relative to the anode made of the titanium. The method has good production flexibility and high efficiency.

Owner:HARBIN INST OF TECH

Process for heating titanium oblique perforating rod ingot

InactiveCN100562587CHeating fastReduce oxidationTemperature control deviceIncreasing energy efficiencyPunchingMonitoring system

Process for heating titanium-oblique rolling punch rod blank adopts horizontal step-by-step medium-frequency induction heating finance as tool. The heating furnace consists of automatic skip mechanism, core-watch temperature differential monitoring system and fast-extraction discharge mechanism. The process is carried out by hoisting titanium rod onto bedding rack by overhead traveling crane, arranging on movable bedding rack paralleled, lifting titanium-rod onto charge rack on slop by production beat, entering into horizontal step-by-step medium-frequency induction heating furnace successively, moving titanium-rod forwardly by step-by-step mode, raising temperature while homogeneous heating, discharging, entering into blow tank of oblique-rolling punch, nipping and punching to raw pipe. It's simple, safe and cheap and has no environmental pollution.

Owner:WESTERN TITANIUM TECH

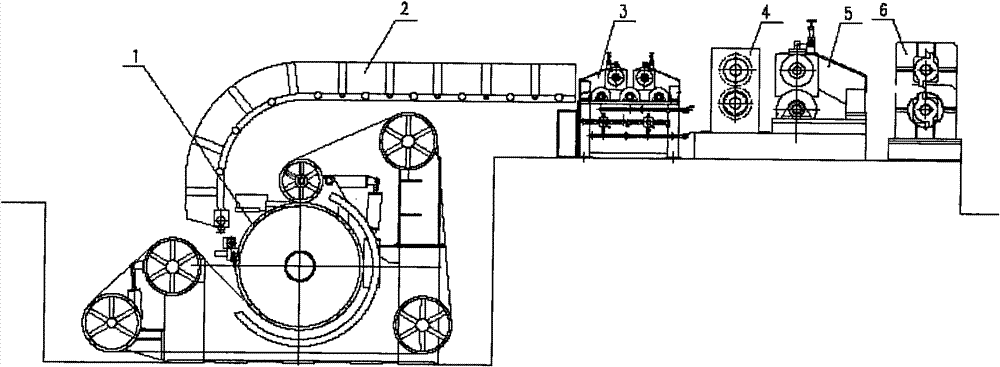

Method and device for producing A356 aluminum alloy by belt casting

The invention discloses a method and a device for producing A356 aluminum alloy by belt casting. The prepared A356 aluminum alloy liquid is subjected to furnace refining and on-line degassing filtration, and then is continuously poured into a crystallizer of a casting machine; and the periphery of the crystallizer is continuously filled with cooling water for crystallization. A crystalline regionis divided into five sections from the higher temperature to the lower temperature, and a cooling region is divided into twelve regions according to different flow rates of the cooling water distributed at the periphery of the crystallizer. The belt casting machine comprises a casting machine, a straightening machine, a blank guiding machine, a rolling code machine, a roller shearing machine, andthe like, which are arranged in turn; and an approach bridge is arranged between the casting machine and the straightening machine. Compared with the prior art, the method and the device have the advantages of simple production equipment, less investment, short production flow, low production cost, advanced technology, low gas-slag content in the products, low composition segregation, stable product quality, and excellent production flexibility, quickly adjustable product types, and safe working environment.

Owner:YUNNAN ALUMINUM

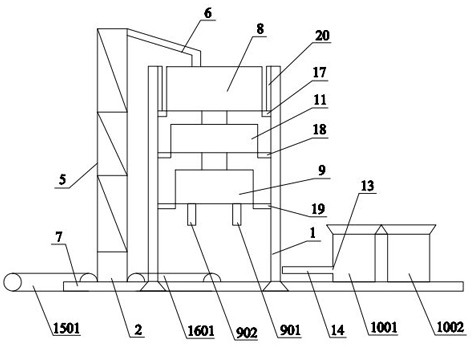

Automatic precision core assembly moulding production line, casting production line and production method thereof

ActiveCN102284683BReduce labor intensityHigh degree of automationCasting plantsMoulding plantsProduction lineWorking environment

Owner:CMCU ENG

Tower type sand making unit

The invention relates to a tower type sand making unit. The tower type sand making unit comprises a multi-layer vertically-arranged steel structure supporting frame body and a PLC control system; a movable feeding mechanism is arranged outside the steel structure supporting frame body; a crushing and screening mechanism and a dust collecting mechanism are arranged in the steel structure supportingframe body; the movable feeding mechanism comprises an elevator and a Y-shaped discharging articulated chute; double rails are arranged at the bottom of the steel structure supporting frame body; theelevator is arranged on the outer rail of the double rails; the Y-shaped discharging articulated chute is arranged above the crushing and screening mechanism; the dust collecting mechanism is arranged on one side of the crushing and screening mechanism; the crushing and screening mechanism and the movable feeding mechanism realize a cycle; the crushing and screening mechanism comprises a crusher,a screening machine and a movable material receiving bin; the movable material receiving bin is arranged on the inner rails of the double rails and comprises a coarse crushing product bin and a finecrushing product bin; a vertical main pipe of the Y-shaped discharging articulated chute is connected with the crusher; and a first branch pipe and a second branch pipe are both connected with the elevator. The tower type sand making unit is provided with sandstone feeding, crushing, screening and shaping mechanisms, so that the requirement that sandstones with different particle sizes are discharged at the same time is met.

Owner:洛阳耐锐机械设备有限公司

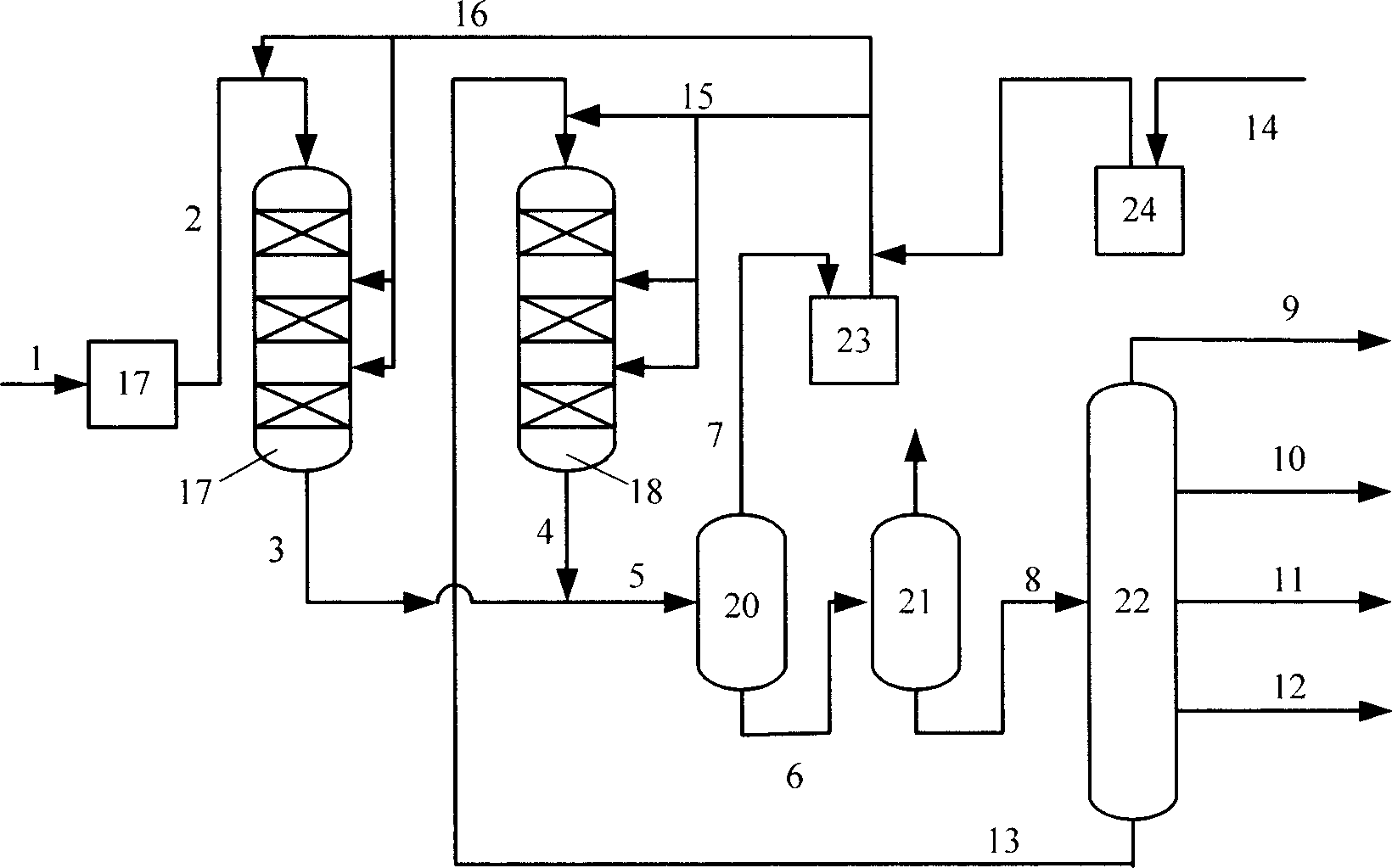

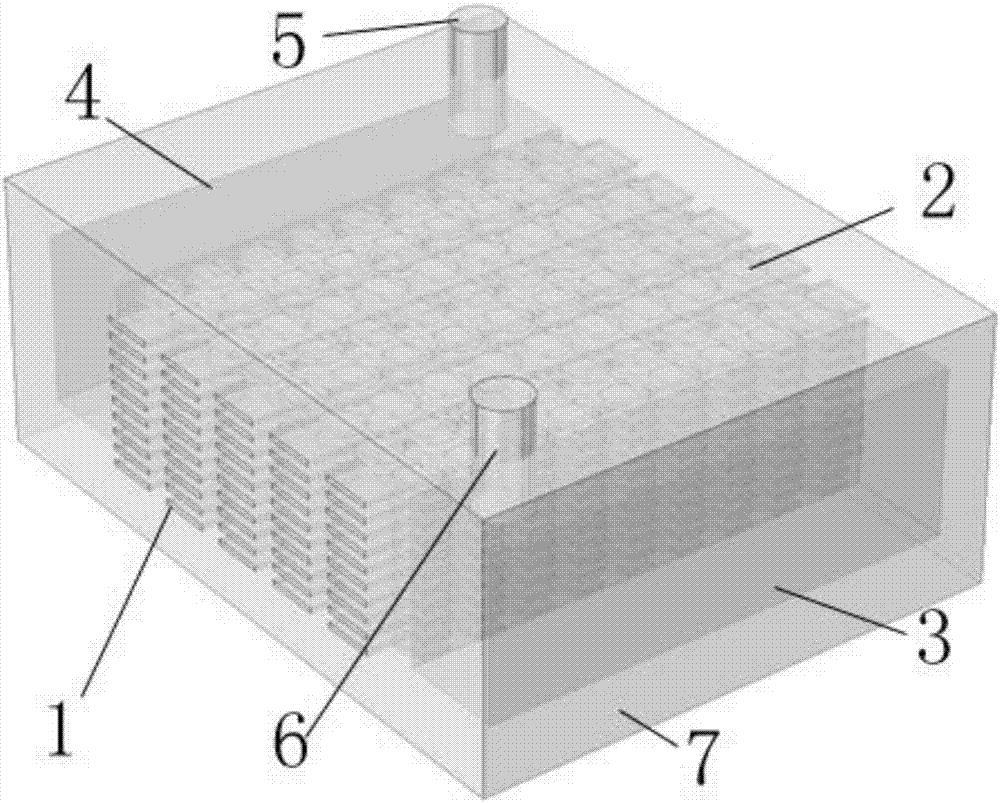

A method of producing clean diesel from hydrogen and carbon monoxide

ActiveCN103773414BEnhanced mass transferImprove responseLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesHydrogenDeoxygenation

The invention discloses a method for producing clean diesel by hydrogen and carbon monoxide. The method comprises the following steps: hydrogen and carbon monoxide enter a heat transfer fixed bed reactor to be in contact with a catalyst to participate in a Fischer-Tropsch synthesis reaction, the synthesized product passes through a hot-cold separator so as to respectively separate heavy hydrocarbons and light hydrocarbons, the light hydrocarbons and hydrogen enter a hydrofining reactor to be in contact with a catalyst to carry out a hydrogenization saturation reaction and a hydrogenization deoxygenation reaction after being mixed, the hydrofined reaction product enters a separation system, the separated tail oil and the heavy hydrocarbons enter a hydrogenization isocracking reactor after being mixed, the product enters the separation system to obtain an intermediate fraction oil product. The method solves the problem that when the Fischer-Tropsch synthesis reaction happens, reaction heat is difficult to control, and difficult heat transfer and hot spots exist in the reactor, and provides the method for producing the clean diesel economically and effectively, and hydrocarbon is produced in the producing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

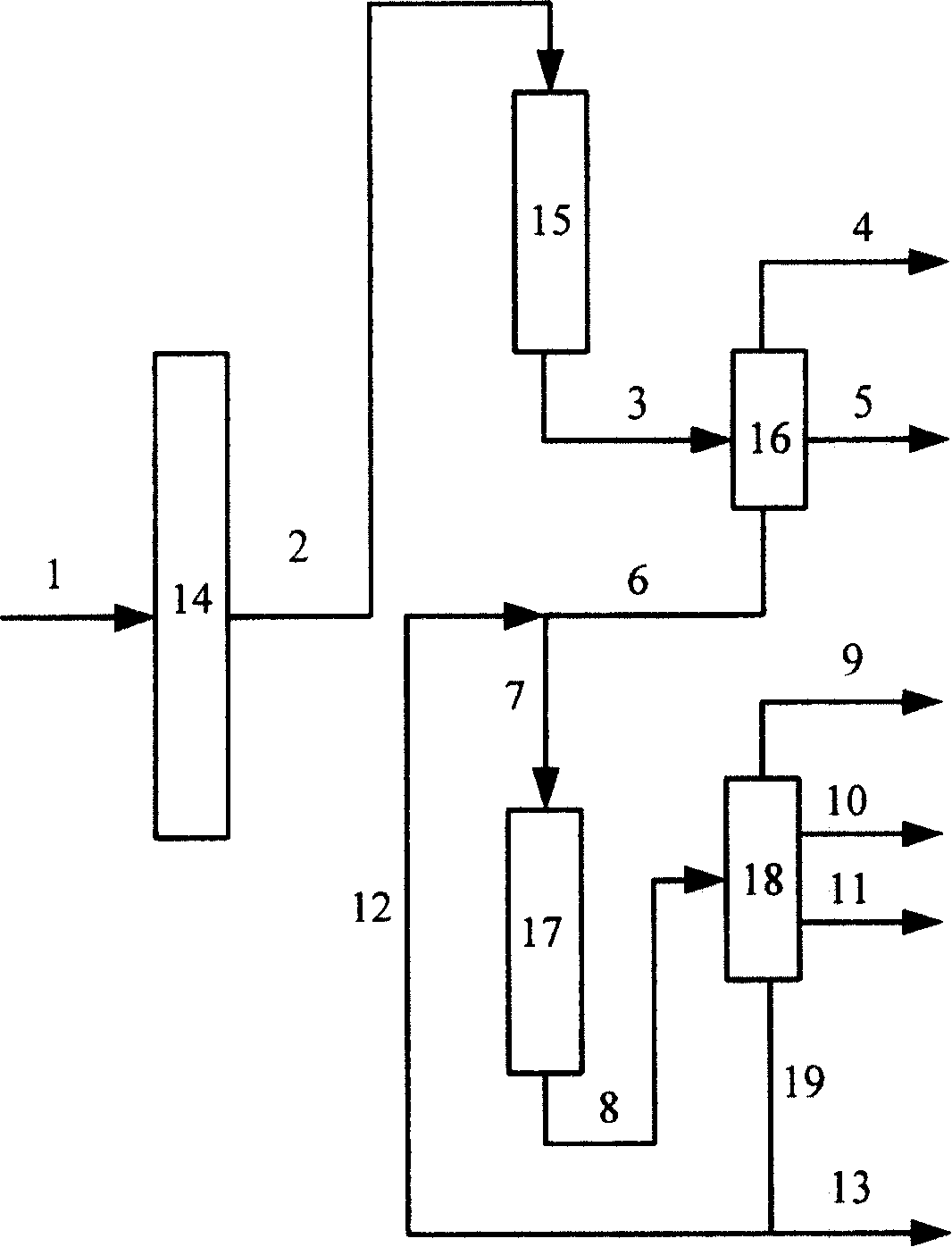

System and method for converting biomass raw material into clean diesel

ActiveCN108003940AEasy loadingGood removal effectWaste based fuelGasification processes detailsHigh energyProcess engineering

The invention discloses a system and method for converting a biomass raw material into clean diesel. The system comprises a biomass gasification unit, a synthetic gas purification unit, a Fischer-Tropsch synthesis reaction unit, a hydrofinishing unit and a hydroisomerization cracking unit. The system has the advantages of simple processes, high integration, high energy efficiency and good economy.The system and method realize efficient conversion and utilization of biomass.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of intermediate fractional oil from Fischer-Tropsch synthetic oil

ActiveCN100389181CDifferent performanceLow priceTreatment with hydrotreatment processesHydrogenNaphtha

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous extraction method and device of papermaking reconstituted tobacco

ActiveCN102488319BRemain suspended on the surface of the liquidThere will be no suspension on the liquid surfaceTobacco treatmentScrew conveyorContinuous production

The invention discloses a continuous extraction method and device of papermaking reconstituted tobacco. The continuous extraction device of the papermaking reconstituted tobacco is characterized by comprising a mixer, a first spiral conveyor, a downflow extraction tower, a medium-consistency pulp pump, a press master, a fluffer and a second spiral conveyor, wherein the mixer, the first spiral conveyor, the downflow extraction tower and the medium-consistency pulp pump are orderly connected, a material discharge hole of the medium-consistency pulp pump is connected with a material feeding hole of the press master, a concentrated material discharge hole of the press master is connected with the fluffer, the fluffer is connected with the second spiral conveyor, a material discharge hole of the second spiral conveyor is connected to the next level of extraction section or pulping section, and an extract liquor discharge hole of the press master is connected to an extract liquor feeding hole of the mixer in a concentration section of the extract liquor or the last extraction section. The continuous extraction device of the papermaking reconstituted tobacco, disclosed by the invention, has the advantages of simple operation, good production flexibility, capability of continuously producing, low water consumption and high extraction rate.

Owner:CHINA HAISUM ENG

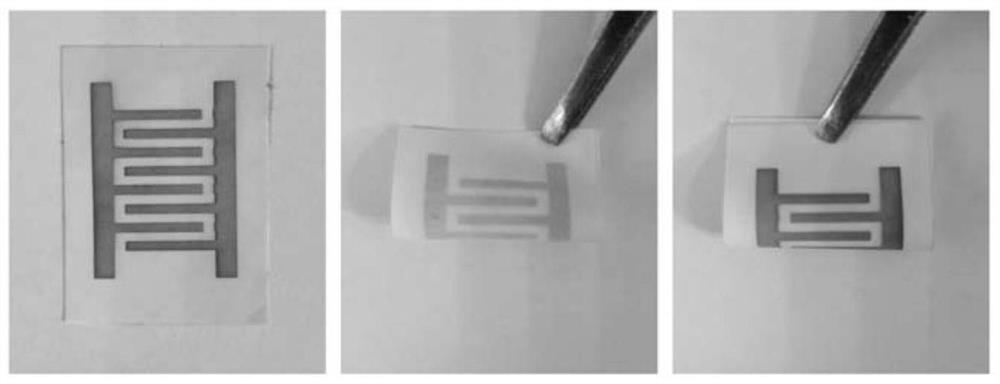

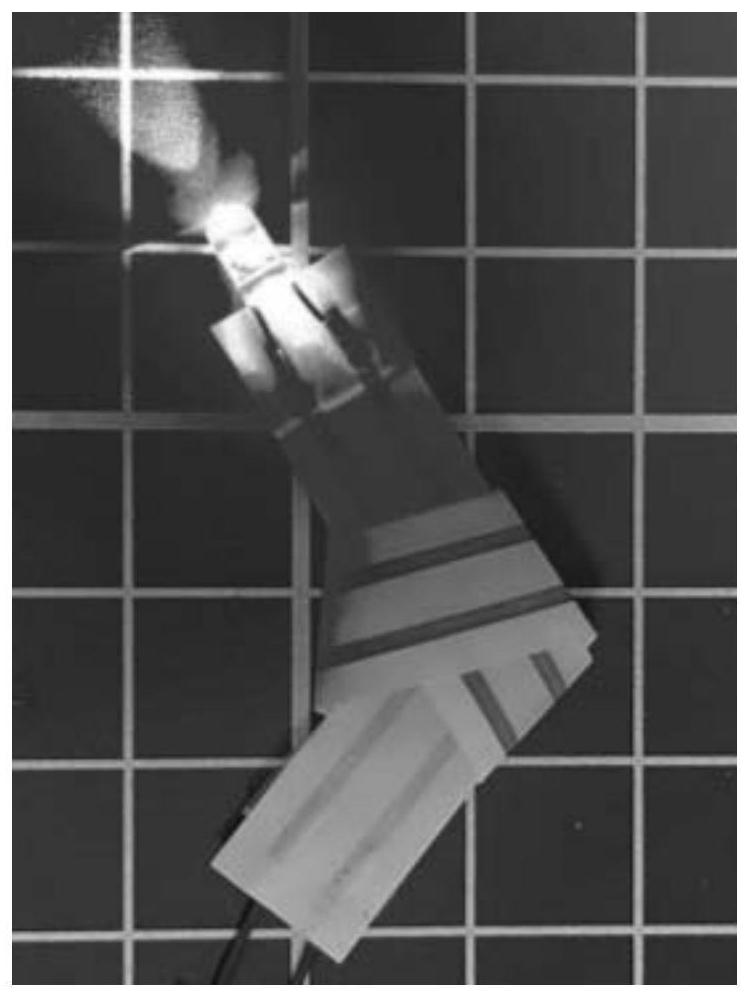

Flexible bendable metal pattern based on laser technology and preparation method and application thereof

PendingCN114786342AGood production flexibilityEasy to operateDielectric materialsFlexible printed circuitsLaser technologyScreen printing

The invention provides a flexible bendable metal pattern based on a laser technology and a preparation method and application thereof, and belongs to the field of flexible circuits. According to the preparation method, the conductive metal pattern or circuit is prepared on the flexible polymer film coated with the laser sensitizer through laser activation selective metallization. The prepared flexible metal pattern has ultrahigh bending resistance, after 10000 times of bending with the bending radius of 1 mm, the resistance value of the flexible metal pattern is kept basically unchanged, and connection of a metal circuit can be kept under the condition of complete folding. The preparation method does not need a mask or expensive equipment, and compared with a traditional etching method, a silk-screen printing process and an ink-jet printing process, the method is good in production flexibility, easy to operate, controllable in cost and good in universality and has a large-scale industrial application prospect.

Owner:SICHUAN UNIV

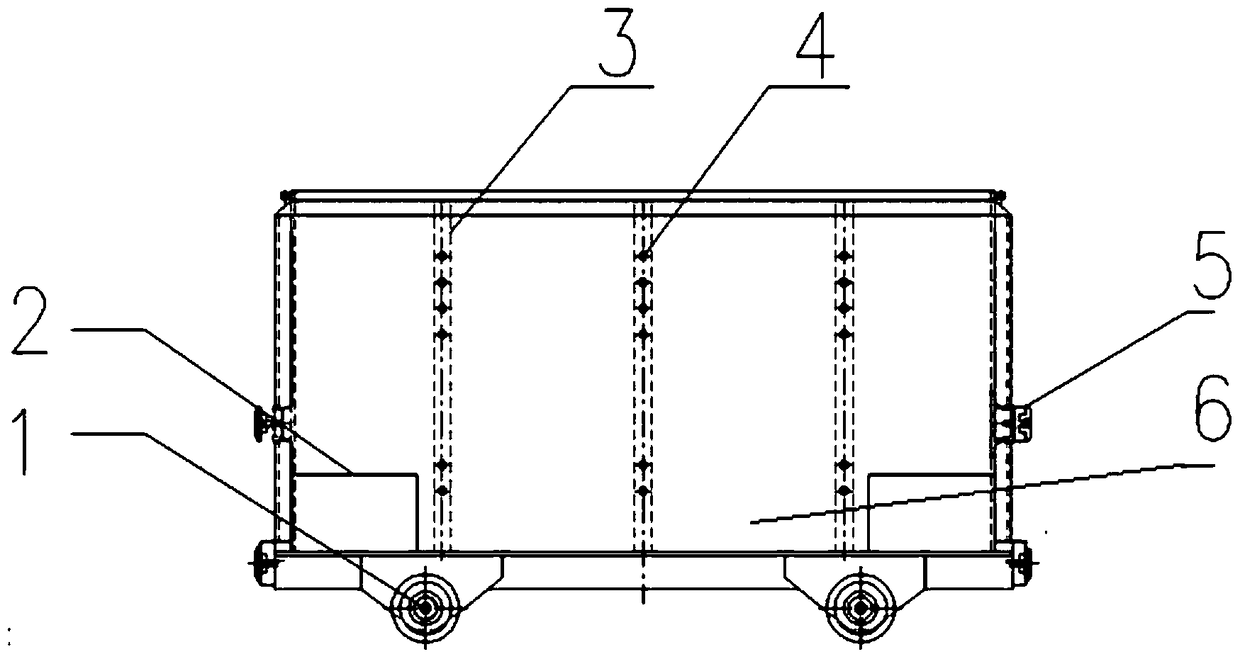

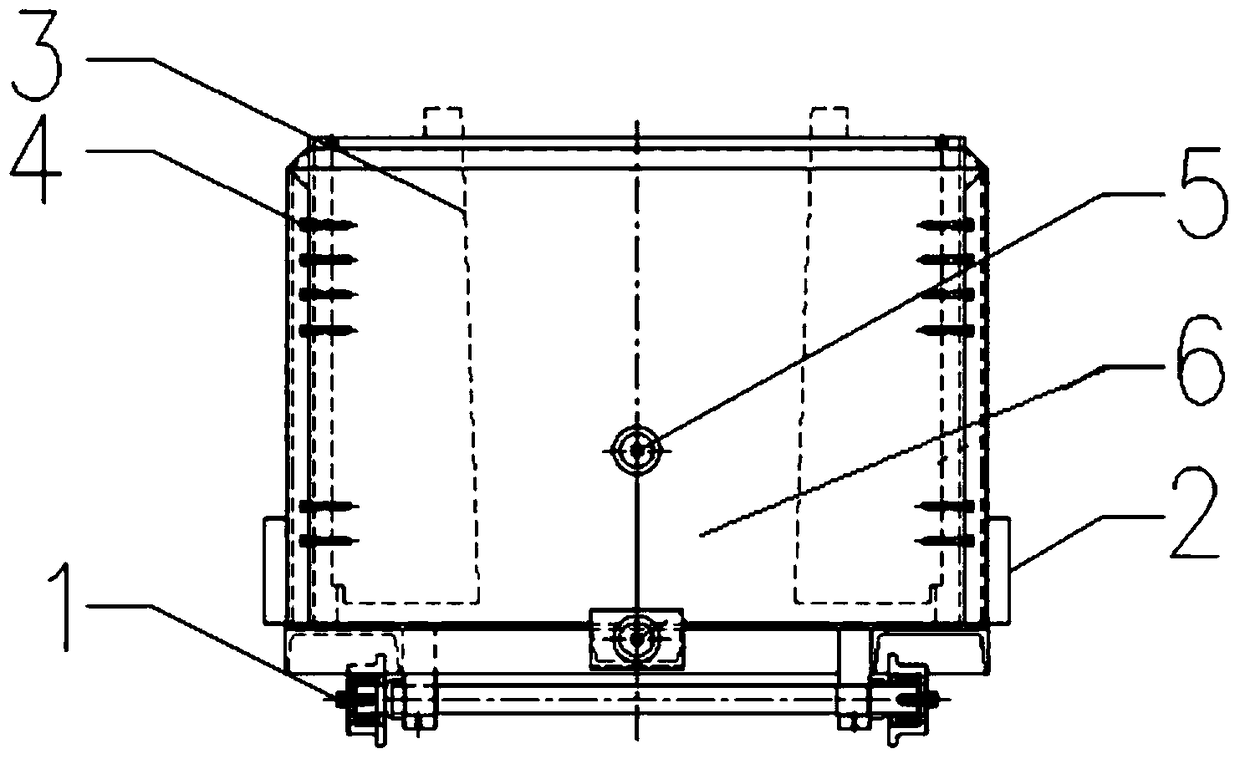

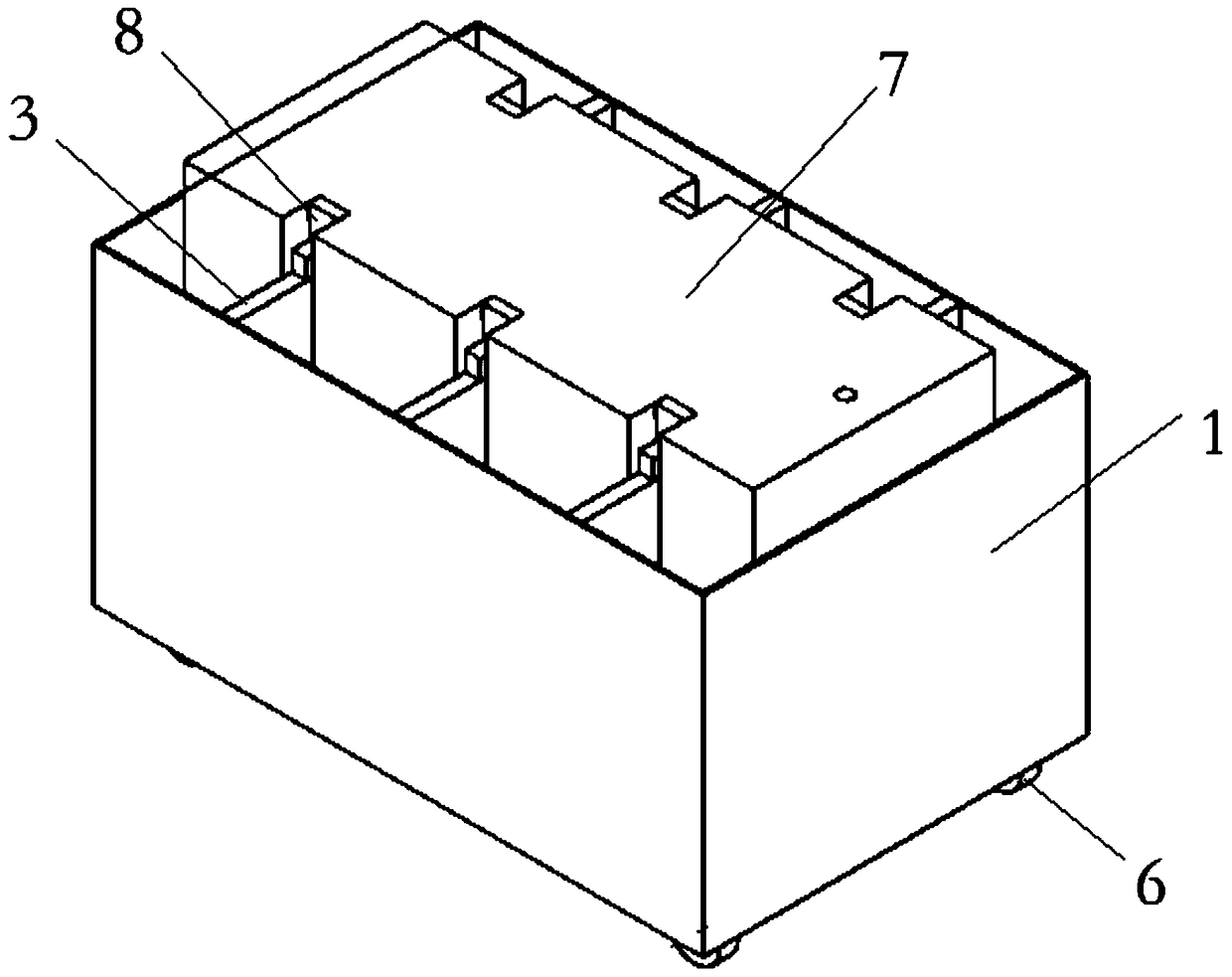

Sand box trolley and casting production method

InactiveCN105562664BReduce labor intensityImprove reliabilityCasting plantsMould handling equipmentsEngineeringUltimate tensile strength

The invention discloses a foundry production tool, particularly relates to a sand box trolley, and provides a sand box trolley which facilitates conveying and fixing of sand molds. The sand box trolley comprises a box body, rollers and sand mold fixing diagonal bars, wherein the rollers are mounted on the bottom of the box body to drive the box body to move; the sand mold fixing diagonal bars are arranged on at least one pair of opposite inner side walls of the box body; and a surface, which faces the inside of the box body, of each sand box fixing diagonal bar is an inclined plane which is gradually inclined from top to bottom. Tapered slots in the sand molds and the sand mold fixing diagonal bars in the sand box trolley are fastened in a matched wedging manner, a process of mounting fasteners on empty sand molds is avoided, and the labor intensity of workers is greatly reduced; and meanwhile, the sand molds can be pushed and mounted into the sand box trolley by automatic equipment, influence of artificial operation factors is small, and stability and reliability of a sand mold fastening process are guaranteed effectively.

Owner:重庆机电控股集团铸造有限公司

A short-process rolling forming device and method for a three-layer metal composite plate

ActiveCN104525564BRealize integrationImprove continuityMetal rolling arrangementsMetallurgySemi solid

A short-process rolling forming device and method for a three-layer metal composite plate, comprising a frame, two rollers installed horizontally side by side on the frame, a crystallizer installed on the two rollers, and two rollers installed on the crystallizer A tundish and a preheating device installed in the middle of the crystallizer and between the two tundishes, the center of the crystallizer and the center of the preheating device are provided with a rectangular channel for the core metal plate to pass through. The present invention has adopted the structure that two crystallization cavities are arranged between the crystallizer and the two rolls and a rectangular passage for the core layer metal plate to pass is arranged at the center of the crystallizer. In the two crystallization cavities, the The two cladding layer metal liquids are continuously cooled and stirred into a semi-solid slurry, and then they are directly compounded and rolled with the core metal plate to form a three-layer metal composite plate. The board quality is good and so on.

Owner:GUANGDONG INST OF NEW MATERIALS

A method for disposal of landfill sludge

ActiveCN107628737BStrong construction operabilityLow input costSludge treatment by oxidationSocial benefitsSludge

The invention relates to a landfill sludge treatment method. The method comprises the following steps: sampling and analyzing sludge, determining the pH value, the type of smelly pollutants, the landfill depth and the horizontal distribution of the sludge, preparing an oxidation preparation, injecting the oxidation preparation into underground sludge by virtue of in-situ mixing and stirring equipment, and simultaneously stirring the oxidation preparation and the sludge underground by virtue of an impeller stirring head of the in-situ mixing and stirring equipment; after uniform stirring, carrying out standing reaction for 3.5-5.5 hours, and putting a curing agent into sludge by using an engineering machine, and stirring continuously by using the in-situ mixing and stirring equipment; afteruniform stirring, standing for 24-48 hours, carrying out open type excavation and transfer on the solidified sludge. By sequentially carrying out in-situ treatment and excavation, the construction operability is strong, the investment cost of the equipment is low, the treatment period is short, the treatment is thorough, the secondary pollution is avoided, the problem of stink pollution in the excavation process of the sludge is solved, and meanwhile, the treatment of the sludge is realized; and the method has relatively good economic and social benefits.

Owner:中节能大地(杭州)环境修复有限公司

Integrated Fischer-Tropsch synthetic oil hydrogenation purification

ActiveCN100389180CLow investment costLow operating costTreatment with hydrotreatment processesHydrogenNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

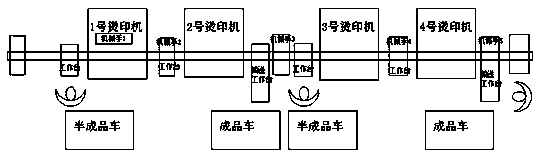

Air intake grill hot stamping process and automatic hot stamping line using this process

ActiveCN107901592BReduce demandSimple processTransfer printingPattern printingHot stampingAssembly line

The invention discloses a gas inflow grate hot stamping process and an automatic hot stamping assembly line adopting the process. The gas inflow grate hot stamping process includes the following stepsthat firstly, a gas inflow grate is arranged on a base; secondly, a chromium film is attached to the corresponding position of the gas inflow grate according to the requirement; thirdly, a silica gel profiling plate capable of heating the chromium film to achieve hot stamping and cutting off the excessive chromium film is placed on the chromium film according to the hot stamping pattern requirement, the silica gel profiling plate is provided with an aluminum plate, and the aluminum plate is connected with a heating element to be used for heating the silica gel profiling plate; fourthly, thesilica gel profiling plate is used for cutting off the excessive chromium film, that is to say, hot stamping patterns are left to complete heating and pressurizing of the hot stamping profiling plateon the chromium film to achieve hot stamping on the chromium film; and fifthly, the silica gel profiling plate is used for cutting off the excessive chromium film, that is to say, the hot stamping patterns are left to complete hot stamping. The gas inflow grate hot stamping process is simplified and efficient in procedure, the procedure is environment-friendly, the effect is the same with the electroplating effect, and colors can be diversified.

Owner:江阴精力汽车装备有限公司

A system and method for converting biomass feedstock into clean diesel

ActiveCN108003940BHighly integratedImprove energy efficiencyWaste based fuelGasification processes detailsSyngasProcess engineering

The invention discloses a system and method for converting a biomass raw material into clean diesel. The system comprises a biomass gasification unit, a synthetic gas purification unit, a Fischer-Tropsch synthesis reaction unit, a hydrofinishing unit and a hydroisomerization cracking unit. The system has the advantages of simple processes, high integration, high energy efficiency and good economy.The system and method realize efficient conversion and utilization of biomass.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com