Preparation device of large-area titanium dioxide thin film catalyst and preparation method thereof

A titanium dioxide and catalyst technology, which is applied in the field of preparation equipment of titanium dioxide thin film catalysts, can solve the problems of difficulty in efficiently preparing large-area titanium dioxide thin film catalysts and the like, and achieves the effects of flexibility, easy control, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

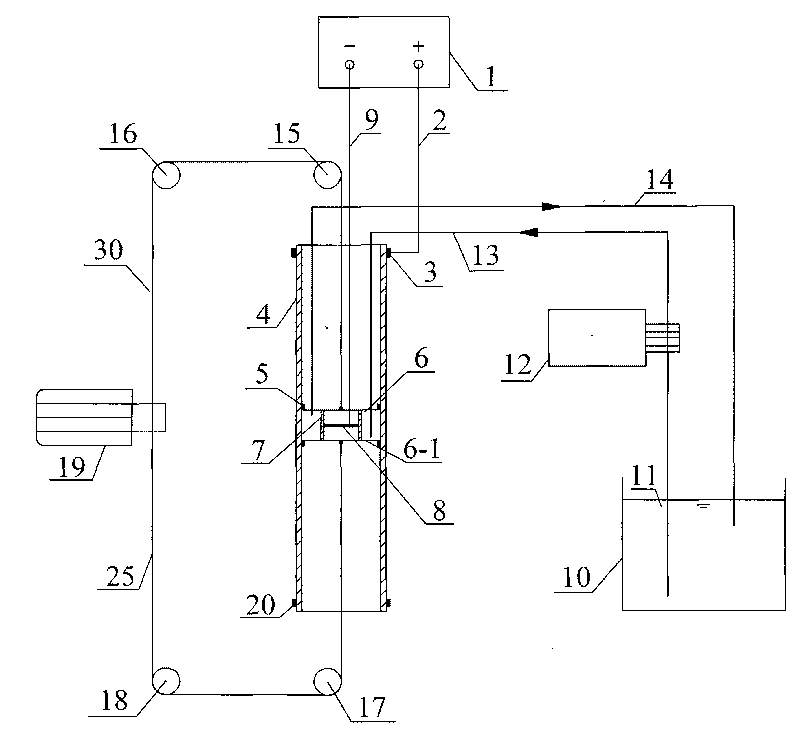

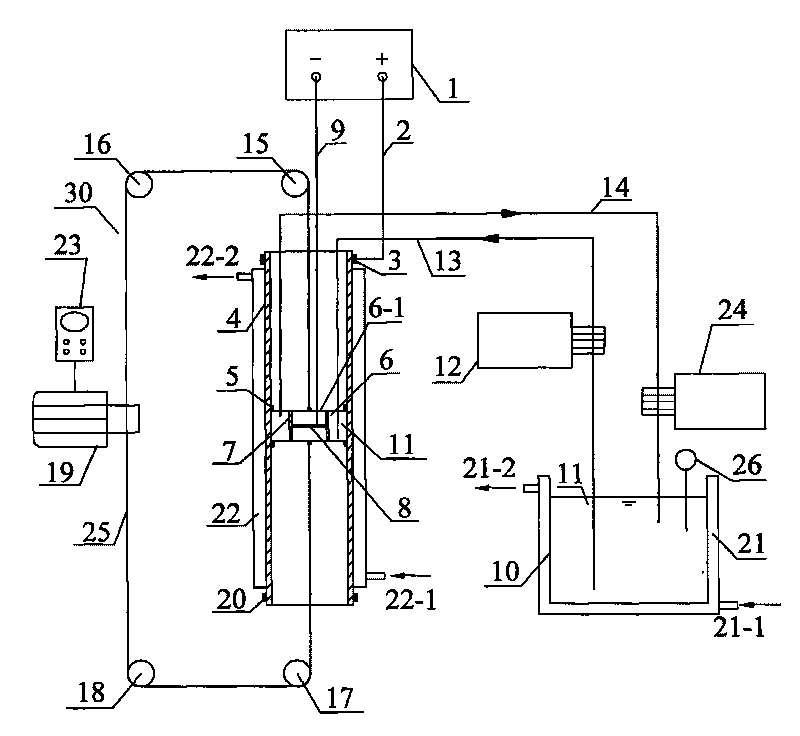

[0015] Specific implementation mode one: as figure 1 with 2 As shown, the preparation equipment of a large-area titanium dioxide thin film catalyst described in this embodiment includes a DC switching power supply 1, an anode 4 made of titanium, a cathode 7, an electrolyte tank 10, an anode connecting wire 2 and The cathode is connected to the wire 9, the positive pole of the DC switching stabilized current power supply 1 is connected to the anode 4 made of titanium through the anode connecting wire 2, and the negative pole of the DC switching stabilized current power supply 1 is connected to the anode through the cathode connecting wire 9. The cathode 7 is connected; the preparation equipment also includes a reaction monomer tank 6, an electrolyte return pipe 14, an electrolyte delivery pipe 13, a drive mechanism 30 and an electrolyte delivery pump 12, and the reaction monomer tank 6 is a closed cavity , the length of the negative electrode 7 is far less than the length of t...

specific Embodiment approach 2

[0017] Specific implementation mode two: as figure 1 with 2 As shown, the driving mechanism 30 in this embodiment is composed of a synchronous belt 25, a first fixed pulley 15, a second fixed pulley 16, a third fixed pulley 17, a fourth fixed pulley 18 and a motor 19, and the synchronous belt 25 is respectively wound around Be located on the first fixed pulley 15, the second fixed pulley 16, the third fixed pulley 17 and the fourth fixed pulley 18 on the same horizontal plane and rectangular distribution, and the reaction monomer groove 6 is located at the first fixed pulley 15 and the third fixed pulley Between 17; driven by the motor 19, the synchronous belt 25 rotates circumferentially along the track constructed by the above four fixed pulleys, so that the reaction monomer tank 6 moves relatively along the side of the anode 4 made of titanium. Driven by the motor 19, the synchronous belt 25 can move between the tracks set by the first fixed pulley 15, the second fixed pul...

specific Embodiment approach 3

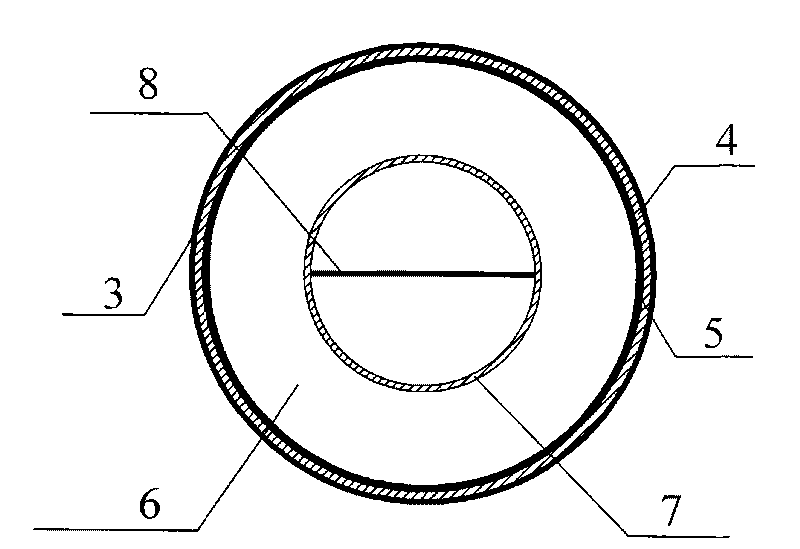

[0018] Specific implementation mode three: as Figure 1~3As shown, the preparation equipment described in this embodiment also includes two insulating sealing rings 5, the anode 4 and cathode 7 made of titanium are both round tubes (anode titanium tube 4), and the cathode 7 is located in the titanium anode In the inner cavity of the anode 4; the reaction monomer tank 6 is composed of two end caps 6-1 and an annular cavity formed between the anode 4 and the cathode 7 made of titanium, and the two end caps 6-1 Located in the inner cavity of the anode 4 made of titanium, an end cap 6-1 is hermetically arranged on the upper end and the lower end of the cathode 7; between each end cap 6-1 and the anode 4 made of titanium, there is a Insulating sealing ring 5; one end of the timing belt 25 is connected with the upper end cover of the reaction monomer tank 6, and the other end of the timing belt 25 is connected with the lower end cover of the reaction monomer tank 6. The reaction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com